6 (24)

2. Designed purpose of use

The AVANT Log cutter/splitter is an attachment that is suitable for use with AVANT compact loaders that are

shown in Table 1. The attachment is intended to be used by one person at a time for cutting and splitting

firewood. The log cutter/splitter can be used either attached to the loader, or with an optional hose extension

kit, it can be used further away from the loader. The Log cutter/splitter must be placed firmly on the ground.

The Log cutter/splitter is equipped with a hydraulic infeed belt and discharge conveyor as standard. The log

lifter option must not be used with 400 series loaders.

The Log cutter/splitter cuts the log with a chain saw blade to the adjusted length between 200 and 500 mm.

The splitting activates automatically after cutting. The attachment splits wood with a hydraulic cylinder, which

presses the wood against a splitting wedge. The diameter of the log can be up to 310 mm. The hydraulic

cylinder returns to set position after the wood has been split. A 4 way splitting wedge is standard equipment; 6

way wedge is available as an option. The splitting wedge is adjustable, making it possible to split the wood

into only 2 pieces, when needed.

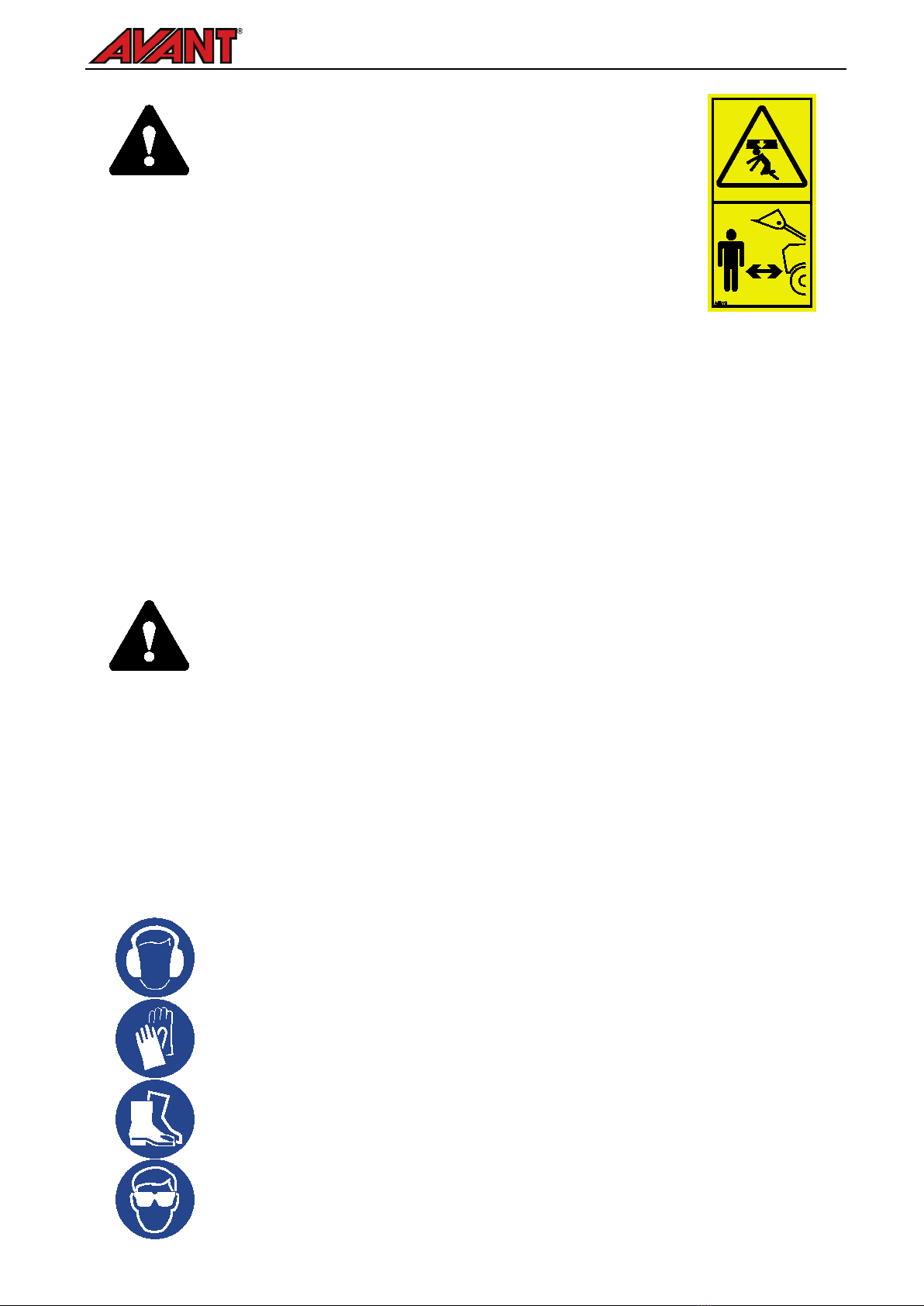

The Log cutter/splitter is not designed for any other use than what is specified in this manual and must not be

used for any other purposes than what is intended for. The Log cutter/splitter is intended strictly for one

operator only. Others must not get near the attachment or the loader. The Log cutter/splitter is intended for

outdoor use only.

Always read the original manual of the Japa 315 and this Avant operator's manual. This operator's manual

includes additional information that is important when using the Japa 315 firewood processor with the Avant

loaders.

The attachment has been designed to require as little maintenance as possible. The operator can perform

regular maintenance tasks. All repair work can’t be performed by the operator, and demanding repair and

maintenance operations are to be left for professional technicians. All maintenance work must be done using

proper safety equipment. Spare parts must be identical with original specifications, which can be ensured by

using only original spare parts. A separate spare parts catalogue may be available, consult your Avant dealer.

Familiarise yourself with the manual's instructions regarding service and maintenance. Please contact your

AVANT dealer if you have additional questions about the operation or maintenance of the equipment, or if you

require spare parts or maintenance services.

Table 1 - Log cutter/splitter - Compatibility with Avant loaders

Avant

220 series 2

225

225LPG

313S

320S

420

423

520

523

R20

525LPG

R28

528

530

630

R35

635

640

645i

650i

735

745

750

755i

760i

850

860i

e5

e6

A446852 - - (•) •••••(•)

It is recommended to use the attachment only with loaders marked with •in Table 1. When using with models

marked with (•), additional counterweights may also be required. For compatibility with a model not shown in

table, contact your Avant dealer. Log lifter is not available for 400 series loader.

With electric loaders the available battery capacity may limit operating time.