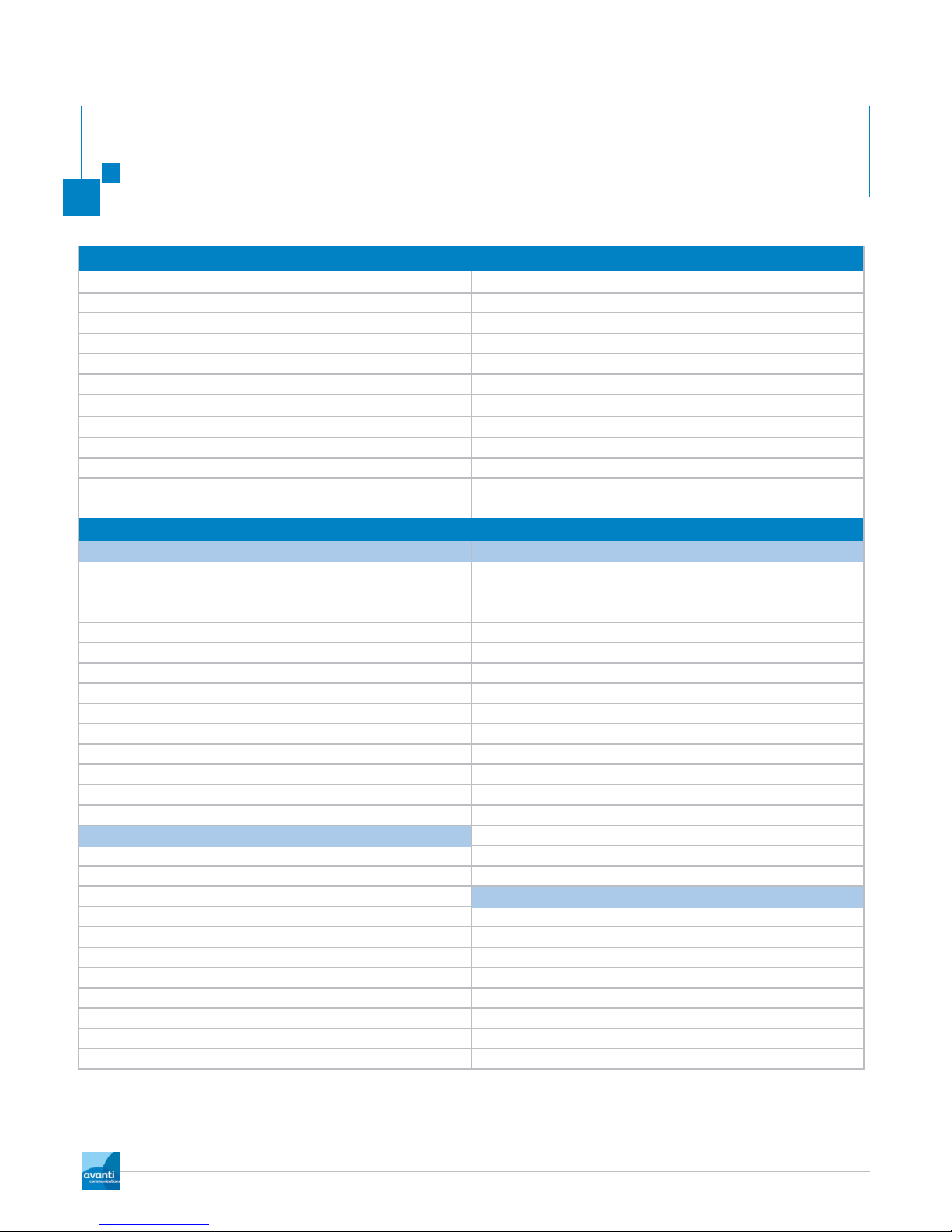

6.

CONSUMABLE REQUIREMENTS

Standard Installation Consumables

NOTE:

Cable ties 300mm black / white /clear. ALL INSTALLATION ENGINEERS SHOULD HAVE

WF100 Cablecon 5.1 compression connector. ACCESS TO THE COMPLETE INSTALLATION

WF125 Cablecon 6.0 compression connector. CONSUMABLES LIST OPPOSITE TO ENSURE

Hi-grade multi use barrel F-F connector. ALL INSTALLATIONS CAN BE COMPLETED ON

Silicon Dielectric grease. THEIR SCHEDULED DATE.

Silicon based self

–

amalgamating tape.

RX and TX labels.

M8-M10 Rawl-bolts.

WD 40 or equivalent.

WF100 Twin-sat CAI approved foam dielectric.

Installation Consumables.

BRACKETS and FIXINGS. CABLE.

Standard

WF100 Twin-sat CAI approved foam dielectric.

Standard 60mm

L

bracket long. 55cm WF125 green direct burial CAI approved.

K+K

or

A

frame (Both to have support leg) Cat5e external grade 100 meter.

20cm / 8in. Cat5e 2 meter straight patch lead.

46cm / 18in. 4 gang surge protected mains extension.

55cm / 24in. Twin-sat 7 mm Grommet black / white.

60mm / 2meter or 3meter pole. 7 mm grommet black / white.

V

bolts for 60mm pole including washers. 10 mm grommet black / white. (WF125)

Universal Clamp. Cable clips 2 x 7mm masonry grade.

Non penetrating roof mount 60mm. Cable clips 9mm round masonry grade.

4 x 600mm x 600mm x 50mm flags. Cable clips 6-7mm round masonry grade.

M10 / 16mm Rawl-bolts. Pin plugs.

Rapid set postcrete. Brick plate terracotta.

DRILL BITS. Brick plate white.

16mm 200mm masonry External grade clear silicon.

16mm 600mm masonry Cable ties 300mm black / white /clear.

16mm 1000mm masonry CONNECTORS.

5.5mm 100mm masonry WF100 Cablecon 5.1 compression connector.

Grinder cutting disks. WF125 Cablecon 6.0 compression connector.

Hi-grade multi use barrel F-F connector.

Silicon Dielectric grease.

RJ 45 connectors.

Silicon based self

–

amalgamating tape.

Replacement Cable stripper blades.

RX and TX labels.