P

PR

R-

-4

42

22

2C

CA

A

M

Ma

ar

ri

in

ne

e

A

AM

M/

/F

FM

M/

/T

TV

V

A

An

nt

te

en

nn

na

a

f

fo

or

r

S

Sh

hi

ip

ps

s

P

P

-

-4

42

20

0C

C

M

Ma

ar

ri

in

ne

e

F

FM

M-

-T

TV

V

n

nt

te

en

nn

na

a

f

fo

or

r

S

Sh

hi

i

s

s

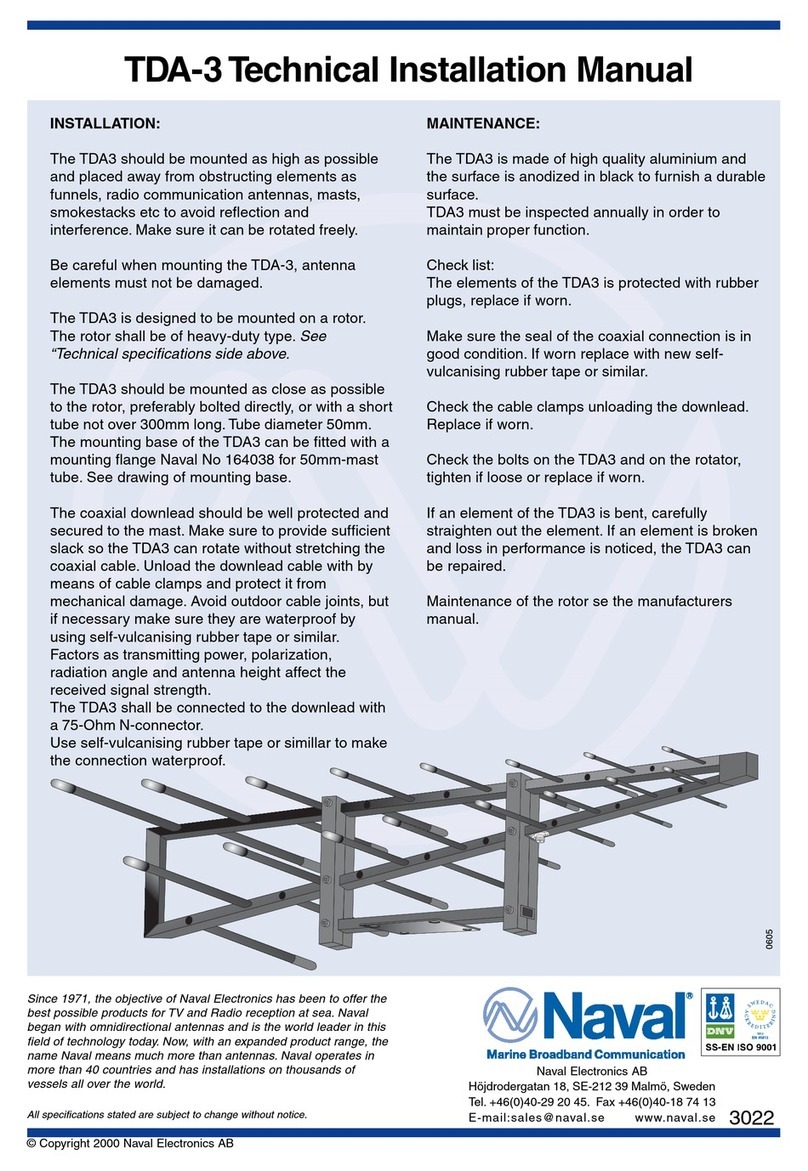

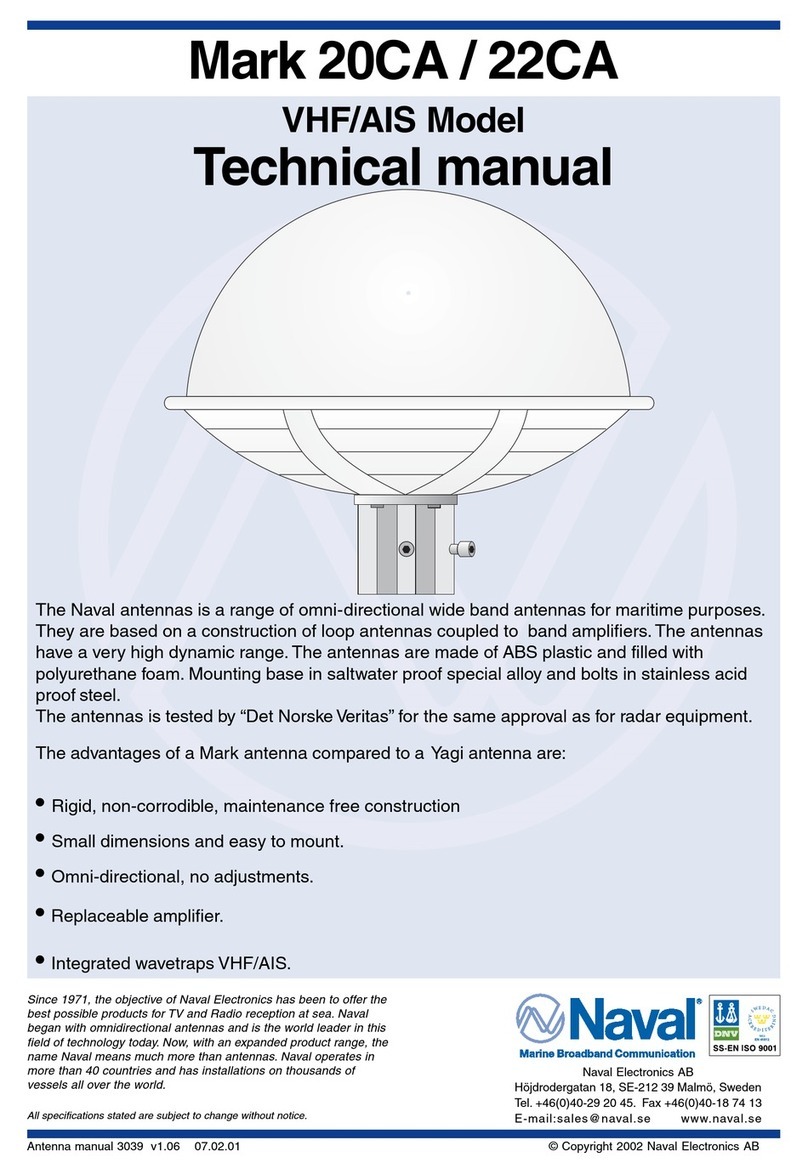

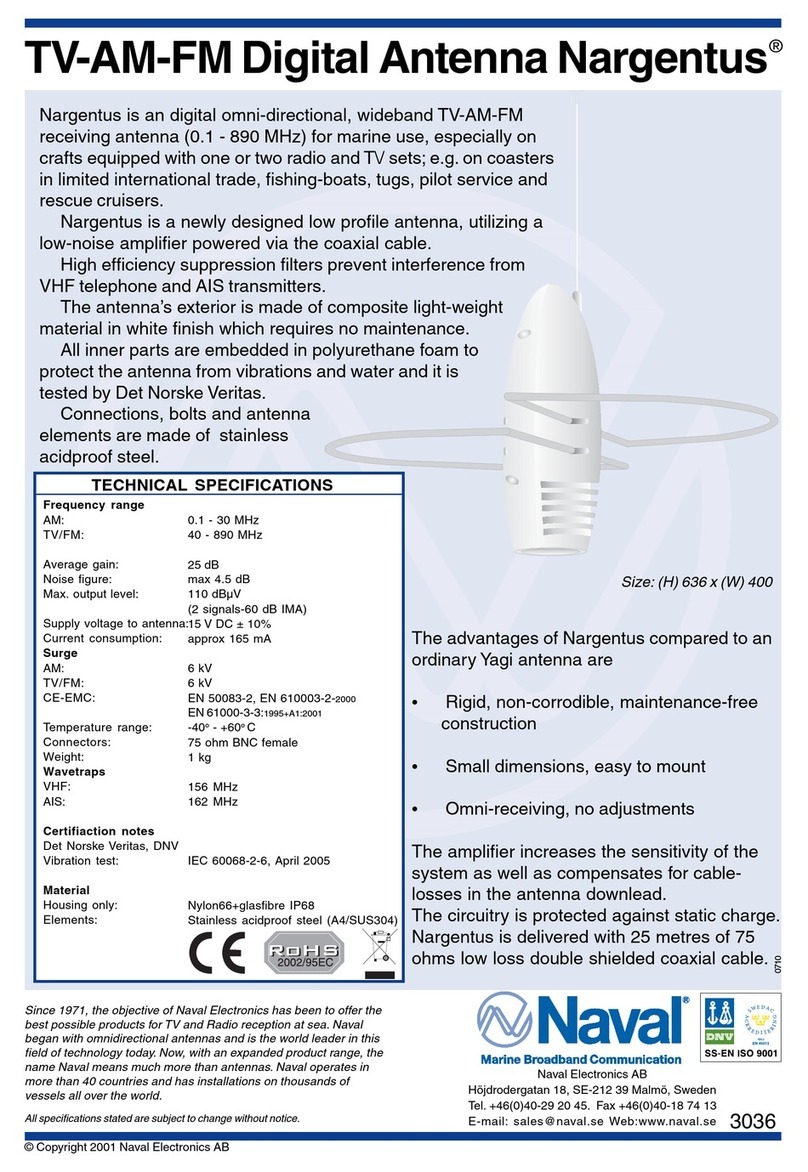

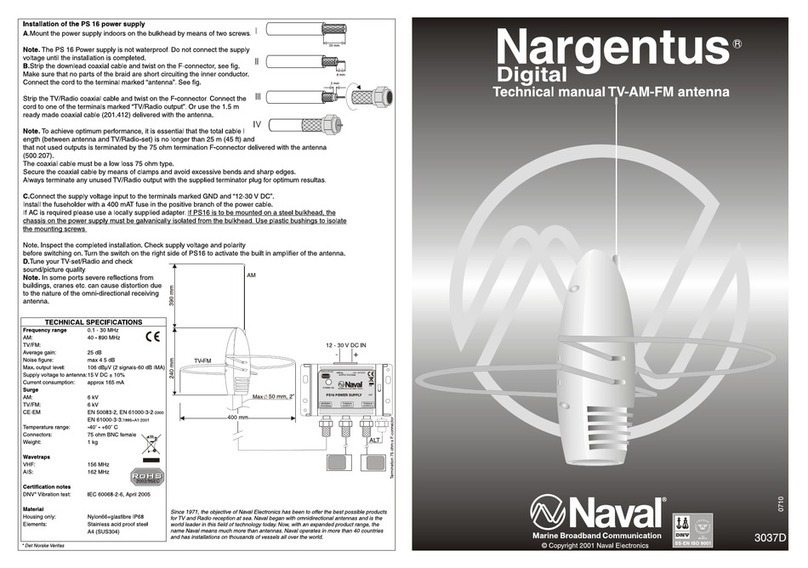

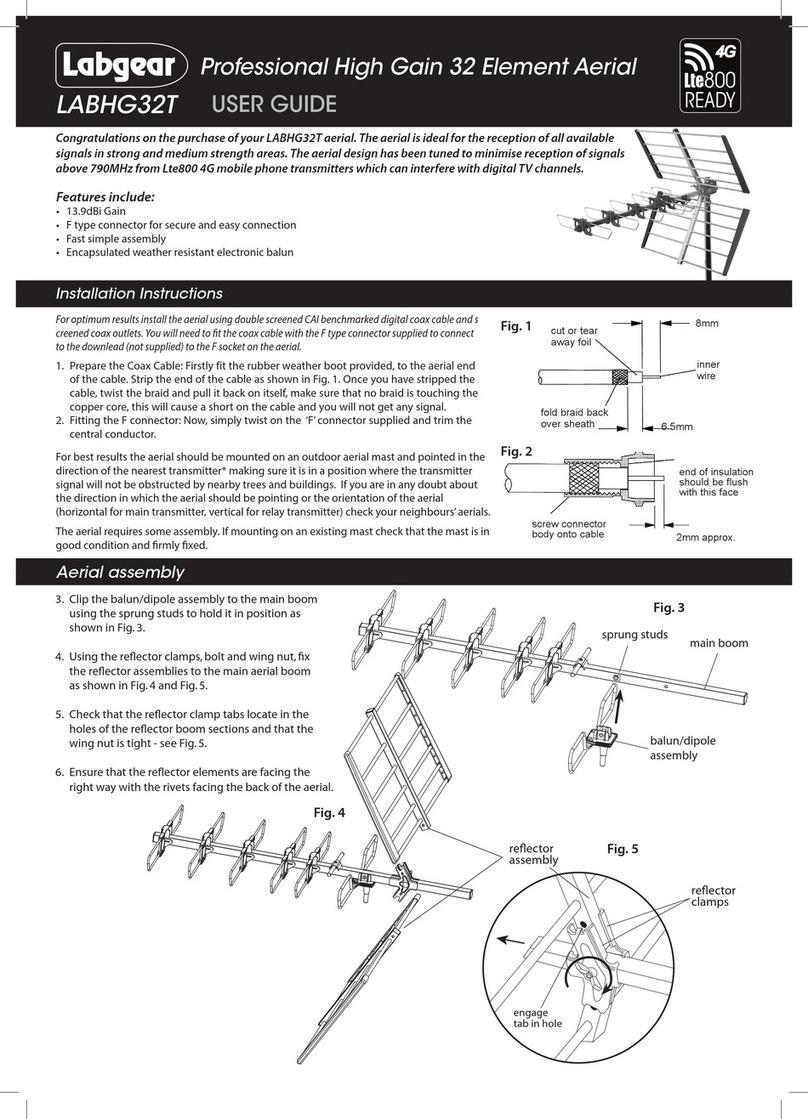

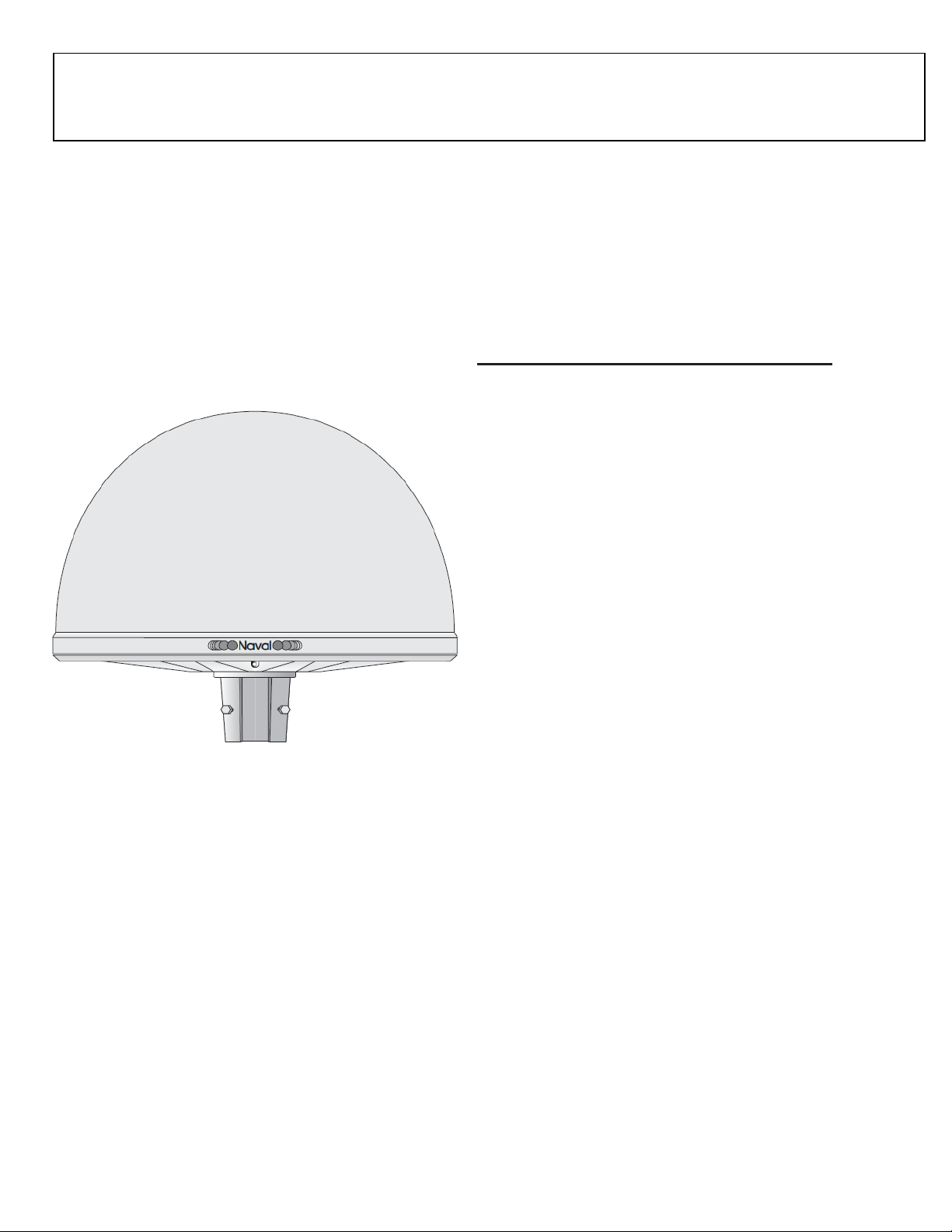

The PR-422CA is an Active Extra High Performance Omni-directional wide-band Terrestrial AM-FM-

TV Antenna ( 0.1-30 and 40-860 MHz) designed for Maritime purposes where second rate efficiency

is unacceptable. Constructed for High End Commercial and Military use, this compact and robust

antenna shell is made of thick UV protected ABS plastic filled with polyurethane foam which

provides both structural support and environmental protection. The mounting base is cast from

Almag Marine Aluminum Alloy which is powder coated and then oven baked. Mounting hardware is

made of acid-proof stainless steel. The Shielded Low Noise Amplifier is protected from static

charges and is removable for field repair or replacement.

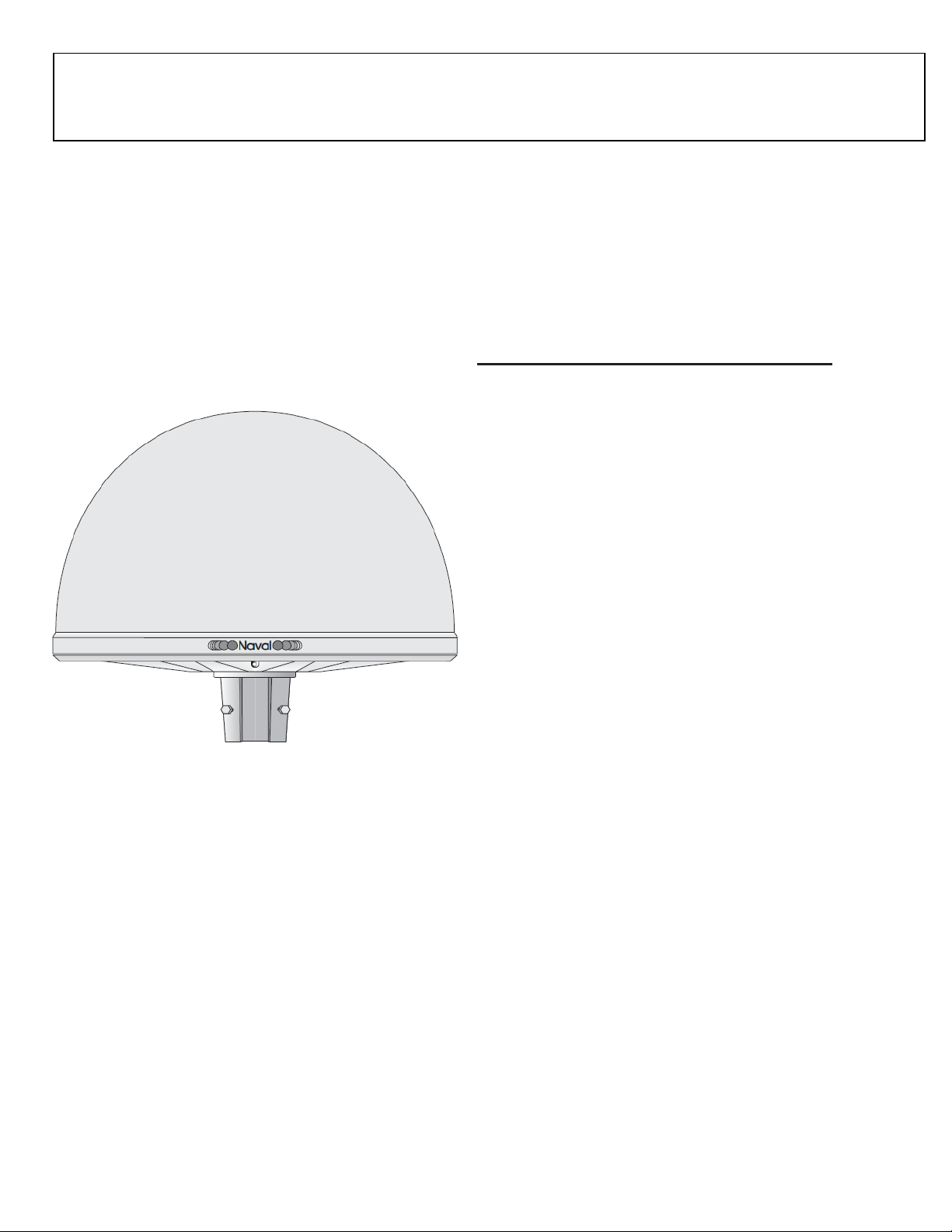

Specifications: PR-422CA antenna

Frequency range: PR-422 (0.1-860 MHz), PR-420 (40-860 MHz)

Average VHF gain: 25 dB (amp)

Average UHF gain: tilt 16-20 dB (amp)

VHF Noise figure: 3.0 dB (amp)

UHF Noise figure: 2.5 dB (amp)

Max output level: 111 dBuV min (2 signals-60 dBIM)

Third order intermod products: >20dB IP3

Antenna factor: Ka = 0.12 AM

Filters: Band pass 100 KHz- 30 MHz., 47-108 MHz.,

174-230 MHz.,470-860 MHz.

Broadband rejection filter: 140-165 MHz.

Polarization: horizontal

Antenna pattern: omni-directional

Supply voltage to antenna: 15VDC nominal

Current consumption: 130 mA Nominal

Operating temperature: -40 to +55 C.

Protection circuits: static discharge device fires at 65 volts

Impedance: 75 ohm nominal

Connector "F" type Gold electroplate or BNC-75

Return loss: >10dB with optional output connector.

Radome material: UV protected ABS

Flange material: Stainless, Almag or Powder Coated Almag

Internal stabilization material: Polyurethane foam injection

Element material: copper foil

Element type: three looped dipoles with Z match pcb

Shipping Weight: 12-13 lbs with 1 ft coax and aluminum flange

Shipping container dim : 19 x 19 x 16 inches

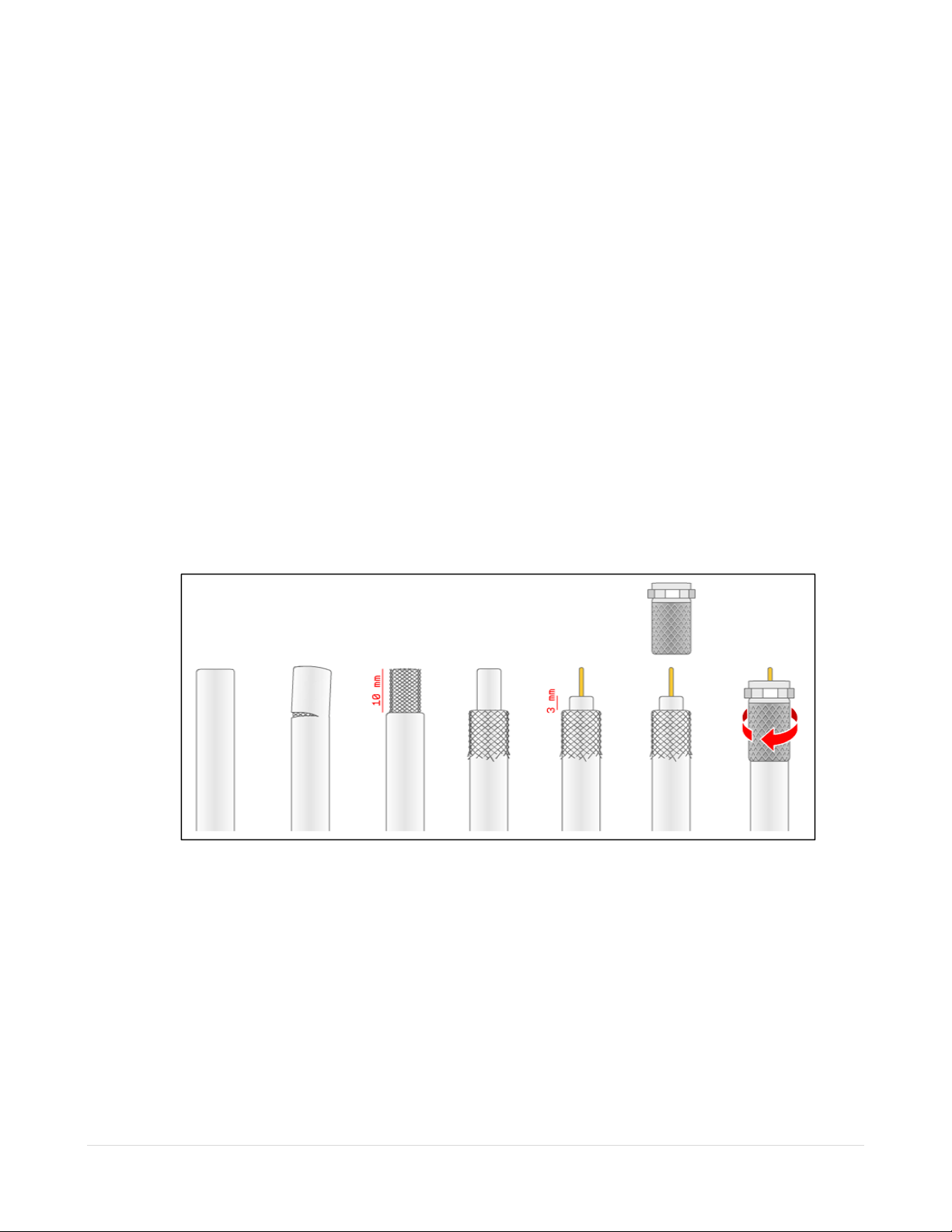

The PR-422CA is based on a construction of 3 circular dipoles coupled to a low noise amplifier via a

broadband filter network. Maximum performance is assured through the extensive use of a Network

Analyzer in the initial design and in the final construction and tuning of each unit. Microwave

transistors provide needed gain with a minimum of internally generated noise. Careful engineering

and the use of very high quality components yields excellent intermod performance and sharp hand

tuned filters greatly reduce the chance of interference from outside of the TV bands

The PR-422CA is at the head of a new 4000 Series Marine Cassette Amplifier System with

distribution passives introduced in 1998. The Series 4000 is the result of painstaking engineering

and the use of state of the art components such as high performance GaAs Heterojunction Bipolar

Transistors.

PR- 420CA is identical with the omission of AM-SW radio rece

tion.