Avery Berkel A301CE Operating instructions

76102-905 ENGLISH issue 2 18.07.00

RP-series slicer

A301CE/A351CE/A355CE

ServiceInstructions

2.1 — Safety

Service Instructions RP-A301CE/RP-A351CE/RP-A355CE i

Contents

Table of Contents:

1 Introduction

2 Safety

3 Operation

4 Installation

5 Electrical Drawings

6 Technical Information

7 Appendices

2.1 — Safety

ii Service Instructions RP-A301CE/RP-A351CE/RP-A355CE

Section 1

Introduction

Table of Contents:

page no

Service Instructions RP-A301CE/RP-A351CE/RP-A355CE 1 - 1

1.1 General 1-3

1 — Introduction

1 - 2 Service Instructions RP-A301CE/RP-A351CE/RP-A355CE

1 — Introduction

Service Instructions RP-A301CE/RP-A351CE/RP-A355CE 1 - 3

1.1 General

The Avery Berkel slicing machine and its accessories are manufactured in

accordance with the EEC 89/392 Machinery Directive and further modifications.

They meet all legislative requirements valid at the date of manufacture.

Its principle characteristics are easy cleaning, robust manufacture, safe and

reliableoperation.

The materials utilised, anodised aluminium, stainless steel and plastics have

been selected with due regard to hygiene regulations and ensure that the

machine has a long life.

1 — Introduction

1 - 4 Service Instructions RP-A301CE/RP-A351CE/RP-A355CE

Section 2

Safety

Table of Contents:

page no

Service Instructions RP-A301CE/RP-A351CE/RP-A355CE 2 - 1

2.1 RP-A301CE/A351CE 2-3

2.1.1 Electrical safety devices 2-3

2.1.2 Mechanical safety devices 2-4

2.2 RP-A355CE 2-5

2.2.1 Electrical safety devices 2-5

2.2.2 Mechanical safety devices 2-6

2 — Safety

2 - 2 Service Instructions RP-A301CE/RP-A351CE/RP-A355CE

2 — Safety

Service Instructions RP-A301CE/RP-A351CE/RP-A355CE 2 - 3

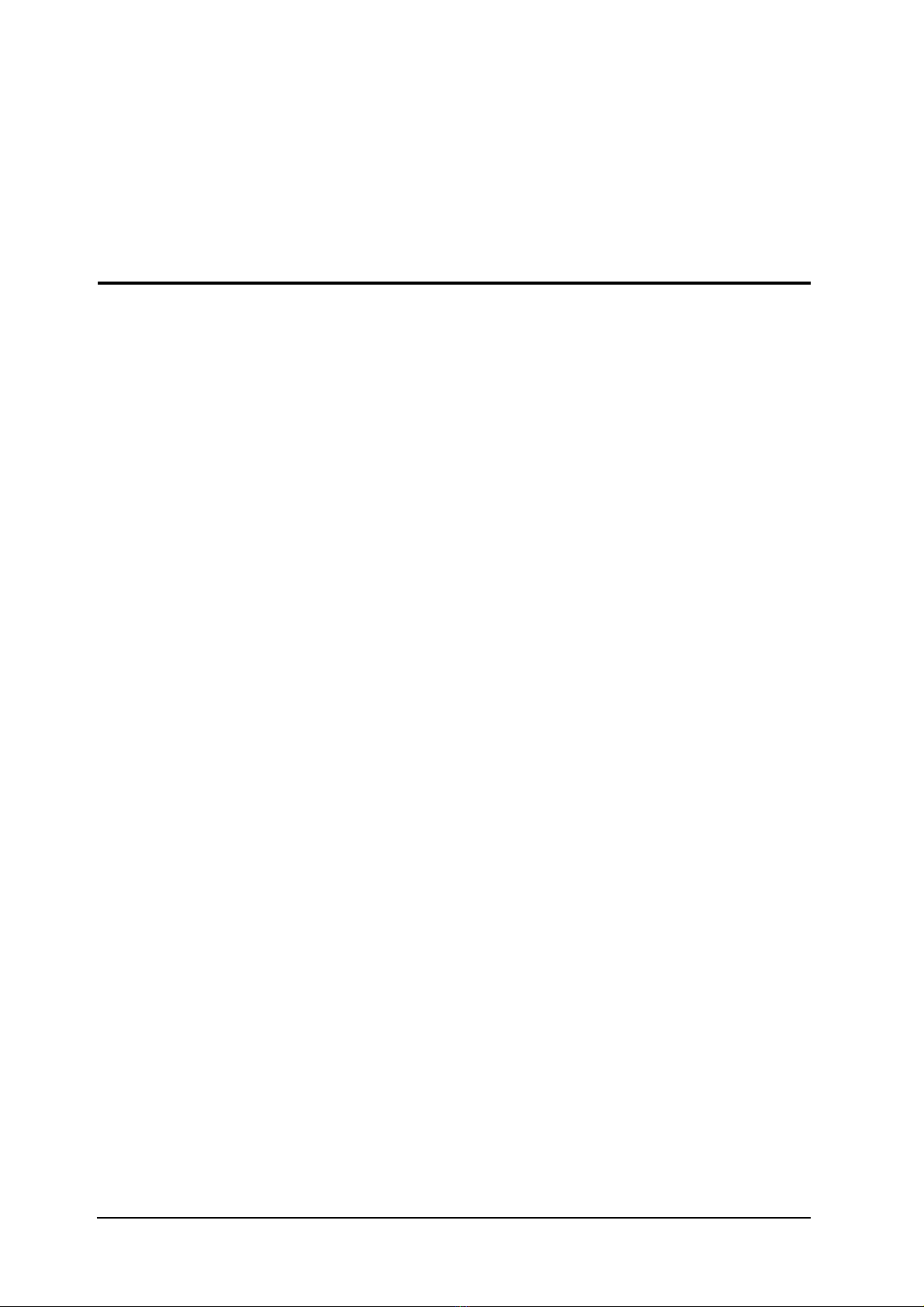

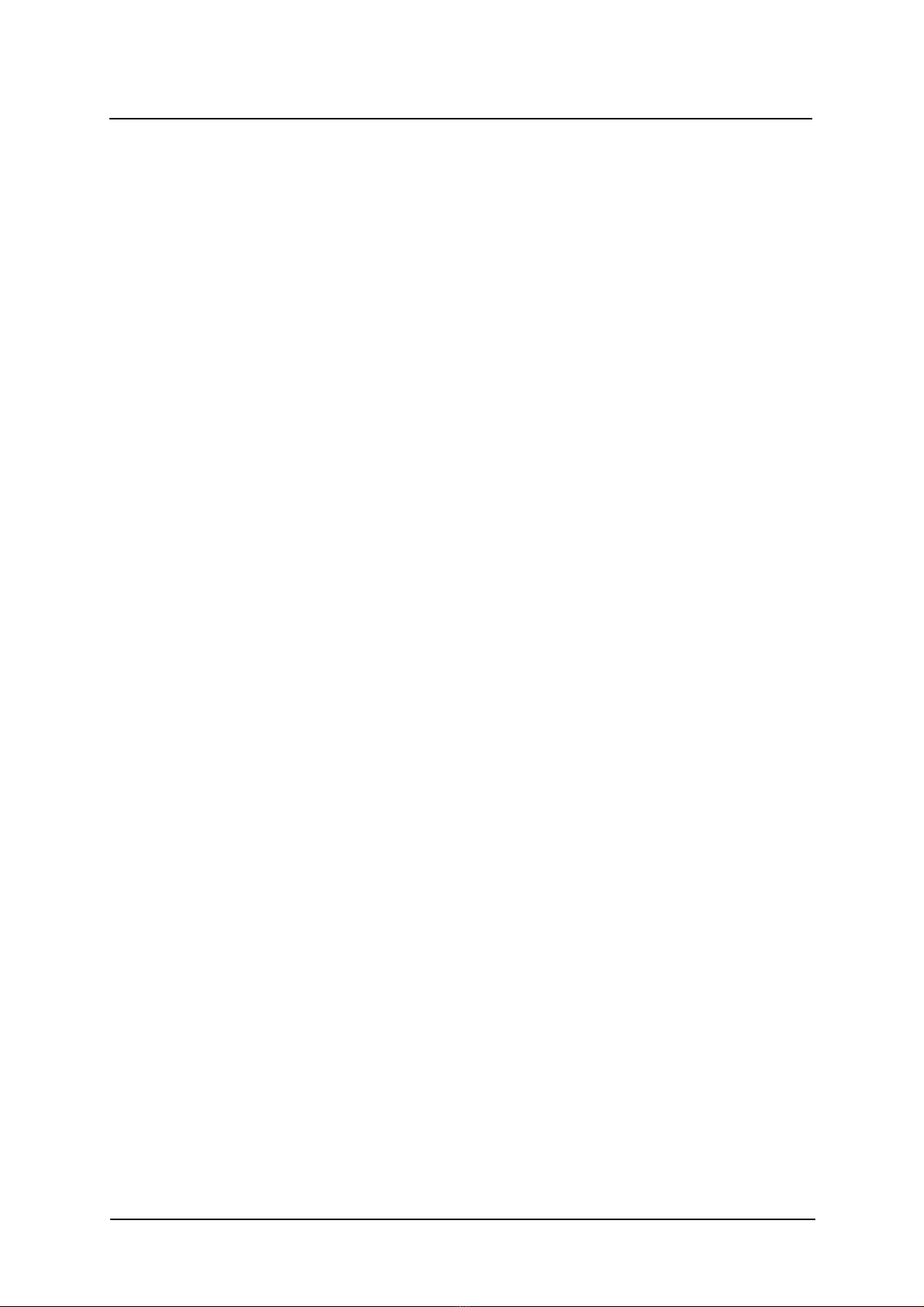

2.1 RP-A301CE/A351CE

2.1.1 Electrical safety devices

The electrical safety devices in accordance

with the EN 60204 standards are:

• Start and stop pushbuttons.

• Control circuit provided with electric

servo-control; in the case of blade

clamping the machine must be re-

started manually.

• Device to stop the rotation of the

blade if the clamping handle of the

blade guard is released.

Note:

When the machine is not used:

• Make sure that it is off.

• Re-position the slice thickness control

to zero.

Do not remove the labels placed on the

machine. Only replace them if damaged.

V 230

2 — Safety

2 - 4 Service Instructions RP-A301CE/RP-A351CE/RP-A355CE

2.1.2 Mechanical safety devices

The slicer is manufactured according to

EEC 89/392 Machinery Directive and

further modifications.

The mechanical safety devices are:

• Product holder removable only with

the slice thickness control on 0 (slice

thickness plate positioned to protect

the blade). After removing the

product holder the slice thickness

plate is mechanically clamped.

• Protection devices mounted on the

product holder to prevent the operator

from any accidental contact with the

blade.

• Blade guard. This fixed ring protects

that part of the blade which is not

used for the cutting operation.

• Aspecial mechanical safety device

which permits sharpening of the

blade, keeping the fingers of the

operator away from the cutting edge

of the blade.

2 — Safety

Service Instructions RP-A301CE/RP-A351CE/RP-A355CE 2 - 5

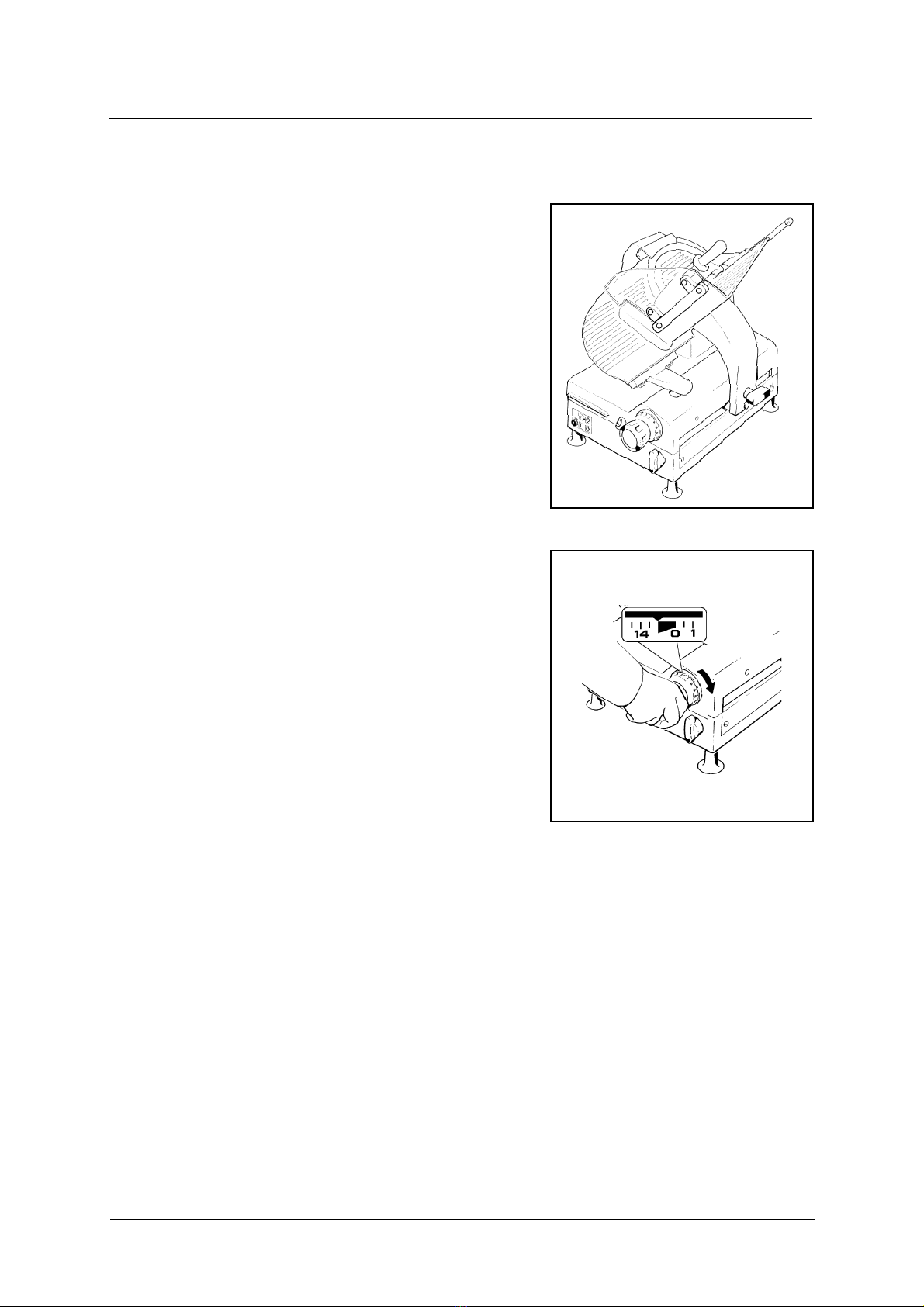

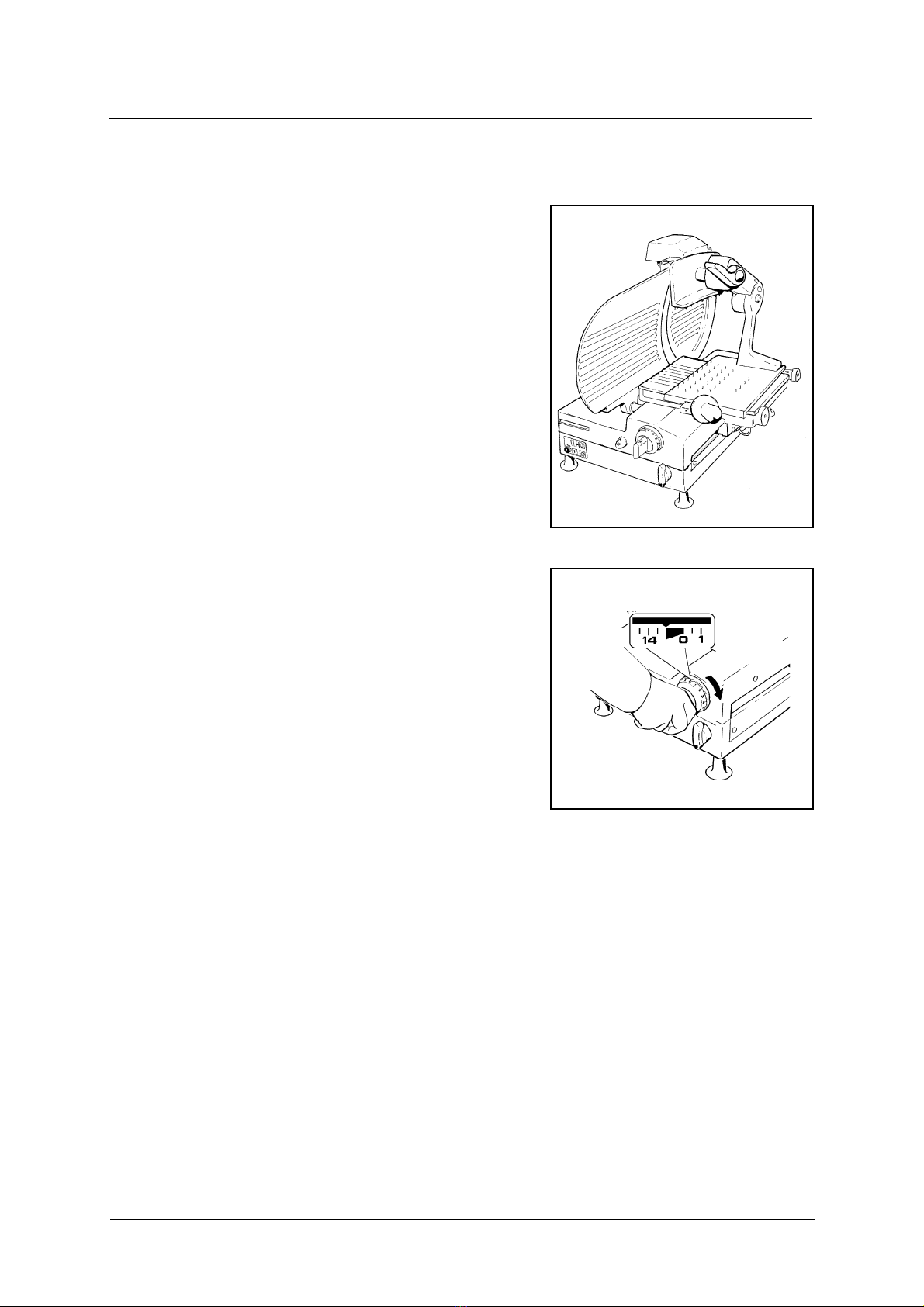

2.2 RP-A355CE

2.2.1 Electrical safety devices

The electrical safety devices in accordance

with the EN 60204 standards are:

• Start and stop pushbuttons.

• Control circuit provided with electric

servo-control; in the case of blade

clamping the machine must be re-

started manually.

• Device to stop the rotation of the

blade if the clamping handle of the

blade guard is released.

Note:

When the machine is not used:

• Make sure that it is off.

• Re-position the slice thickness

control to zero.

Do not remove the labels placed on the

machine. Only replace them if damaged.

V 230

2 — Safety

2 - 6 Service Instructions RP-A301CE/RP-A351CE/RP-A355CE

2.2.2 Mechanical safety devices

The slicer is manufactured according to the

EEC 89/392 and 91/368 standards, from

their initial publication up to September

1993.

The mechanical safety devices are:

• Product holder removable only with

the slice thickness control on 0 (slice

thickness plate positioned to protect

the blade). After removing the

product holder the slice thickness

plate is mechanically clamped.

• Protection devices mounted on the

product holder to prevent the operator

from any accidental contact with the

blade.

• Blade guard. This fixed ring protects

that part of the blade which is not

used for the cutting operation.

• Aspecial mechanical safety device

which permits sharpening of the

blade, keeping the fingers of the

operator away from the cutting edge

of the blade.

Section 3

Operation

Table of Contents:

page no

Service Instructions RP-A301CE/RP-A351CE/RP-A355CE 3 - 1

3.1 RP-A301CE/A351CE 3-3

3.1.1 Definitions 3-3

3.1.2 Technical specification A301CE 3-5

3.1.3 Technical specification A351CE 3-6

3.1.4 Slicer functioning and use 3-7

3.1.5 Cleaning and operator removable parts A301CE 3-14

3.1.6 Cleaning and operator removable parts A351CE 3-17

3.1.7 Sharpening A301CE 3-20

3.1.8 Sharpening A351CE 3-23

3.1.9 Lubrication 3-26

3.2 RP-A355CE 3-27

3.2.1 Definitions 3-27

3.2.2 Technical specification 3-28

3.2.3 Slicer functioning and use 3-29

3.2.4 Cleaning and operator removable parts 3-33

3.2.5 Sharpening 3-37

3.2.6 Lubrication 3-40

3 — Operation

3 - 2 Service InstructionsRP-A301CE/RP-A351CE/RP-A355CE

3 — Operation

Service Instructions RP-A301CE/RP-A351CE/RP-A355CE 3 - 3

3.1 RP-A301CE/A351CE

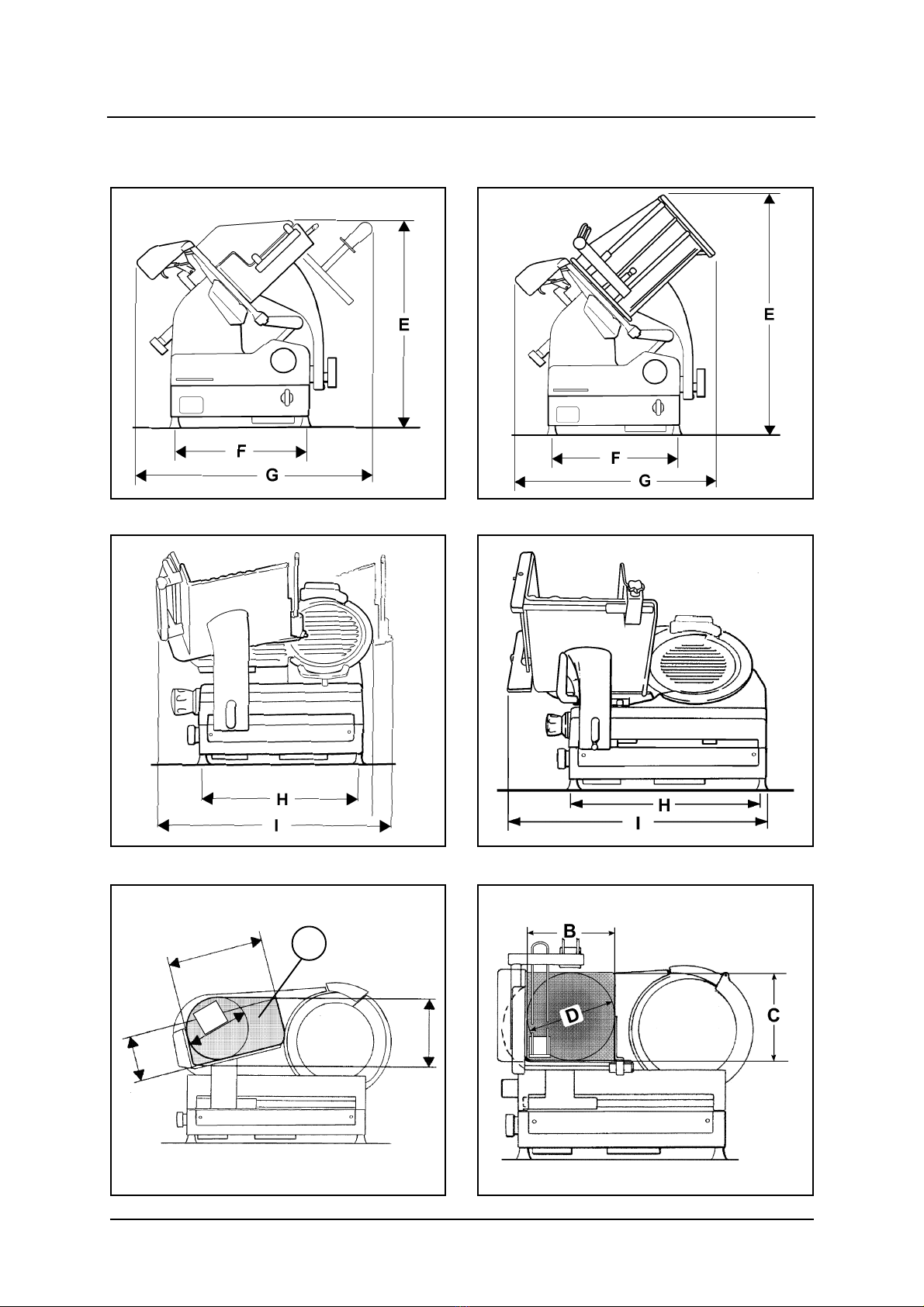

3.1.1 Definitions

1 Control pushbuttons

1a Start blade

1b Indicator light

1c Stop blade

1d Stop product holder

1e Start product holder

1f Product holder stroke

adjustment knob

2 Slice thickness control

3 Carriage release handle

4 Carriage

5 Product holder clamping

handle

6 Product holder

7 Product holder pushing

handle

8 Last slice device

9 Pusher

10 Carriage bar oiler

11 Blade

12 Bladecover

13 Blade guard

14 Slice thickness plate

15 Slice deflector

16 Slice receiving tray

17 Blade cover fastener

handle

18 Blade sharpener cover

19 Integratedblade

sharpener

2

1

3

14

11

4

5

7

13

12 9

8

1f 1e

1b 1c

1a

1d

1

16

10

17

15

19

18 9

3 — Operation

3 - 4 Service Instructions RP-A301CE/RP-A351CE/RP-A355CE

BN BC2 (Option 93)

B

A

D

C

10

3 — Operation

Service Instructions RP-A301CE/RP-A351CE/RP-A355CE 3 - 5

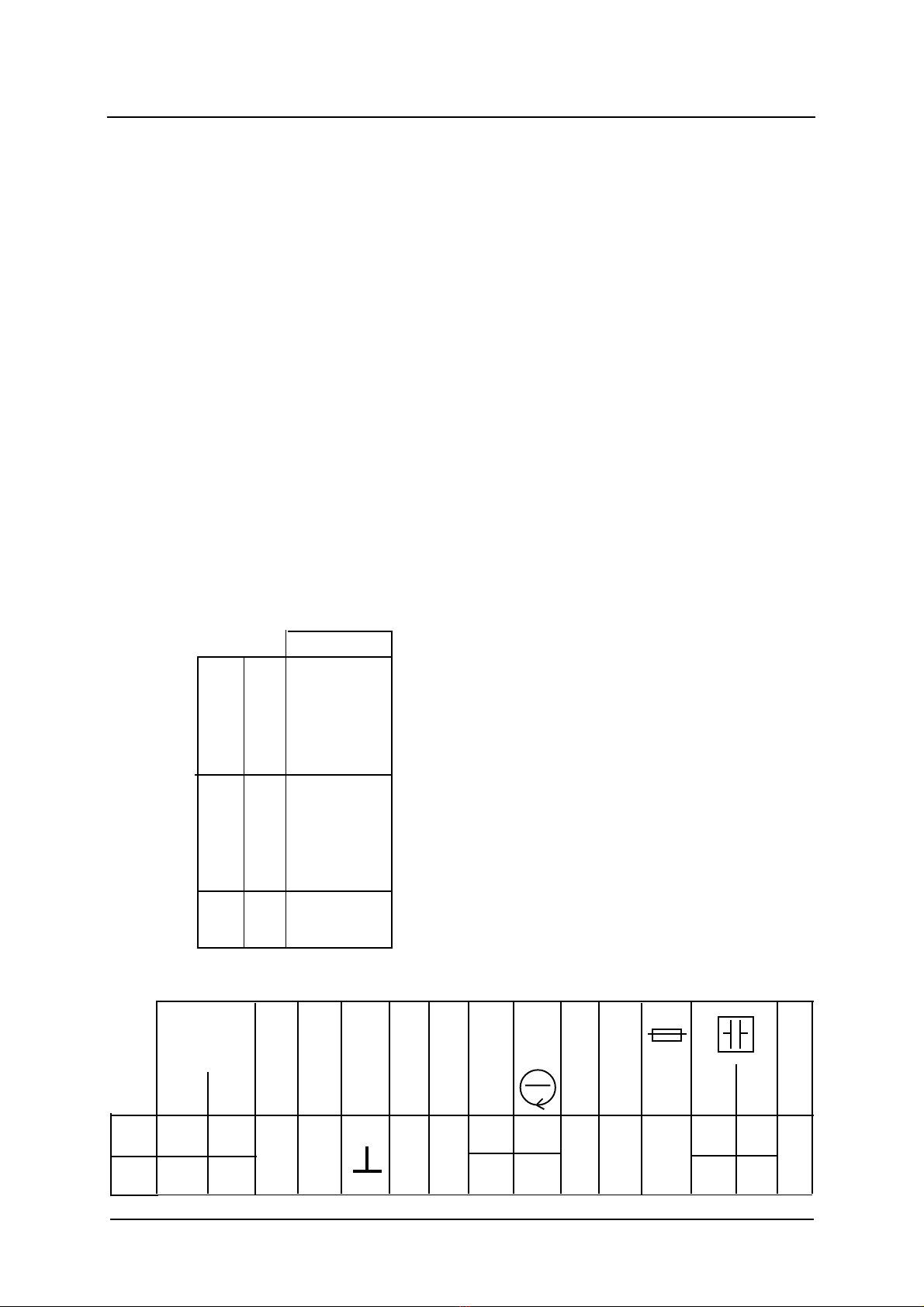

3.1.2 Technical specification A301CE

1 Blade Ø 300 mm

2 Slicing capacity

3 Dimensions mm

4 Weight Kg

a without packaging

b with packaging

5 Rangetemperature+5C-+40C

6 Slice thickness control 0 - 14 mm

7 Blade 300 rev/min

8 Acoustic <70 dB

9 Protection of the electrical system

and switches grade IP 33

10 Cutting zone

11 Blade motor

12 Carriage motor

Motors electrical data

11 130 270 2 1450 400 8

12 160 120 1 700 400 14

230 50 B S1 7 33

1~ 0,8

W

V Hz A CL A VL F IP

n

min

Nominal

Max.

Connection

Phase No.

Cos ϕϕ

ϕϕ

ϕ

Service

Degree of

Protection

RP A301CE

BN BC2

2 A 170 ==

B 210 215

C 220 205

D 200 205

3 E 530 650

F 300 300

G 550 480

H 400 400

I 640 610

4 a 40 40

b47 47

3 — Operation

3 - 6 Service Instructions RP-A301CE/RP-A351CE/RP-A355CE

3.1.3 Technical specification A351CE

1 Blade Ø 350 mm

2 Slicing capacity

3 Dimensions mm

4 Weight Kg

a without packaging

b with packaging

5 Rangetemperature+5C-+40C

6 Slice thickness control 0 - 14 mm

7 Blade 200 rev/min

8 Acoustic <70 dB

9 Protection of the electrical system

and switches grade IP 33

10 Cutting zone

11 Blade motor

12 Carriage motor

Motors data

11 160 330 2 1450 250 35

12 160 120 1 700 400 14

230 50 B S1 7 33

1~ 0,8

W

V Hz ACL A VL F IP

n

min

Nominal

Max.

Connection

Phase No.

Cos ϕϕ

ϕϕ

ϕ

Service

Degree of

Protection

RP A351CE

2 A 190

B 250

C 260

D 250

3 E 625

F 420

G 650

H 540

I 760

L 950

4a 59

b70

This manual suits for next models

2

Table of contents

Popular Kitchen Appliance manuals by other brands

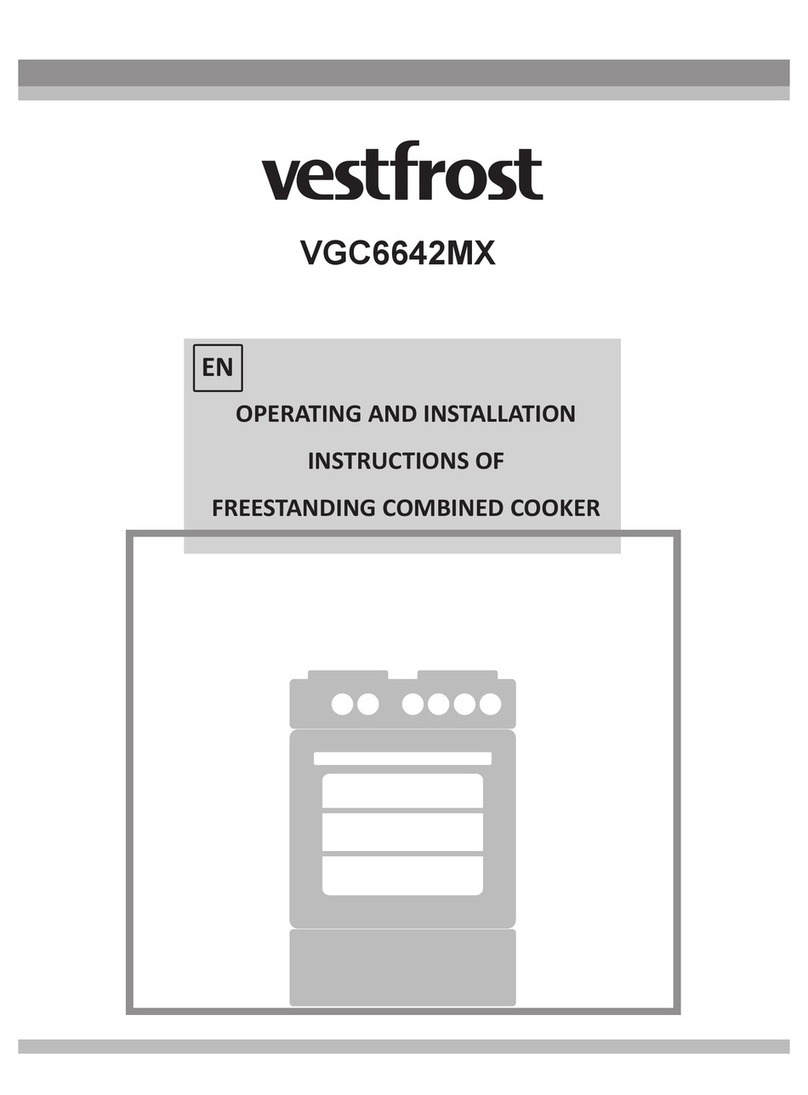

Vestfrost

Vestfrost VGC6642MX Operating and installation instructions

Roots & Harvest

Roots & Harvest 1566 Use & maintenance

Oliver

Oliver 758-N User operating instructions

Aurora

Aurora AU 3343 manual

Breville

Breville simplicity VHB113 Instruction booklet

Electrolux

Electrolux Dito 601563 Specification sheet