Aviattic ANSALDO A.1 BALILLA User manual

“ANSALDO A.1 BALILLA”

BUILD LOG

1/32 Ansaldo Balilla A1

Firstly, thank you for buying this Aviac kit!

Much love and aenon was lavished on its creaon and we very much look forward to seeing customers geng the best from the parts

and enjoying the process…

Having tried numerous approaches to a build guide or a set of instrucons it seemed a modellers approach to the various challenges best

suited this kit. This guide is an edited and enhanced version of Rons original prototype build log (hence the poor quality of some of the

photos) and is to be read in conjuncon with the kits booklet, photo cards and website galleries. Our sincere thanks to Dave Hooper for

his considerable eorts in presenng this guide.

There will be links posted on the website (www.aviac.co.uk) to other modeller’s builds as they appear on the various modelling forums

etc. Between those sources and careful examinaon of each stage and the parts concerned you should gain a good understanding of this

wonderful lile aeroplane and its construcon before you start.

With the recent advances in resin quality (and we have used the best) we hope you will not nd the build too much dierent from

regular plasc, though some “resin rules" sll apply…

PLEASE NOTE THE FOLLOWING...

1) Only remove the parts from their casng blocks when you are ready to use them. Store them carefully, away from heat and light.

2) Any warpage of parts that may have occurred in storage can be reced by immersion in very hot water and leaving on a at

surface to dry.

3) Wash all parts thoroughly in soapy water, or beer sll, household de-greaser or alcohol.

4) Resin dust is harmful if inhaled. Wear suitable parcle mask or respirator when cung, scraping or sanding parts.

5) For best results prime all parts before paint or decal applicaon. In the case of decals a gloss surface, polished and dust free is

essenal.

TOOLS AND EQUIPMENT

You will noce a variety of drill bits are required, these should be

part of your tool collecon and are a great help in any modelling

project.

A selecon of razor saws, wet and dry paper, needle les, etc.

Cyano glues of various drying mes, white or “PVA” glue, two-part

epoxy may be a preference and “Gorilla" glue has proved excellent

for aaching photo-etch over the varnish-sealed decals.

A PE folding tool will be an essenal aid to obtaining a clean fold on

the photo etch parts.

As Ron explains in his notes, you may want to add soldering to your

skill set. It certainly creates a beer bond and shouldn’t take long to

master on some scrap P/E…

AVIATTIC DIGITAL AND PRINTED DECALS

If are not familiar with “Aviac” digitally printed decals and you

wish to use the wood grain, linen and camouage supplied, please

read the instrucons provided. The various shapes need to be cut

exactly to the indicated outlines as they do not trim well whilst

wet.

Apply ONLY to gloss prepared surfaces.

The Pheon Models designed markings decals are applied in the

tradional way, warm water should be sucient to make them

conform, decal solvents are not recommended.

GOOD LUCK!

Our lile mul-media “Balilla” has been designed to look and feel like a wood, plywood, metal and linen biplane of 1918. The ne parts

and extensive photo-etched parts, such as rigging aachment points and internal details, reach new levels of achievement in a WW1 kit

and we hope to produce more kits in the future, promong interest in this fascinang period of aviaon history.

Please enjoy your modelling and let us see the results!

Richard Andrews

1/32 Ansaldo Balilla A1

Secon 1: Building the SPA 220 HP

Step 1: Engine block

Step 2: Cylinders

Step 3: Rear engine detail and camsha

Step 4: Springs and rockers

Step 5: Manifold assembly

Step 6: Magnetos and ignion wiring

Step 7: Turbo Pipe

Step 8: Spark plug wiring

Step 9: Carbureor

Step 10: Exhausts

Step 11: Intakes

Step 12: Pipes

Secon 2: Fuselage interior

Step 1: Fuselage basics

Step 2: Forward bulkhead

Step 3: Fuel tank

Step 4: Aileron control unit

Step 5: Rudder bar and oor

Step 6: Control sck

Step 7: Oponal control bar detail

Step 8: Interior assembly

Step 9: rewall and engine bearers

Step 10: Fuel Mixture Selector Quadrant

Step 11: Radiator Shuer Quadrant

Step 12: Instrument panel

Step 13: Ignion switch

Step 14: Cabane struts

Step 15: Cleaning the rear cowling

Step 16: Front cabane struts

Step 17: Gun mount bar

Step 18: Installaon of cockpit assemblies

Step 19: Oponal aileron control rod assembly

Step 20: Seat installaon

Secon 3: Fuselage exterior, machine gun and engine installaon

Step 1: Windscreen

Step 2: Turtle deck detailing

Step 3: Tail

Step 4: Turtle deck and tail assembly

Step 5: Empty shell drop box

Step 6: Engine installaon

Step 7: Machine gun installaon

Step 8: Oponal cowling trims

Step 9: Oponal Synchronizaon System

Step 10: Rear cowling

Step 11: Radiator shuers

Step 12: Radiator and Front Cowlings

Step 13: Oil tank

Secon 4: Landing gear

Step 1: Basic strut assembly

Step 2: Axle

Step 3: Fing to the fuselage

Secon 5: Fuselage detail

Step 1: Rear fuselage detail

Step 2: Actuator slot detail

Step 3: Air vents

Step 4: Forward fuselage detail

Step 5: Underside engine covers

Step 6: Fuel tank detail

Step 7: Hatches

Step 8: Engine air intake

Step 9: Rudder and Elevators

Step 10: Tail struts

Secon 6: Upper and lower wings

Step 1: Lower wings

Step 2: Lower wing installaon

Step 3: Cabane strut rigging brackets

Step 4: Interplane struts

Step 5: Interplane strut rigging brackets

Step 6: Upper Wing detail

Step 7: Actuator slots

Step 8: Cowling and Lower wing rigging points

Step 9: Fuel lines

Step 10: Upper wing assembly

Step 11: Actuator rod

Step 12: Fuel lines and windscreen

Secon 7: Final details

Step 1: Tail details

Step 2: Wheels

Step 3: Tail skid

Step 4: Propeller

Appendix

Jigs

Instrument panel layout

Glue part i14 in place so that is

protruding by 3.6mm

Note: All the parts required to build the engine are provided in a separate bag

with excepon of a few which are on the casng block marked ‘i’.

Step 1. (Engine block)

Clean the engine block and drill out the back of the engine with 3.5 mm drill

bit to later t part 26D. Clean up the slot to accept part 26D thoroughly!

Drill out two holes in

front of the engine to

t part i14. Also using a

0.55 drill bit, drill out

i14.

Step 2. (Cylinders)

Clean up parts 7,8,9

Part 9

Mounng holes for PE parts 22 / 23 on both sides of parts 7, 8

& 9 should be drilled with a 0.5mm drill bit.

Note that the slots are cut out on the boom of the cylinder's. To

ensure a good t of the parts drill shallow holes of 2mm in parts

7,8,9 and engine block.

Use a 2 part epoxy or CA glue to t the cylinders in to posion.

BUILDING THE SPA 220 HP

1/32 Ansaldo Balilla A1

i14

Part 8 Part 7

1/32 Ansaldo Balilla A1

Step 3. (Rear engine detail and Camsha)

clean up parts 12, 26A, 26B, 26C, 26D. They are glued in

the posions shown below (for addional informaon

refer to the booklet and website galleries). Glue these on

the engine with CA or epoxy glue.

26A

26B

26D

26C

12

26A

26B26D

26C 12

26A

26B

12

26D

26C

You have the opon to remove the

propeller sha of and replace it with 2mm

brass rod . Leave it longer than needed so

you can hold it for painng later!

?

Next, drill out 2 holes in the front of the camsha part 10 using

a 0.55mm drill bit to later t pipes of lead/copper.

Clean up the camsha part. 10

Glue part 10 on to the cylinder heads ensuring that the outside edges of

part 10 align to the outside of the cylinder head part (as shown le)

10

1/32 Ansaldo Balilla A1

Step 4. (Springs and rockers)

16

Drill out part 11 with a 2mm drill bit and then remove and clean the part.

Next, trim part 26A and drill out the hole with

0.9mm drill bit to t part 11 in place.

26A

11

16

28

At this stage your engine should look something

like this (pictured below)

Clean up the springs, (parts 16),

then glue all springs in place with

CA glue. Then clean t the rocker

arms (parts 28) making sure they

are in the middle of the camsha

slot and that the end rests on the

top of each spring as pictured le

28

16

1/32 Ansaldo Balilla A1

Step 5. (Manifold assembly)

5

2

Clean up the part 5 and open up the two centre holes using a 0.5mm

drill bit.

Then dry t part 5 on to part 6 leaving it on the casng block for now.

Drill a 0.5mm hole in part 6 through .

5

6

Glue part 5 on to part 4. Drill through the holes

in part 5 in part 4 deep enough to accept brass

rod. Glue 0.5mm brass rod in to these holes.

54

Next glue the parts together as in the picture on the right. You can

clean up part 6 now.

Carry out the same procedure for

pinning the part 2 pieces to the ends of

the part 4. Do not glue yet! (right) 2

1 and 3

5

6

2

4

Note: The following illustrates a method for assembling the manifold by pinning the parts with brass

rod. Alternavely parts can simply be glued together without pinning

Clean up the part 2 (2 pieces) and

open up the centre hole using a

0.5mm drill bit

Dry ng part 2 , drill out parts 1

and 3 with 0.5mm holes

1/32 Ansaldo Balilla A1

Step 5 (Connued)

To aid in the nal assembly of the manifold either use the engine as

a jig or construct a jig from plascard or wood. A jig is included in

the appendix secon at the rear of this build log.

To use the jig drill six 0.8mm holes in the posions dened and

assemble the manifold as illustrated right

Step 6. (Magnetos and ignion wiring)

Drill six holes of 0.3mm into the two

magnetos corresponding to each

connecon point and glue 0.3mm lead

wire into the holes represenng

ignion wires. Note: This best done

while the part is sll on the casng

block

Remove the ignion wire sheath parts from

the photo etch fret (parts 22 and 23). Anneal

these parts as well as a length of 0.3mm

copper wire before assembling.

22

23

22

Then bend both sides of part 22 inside as

pictured right.

Bend the copper wire in U shapes and feed

the rst one through the rst hole. The

second wire loop is fed through the next two

holes and so on...unl you have 6 separate

wires. Use CA glue or soldering to hold in

place.

1/32 Ansaldo Balilla A1

Step 6 (Connued)

Once all the wires are ed it should look something like

the picture on the right.

Then glue or solder part 23 on the open back edges of part

22.

Test t each Ignion wire tube to the engine assembly and

carefully trim each wire to the required length so that the

wire loosely ts the corresponding spark plug posion. Glue

or solder part 115 to the wires as shown below.

23

115

115

115

115

115 115

Step 7. (Turbo Pipe)

Paint the spark plugs with an

iron colour and brass.

Glue in place the

spark plugs on both

sides.

Then glue the turbo pipe in place which ts in to three holes near the base of the cylinder on

the starboard side of the engine. The thicker end of the turbo pipe should t into part 12

(above).

Glue the two magneto / ignion assemblies in place as

pictured right

12

1/32 Ansaldo Balilla A1

Step 8. (wiring)

Aach the assembled Ignion wire

sheath to each side of the engine

cylinders using brass rod or similar to pin

the tube into the three holes pre-drilled

into the cylinders just below the spark

plugs on each side of the engine.

Fit each spark plug connector (part 115)

to the corresponding spark plug as

pictured right.

Step 9. (Carbureor)

Glue the carbureor assembly in place.

Step 10. (Exhausts)

Do not cut o exhausts at an angle - cut them o

straight and drill out with a 1.4mm drill bit , then trim

and sand to marked angle.

Tip: To do this I made a jig of brass rod but styrene

also works. Drill a hole of about 9 - 10mm depth with a

1.4mm drill bit. then drill out 5mm with a 2.00 mm drill

bit.

Glue the exhaust parts in place on to the engine.

Twist and glue the six ends of

wire ed in to each magneto in

to the wide open end of the

corresponding ignion wire tube. Ignion wire tube ng points

1/32 Ansaldo Balilla A1

Step 11. (Intakes)

Drill 4 holes in the engine block

of 1mm (two each side)

Clean up resin parts i16 and i17

and glue in to the drilled out

holes . Check reference photos

for direcons part i17 ts on to

the manifold side of the engine.

Note; Ansaldo and Breda engines

had dierent arrangements for

what we believe were cooling

intakes. Also, some engines only

had intakes on the exhaust side of

the engine.

i16/17

i16/17

Step 12. (Pipes)

To bend the front copper pipes use the jig

supplied in the appendix secon of these

instrucons, I used an aluminium plate as a

basis for the jig but wood or plasc card is

also an opon.

Drill holes according to the supplied

template and glue in brass rod of 0.5mm

and 2mm.

Either used the supplied copper wire or cut

o 2 pieces of brass rod of 30mm length

0.5mm diameter and anneal the rods.

Place the rods in the jig and bend them at to the

surface. Use pliers to bend the wire around the 2mm

brass rod unl the shape is complete.

The picture below should be what the end result looks

like. Glue in place on to the engine between the front

of the camsha and part i14. Paint copper, or if using

copper wire leave unpainted.

1/32 Ansaldo Balilla A1

The nished engine should look some-

thing like this…..

FUSELAGE INTERIOR

1/32 Ansaldo Balilla A1

Step 1. (Fuselage basics)

Clean up the fuselage and sand away any imperfecons so it is completely smooth.

Drill hole out

to 3.9mm

Drill 1.0mm

holes both sides

Trim slot to a width of 1mm and extending downwards to a length of 9mm

to later t PE part 19/35, both sides

Cut fuselage to a length of 9.1 mm from the rst frame removing the

casng block if applicable (see le)

Trim the locaon stub on

the turtle deck to give some

room for correcons. dry t

only at this stage.

Clean up the bulkheads, parts 19/20/21. Also

clean up the turtle deck and dry t the parts.

20

Ensure sure the indentaons at the boom of

part 20 are facing forwards as indicated below

9.1 mm

?

Oponal : There are two methods of

ng the fuel tank (see Secon 2:

Step 3). The more accurate method

requires the removal of a secon of

fuselage underside between the rear

engine bulkhead and the forward

cockpit bulkhead (moulded in to the

fuselage). This secon can be

removed with a scalpel. If possible

keep the removed piece of fuselage

underside for later use.

When happy with the t of all the parts, glue in the bulkheads, parts 19

and 20 using CA glue to x in place making sure there is no interference in

the t in the slots. Do not glue the turtle deck yet!

Modelers Tip: Paint all interior

wood parts before nal ng of

bulkheads. Suitable wood grain

decals are available from Aviac.

Step 2. (Forward bulkhead)

Cut away PE part 30 and bend

to shape using a right angled

edge tool as an aid.

Modelers p: The joints can be

soldered together for extra

strength.

30

30

Glue PE part 30 in posion at the

front of the fuselage. You may need

to gently bend the two fuselage

sidewall edges inward to t the PE

part.

Remove the casng

block from the cockpit

oor with a ne razor

saw. Cut o the red

areas shown in the

picture on the le and

drill out the holes if

necessary .

1/32 Ansaldo Balilla A1

30

30

Remove the moulded detail marked in red in the picture on the

right and thin the inside fuselage walls to 0.3 mm in this area.

Note: There is an opon to sand away the detail of the ange and use PE part 11 instead

Step 3. (Fuel tank).

Step 3. (connued).

Clean up the fuel tank as well as parts F1 and F3. Drill two holes of 0.9mm in to the tank as shown in the picture above right.

F3

F1

Glue parts F3 in posion on to the fuel tank (pictured le)

1/32 Ansaldo Balilla A1

Dry t the cockpit oor on

top of the fuel tank.

Gently spot drill the fuel tank using a 2.4mm drill bit

using the two holes in the cockpit oor as guides

?

Dry t the tank in to the fuselage (DO

NOT GLUE YET!), ensuring that the lug

on the underside of the tank ts in to

the corresponding hole in the fuselage

(see below).

If building the opon with the accurate

fuel tank assembly (See Secon 2: Step

1) place the fuselage on a at surface

and slot the fuel tank in to posion using

the at surface to hold the tank in

posion.

F3

F3

1/32 Ansaldo Balilla A1

Step 3 (Connued).

Remove the ooring and tank

from the fuselage and drill two

1.8mm holes with a depth of

approx. 0.5mm at the posions

that were previously spot

drilled .Glue in parts F1 in to

these holes

F1 F1

Now remove PE parts 28 from the PE fret and bend in to shape

(above le). Then glue them on to the tank so that they t in-

between the central rows of rivets on each side.

28 28 28

28

= Rivets

The fuel tank can now be painted and glued in to posion UNLESS opng for the accurate fuel tank assembly (as below):

Remove the lug from the underside of the fuel tank. Either glue

the retained piece of removed fuselage underside (see Secon 2:

Step 1) or glue a piece of plascard of a similar substance to the

underside of the fuel tank and trim ush to the edge of the fuel

tank (see le).

?

?

Glue PE fuel tank underside on to the underside of the fuel tank as

illustrated right.

Oponal: If the intenon is to build the accurate fuel tank

assembly opon:

Set the fuel tank aside. Do not glue in to the fuselage yet!

1/32 Ansaldo Balilla A1

Glue or solder two 0.3mm 4mm long pins in to

the ends of PE parts71 Then glue the two PE

parts 71 in place on to the four brass pins ed

above. Trim the ends of these four brass pins so

that they are ush with PE parts 71

2 x 0.3mm Pins

Step 4 (Aileron control unit ).

Cut away part 18 from its casng block and drill

4 holes of 0.3mm as pictured le.

Glue 4 pins of 0.3mm brass in to the holes that

you have just drilled.

18

18

71 71

Glue or solder two 0.3mm pins that are 5mm in

length in to the top edge of PE part 101

101

2 x 0.3mm Pins

101

Sandwich PE parts 101 between and at each

end of PE parts 102 so that the 5mm brass rods

ed to PE parts 101 (as described above) are

threaded through the holes at each end of parts

PE 102. Glue PE parts 102 together but avoid

gluing each end, leaving PE parts 101 free to

move

101

101

102

102

Glue or solder 0.5mm brass rod in to the center of PE part 102 shown in picture above.

0.5mm brass rod

Note: This unit will not be seen as it sits

under the seat and this step can therefore be

treated as oponal.

Step 4 (Connued).

Glue PE parts 72 each side of PE parts

102 so that the hole in PE parts 72 ts

over the 0.5mm brass rod ed above.

The slot PE part 73 over the ends of PE

part 72 as pictured le.

Fit the aileron control bar assembly to

assembly detailed at the beginning of

step 4 via the pins in PE parts 71.

Do not glue yet!

72

73

71 71

1/32 Ansaldo Balilla A1

In this posion of the ailerons are neutral

If PE part 71 is poinng upwards

to the right of the picture and

the le is down that means the

ailerons are from the pilots view,

le side down and right side up.

The opposite would be true if

the aileron control bar points

towards the le.

Glue or solder the aileron control bar to required posion

dependent on aileron posions (See le and below).

When the assembly is complete

paint it and glue in to the slot on

the fuselage ensuring that the

assembly sits at the base of the

slot as pictured right.

Step 5 (Rudder bar and oor).

Clean up all of these parts which can all

be found on block “i”.

We suggest replacing part i4 with brass

rod, 22mm x 0.8mm.

i 9 i 19 i 2 i 1 i 3 i 4

102

Note; In most period photographs of the A1, ailerons appear to be

in a neutral posion when the aircra is staonary.

Anneal PE part 63 and bend to shape using tweezers then

glue in place on to each end of part i9.

72

1/32 Ansaldo Balilla A1

Drill two 0.3mm holes through Part i9 for control wire as pictured above

i 9

Drill 0.3mm holes here

Glue part i1 in place on to the cockpit oor ensuring

that the inversed ‘T’ sits ush with the edge of the

slots.

Step 5 (Connued).

Step 6 (Control Sck).

The modeller has a choice of either gluing in all of the parts or with very careful drilling, leaving an ‘arculated’ assembly

Drill a hole of 0.8mm in to the end of

part i19. Glue in part i4 or a 0.8mm

brass rod replacement 22mm in length. i 19 i 4

Drill a 0.5mm hole in the end of part i2

i 2

Also Drill a 0.3mm hole here i 2

i 1

1/32 Ansaldo Balilla A1

Step 6 (connued).

Drill a 0.3mm hole of in to

part i19 and press in a piece

of 0.3mm brass rod

sandwiching i2 between i19

Don't glue it so that it can

move freely.

i 19

i 2

i 4

Drill a 0.5mm hole in the end of part i3.

i 3

Pin part i3 to the end of part i2 with two 0.5mm resin hex

nuts or with brass rod as pictured right.

i 3

i 2

Or the parts can be all be glued as illustrated on the le.

?

Cut away PE parts 92, 93 and 95.

Glue PE part 92 in to part i2 as in middle picture

cung a 0.2 slot half way through the sck to accept

PE part 92. Fit PE parts 93 and 95 to PE part 92 as illus-

trated above.

92

i 2

92

92

95

93

Table of contents

Popular Toy manuals by other brands

Hasbro

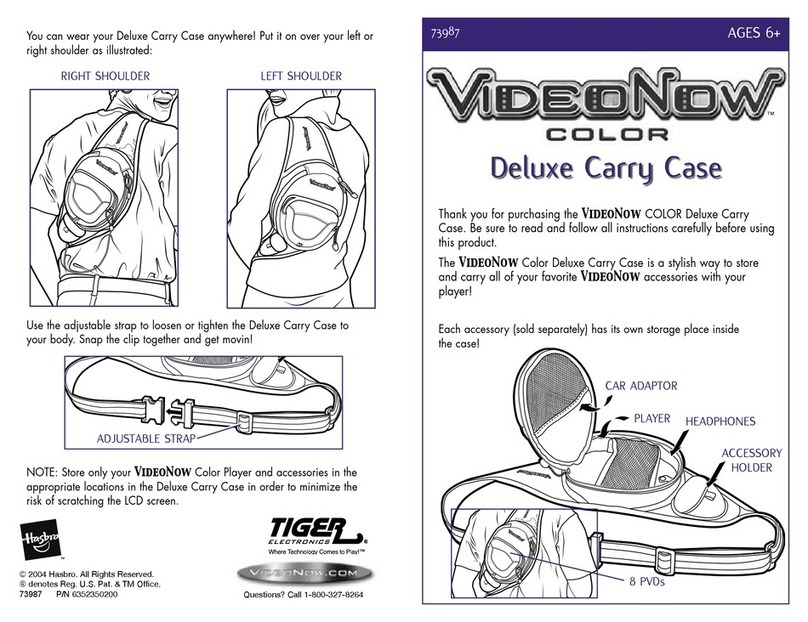

Hasbro Video Now Color Deluxe Carry Case 73987 instruction manual

Phoenix Model

Phoenix Model Diabolo Instrction manual

Skynetic

Skynetic Shrike Glider instruction manual

Passione 3D

Passione 3D MB339 Mounting instruction

Bladez Toyz

Bladez Toyz BTSW008 operating instructions

LeapFrog

LeapFrog Touch Magic Rockin' Guitar Parent guide & instructions