Manufacturing instructions Cubola®Summerlight®

Cubola Summerlight EN 26-04-2017 page 6

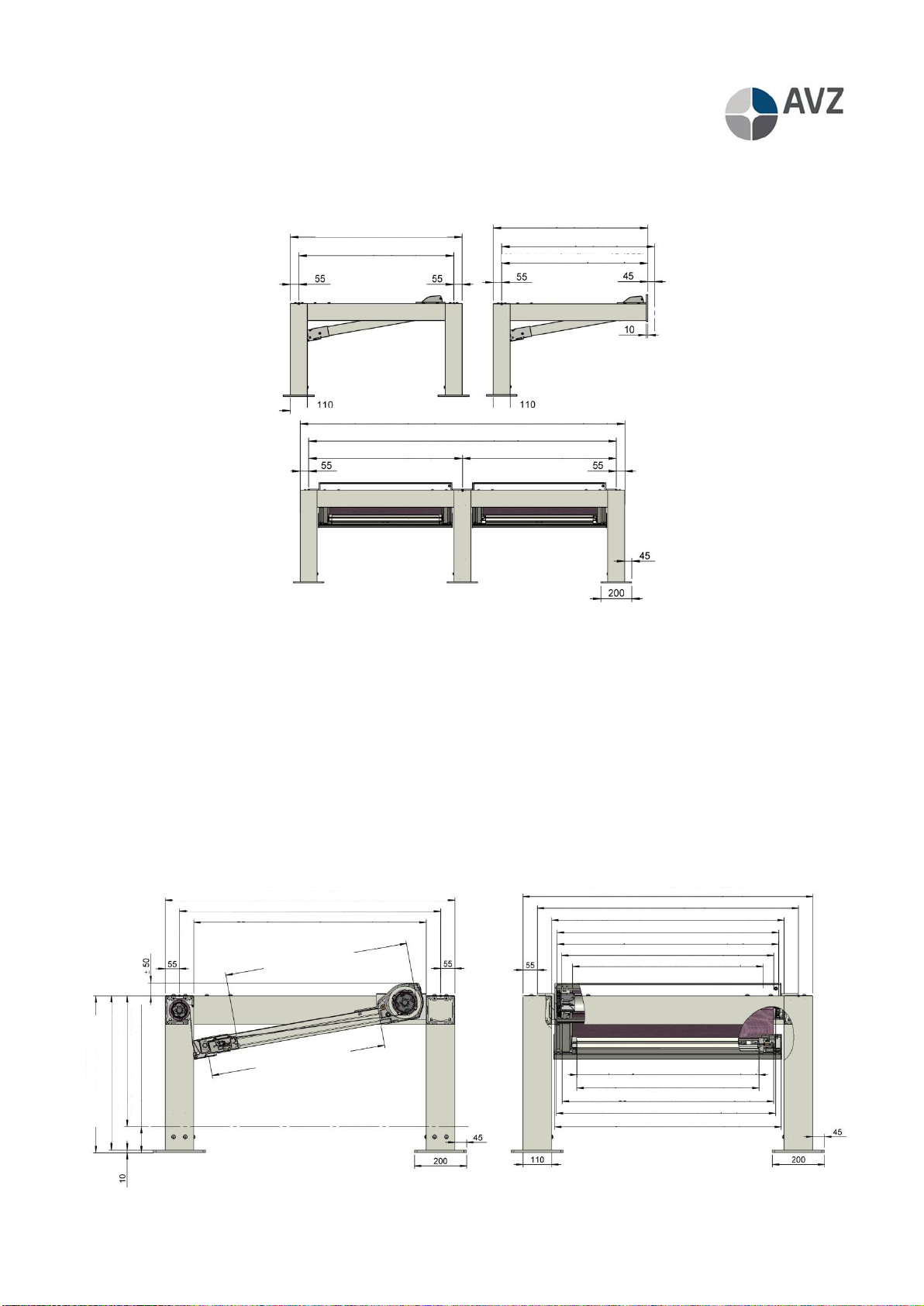

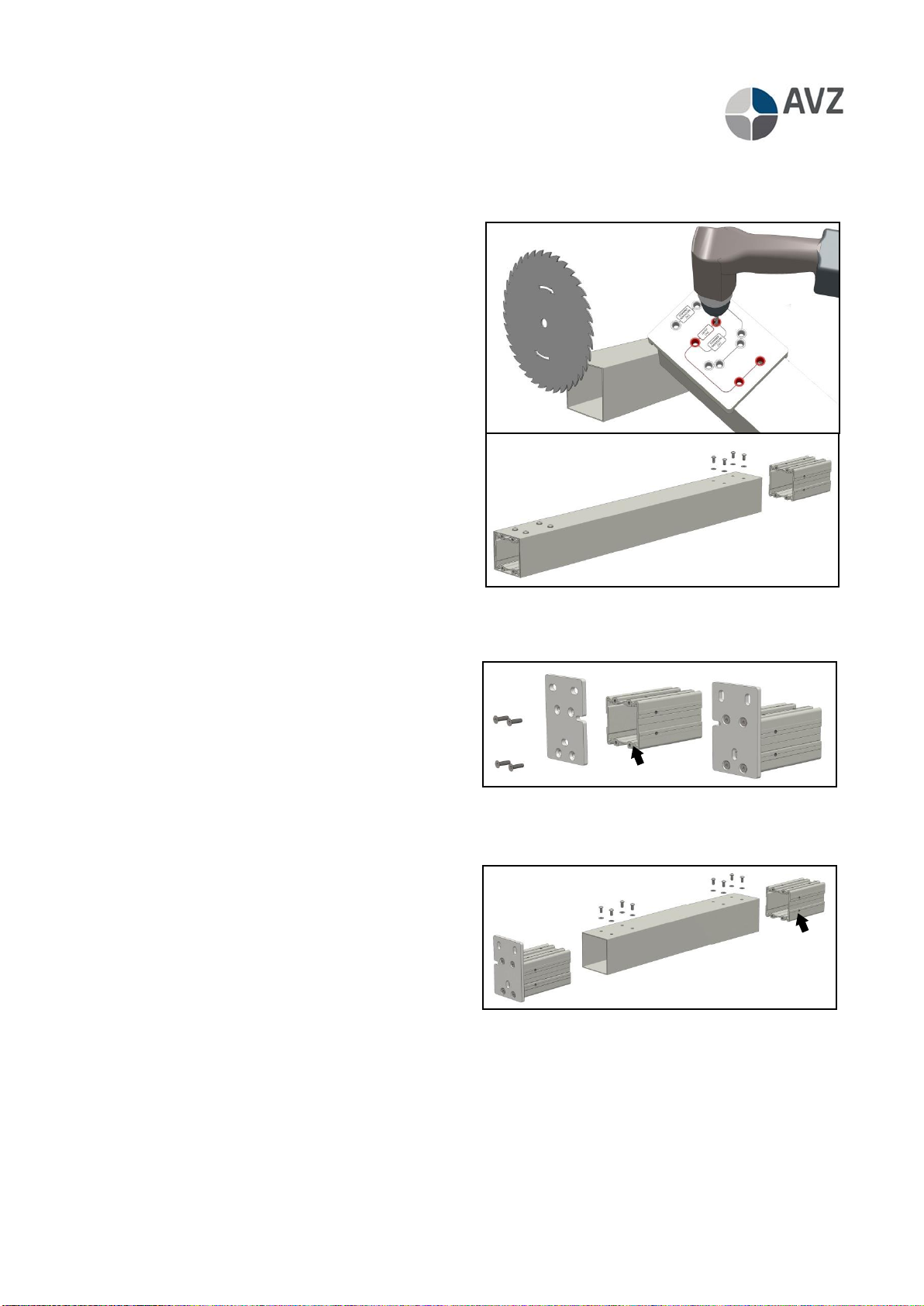

Beam assembly

This pre-assembly occurs several times, depending on the chosen Cubola Summerlight model. In case of a choice for

wall mounting, only wall-mounted beams will be provided (see next page).

a. Shorten the beam lengthways, cut off at right angle.

b. Place the drilling template and drill 4 holes

according to the 'beam' pattern. Do the same on the

other side of the profile.

c. Insert the corner mounting piece in the beam. Note:

Turn the side with the most holes towards the

centre of the profile so that the corner mounting

piece is laid 2 mm into the beam. N.B.: When the

profile is turned around, the corner mounting piece

will be flush with the profile. This is used for wall

mounting and thus not desired for this application!

If the beam is used for wall mounting, a corner

mounting piece will only be fitted to one side of the

profile. A wall mounting support will be fitted on site

to the other side of the profile.

d. Fasten the corner mounting pieces with the bolts on

the top.

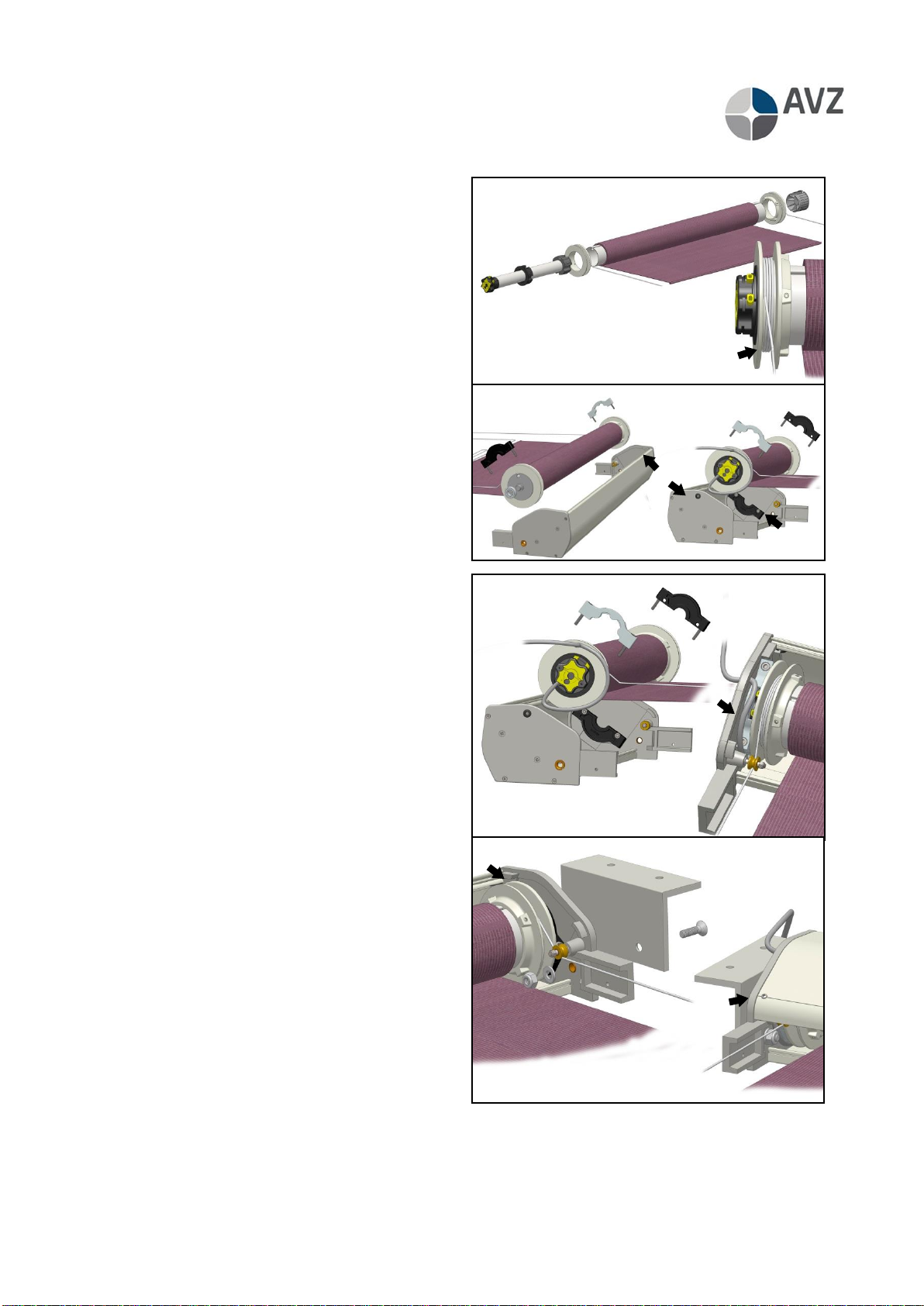

Pre-assembly beam for wall mounting

In case of a choice for a wall-mounted system, the beams to be fitted against the walls will be provided with a wall

mounting plate.

a. Screw the wall mounting plate to the mounting

profile.

b. Note: 4 holes of the wall support should be directed

upward so that the outside of the profile is flush

with the end of the beam. The distance between the

wall mounting plate and the first holes is then 50

mm.

c. Slide the mounting profile into the tubular profile

(sawn and drilled as under beam pre-assembly).

d. Temporarily fasten the top of the wall mounting support or deliver the support separately with the profile.

First mount the support on site to the wall before attaching the beam.

e. Insert the other corner mounting piece into the

beam and fasten it.

f. Note: Turn the side with the most holes towards

the centre of the profile so that the corner

mounting piece is laid 2 mm into the beam.

N.B.: When the profile is turned around, the corner

mounting piece will be flush with the profile.