2

Table of Contents

Unpacking.....................................................................................3

Quick Start Guide...........................................................................3

Power ..........................................................................................3

Installation.....................................................................................3

Product Description................................................................................. 3

Technical Specifications...................................................................4

Part Number Guide.........................................................................4

Wiring Connections ................................................................................. 5

Power Supply .......................................................................................... 6

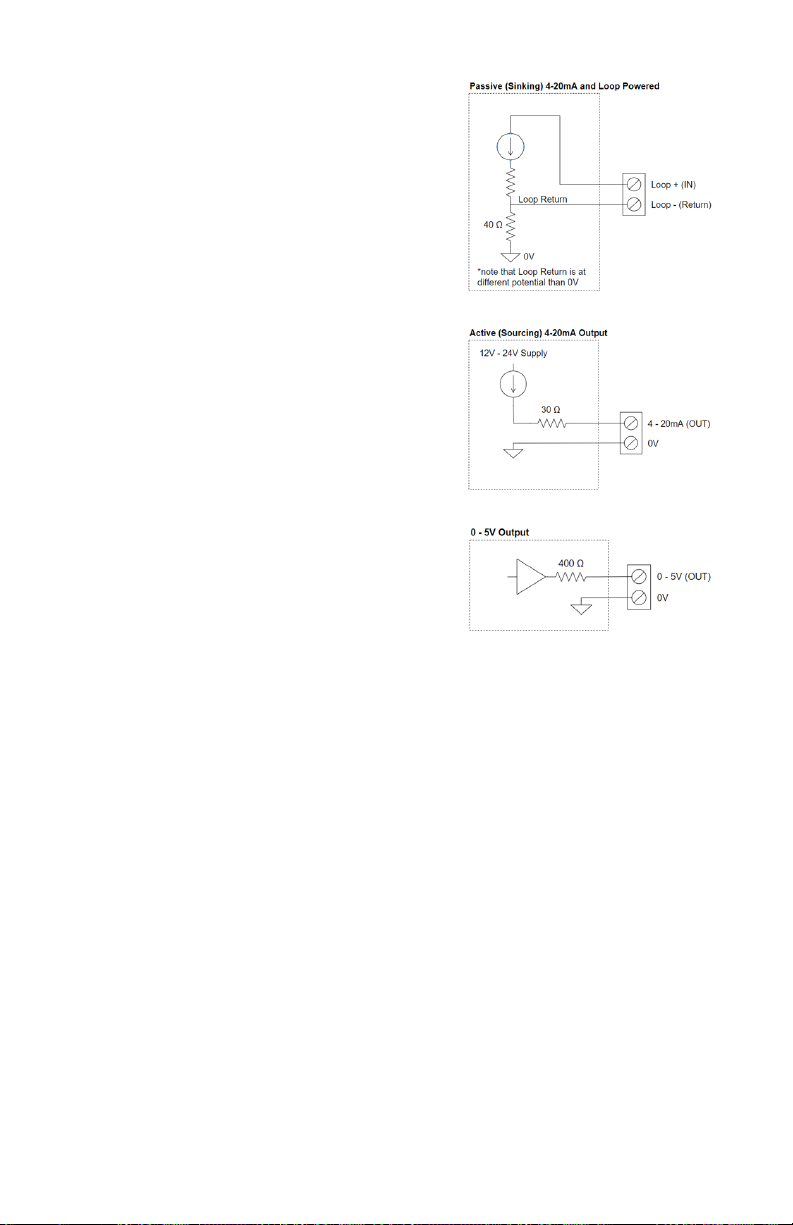

Isolated Outputs ...................................................................................... 6

Analog Outputs........................................................................................ 7

Navigational Buttons ............................................................................... 8

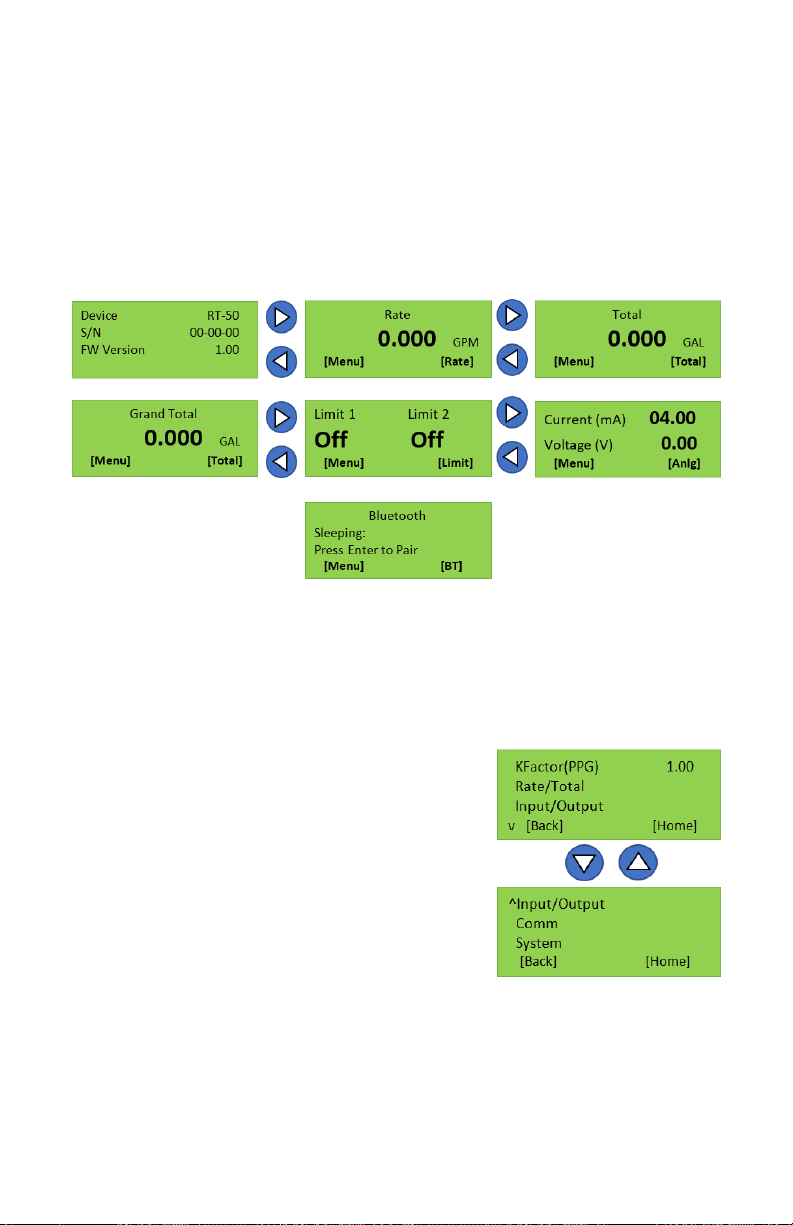

Run Mode Screens .................................................................................. 9

Menu Navigation ............................................................................9

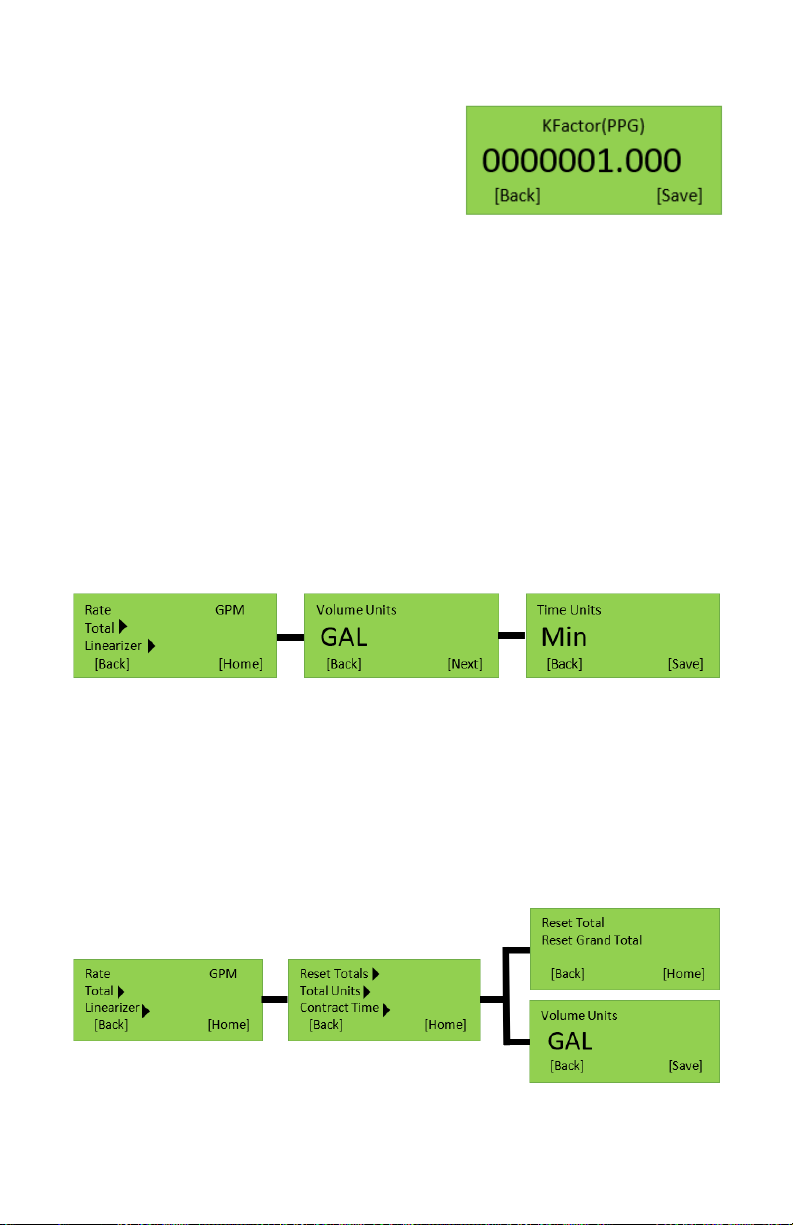

K-Factor......................................................................................10

Rate ...........................................................................................10

Total...........................................................................................10

Contract Time................................................................................11

Linearizer......................................................................................11

Input/Output.................................................................................12

System........................................................................................12

Bluetooth ............................................................................................... 13

Mobile Bluetooth App ............................................................................ 13

Menu Navigation ...........................................................................14

System Settings ............................................................................15

Output Settings .............................................................................16

Output Calibration..........................................................................16

Limit Settings................................................................................ 17

Linearizer.....................................................................................18

Device Log............................................................................................. 19

Date/Time Settings ................................................................................ 19

Compter Toolkit ..................................................................................... 20

Connecting..................................................................................20

Updating Firmware.........................................................................21