Adjust K Factor:

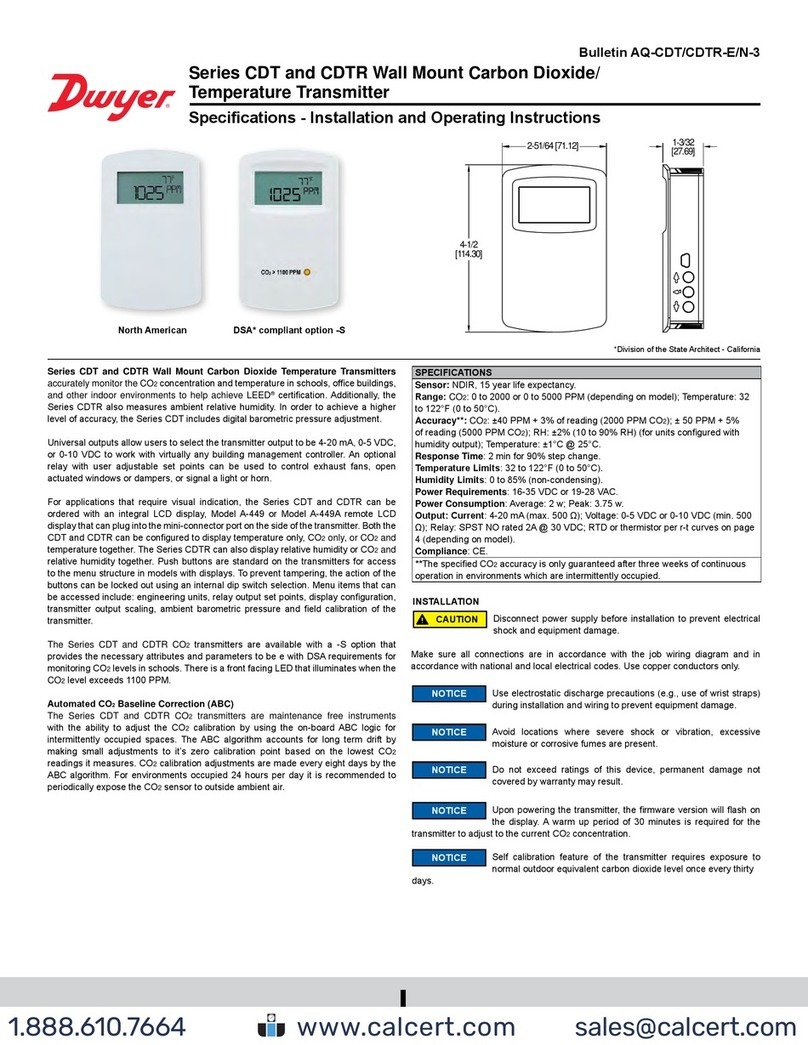

If the optional display is present, the K factor used in velocity mea-

surements may be adjusted. This is done by activating the K fac-

tor adjustment function of the unit. To activate the K factor adjust-

ment function, take the shorting jumper from programming block

PJ5 and place it on the upper two terminals next to the letter “K”.

See Fig. 5. The display will now show the programmed Pitot tube

K factor. The K factor can be adjusted up and down by using the

zero and span buttons as up and down buttons. Once the desired

K factor has been set, replace the shorting jumper on PJ5 to its

velocity position (“V”). The shorting jumper must not be left in the

“K” position for proper operation of the unit. The factory setting for

the K factor is 1.0 and it is adjustable from 0.5 to 3.

Adjust Filter Time Constant:

If the optional display is present, the dampening filter time constant

of the output may be adjusted from 0.5 to 15 seconds in 1-second

increments. In turbulent air, the pressure reading may be unstable.

The dampening filter time constant is provided to reduce such

noise. The time constant is the actual filter time constant, not aver-

aging time. For an abrupt change in pressure it will take three time

constants to reach 95% of the final value.

To activate the filter adjustment function, take the shorting jumper

for programming block PJ3 and place it on the upper two termi-

nals next to the letter “F”. See Fig. 5. The display will now show the

filter time constant. The time constant can be adjusted up and

down by using the zero and span buttons as up and down but-

tons. Once the desired time constant has been set, replace the

shorting jumper on PJ3 to its original position. The shorting jumper

must not be left in the “F” position for proper operation of the unit.

The factory setting for the time constant of the filter is 0.5 Seconds.

USER CALIBRATION

The transmitter may be user calibrated. With the two buttons

marked "Zero" and "Span" (see Fig. 5) four calibration coefficients

may be altered: Pressure zero, Pressure span can be calibrated

with the two buttons marked “zero” and “span” (see Fig. 5). Analog

output zero, either 0 V or 4 mA, and Analog output Full Scale,

either 10 V or 20 mA may be adjusted with two buttons marked

“zero” and “span” in conjunction with jumper settings. Pressure

and output are calibrated separately to ensure the displayed pres-

sure is correct and the analog output has accurately calibrated end

points. These calibration coefficients are stored in nonvolatile

memory, which retains its content indefinitely without external

power or batteries. Factory calibration may be easily restored.

To calibrate the transmitter you will need three pieces of equip-

ment. First, you will need a calibrated pressure source capable of

generating a stable pressure value for the maximum range of the

unit under test. You will need a manometer or gage capable of val-

idating the calibration pressure unless that is built into the pressure

source. You will also need a voltmeter or milliammeter to calibrate

the output. The transmitter is calibrated using the following proce-

dure.

Preparation – Depending upon if it is a 2-wire or 3-wire system,

connect the voltmeter or milliammeter and power supply, being

careful to observe polarities. The transmitter must be calibrated in

a vertical position.

Calibrating Pressure Zero – Leaving the hose barbs

vented,press and hold the “Zero” switch for about 4-5 seconds.

The zero point should now be set and if the display is present, the

display will read zero. Calibrating pressure should begin with the

zero then the span since the zero setpoint will affect the span

value.

Span – PJ3 Jumper must be in “H” position to calibrate the span.

Connect the pressure source and apply the high range rated pres-

sure. When the pressure has stabilized, press and hold the “Span”

switch for about 4-5 seconds. The display, if present, will now read

the calibration pressure. Span may only be calibrated on the high-

est range for the unit.

Calibration of Analog Output – To adjust the analog output zero;

set jumper settings PJ3 (F) and PJ5 (K) (see Fig. 5), “double click”

the Zero switch. The zero switch must be pressed twice within

about one second. “Double clicking” too fast may not be recog-

nized. Depending upon the configuration the analog output should

now read approximately either 0 V or 4 mA. This can be changed

by pressing the “Zero” switch to decrease the reading or pressing

span to increment the reading. Set the current output to 0.00 V or

4.000 mA. End the analog zero calibration mode by pressing

“Span” and “Zero” switches simultaneously. The output should

then vary with pressure.

The analog output’s zero and full scale settings do not interact so

they may be performed in any order or only one may be adjusted.

They are independent of pressure so no pressure source is

required for output calibration.

Note: When the jumpers are in position (K) and (F) the pressure

zero and pressure span calibration is not operative.

Analog Full Scale Calibration – To adjust the analog output

span; set jumper settings PJ3 (F) and PJ5 (K) (see Fig. 5), With the

voltmeter or milliammeter connected to the transmitter output,

“double click” the “Span” switch as described above for the ana-

log output zero calibration. The reading on the meter should now

read about 10 V or 20 mA. Change this value by pressing the

“Zero” switch for down and the “Span” switch for up as described

above. When complete, press the “Zero” and “Span” switches

simultaneously to return operation to normal. The analog output

reading should now indicate the process value.

Note: When analog calibration is complete move the jumpers back

to their appropriate position.

Restoring Factory Calibration Coefficients:

The user calibration does not affect the factory calibration coeffi-

cients. The factory defaults are easily restored if the user calibra-

tion must be "erased". Simultaneously press both the "Zero" and

"Span" buttons and hold them for approximately 4-5 seconds. The

factory calibration should now be restored.

MAINTENANCE

Annual recalibration is suggested. No lubrication or other periodic

servicing is required. Keep exterior and cover clean. Occasionally

disconnect pressure lines to vent both sides of gauge to atmos-

phere and re-zero. Do not use solvent to clean transmitter. Use

only plastic compatible cleaners or water.

The Series MS is not field serviceable and should be returned if

repair is needed (field repair should not be attempted and may void

warranty). Be sure to include a brief description of the problem plus

any relevant application notes. Contact customer service to receive

a return goods authorization number before shipping.

Bulletin A-26

Page 4

©Copyright 2006 Dwyer Instruments, Inc. Printed in U.S.A. 6/06 FR# 01-443337-00 Rev. 3

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. Box 373 • Michigan City, IN 46361-0373, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

A-26 6/6/06 1:11 PM Page 4