DRAGSTER CONFIDENTIAL

A ter this we should make the o set correction in order to use again all the ADC range,

otherwise the irst DN are wasted or the black signal and we'll never get pixels with values under what

was set. This should be made on chip using the Control 2 and Control 1 register. The next sequence is

the most adequate and although others might also work these steps are the sa est.

Using the “Send” buttons o the individual registers, ollow this sequence:

1. Start by making sure that in Control 1 "Subtract o set" bit is 0 and "Update request" to 1. Click

“Send”

2. Set the sensor to dark condition and adjust the black level to the smallest output value over 0,

like described in this document. Avoid any pixel value o 4DN,i.e., the lowest ADC output

value.

3. Set in Control 2 "Write O set" bit to 1. Click “Send”.

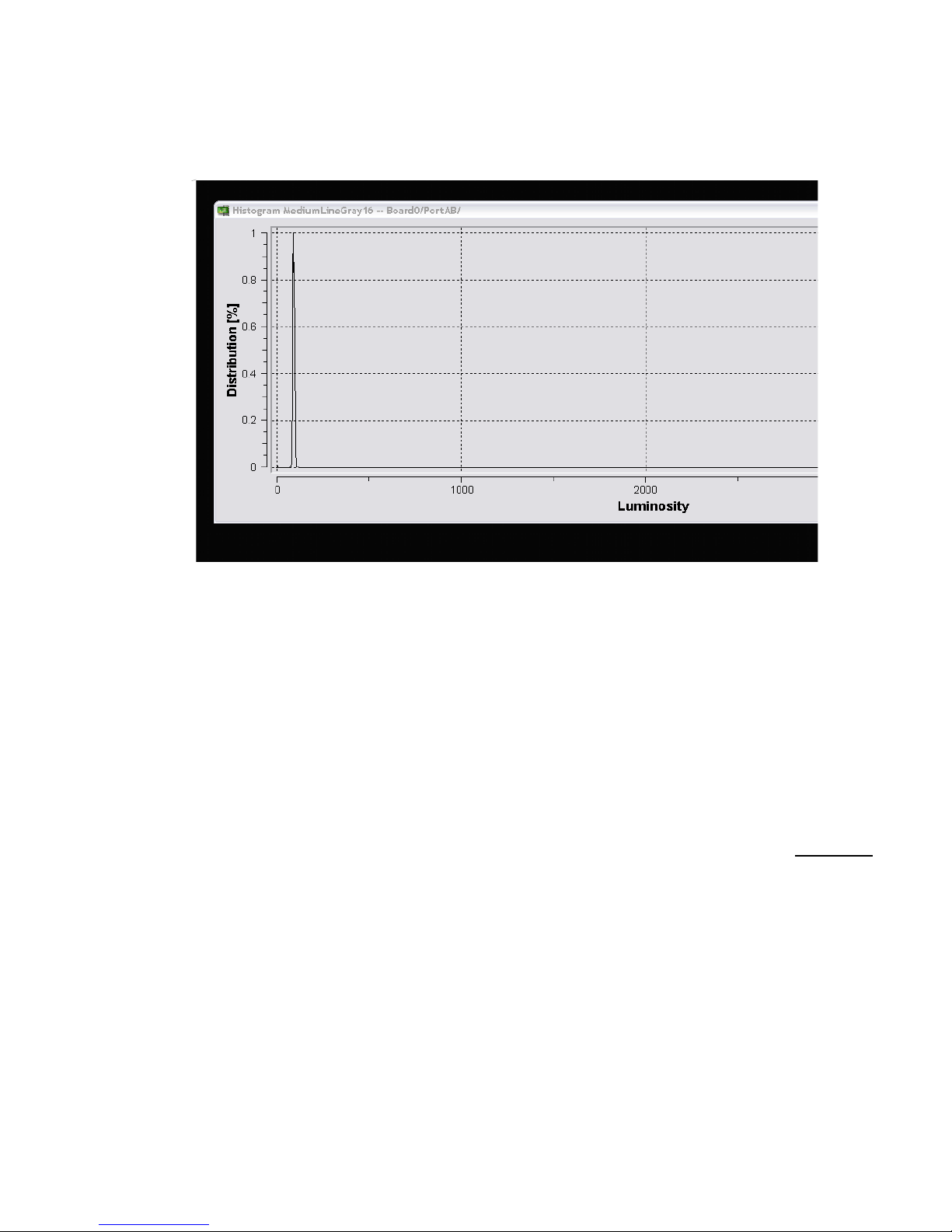

4. Using Control 1 send the "Update request" on 1. Click “Send”. The image will ALWAYS

reeze, i.e, is not light sensitive, and the new acquired values are written to the internal o set

register. Looking at the histogram, i it did not reeze, the sequence has to be restarted.

5. Set in Control 2 "Write O set" bit to 0. Then “Send”.

6. Set in Control 1 "Subtract o set" bit to 1 and "Update request" to 0. Click “Send”.

7. Set again in Control 1 the "Update request" bit to 1 and click “Send”.

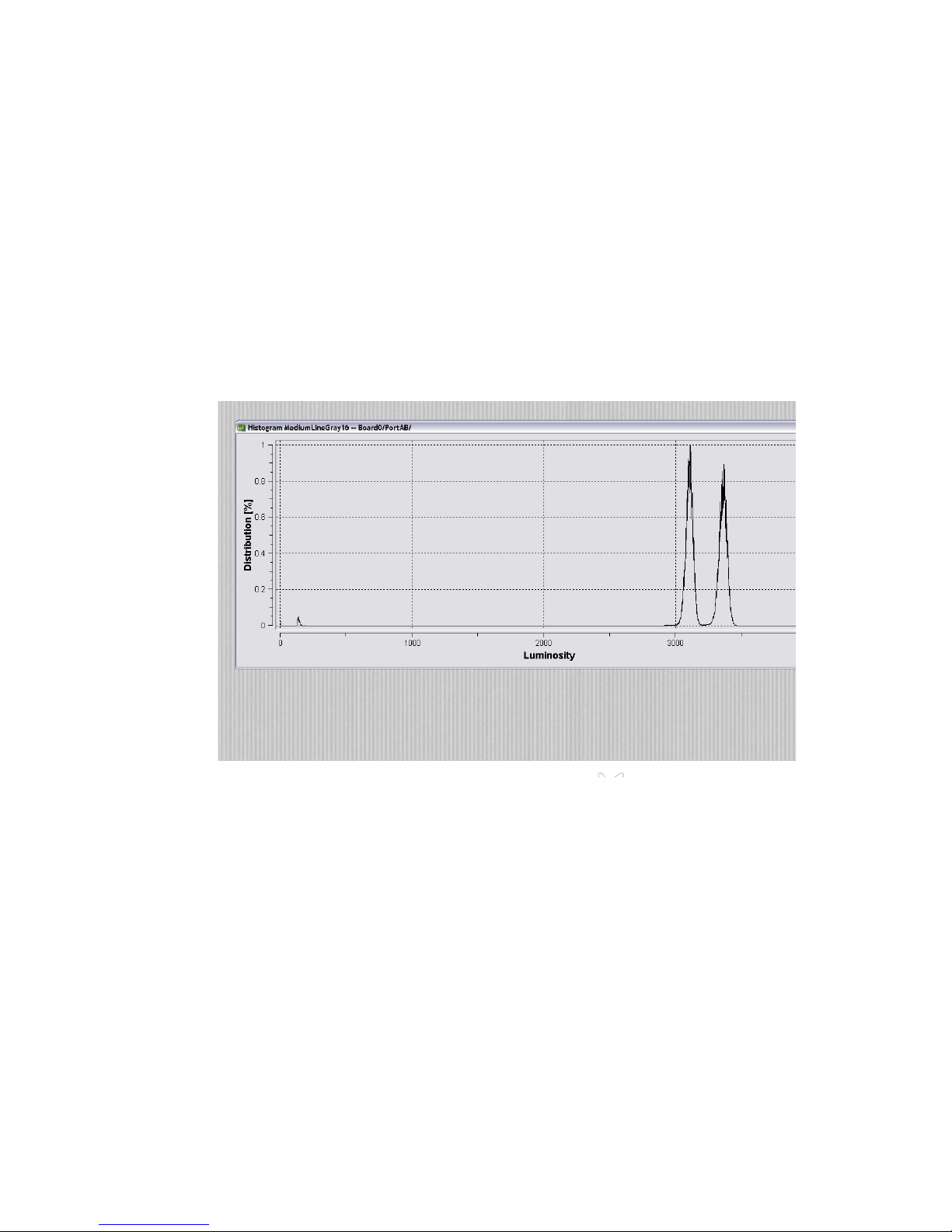

Now the dark image will be subtracted on chip rom the illuminated image.

When turning "Subtract o set" bit in Control 1 to 0 the stored o set image is lost and needs to

be reacquired with the same step sequence.

DATE: 25/06/09 DRAGSTER Evaluation

Version 0.0.04 PAGE: 4/6

Illustration 1: Black level calibrated