6

INSTALLATION _______________________________________

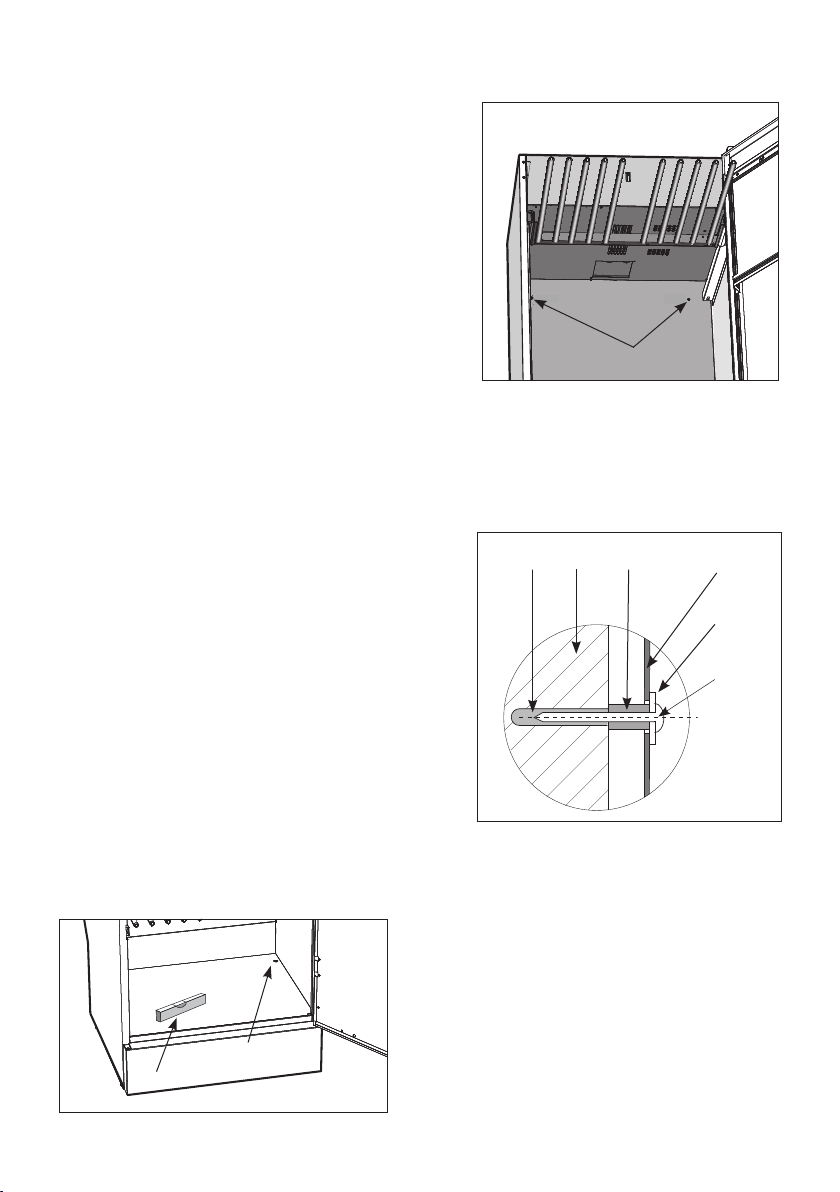

Check that all transport safety devices have been

removed before connecting the drying cabinet.

_______________________________________

Keep packaging materials such as plastics and

polystyrene foam away from children

______________________________________

________________________________________

Take care, as the drying cabinet is

top-heavy and can easily tip over.

Do not move the cabinet alone,

make sure you are at least two.

________________________________________

Complete delivery should include:

Cabinet with pre-installed fan unit

Installation kit

User manual

_______________________________________

Check that the goods have not been damaged

in transport. Any transport damage must be

reported to the retailer within 7 days

______________________________________

UNPACKING

Remove all packaging material; do not use sharp tools that could damage the product.

_______________________________________

After unpacking the product, check that it is free

from damage. Any damage, faults or missing parts

must be reported to the retailer immediately

_______________________________________

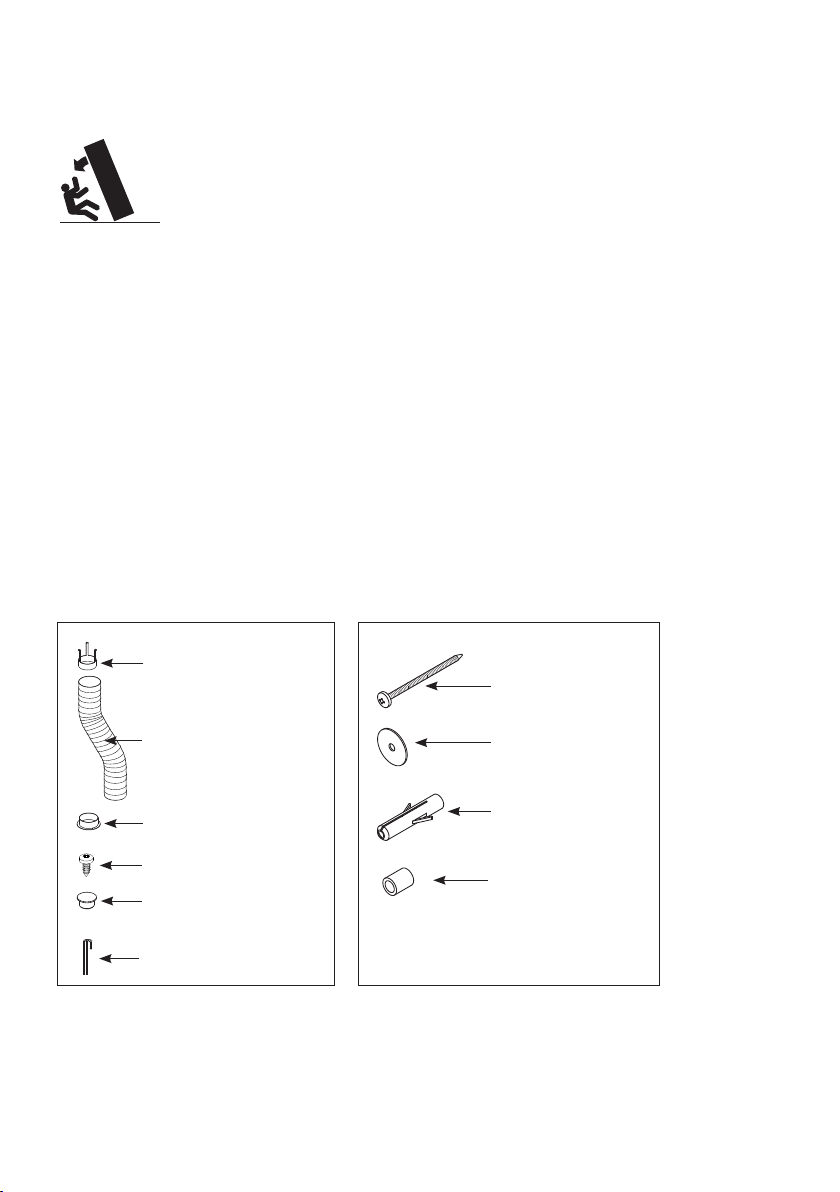

Installation kit,

- for cabinet - for wall fixing

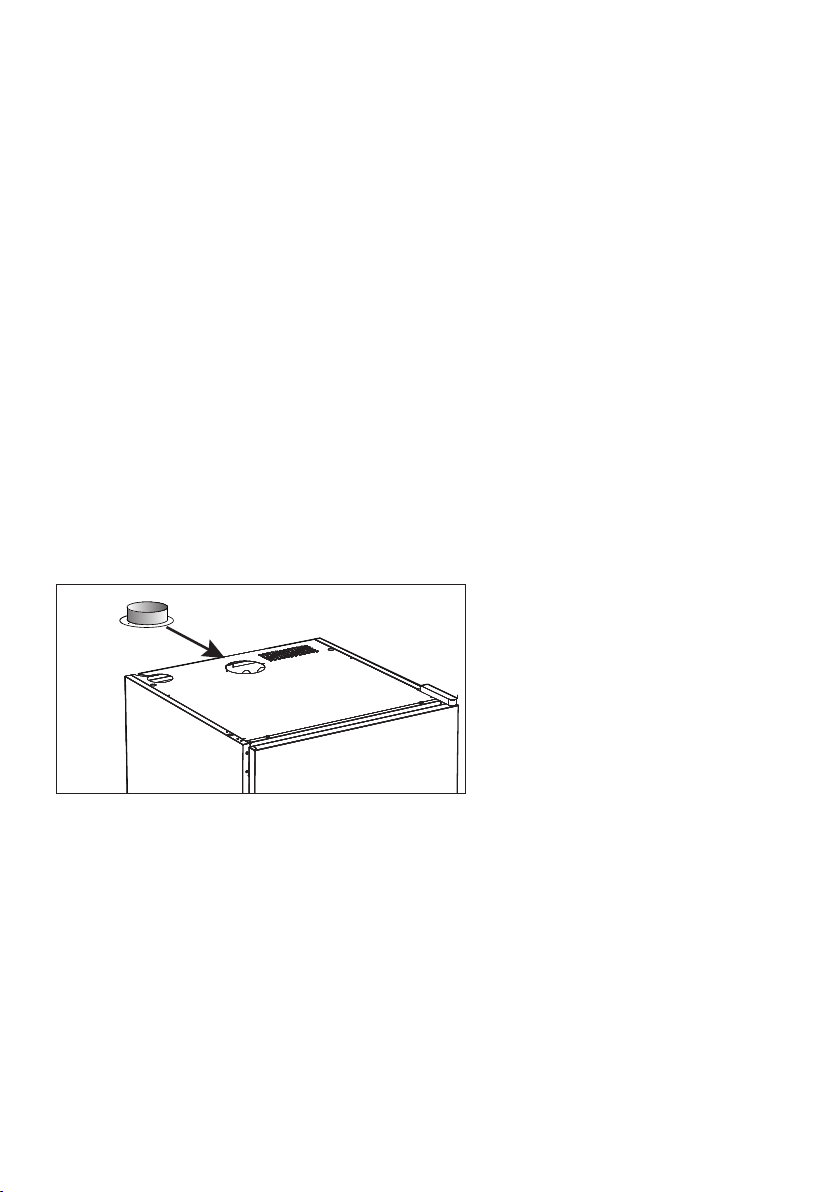

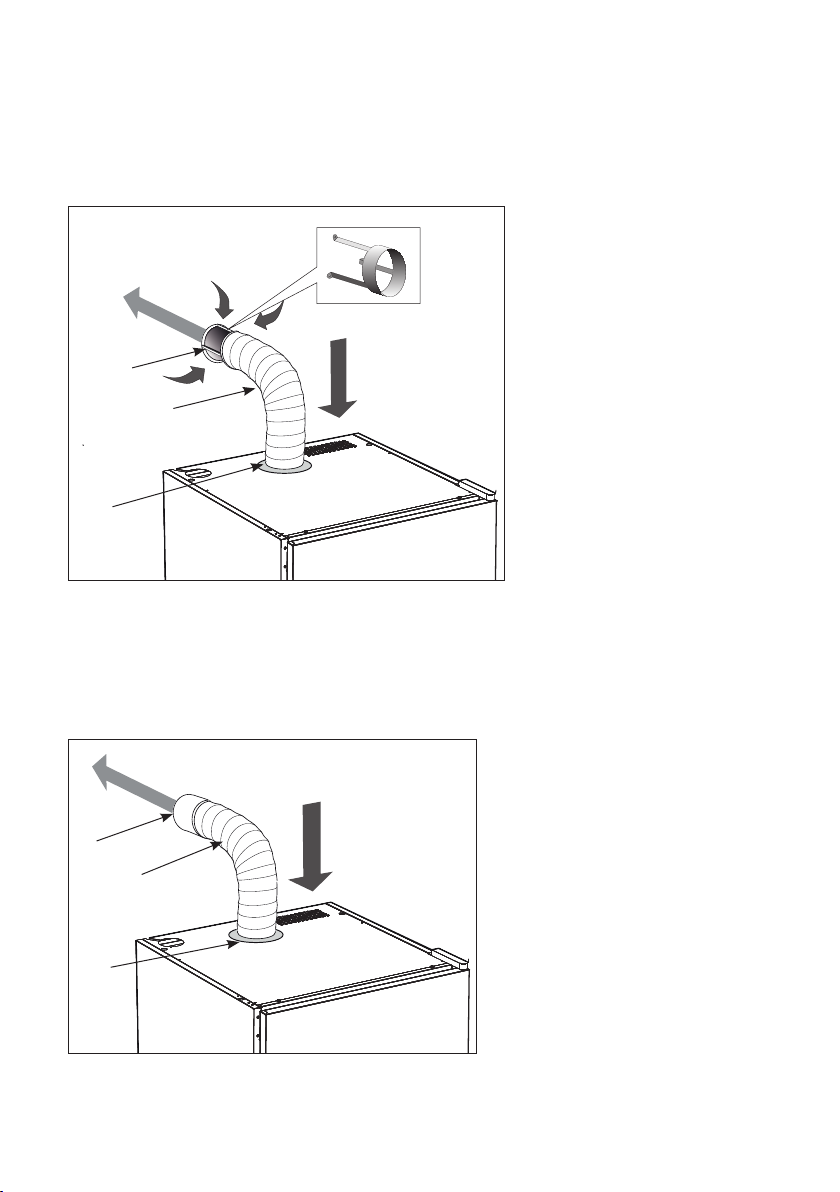

Draft stabilizer (1)

Hose (1)

Spigot (1)

Fixing screw for spigot (2)

Cover plug, white (4) for

adjustable feet

Allen key (1)

Screw TRX 5x70 zinc-

plated (2)

Washer NB 5x25 (2)

Wall plug (2)

Spacer 8.2x12x15 (2)

REVERSING THE DOOR

The cabinet is supplied from the factory with a right-hung or left-hung door. The door can be reversed

afterwards.

If this is required, contact Award Appliances.