3

TABLE OF CONTENTS

1. OPERATOR’S MANUAL

1.1. IMPORTANT INFORMATION/SAFETY INSTRUCTIONS................................................................................................... 4

1.2. INTENDED USE ............................................................................................................................................................. 5

1.3. TRANSPORT AND STORAGE ......................................................................................................................................... 5

1.4. SAFETY MEASURES REGARDING OPERATING OF THE UNIT ......................................................................................... 5

1.5. TECHNICAL SPECIFICATION .......................................................................................................................................... 6

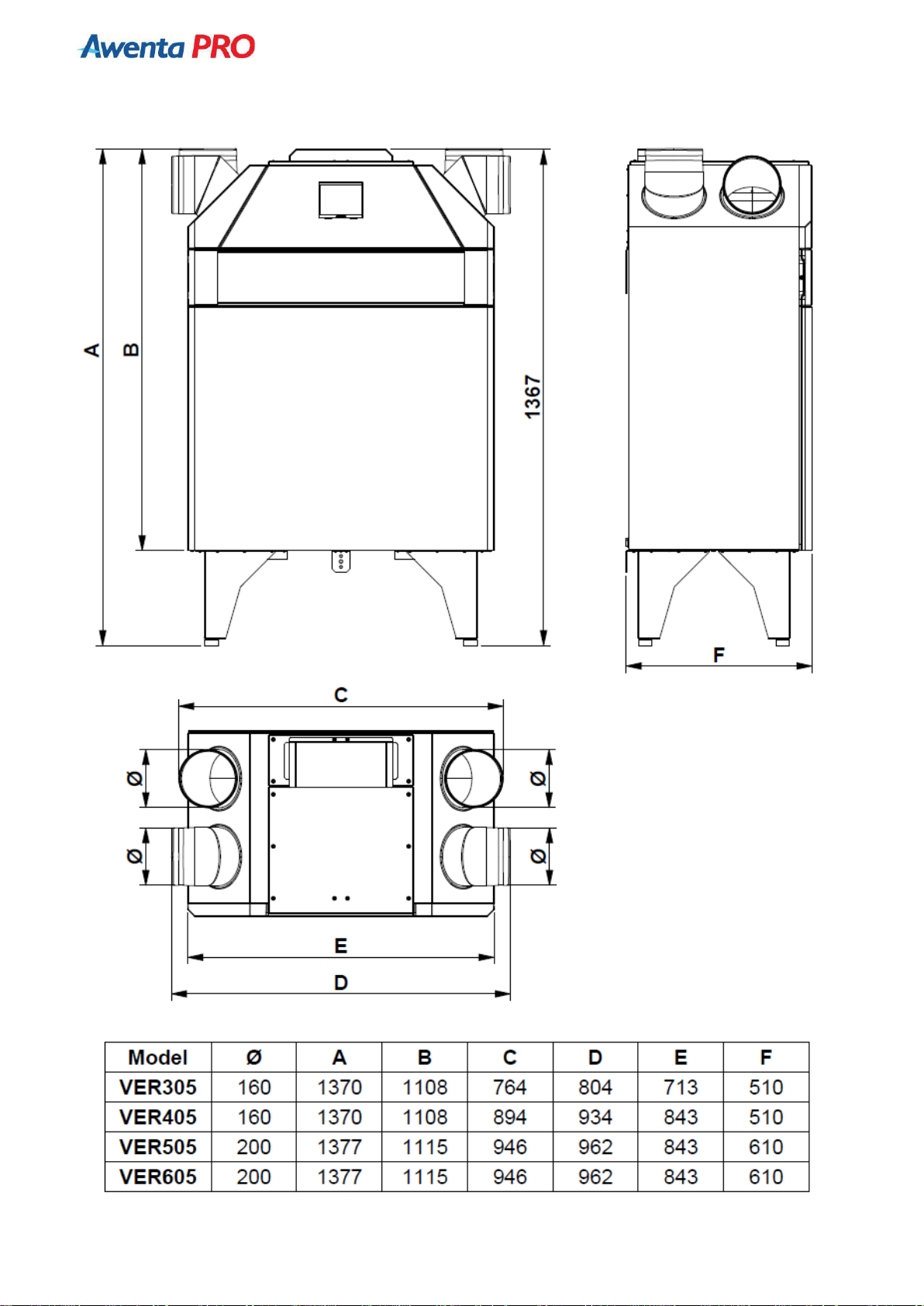

1.6. TECHNICAL DRAWINGS ................................................................................................................................................ 7

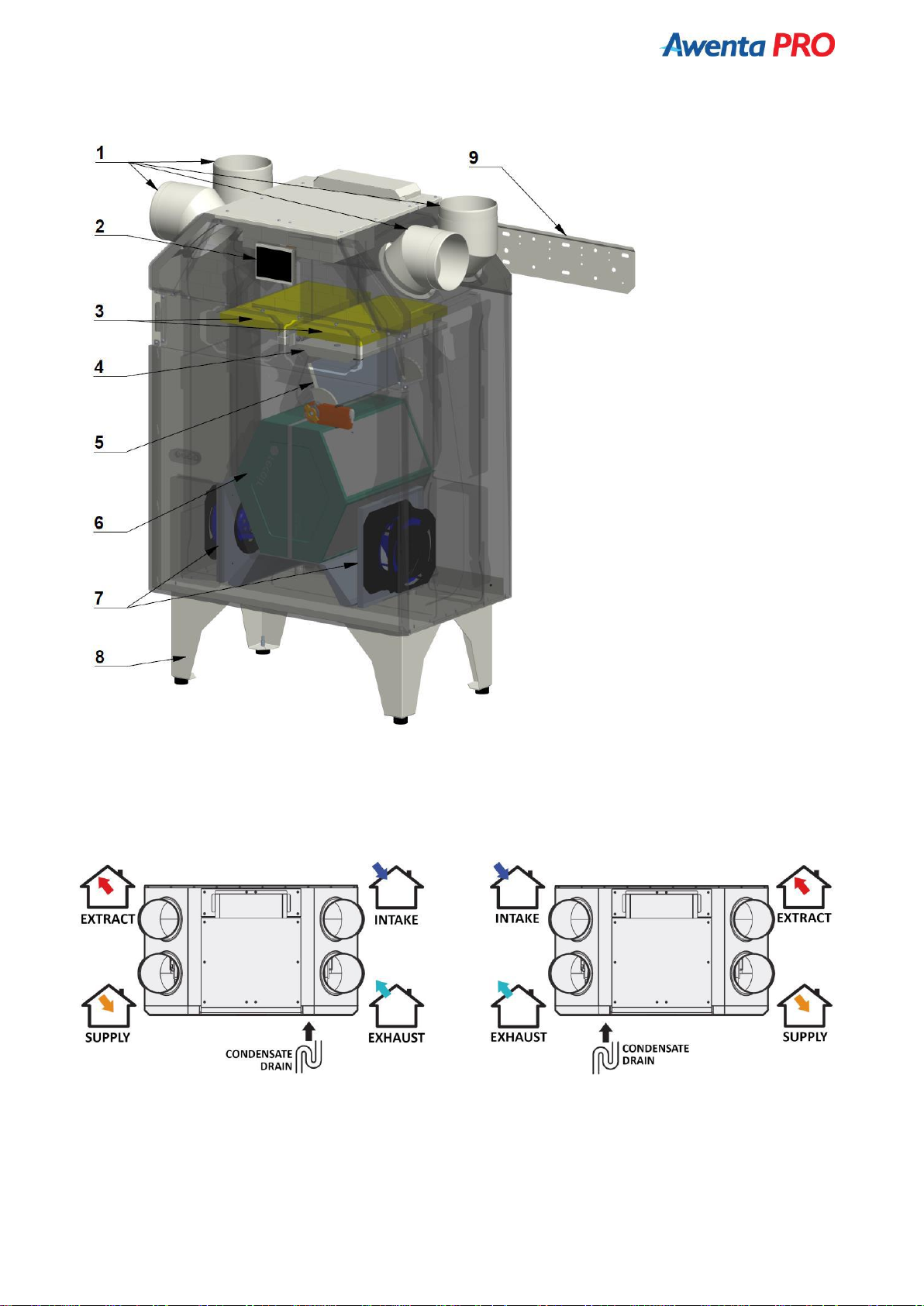

1.7. BASIC COMPONENTS OF THE UNIT.............................................................................................................................. 9

1.8. LAYOUT OF CONNECTIONS .......................................................................................................................................... 9

1.9. OPERATION PRINCIPLE............................................................................................................................................... 10

1.10. ITEMS OF EQUIPMENT............................................................................................................................................. 10

1.11. INSTALLING AND PREPARING THE UNIT FOR OPERATION ....................................................................................... 10

1.12. MAINTENANCE......................................................................................................................................................... 13

1.13. PRE-HEATER ............................................................................................................................................................. 15

1.14. WASTE MANAGEMENT NOTICE ............................................................................................................................... 15

2. NANO COLOR CONTROL PANEL

2.1. OPERATION PRINCIPLE............................................................................................................................................... 16

2.2. INSTALLATION ............................................................................................................................................................ 16

2.3. DESCRIPTION OF THE MAIN SCREEN ......................................................................................................................... 18

2.4. OPERATION MODE ..................................................................................................................................................... 20

2.5. SETTINGS.................................................................................................................................................................... 21

2.6. TEMPERATURE SETTINGS........................................................................................................................................... 21

2.7. THERMOSTAT INFO .................................................................................................................................................... 22

2.8. VENTILATION INFORMATION SCREEN........................................................................................................................ 22

2.9. FIREPLACE MODE ....................................................................................................................................................... 23

2.10. CHANGING THE SYSTEM OPERATION MODE ........................................................................................................... 23

2.11. SENSORS .................................................................................................................................................................. 24

2.12. VEX4 MODULE ......................................................................................................................................................... 26

2.13. SMART MODE .......................................................................................................................................................... 27

2.14. FOULED FILTER INDICATION..................................................................................................................................... 28

2.15. MAIN MENU............................................................................................................................................................. 28

2.16. SCHEDULE SETTINGS................................................................................................................................................ 29

2.17. SERVICE MENU......................................................................................................................................................... 29

2.17.1. IN-OUT .................................................................................................................................................................. 30

2.17.2. DISTRIBUTOR ........................................................................................................................................................ 30

2.17.3. NANO .................................................................................................................................................................... 31

2.17.4. VENTILATION......................................................................................................................................................... 32

2.17.5. SENSORS ............................................................................................................................................................... 34

3. NANO WIRELESS NETWORK ...................................................................................................................................36

4. MODBUS RTU PROTOCOL CONFIGURATION...........................................................................................................36

5. VLAN INEXT INTERNET MODULE ...........................................................................................................................36

6. WIRING DIAGRAMS

6.1. ELECTRICAL DIAGRAM OF THE AERO 4 CONTROLLER –version for operation diagram 1. Standard......................... 37

6.2. CONNECTING THE NANO COLOR CONTROL PANEL ................................................................................................... 38

6.3. CONNECTING THE NANO COLOR CONTROL PANEL WITH C14 - VRS NETWORK CONVERTERS ................................. 38

6.4. CONNECTING THE NANO COLOR CONTROL PANEL WITH THE iNEXT VLAN INTERNET MODULE .............................. 39

6.5. CONNECTING THE NANO COLOR CONTROL PANEL WITH VACS-1 or VSPM AIR QUALITY SENSOR............................ 38

6.6. CONNECTING THE NANO COLOR CONTROL PANEL WITH THE VSHC or VSHW SENSOR………………………………………… 39

6.7. CONNECTING THE NANO COLOR CONTROL PANEL WITH VSHC or VSHW and VACS-1 or VSPM SENSORS ............... 39

6.8. CONNECTING THE VGER405/605 PREHEATER ........................................................................................................... 40

7. ATTACHMENTS

7.1. PRODUCT DATA SHEETS/ENERGY LABELS .................................................................................................................. 41