AWG I Operating manual I Nozzles I Turbo nozzles EVO CONTENT

M1129B10 I Rev. 01-10/21 3 / 24

CONTENTS

FOREWORD......................................................................................... 2

CONTENTS .......................................................................................... 3

1Introduction ................................................................................. 4

1.1 Key to the symbols............................................................... 4

1.2 Figures ................................................................................. 5

2Safety Information....................................................................... 6

2.1 General safety instructions .................................................. 6

2.2 Safety during operation........................................................ 6

2.3 Qualifications of the operators ............................................. 7

2.4 Personal protective equipment ............................................ 7

3Description................................................................................... 8

3.1 Function ............................................................................... 8

3.2 Intended use ........................................................................ 8

3.3 Foreseeable misuse ............................................................ 9

3.4 Characteristic values ........................................................... 9

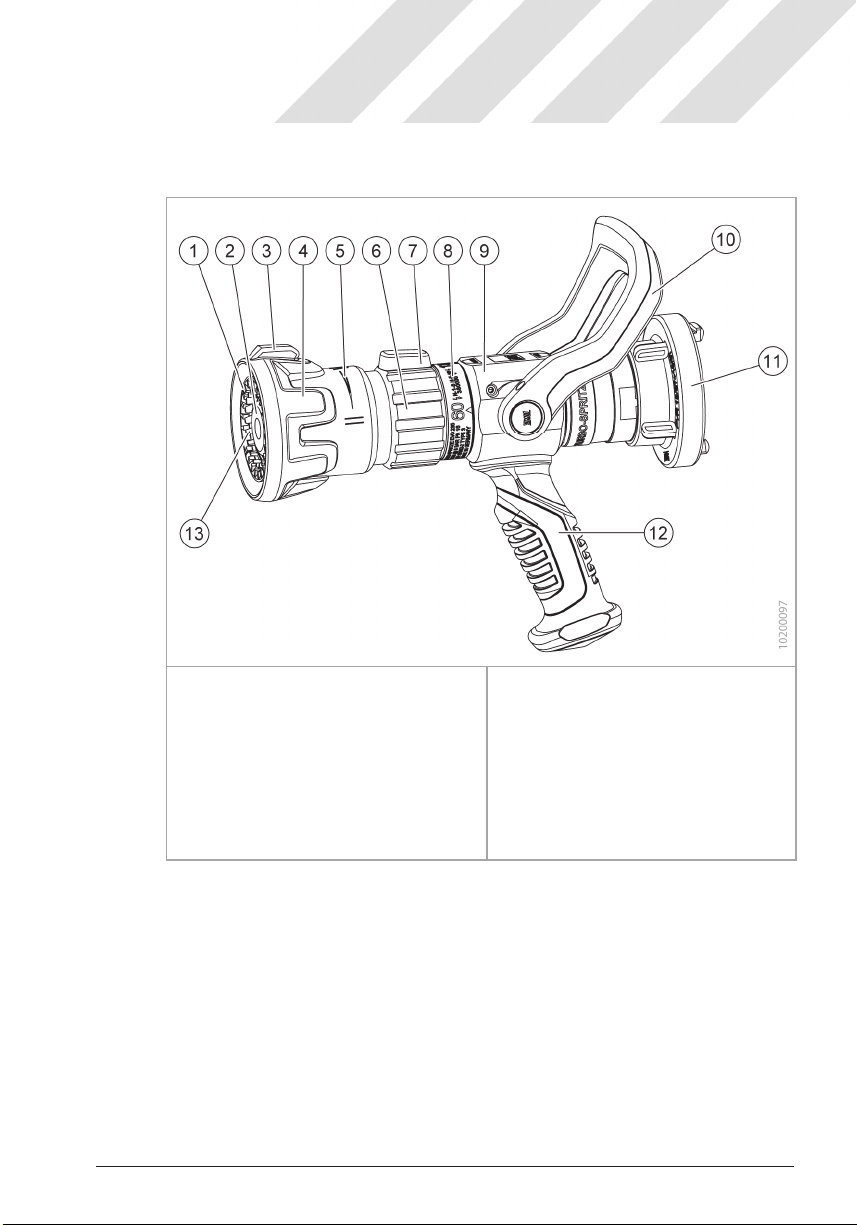

3.5 Overview ............................................................................ 10

4Delivery, transport, storage ..................................................... 11

4.1 Delivery .............................................................................. 11

4.2 Transport in a vehicle, storage .......................................... 11

5Use.............................................................................................. 12

5.1 Notes.................................................................................. 12

5.2 Handling............................................................................. 14

5.3 Visual inspection after each use ........................................ 17

6Functional test........................................................................... 18

6.1 Prerequisites ...................................................................... 18

6.2 Performing the inspection .................................................. 19

7Maintenance............................................................................... 20

7.1 Inspection and maintenance.............................................. 20

7.2 Repair ................................................................................ 20

7.3 Disposal ............................................................................. 22

8Accessories / spare parts......................................................... 23