9

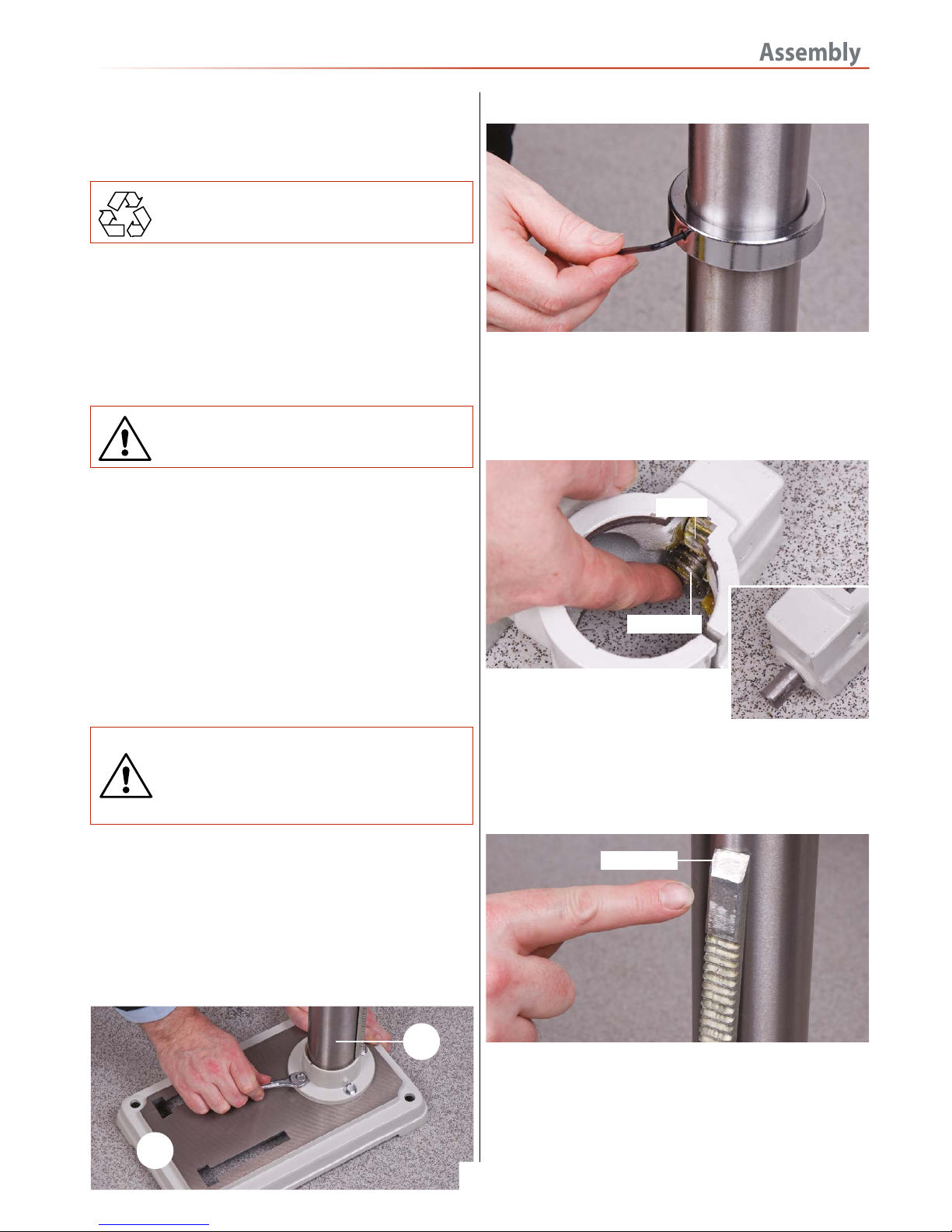

PLEASE DISPOSE OF THE PACKAGING RESPONSIBLY;

MUCH OF THE MATERIAL IS RECYCLABLE

The machine and its accessories will arrive coated with heavy

corrosion preventative grease and greased wax paper or plastic

wrapping.These will need to be cleaned from the machine, its

components and accessories prior to it being set up and

commissioned. Use water soluble de greaser to remove the

barrier grease. Be warned, it will stain if you splash it on

clothing etc. After cleaning, lightly coat the exposed metal

WARNING! WEAR OVERALLS, RUBBER GLOVES

AND EYE PROTECTION!

surfaces of the machine with a thin layer of light machine oil.

N.B If you used water soluble de greaser make sure you apply

this thin film sooner rather than later.

Please read the Instruction Manual prior to using your new

machine; as well as the installation procedure, there are

daily and periodic maintenance recommendations to help

you keep your machine on top line and prolong its life.

Keep this instruction manual readily accessible for any

others who may also be required to use the machine.

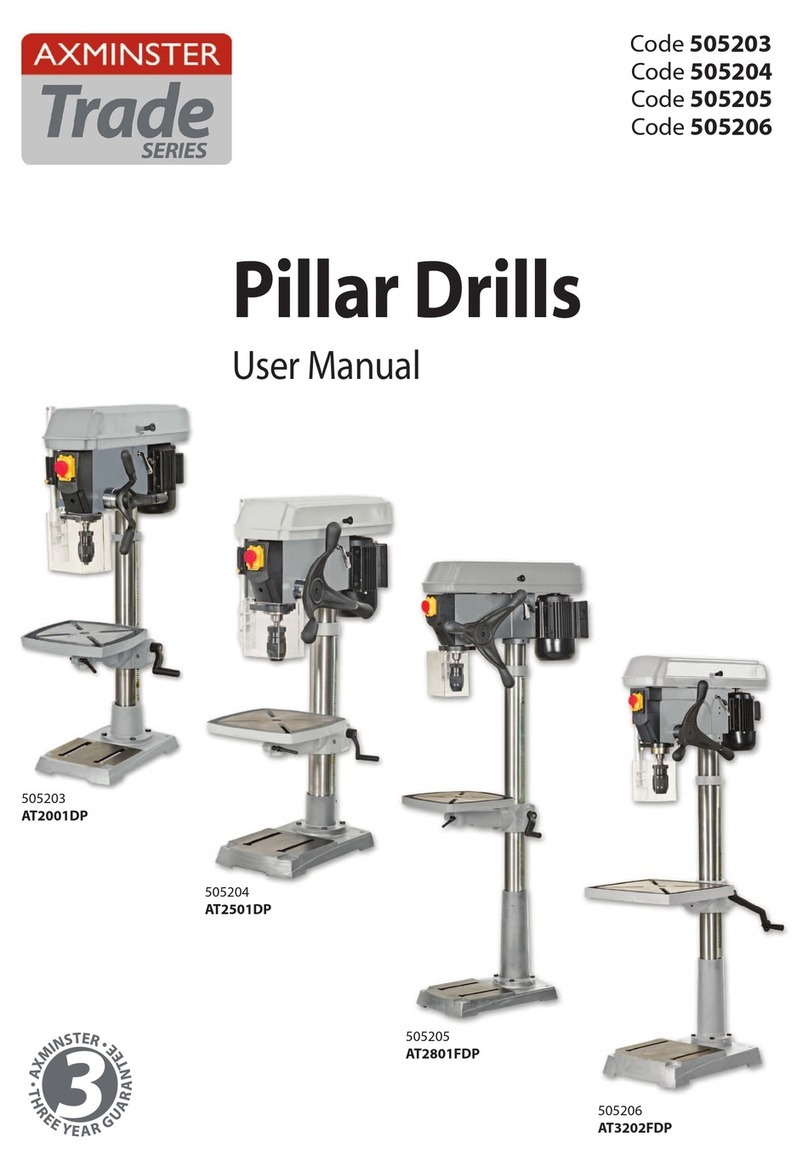

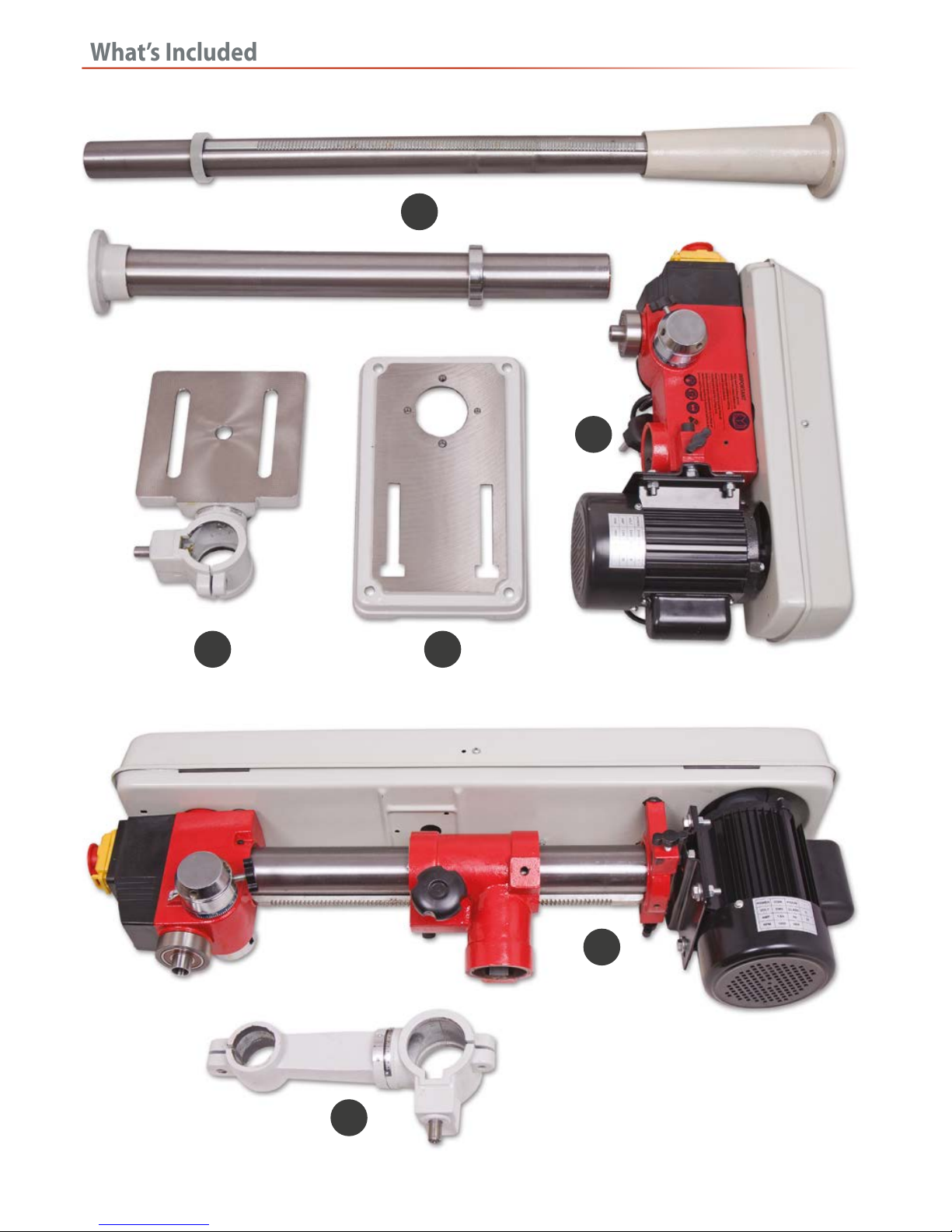

Having unpacked your machine and its accessories, please

check the contents against the equipment list ”What’s Included”,

if there are any discrepancies, please contact Axminster Tool

Centre using the procedures laid down on our website.

Please read through the section entitled illustration and

parts description, to identify the parts quickly and easily.

WARNING! THE DRILL HEAD IS A HEAVY AND

SUBSTANTIAL PIECE OF MACHINERY,YOU ARE

ADVISED TO HAVE HELP TO LIFT IT CLEAR OF THE

BOX AND FIT IT TO THE COLUMN.

1. Place the base (3) on the bench or floor and place the

mounting flange of the column (1) onto the seating flange of

the base, align the holes. Use the four Hex bolts and secure the

column to the base, see fig 1. Loosen the grub screw holding

the chamfered retaining collar on the column with the supplied

Hex key, place it and the rise and fall rack assembly aside,

see fig 2.

Fig 01

Fig 02

2. Take the drill table mounting bracket arm (2,2a,2b,2c) and

twist the worm drive shaft with your fingers so that the whole

shaft protrudes from the casting and the worm gear

itself is clear of the square recess in the main body of the

casting (see fig 3). Fig 03-04

3. Pick up the rise and fall gear rack,

identify the top and the bottom, (the

rack gearing is cut asymmetrically, with

the gear cut extending closer to the bottom), make sure you

have the rack the right way up, as it will allow you to drive the

drill table up and down over its full range, see fig 5.

Fig 05

4. Fit the rise and fall rack into the square recess in the

mounting body casting, ensure that it is engaged with the

pinion, see figs 6 and lower the combined mechanism over the

column (1). Allow it to slide down the column until the rise and

fall rack is located in the cup chamfer in the top of the mount-

ing flange, see figs 7. Replace the cup chamfered retaining

3

1

Worm gear

Pinion

Top of rack

Worm gear shaft

Continues Over....