5

6. OPERATION

In bi-metallic traps, the main element is the valve and the bi-metal itself. Bi metal

is a composite material consisting of two separate plates with different expansion

coefficients.

OPENING

When the system is cold, the valve is open and non-condensable gases and cold

condensate are discharged. While the system is in operation, the bi-metallic

plates, which contract with the cooling of the condensate coming to the trap, push

the valve from the seat and allow the condensate to be discharged.

CLOSING

When hot condensate comes, the amount of bending at different temperatures is

proportional to the length of the protrusions, so the long protrusions and then the

short ones are bent respectively. Therefore, they gradually pull the valve towards

its seat. As the temperature increases, the applied force also increases and

stabilizes the bearing. As can be understood from its working principle, it keeps

the condensate in the steam chamber and waits for the temperature to drop a few

degrees below. This feature should be considered in practice .

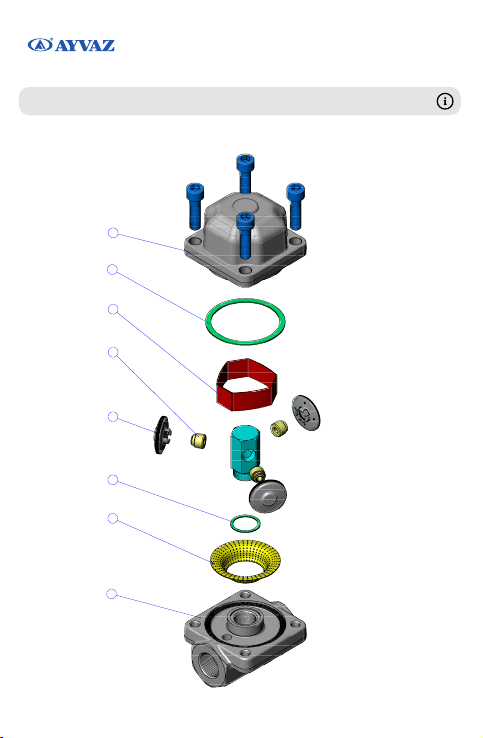

INSTALLATION STEPS

a- Unscrew the cover body connection bolts.

b- Take out the capsule.

c- Unscrew the capsule seat.

d- Clean the entire body, interior parts and gasket seating surfaces.

e- Use a new cover gasket while assembling. Check the operation of the

capsule. Replace with a new one if necessary.

TKK-3 THERMOSTATIC STEAMTRAP

5. INSTALLATION

Before the installation, you should read safety instructions carefully.

a- Check the label and technical information sheet if the product is

suitable for the required installation.

b- Check the maximum pressure and temperature values. lf the pressure

in the system is higher than the maximum value of the product, provide the

use of safety tools in order to prevent the excess pressure.

c- Remove the product from package carefully. Parts of the product may

resemble the packaging element. In this case, please contact your dealer.

d- Consider the temperature of the released condense as 100ºC if there

is discharge of condense into atmosphere. Be sure that the system is

working correctly after the installation and maintenance.

e- Be sure to install on the correct equipment by referring to the

product label.

f- Make sure that the straps are fully seated and tightened.

g- Tighten the jacket by using metal wires.