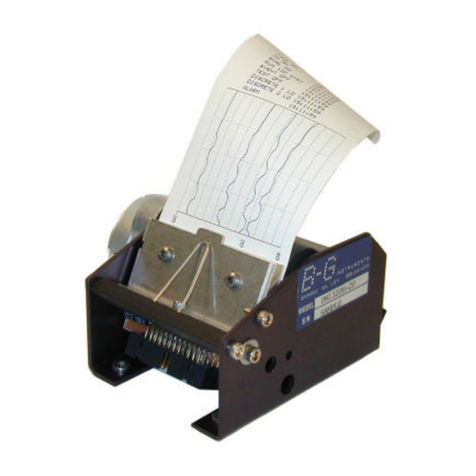

B-G Instruments PM1416 User manual

Page1of 2

GENERAL DESCRIPTION

The DataPlot model PM

1416 Print Mechanism incorporates a thermal printhead with

416 heat element dots arrayed in a single line across the width

of the paper. The mechanism holds a supply roll of 4.5" wide

thermal paper and moves the paper past the printhead in steps

of approximately .005 inch. When driven by a DataPlot CB

1416 or CB 1100 Control Board, the print mechanism steps the

paper forward, pausing after each step to heat selected dots. In

this manner, a dot matrix representation of alphanumeric and/or

graphic data can be printed.

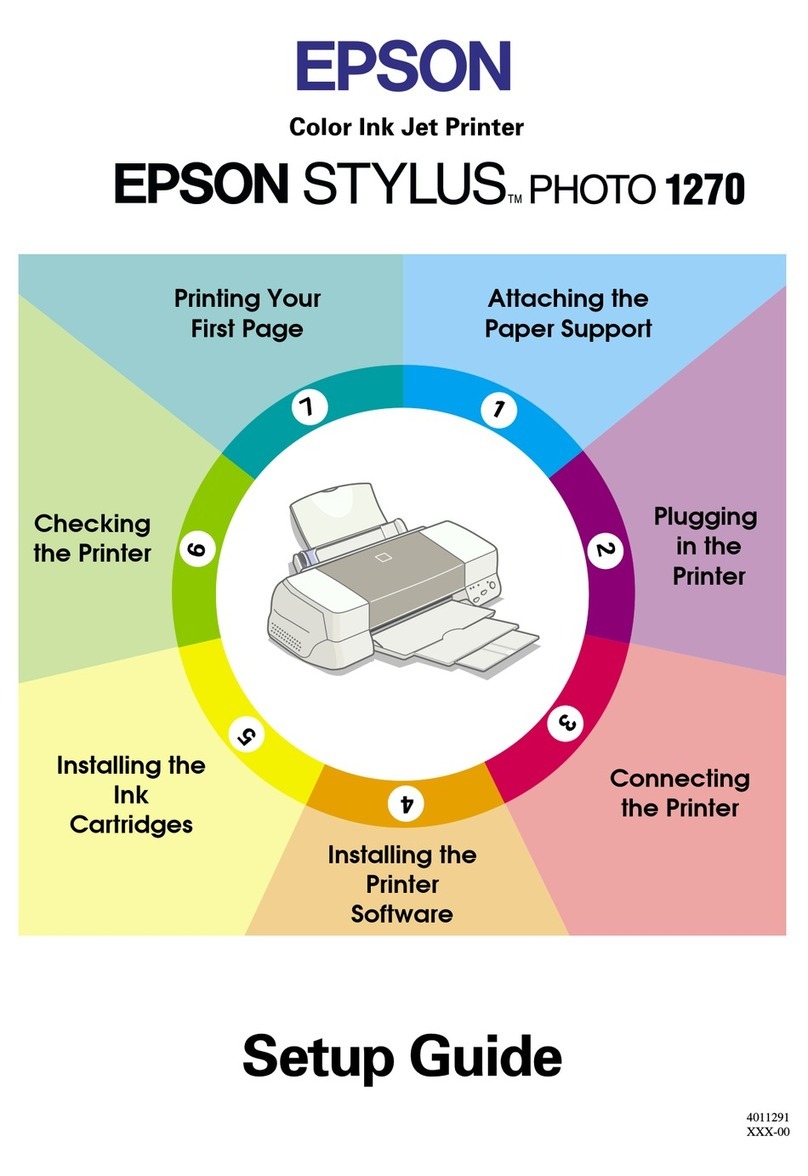

MOUNTING

The DataPlot model PM 1416 print mechanism is designed to

mount to the rear surface of a panel, using four 6-32 screws.

The mounting and cutout dimensions are shown on the

reverse side of this sheet. If you prefer to use mounting studs,

we can eliminate the mating PEM nuts and you can use nuts

to secure the print mechanism to the panel.

CONTROL BOARD CONNECTION

This print mechanism is designed to operate reliably when

driven by the B-G Instruments' DataPlot model CB 1416 or

CB 1100 control board or another board specifically approved

by B-G Instruments for that purpose. Attempting to operate it

in any other way may cause permanent damage that would not

be covered by warranty. With all system power off, attach the

supplied ribbon cable between the 26-pin printhead connector

and connector J3 on the control board, being sure to observe

correct polarity by aligning the red dots on the connectors with

those on the cable ends. Also connect the 8

RE

SOLUTION

The 416 thermal dot elements are uniformly spaced at 100 dots

per inch, with centers 0.010 inches apart. The mark made by

each element is slightly larger than this spacing, so that the

printer can print solid lines and solidly filled areas. The

standard mechanism advances the paper approximately 0.005

inches between steps, providing a dot matrix pitch of .010"

across the paper by .005" along its length. The CB 1416 and

CB 1100 Control Boards and software use this dot matrix to

produce printed characters and graphic images.

PAPER LOADING

A paper sensor in the PM 1416 provides signals that are used .

by the control board to stop printing when paper runs out and

to "autoload" a new paper roll. To load the printer, be sure the

power is on and insertthe paper end into the slot behind the

rubber platen with the sensitive side (outside on the roll) away

from the platen. When the paper is inserted, the platen will run,

pulling about 2 inches of paper through. On print mechanisms

with a head lift tab, you may also install paper by lifting the

printhead and inserting the paper manually.

MAXIMUM PRINT SPEED

When driven by a CB 1416 or CB 1100 Control Board, the

PM 1416 Print Mechanism can print approximately 125 dot

rows per second (somewhat slower for rows containing more

than 64 printing dots). At .005" per step, the maximum paper

speed is about .6 inches per second. Rows of 5x7 characters

can be printed at a rate of about 5 lines/second.

pin stepper motor connector cable to

connector J1 on the controlboard. This

connector is keyed to facilitate correct

polarity assembly. Refer to the control

board data sheet for instructions on

applying power and operating the printer.

The standard length of these cables is 18

inches. Contact us if you need shorter or

longer cables in your application.

PM1416

-

PTVF

Print Mechanism

DataPlot Print Mechanism

Model PM1416

Technical Data and Instructions

Release C, March 15, 2000

Page 2of 2

THERMAL PAPER

We recommend using B-G Instruments' type TP-4 thermal

paper in the DataPlot model PM 1416 Print Mechanism. This

paper produces a stable black on white image. Unlike some

waxy coated papers, it does not stick to or-cause material to

build-up on the printhead. TP-4 is a 4.5 inch wide, high quality

facsimile grade paper that can produce high resolution

permanent copy in the PM 1416 printer. It is available from

B-G Instruments in cartons of 24 rolls, or larger quantities.

CAUTION --- PRINTHEAD DAMAGE

The DataPlot CB 1416 and CB 1100 Control Boards apply

power to the selected thermal dots for a period of time

sufficient to exceed the thermal paper activation temperature,

orabout 2 milliseconds. If electrical power is applied to these

elements for a significantly longer period, or for too high a

duty cycle, or in any other improperly controlled manner,

irreversible printhead damage may occur. Such damage can be

readily detected, as the affected dots will print only lightly, if

at all, and isnot covered by warranty. For this reason, it is

important that the print mechanism be operated only by the

DataPlot model CB 1416 or CB 1100 Control Board and that

the applied power be as specified in the control board's

Technical Data and Instructions Sheet.

Locations and dimensions for panel

mounting holes and paper exit

cutout are shown at the left. We

recommend inserting a transparent

tear-off bar in this cutout. Contact

B-G Instruments for further

information.

The paper supply roll

compartment is usually covered by

a removable door set flush in the

front panel and secured by captive

screws to the two leftmost nut

inserts shown.

Brackets are also available from

B-G Instruments for attaching the

printer control board to the rear of

the print mechanism.

ALTERNATE PAPER SUPPLY HOLDERS

The PM 1416 print mechanism is available in several versions,

varying only in the manner of holding the paper supply roll.

The version pictured in this data sheet is model PM

1416-PTVF, one of the more popular versions, that holds the

paper roll in a front-loading tray. We also offer these

mechanisms fitted with a rear-loading tray,. an axle paper roll

mount or a spring holder. Upon your request, drawings of the

other standard configurations will be sent to you by phone or

fax. Other paper supply holding fixtures have been designed

for other customers with special mounting requirements. Let

us know what works best in your application.

WARRANTY

B-G Instruments will repair or replace, at its option, any model

PM 1416 Print Mechanism that malfunctions because of faulty

manufacture within one year after its original date of sale,

provided that the mechanism has been used exclusively with a

properly functioning CB 1416 or CB 1100 Control Board (or

other control board specifically authorized by B-G Instruments)

and B-G Instruments' type TP-4 thermal Paper, and:

1. neither the print mechanism nor its control board have been

modified in any way not specifically authorized by B-G

Instruments, Inc., and

2. electrical power applied to the control board has

always been within specifications for that board, and

3. the mechanism shows no evidence of electrical, thermal

or mechanical damage, and

4. the mechanism has printed fewer than 100 million dot

rows and less than 100,000 feet of paper.

B

-

G Instruments, Inc.

13607 E. Trent,

Spokane Valley, WA 99216, U.S.A.

www.bginstruments.com

Toll Free: (888) 244-4004

Phone: (509) 893-9881

Fax: (509) 893-9803

Email: [email protected]

Other B-G Instruments Printer manuals