B.M. Tecnologie Industriali TTFM100-NG Series User manual

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 1 of

110

ULTRASONIC TRANSIT TIME FLOWMETER

TTFM100-F18-NG

STATIONARY TYPE

INSTRUCTION MANUAL

Rev. 2.0

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 2 of

110

1WORKING PRINCIPLE ......................................................................................................................................4

1.1 TYPICAL USE ..................................................................................................................................................5

1.2 PACKING LIST ................................................................................................................................................6

1.2.2

Connections

...............................................................................................................................................9

2INSTALLATION AND OPERATION...............................................................................................................11

2.1 MEASURING POINT.....................................................................................................................................11

2.2 REQUIRED INFORMATION .........................................................................................................................12

2.3 APRACTICAL EXAMPLE OF RAPID SETTINGS .........................................................................................13

2.3.1

Fluid & pipe’s features

...........................................................................................................................13

2.3.2

Data entry

................................................................................................................................................13

2.4 INSTRUCTIONS FOR CLAMP-ON SENSORS INSTALLATION..................................................................20

2.5 TRANSDUCERS MOUNTING METHODS ....................................................................................................29

2.5.1

Mounting Analysis

...................................................................................................................................36

2.5.2

Signal strength and quality M90

...........................................................................................................36

2.5.3

Total spreading time, time difference M93

.........................................................................................36

2.5.4

Relation between calculated and measured transit time

..................................................................37

3DISPLAY WINDOWS ........................................................................................................................................38

3.1 FLOW RATE- TOTALIZERS MENU..............................................................................................................38

3.2 INITIAL SETTING MENU.............................................................................................................................38

3.3 FLOWRATE UNITS MENU ...........................................................................................................................39

3.4 OPTIONAL SETTING MENU ........................................................................................................................39

3.5 INPUTS/ OUTPUTS MENU ..........................................................................................................................39

3.6 DIAGNOSTICS MENU ..................................................................................................................................41

3.7 OTHER DISPLAY MENU...............................................................................................................................41

3.8 FLOW RATE -TOTALIZERS MENU ANALYSIS ..........................................................................................41

3.9 INITIAL SETTINGS MENU ANALYSIS ........................................................................................................43

3.10 FLOWRATE UNITS MENU ANALYSIS.........................................................................................................50

3.10.1

Inputs/ Outputs Menu Analysis

........................................................................................................56

3.11 DIAGNOSTICS MENU ANALYSIS................................................................................................................73

3.12 OTHER DISPLAYS MENU ANALYSIS ..........................................................................................................74

4DIAGNOSTICS AND PROBLEM SOLVING..................................................................................................76

4.1 AUTOTEST DURING SWITCH ON AND POSSIBLE SOLUTIONS .............................................................76

4.2 ERROR CODES, CAUSES AND SOLUTIONS DURING FUNCTIONING ....................................................76

5APPENDIX 1........................................................................................................................................................77

5.1 SOUND SPEEDS IN SOLIDS........................................................................................................................77

5.2 SOUNDSPEEDS IN FLUIDS ........................................................................................................................80

5.3 SOUND SPEEDS IN WATER AT DEFINITE TEMPERATURES...................................................................94

5.4 PIPE SIZE DATA ...........................................................................................................................................96

6. APPENDIX 2 –MODBUS PROTOCOL ........................................................................................................100

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 3 of

110

IMPORTANT NOTICE!

EACH DEVICE HAS TO BE CONNECTED TO THE SENSORS WITH THE SAME

SERIAL NUMBER OF THE DEVICE.

THE SERIAL NUMBER IS WRITTEN ON THE ID LABEL OF THE DEVICE AND

SENSORS.

INTRODUCTION

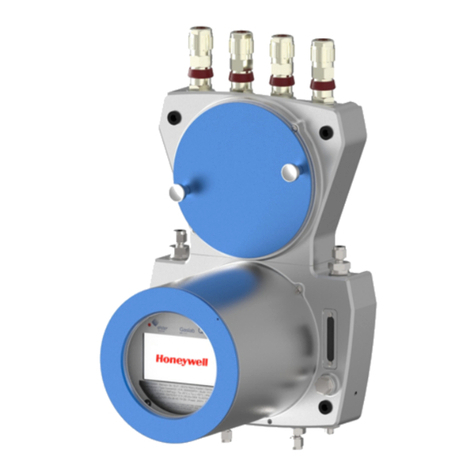

Thanks for buying an Ultrasonic Transit Time Flow meter TTFM100-NG series.

The device measures flow rate by calculating the spreading time of an ultrasonic wave in a

liquid, going upstream and downstream into a pipe. This flow meter is mostly used to

measure the flow rate of homogeneous fluids, with a very little percentage of suspended

solids and possibly without gas bubbles.

Its peculiar installation makes these devices suitable for measuring aggressive fluids

(acids, basic and dissolvent) or very soiling fluids (oil and fuels).

The measuring system is composed of a couple of ultrasonic transducers acoustically

coupled to the external pipe’s wall (it is also possible to use transducers in direct contact

with fluid to be measured) and a HOST unit elaborating the sent and received signals from

the transducers. The HOST unit has a DSP microprocessor; it gives signals to interfacing

with the process or the control systems.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 4 of

110

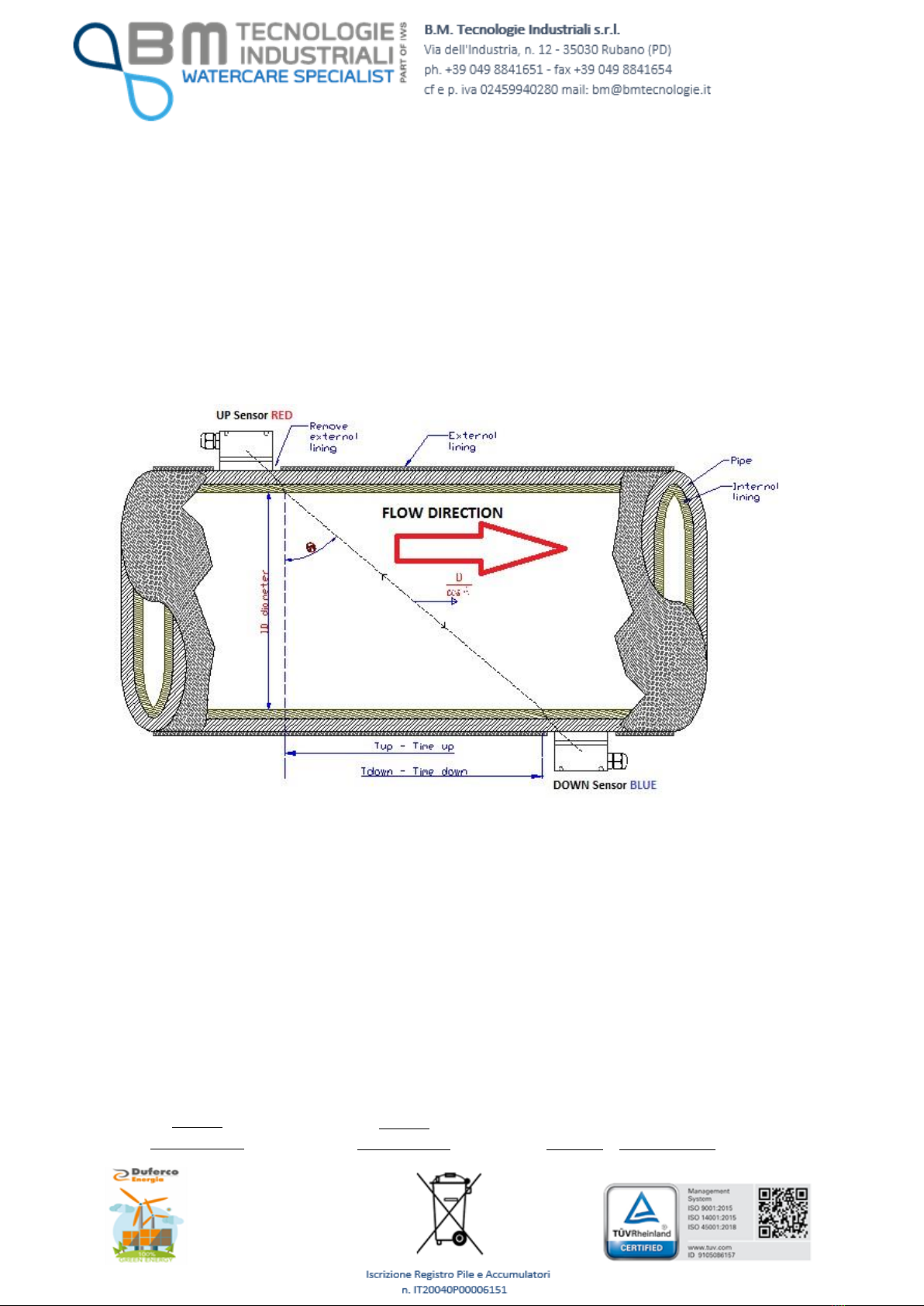

1WORKING PRINCIPLE

When the ultrasonic wave spreads in a liquid, the flow will cause a changing in the

spreading time depending on downstream or upstream current.

The ultrasonic wave going towards the same directions of the flow increases the spreading

speed, while the ultrasonic wave going towards the opposite side of the flow decreases

the spreading speed.

If the difference between the two spreading times is accurately measured, it would be

possible to calculate the flow speed (see the following picture).

The measures are taken by 2 sensors in direct contact with the pipe’s external surface.

The UP sensor (RED) is placed on the upper side of the pipe’s external surface, the DOWN

sensor (BLUE) is placed on the lower side of the pipe’s external surface.

The sensors positions could look like a “Z” or like a “V” or a “W”, if the pipe has a small

diameter (in the previous sketch, the sensors are “Z” mounted).

The sensors are alternatively used to receive the ultrasonic pulses sent through the way

pipe - fluid - pipe.

The difference between the transmitted and received signals upstream and downstream is

calculated as follows:

(1) (2) (3)

+

=VSINCoCOSDM

Tup

−

=VSINCoCOSDM

Tdown

TdownTup T

SIN DM

V*

*

2

*

=

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 5 of

110

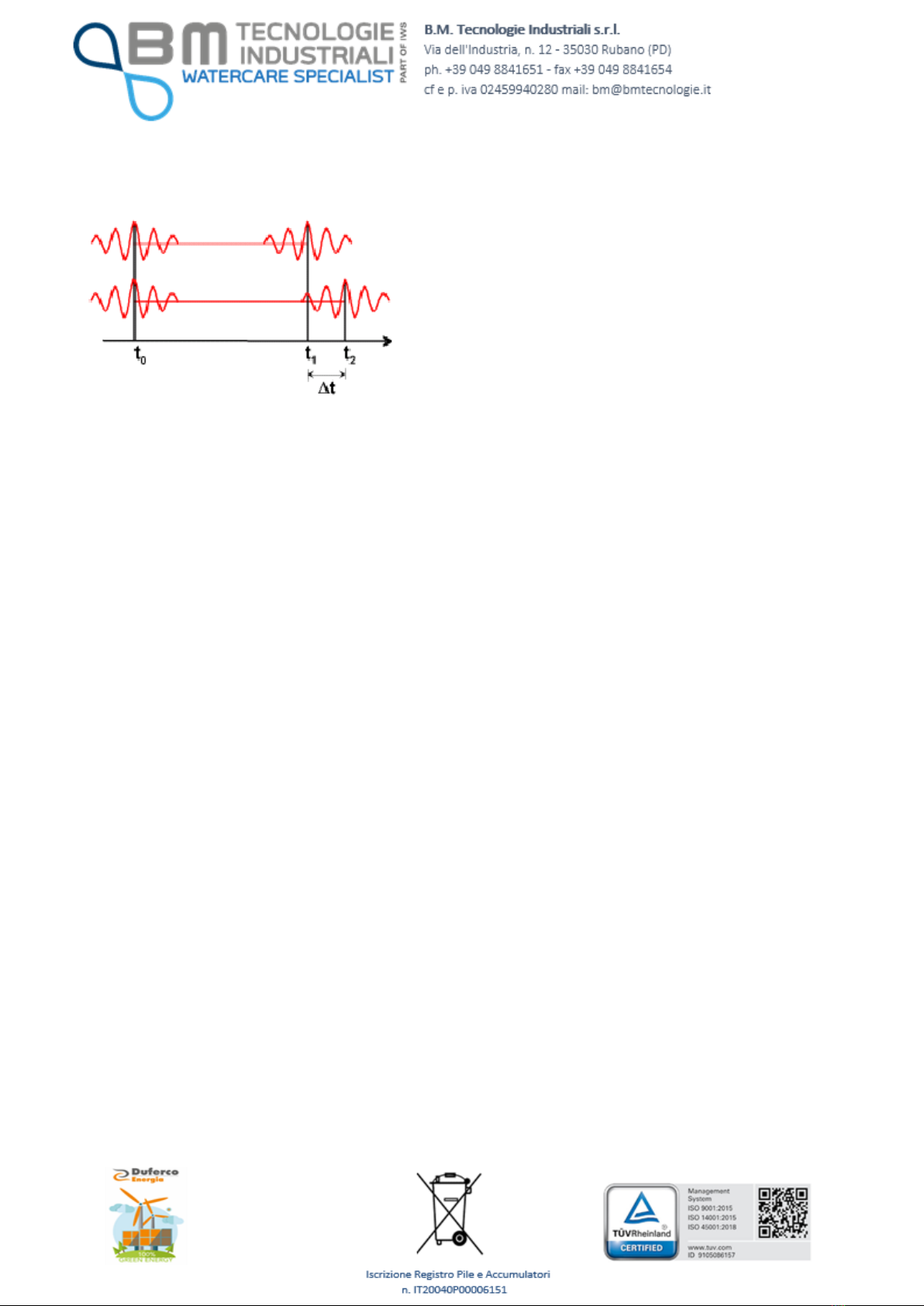

Typical timing signal

T1Downstream time

T2Upstream time

DT = T2-T1

Where:

M Spreading time

D Pipe’s internal diameter

ӨTransmission angle

Co Sound spread speed through the fluid in static conditions

Tup Positive spreading time

Tdown Negative spreading time

V Flow Velocity

The DT value is the difference of the spreading time into a homogenous fluid without gas

bubbles.

The equation (3) for calculating the average speed “V” could be used for all the types of

fluids in ideal conditions. The fluid speed measuring is in fact conditioned by different

factors which make the precision decrease: for example the dumps on the pipe are

internal walls: they change the measuring principle of the transit time flow meter.

TTFM100 series has are a lot of solutions trying to solve these problems, compensating

the temperature influence, the dumped internal walls and the asymmetry in the speed

distribution, in order to measure in critical conditions too.

It is possible to adjust the zero point of the device: if the fluid is in static conditions, this

operation makes the repeatability precision increase until reaching values near to 0.5%.

1.1

TYPICAL USE

•Water treatment, slurry and process water pumping;

•Oil and chemical industries;

•Hydro-electric, cooling, anti-fire stations;

•Extraction industries;

•Food, paper and pharmaceutical industries;

•Car industries;

•Flow balancing;

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 6 of

110

•Heat measuring in central systems.

1.2

PACKING LIST

•Ultrasonic Transit Time Flow meter TTFM100-F18-NG 1pcs

•

Standard Clamp-on sensors TS2 2pcs

•

Standard Clamp-on sensors TM1 2pcs

•

Standard Clamp-on sensors TL1 2pcs

•Acoustic coupling gel 1pcs

•Sensors mounting kit (optional) 1pcs

•Quality certification 1pcs

•Test Certificate 1 copy

•Instruction Manual 1pcs

*DEPENDING FROM THE TYPE OF SENSORS ORDERED BY THE CUSTOMER.

TECHNICAL FEATURES

ITEM

PERFORMANCE

PIPE

Material

Internal Diameter

Pipe length

Steel, Stainless Steel, cast iron, plastic, with

smooth walls, with rough walls, with very thin

walls.

15 ~ 6000 mm.

Upstream: bigger than 10D and 30D far from

the pump, downstream: bigger than 5D.

FLUID

Type

Turbidity

Temperature

Potable water, sea water, other liquids with

few suspended solids.

Smaller than 10000ppm (mg/l) with a few air

bubbles.

-30°C ~ +90°C, without ice at low

temperatures.

SPEED

Speed

-16 m/s ~ +16 m/s

SENSORS

Type

0. Standard –TS2 DN15…..DN100 mm

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 7 of

110

Cable lengths

1. Standard –TM1 DN50…..DN1000 mm

2. Standard –TL1 DN300…DN6000 mm

Temp. Range: -30°…+90°C

3. High Temperature TTS100-S1-NG-HT

DN15-150mm

4. High Temperature TTS100-M1-NG-HT

DN50-700mm

Temp. Range: -30…+160°C

5. Insertion type B > 50 mm < 2000 mm for

under charge applications. Min. temp. -20°C,

max temp. 160°C, max pressure 60 bars.

4. Sensors pre-mounted between flanges

BNG type from DN50 to DN1000, PN16 until

DN400, PN10 until DN1000, min. temp.

-40°C, max. Temp. 160°C.

Min. 5 m, max. 200 m.

SENSORS

Mounting methods

“V” Method: for pipes with small diameter,

until DN400 mm.

“Z” Method: for pipes with big diameters,

bigger than DN250.

“W” or “N” Method: suitable for very small

pipes, DN15….100.

FLOWMETER

Display & Keypad

Mounting

Input

Outputs

Dimensions

Alphanumeric 2 x 20 digits LCD back lighted.

DIN Rail Mounting.

5 current loop 4 - 20 mA, 0.1% accuracy.

Selection 4 - 20 mA or 0 - 20 mA current

loop, 0.1% accuracy.

Serial port RS485.

Programmable output frequency: 12…9999

Hz.

Output relays 1A/125VAC or 2A/30VDC for

volume pulses or alarms.

90 x 90 x 36 mm.

ENVIRONMENTAL

AND OPERATIONG

CONDITIONS

Temperature

Humidity

Device: -20°C…+40°C

Sensors: -20°C…+80°C

Device: 85% RH (40°C)

Sensors: 98% RH (40°C), possible

functioning in water less deep than 2 m.

MEASURING ACCURACY

+/- 1% (after calibration)

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 8 of

110

Repeatability: +/-0.2%...0.5% at

0.6…16mt/s

Linearity: 0.5%

Min measuring cycle: 500 milliseconds

POWER SUPPLY

12…36VDC - 0,12A

Attention!: Negative connector common with

negative 0/4-20 mA output.

FUNCTIONING

Continuous

1.2.1 Wiring

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 9 of

110

1.2.2

Connections

The kind of connection and the number of connections, both depend from the application

the flow meter is used for.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 10 of

110

The minimum necessary connections are:

•Electrical supply 12..36 VDC

•Ultrasonic UP and Down sensors

Warning!!!!!

The sensors must be connected to their clamps only after having momentarily short

circuited the white and brown cables in order to download the electrostatic fields

generated during the sensors movement.

The crystal inside the transducer acts as a converter and turns mechanical energy into

electrical during the mounting process.

When the sensors are connected to the clamp-house, the electrostatic fields into the

capacitor could damage seriously the measuring circuit of the device.

•4-20 ma output and/or frequency and/or pulses signals

•Temperature measure for calorimeter

•RS485 connection for data saving.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 11 of

110

2INSTALLATION AND OPERATION

The ultrasonic flow meter mounting is a quite simple method. It is only necessary to

determine the mounting point in the pipe and knowing some information about the pipe’s

dimension.

2.1

MEASURING POINT

It is very important to select the right measuring point. The fluid has to be a measurable

one and the pipe should be indicated among the ones that are suitable for this technology.

Please do not hesitate to contact B.M. TECNOLOGIE INDUSTRIALI for any further

clarification.

Please proceed as follows:

1) Select the measuring point on the pipe, in order to have a turbulence-free fluid.

2) The distance of the measurement point upstream should be 10D, downstream 5D.

If there are pumps or valves in the upstream part of the pipe, it is suggested to

increase the distance up to 30 D.

3) Actually, the device could be installed in pipes with lining, but it is suggested to

install insertion sensors and no clamp-on sensors, above all if the pipe is old or

damaged.

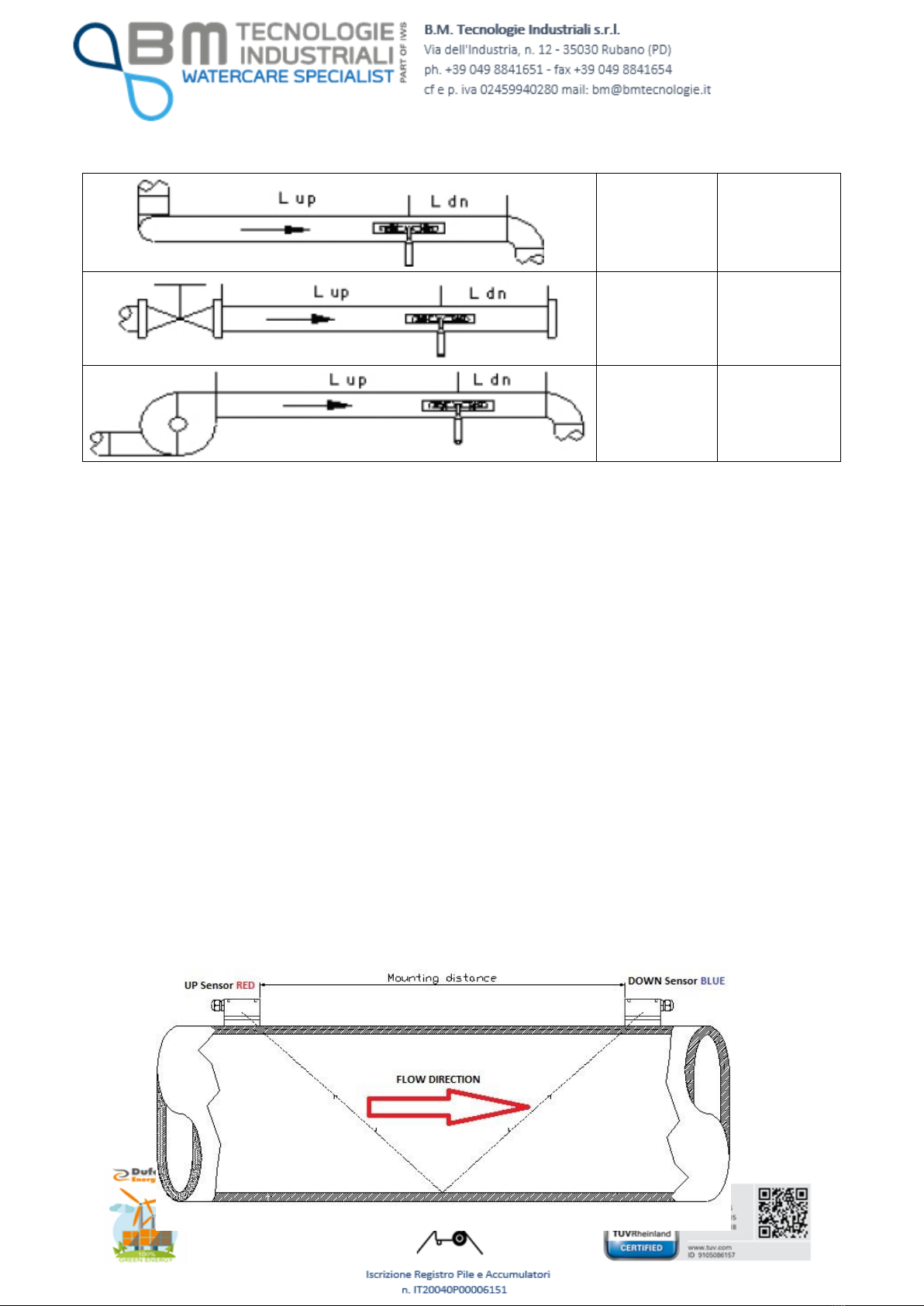

Possibile pipes configuration & possibile transducers position

Upstream

Dimensions

Downstream

Dimensions

L up x

Diameters

L dn x

Diameters

10D

5D

10D

5D

10D

5D

12D

5D

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 12 of

110

20D

5D

20D

5D

30D

5D

2.2

REQUIRED INFORMATION

1) Pipe’s external diameter without liner.

2) Pipe’s internal diameter or thickness.

3) Pipe’s material or speed of sound through that material.

4) Internal liner (if existing), material or thickness or speed of sound through that

material.

5) Fluid type (or speed of sound through this fluid).

6) Transducers type.

7) Transducer mounting method (V, Z method or W, N for little pipes).

Now, in M25 menu it is be possible to see the right mounting distance between the

transducers.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 13 of

110

2.3 A PRACTICAL EXAMPLE OF RAPID SETTINGS

The following example shows an application with a DN 400 carbon steel pipe, no liner,

with “V” mounted sensors.

IMPORTANT NOTICE:

WHEN THE SET-UP IS COMPLETED, THE USER MUST GO BACK TO MENU 26 AND

SELECT OPTION 1. SOLIDIFY SETTINGS, AND THEN PRESS ENTER.

IN THIS WAY THE PARAMETERS WILL BE SAVED EVEN IF THE POWER SUPPLY

GOES OFF.

2.3.1

Fluid & pipe’s features

This is a zinc pipe, so its thickness is not a problem. It is also important to measure the

pipe’s circumference: it should be 1286 mm. The pipe is PN10 and it will measure potable

water.

2.3.2

Data entry

ATTENTION! The XXXXX values indicated in the following windows are only

examples. The value could vary and must not be taken as representative.

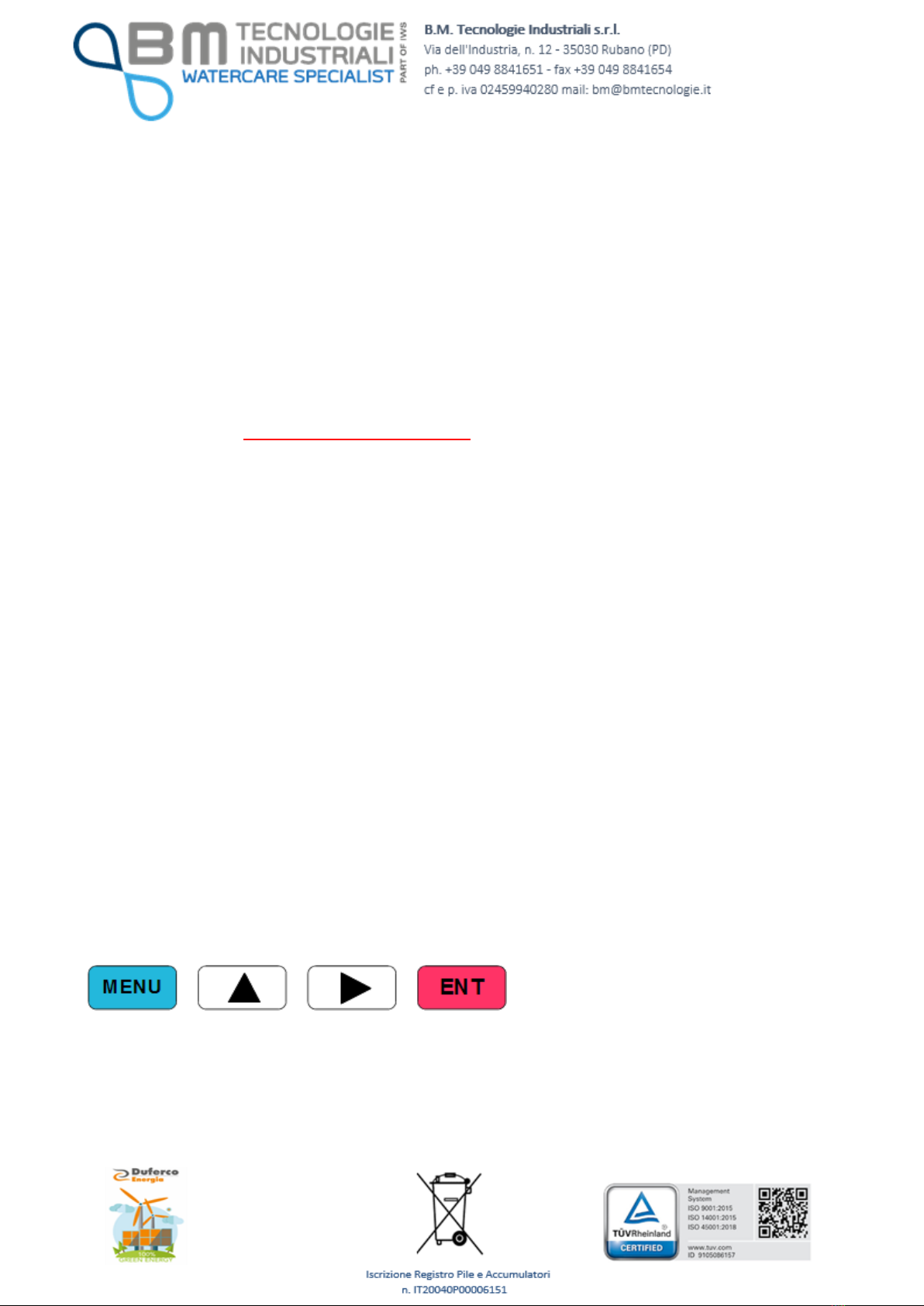

TTFM100-F18-NG –how access to menu items using the 4 keys

The MENU items are the same of all the TTFM series meters; the only difference is the

way to access them.

•Example:

We want to change the “Pipe Outer Perimeter” - MENU 10.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 14 of

110

Simply press the key and the display will be, for example:

F l o w 0 , 0 0 0 0 m 3 / h *R

W i n d o w N o . =

The unit is waiting your input, by pressing the key, the first digit after equal

sign (=) will be

F l o w 0 , 0 0 0 0 m 3 / h *R

W i n d o w N o . =1

Now, pressing the key the display will be:

F l o w 0 , 0 0 0 0 m 3 / h *R

W i n d o w N o . =10

By pressing the key we will access MENU 10, Pipe Outer Perimeter:

P i p e O u t e r P e r i m e t e r

x x x x . x x x m m

Now we want to enter 725 mm to set up our application:

Press the key and the display will show:

P i p e O u t e r P e r i m e t e r

> _ mm

Using the and keys you can change the display value.

Press 7 times and the unit will display:

P i p e O u t e r P e r i m e t e r

> 7_ mm

Press 1 time and the unit will display:

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 15 of

110

P i p e O u t e r P e r i m e t e r

> 70_ mm

Press 2 times:

P i p e O u t e r P e r i m e t e r

> 72_ mm

Press 1 time and the unit will display:

P i p e O u t e r P e r i m e t e r

> 720_ mm

Press 5 times:

P i p e O u t e r P e r i m e t e r

> 725_ mm

Than press , now the unit will display:

P i p e O u t e r P e r i m e t e r

725 mm

Using the keys it’s possible to enter all

the digits you need to program the TTFM100-F18-NG.

The and keys are used to scroll the menu up or down.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 16 of

110

A practical Example:

Switch on the device and it will display:

V e r . XX.XX

S / N = X X X X X X X X

Then it will display, (it depends from the last switch off) for example:

F l o w 0 . 0 0 0 0 m 3 / h *I

N o S i g n a l D e t e c t e d

The transducers are not installed and their mounting distance will be displayed only after

the set-up. Actually the device detects no signals.

Press

MENU

and the device will display:

F l o w 0 . 0 0 0 0 m 3 / h *I

W i n d o w N o . =

Press

1

0

and the device will display window no. 10.

P i p e O ut e r P e r im e t e r

X X X X m m

Press

1

2

8

6

and

ENT

:

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 17 of

110

P i p e O ut e r P er i m e t e r

1 2 8 6 m m

If you press a wrong digit, press to correct.

Press and the device will display:

P i p e O u t e r D i a m e t e r

XXX.XXX mm

Press and the device will display:

P i p e W a l l T h i c k n e s s

X . X m m

Press

6

,

.

,

5

+

ENT

and the it will display:

P i p e W a l l T h i c k n e s s

6 . 5 m m

Press and the device will display:

P i p e I n n e r D i a m e t e r

3 9 6 . 34 7 m m

The device calculates the value based on the entered settings.

It is possible to press again and the device will display the parameters it

calculated until now.

Press and the device will display:

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 18 of

110

P i p e M a t e r i a l [ 1 4

1. S t a i n l e s s S t e e l

The pipe material depends from the material of the pipe.

Press

ENT

and “1” and is blinking.

P i p e M a t e r i a l [ 1 4

>1 . S t a i n l e s s S t e e l

Select the right material by using the

P i p e M a t e r i a l [ 1 4

> 0 . C a r b o n S t e e l

Press ENT and and the device will display:

L i n e r M a t e r i a l [ 1 6

0 . N o n e , N o L i n e r

In this case, the pipe has no internal lining, so “0” is correct.

Press and the device will display:

F l u i d T y p e [ 2 0

0. W a t e r ( G e n e r a l )

Press and the device will display:

T r a n s d u c e r T y p e [ 2 3

16. C l a m p - o n T M1

NOTE:

The standard sensors are Clamp-on TM1 type, for pipes from DN50 up to

DN1000.

It is possible to ask for different sensors, depending from the application.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 19 of

110

Press and the device will display:

T r a n s d u c e r M o u n t i n g

0. V

Press and the device will display:

T r a n s d u c e r S p a c i n g

3 8 5 . 26 8 m m

The displayed value id the sensors mounting distance, as shown in par. 2.2.

It is possible to install the transducers, as shown in the following par. 2.4.

Press and the device will display:

D e f a u l t s e t t i n g s [ 2 6

1 . S o l i d i f y s e t t i n g s

Press and the device will display:

S a v e / L o a d p a r a m e t e r s

>>

Press to go through the parameters:

S a v e / L o a d p a r a m e t e r s

>> T o B r o w s e

Press and the device will display:

S a v e / L o a d p a r a m e t e r s

0: 4 0 9 , 34 7 m m , C a rb o n

This setting refers to the example configuration: DN400 carbon steel pipe.

Mod.BM43

COM

Vers.1.0

16/11/2005

Page 20 of

110

Press and the device will display:

S a v e / L o a d p a r a m e t e r s

E n t r y t o S A V E

Press MENU, 1, ENT and the device will display:

F l o w 0 . 0 0 0 0 m 3 / h *I

N o S i g n a l D e t e c t e d

Now it is possible to install the transducers.

2.4 INSTRUCTIONS FOR CLAMP-ON SENSORS INSTALLATION

If you ordered Clamp-on sensors type TTS100-TS2-NG, TTS100-M1-NG,

TTS100-L1-NG,TTS100-S1-NG-HT, TTS100-M1-NG-HT the following instructions

are very important for a correct installation of the sensors:

1. In order to install the sensors, check if the pipe has features which could affect the

measure, i.e. rust, dirt…

This manual suits for next models

1

Table of contents

Other B.M. Tecnologie Industriali Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Tankvision Multi Scan NXA83 operating instructions

Kurth Electronic

Kurth Electronic KE8000 operating manual

Fluke Calibration

Fluke Calibration 525B user manual

Blaupunkt

Blaupunkt TPMS 3.0 Operating and installation instructions

TSI Instruments

TSI Instruments SidePak AM520 user guide

Toshiba

Toshiba LF232 product manual