B-PWR SG4FB1-1 Manual

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 1 | 13

Thank you for choosing a B-PWR product, designed by passionate riders who focus on what users really need.

1. SAFETY INSTRUCTIONS

To avoid any unfortunate situations, we recommend that you get to know how your modified vehicle handles before using it in extreme

conditions.

Read all the instructions carefully before installing this product.

If you do not have the tools or technical knowledge needed to ensure proper installation, have the product installed by an authorized

dealer.

It is essential that you follow the installation procedures, possess general mechanical knowledge and use appropriate tools to

ensure a safe and reliable installation.

Improper use or installation of the product, or any modifications made to adapt the product for use in a context other than that for

which it was intended, voids the warranty and may result in SERIOUS INJURIES.

B-PWR and all its affiliated companies, as well as its suppliers and distributors, are not responsible for any consequences

whatsoever resulting from an incorrect installation or an improper use of the product.

This guide provides detailed instructions for installing the product.

SG4FB-1

Ski-Doo platform G4 and Expert

For safety reasons, this kit needs to be installed by a person with general mechanical knowledge using the proper tools.

The illustrations in this document indicate the typical structure of the various assemblies. It is therefore possible that they do not

represent the exact form of the parts or the manufacturing details. These illustrations are intended to identify parts that perform an

identical or similar function.

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 2 | 13

2. REQUIRED TOOLS

TOOLS

T1

10 mm Socket

T4

Ratchet

T2

10 mm Wrench Key

T5

Torque Wrench

T3

Drill Bit 1/4"

T6

T27 Torx Socket

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 3 | 13

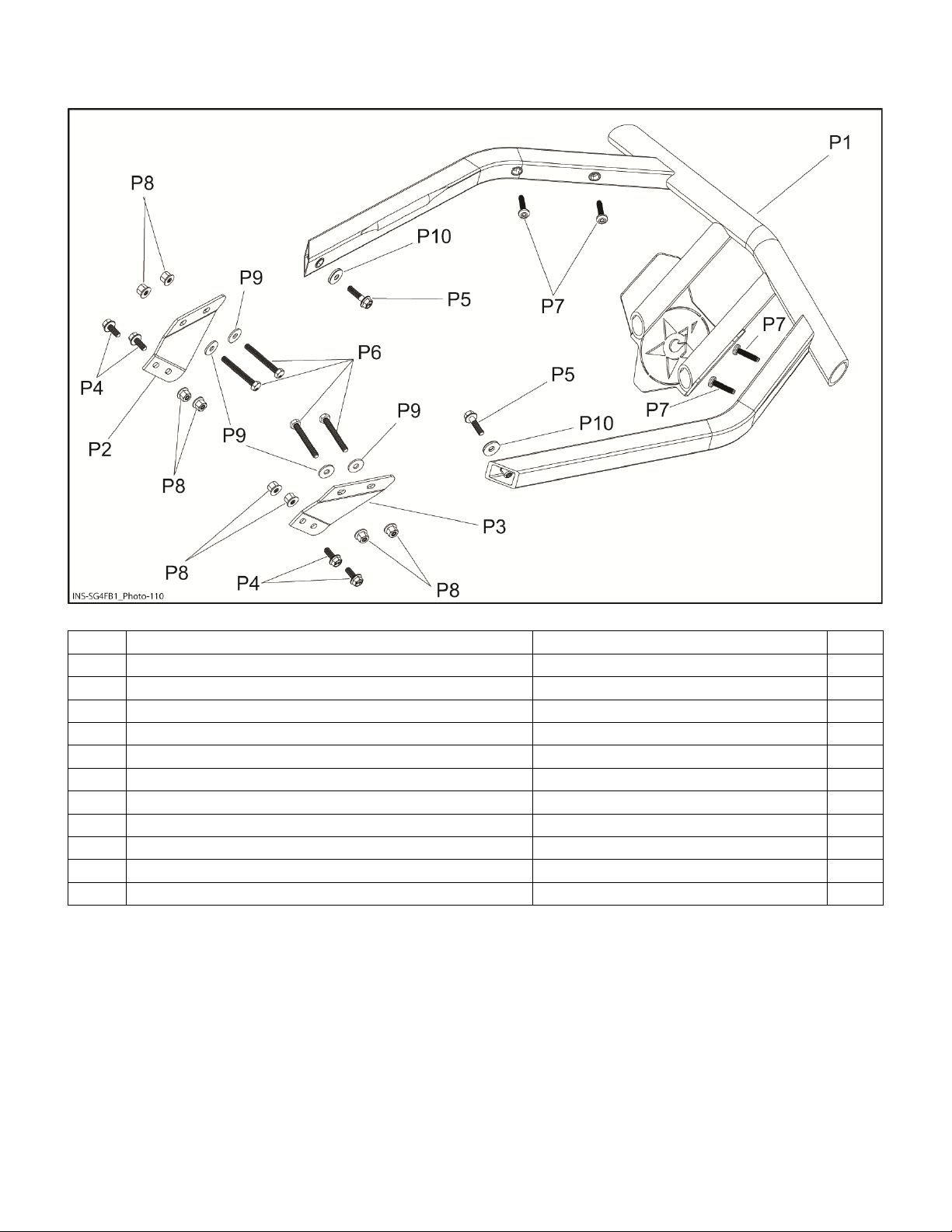

3. PARTS

ITEM

DESCRIPTION

PART NUMBER

QTY

P1

Front Bumper G4

SG4FB-1

1

P2

Aluminum Left Support Plate

555100019-B

1

P3

Aluminum Right Support Plate

555100020-B

1

P4

M6 X 16 mm Hexagonal Flanged Screw

207661654B

4

P5

M6 X 25 mm Hexagonal Flanged Screw

999100024

2

P6

M6 X 50 mm Hexagonal Head Screw

999100033

4

P7

M6 X 25 Rounded Head Screw

250000758B

4

P8

M6 Nylon Lock Nut

233261494B

8

P9

M6 Washer

999100020

4

P10

M6 Rubber Sealing Washer

999100018

2

P11

6" Self-adhesive Aluminum Tape

999100032

1

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 4 | 13

4. VEHICLE PREPARATION

Read all the instructions carefully before installing the product.

Make sure you have enough space to work properly.

Make sure to have the required tools.

Note:Unlessdifferencesoccurbetweenlefthand(LH)and righthand(RH)sides,theprocedures areshown for onlyonesideofthe

vehicle.Repeatforotherside.Rightandleftsidesaredefinedaswhensittingonthevehicle.

4.1 Remove side panel with three (3) locking clip.

1- Locking Clip

4.2 Remove two (2) screws securing bin using T27 Torx socket [T6].

1- Bin Screw

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 5 | 13

4.3 Lift front of gauge panel and remove bin.

4.4 Remove four (4) screws securing front of center panel using T27 Torx socket [T6].

1- Front Center Panel Screw

4.5 Remove two (2) screws securing rear of center panel using T27 Torx socket [T6].

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 6 | 13

4.6 Disconnect headlight connectors and any other connectors attached to center panel. Loosen air intake duct screw and remove

center panel.

4.7 Drill four (4) rivets with drill bit 1/4" [T3] as shown.

1- 3/16" rivet

4.8 Remove two (2) screws and nut securing bumper using T27 Torx socket [T6].

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 7 | 13

4.9 Remove bumper.

4.10 Remove two (2) retaining springs from top of exhaust.

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 8 | 13

4.11 Remove three (3) retaining springs from bottom of exhaust.

4.12 Disconnect connector attached to exhaust.

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 9 | 13

4.13 Remove exhaust.

5. INSTRUCTIONS

5.1 Install 6" self-adhesive aluminum tape [P11] on front bumper G4 [P1] as shown and slide front bumper G4 [P1] from side in position.

1- 6" self-adhesive aluminum tape [P11]

5.2 Locate where exhaust have contact with front bumper G4 [P1] and bend lip of exhaust at that location as shown.

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 10 | 13

5.3 Position front bumper G4 [P1] with two (2) M6 X 25 mm hexagonal flanged screw [P5] and M6 rubber sealing washer [P10]. Hand

tighten only.

1- M6 X 25 mm hexagonal flanged screw [P5]

2- M6 rubber sealing washer [P10]

5.4 Secure front bumper G4 [P1] with four (4) M6 X 25 rounded head screw [P7].

TIGHTENING TORQUE

M6 X 25 rounded head screw [P7]

10 N•m ± 2 N•m

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 11 | 13

5.5 Tighten to specification two (2) M6 nylon lock nut [P8] with two (2) 10 mm wrench key [T2] and drill four (4) holes using pre-drill

location with a drill bit 1/4" [T3] as shown.

TIGHTENING TORQUE

M6 Nylon Lock Nut [P8]

10 N•m ± 2 N•m

5.6 Install aluminum right support plate [P3] with two (2) M6 X 16 mm Hexagonal Flanged Screw [P6] and M6 nylon lock nut [P8] as

shown.

TIGHTENING TORQUE

M6 Nylon Lock Nut [P8]

10 N•m ± 2 N•m

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 12 | 13

5.7 Drill four (4) holes in front bumper G4 [P1] using aluminum support plate [P3,P4] as a template with a drill bit 1/4" [T3] as shown.

5.8 Secure front bumper G4 [P1] with four (4) M6 X 50 mm hexagonal head screw [P6], M6 nylon lock nut [P8] and M6 washer [P9] as

shown.

1- M6 washer [P9]

2- M6 X 50 mm hexagonal head screw [P6]

TIGHTENING TORQUE

M6 nylon lock nut [P8]

10 N•m ± 2 N•m

I N S - S G 4 F B 1 - EN I n s t r u c t i o n G u i d e : S G 4 F B 1 - 1 F r o n t B u m p e r P a g e 13 | 13

5.9 Here is final result of installation of assembly.

5.10 Install various panels in reverse sequence of removal procedure.

Note: Ensurethatpreviouslyremovedconnectionsareproperlymadeto centerpanelandexhaust.

This manual suits for next models

1

Table of contents

Other B-PWR Motorcycle Accessories manuals

Popular Motorcycle Accessories manuals by other brands

Tecmen

Tecmen iMux Series owner's manual

Chicago Electric

Chicago Electric 91214 Owner's manual & safety instructions

ZTechnik

ZTechnik Quantum Z5402 Installation and owner's manual

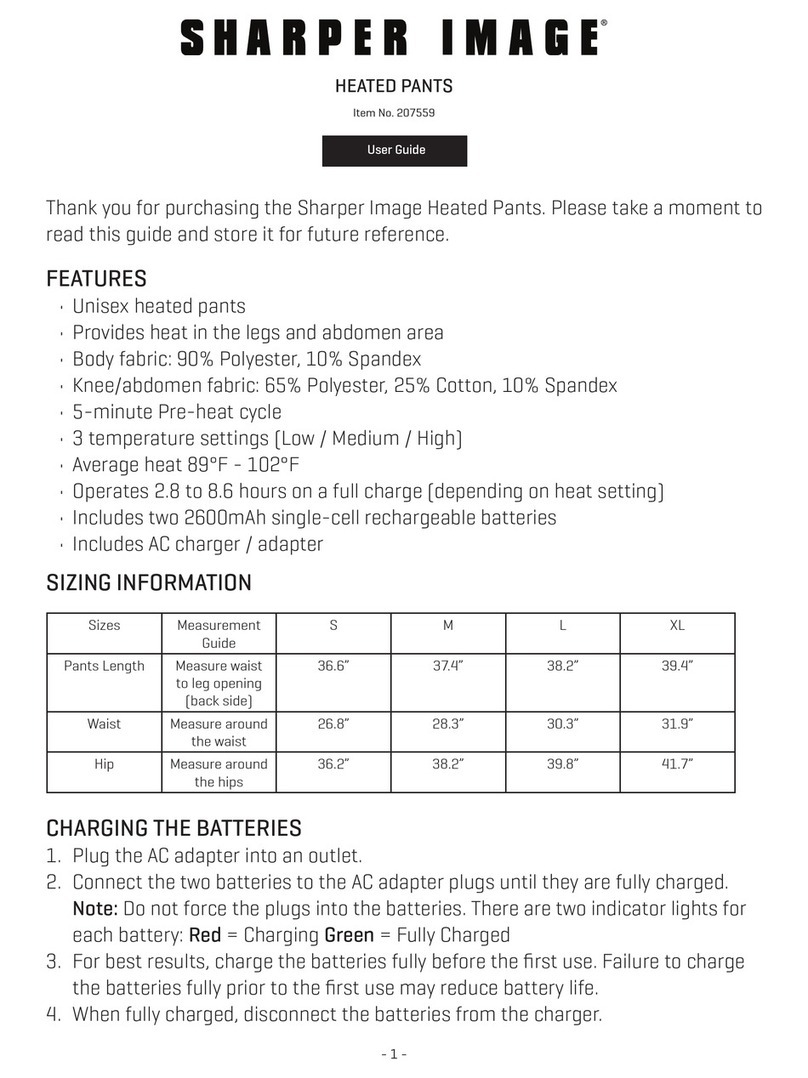

Sharper Image

Sharper Image 207559 user guide

Saddlemen

Saddlemen I14-07 Series User's guide & installation instructions

rizoma

rizoma ZDM131 user manual