-2-

IMPORTANT SAFETY PRECAUTIONS

Please read this manual carefully. Operate your equipment

according to the safety instructions and recommendations found

throughout this manual. Anyone who uses this equipment must read

and fully understand the instructions and be familiar with its

operation.

To receive the greatest possible performance and satisfaction from

your Badger Earth Auger, and to reduce the risk of injury, it is

important that you read and understand the assembly, operating,

maintenance, and safety instructions before using your Badger Earth

Auger. Contact Feldmann Engineering if you do not understand any

of the instructions in this manual.

Your Badger Earth Auger is designed and manufactured to provide

safe and dependable operation, provided it is operated in

accordance with the following safety precautions.

Preventing accidents is the responsibility of every power equipment

operator. The safety precautions identified in this manual must be

fully understood and followed by every operator of this Badger

Auger. Review the safety precautions frequently and never take

chances.

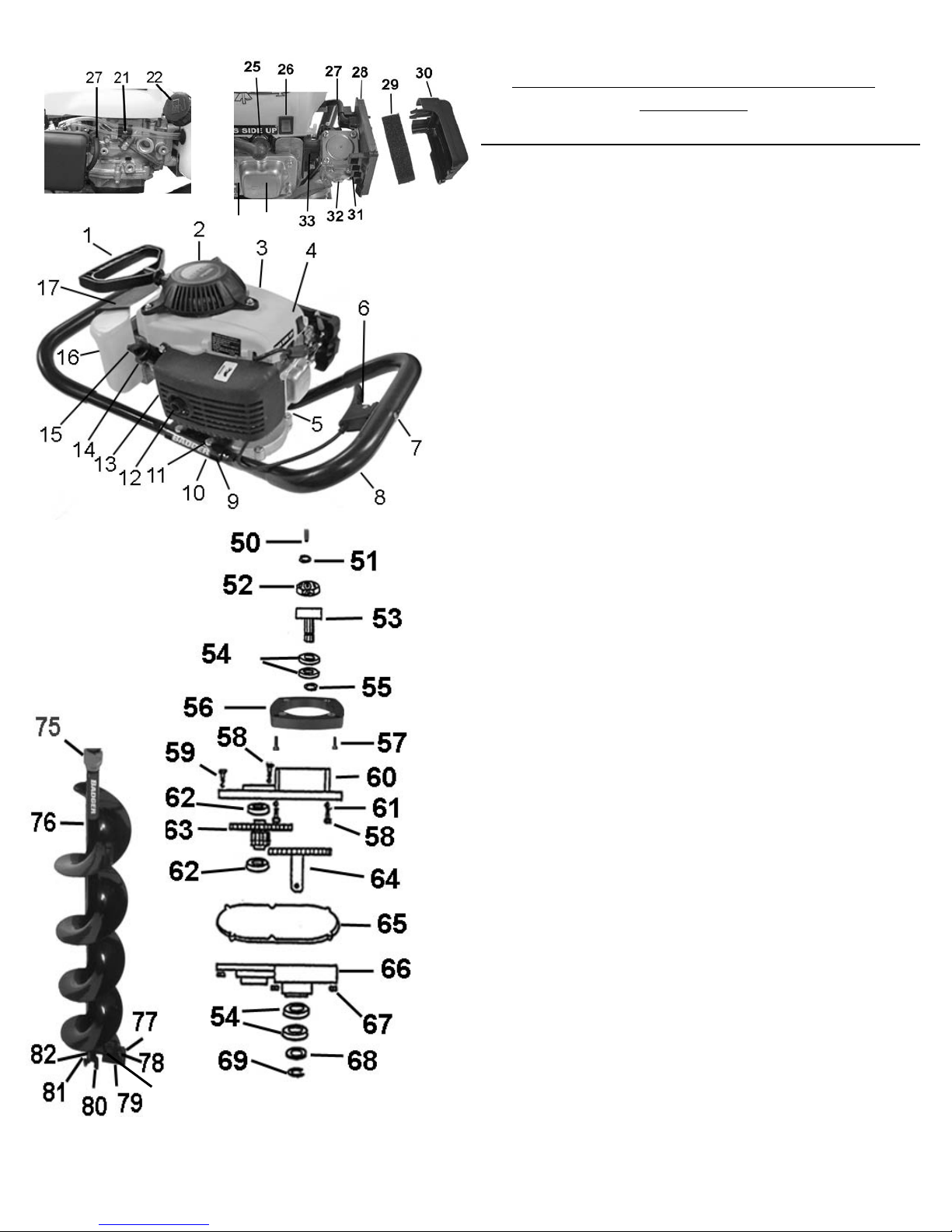

Take the time to become familiar with your Badger Auger and its

components, then operate it in a safe manner. Study the appropriate

sections of this manual for the description of the controls and

function of your Badger Auger. Teach the safety precautions to all

persons who use your Badger Earth Auger.

Avoid mishandling and abuse of your Badger Auger. Handle it

with care, as any rough treatment can cause damage to your

Badger Earth Auger or it can cause a malfunction.

Should the engine stop while drilling, do not attempt to restart it

while the auger bit is in the hole.

Never attempt to adjust or repair your Badger Earth Auger while

the engine is running. Avoid possible injury from moving parts

by first stopping the engine.

+ Never modify your Badger Earth Auger in any way. Only

Badger Earth Augers and accessories supplied by Feldmann

Engineering or expressly approved by Feldmann Engineering

for use with your Badger Earth Auger are authorized for

connection and use. The use of non-Badger or unauthorized

components may cause damage or injury.

Check the tightness of screws, nuts, and bolts at regular

intervals and re-tighten if necessary.

Do not wear loose clothing while operating your Badger Earth Auger

and keep all clothes and parts of the body (hands, feet, etc.) clear of the

rotating earth auger assembly to avoid being drawn into the boring

auger.

Do not allow children to operate your Badger Earth Auger at any time.

Do not allow adults to operate your auger without proper operational

instructions, including all safety precautions.

Do not lend or rent your Badger Earth Auger without providing the

owner’s manual. Be sure that anyone who uses your Badger Earth

Auger understands the information contained in this manual.

Give your complete and undivided attention to the proper operation of

your Badger Earth Auger. To operate it properly, you must be in good

physical condition and mental health and not under the influence of any

substance (alcohol, drugs, etc.) which might impair vision, dexterity, or

judgment.

+ Using your Badger Earth Auger may be strenuous. If you have any

condition that may be aggravated by strenuous activity, check with your

doctor before operating your Badger auger.

+ Do not operate your auger when you are tired. Fatigue may result in

loss of control.

+ Do not carry your Badger auger or leave it unattended while the engine

is running.

Only run your Badger Earth Auger in well-ventilated areas.

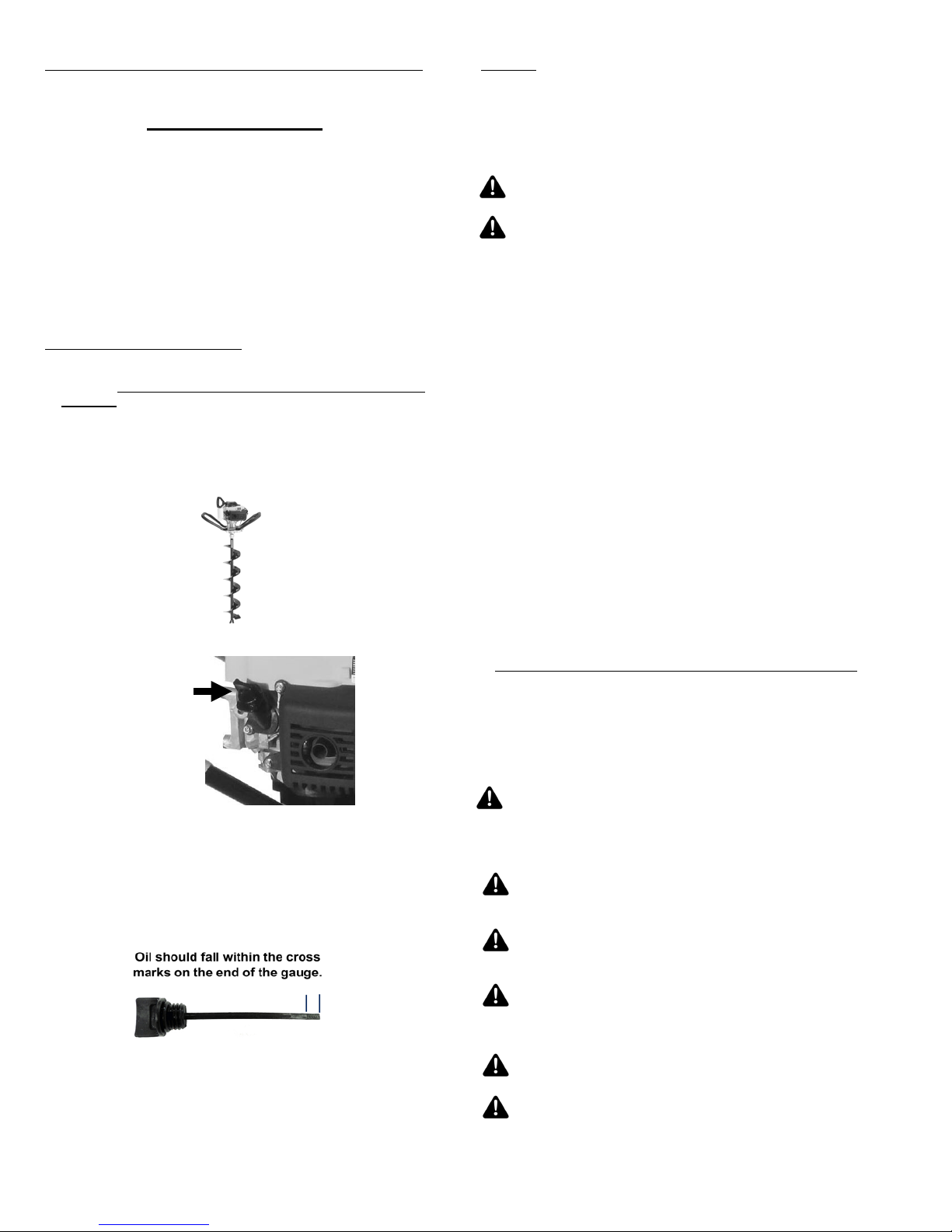

Badger Gasoline Earth Auger must be transported, stored or

placed on the ground with spark plug facing upward, or with

powerhead in upright (operating) position. Failure to do so may

result in oil leakage, excessive exhaust smoke or engine damage.

Always allow engine to cool before storing.

+ When transporting your Badger Auger in a vehicle, properly secure it to

prevent it from tipping over, which may cause oil leakage or engine

damage.

+ Gasoline is flammable and caution must be used when handling or

storing it.

+ Do not fill the fuel tank while your Badger Auger is running, if the engine

is hot, or when in an enclosed area.

Always fill the fuel tank outdoors.

Only use your Badger Earth Auger for its intended purpose.

PRE-USE PROCEDURE

Before using your Badger Earth Auger to drill holes, follow this procedure to

prepare for proper and correct use.

•Find, read, and understand the Badger operating/parts manual.

•Assemble the components of your Badger Earth Auger as indicated

in the Assembly of Drill section of this manual.

•Re-read and follow the Starting Instructions section of this manual.

•If the engine does not run satisfactorily, or if you feel it needs an

adjustment of some kind, contact Feldmann Engineering for the

proper repair information. Do not attempt to adjust the engine

operation yourself. Only an authorized service person may make

adjustments to your Badger Earth Auger’s engine without invalidating

the unit warranty.

•DO NOT RETURN your Badger Earth Auger TO THE RETAILER

THAT SOLD IT TO YOU. THEY ARE NOT AUTHORIZED TO

PROVIDE REPAIRS OR WARRANTY REPLACEMENT. If you have

any questions concerning service, contact Feldmann Engineering as

indicated in the Service & Repair Information section of this manual.