4

CLEANING OF YOUR AIRBRUSH

To clean the airbrush, take a clean color cup or jar

full of cleaner. Insert it into the airbrush, spray

some cleaner through the airbrush at broad and

small patterns. After removing color cup or jar, turn

brush upside down and press trigger. This will

remove any material still in the brush.

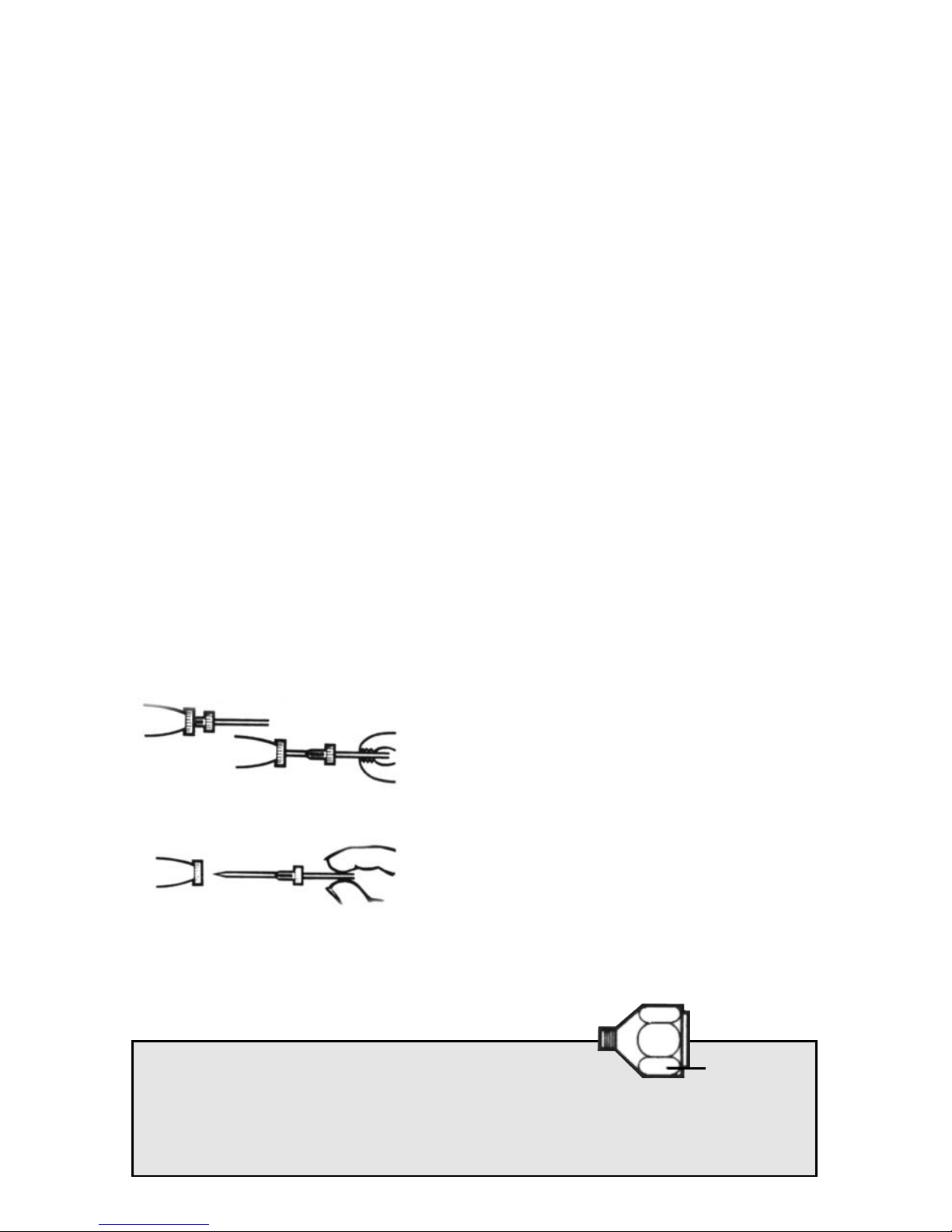

Another method of cleaning the airbrush is back

flushing. Take a soft cloth and cover the spray regu-

lator–depress and pull back on the trigger. This will

cause a bubbling in the color cup or jar. Take away

the cloth and spray and repeat this procedure sever-

al times. After this is done you should remove the

needle for cleaning.

Spray regulator should be cleaned using a soft

bristle brush. Insert into the cavity of the spray

regulator and rotate until the paint is removed.

If the needle is stuck in the airbrush, carefully

loosen the needle chuck, then grasp the end of the

needle with a pair of pliers and twist in a counter-

clockwise direction to release the needle. Inspect for

hardened paint, which causes the needle to bind. If

there is a residual stain on the needle, it can be

polished off using a pink eraser. Hold the needle flat

on a worktable. Rund the pink eraser the full length

of the needle, turn the needle slowly by rolling it

towards yourself and repeat the process. Be careful

not to bend the tip. Remove all eraser particles by

running the needle between your thumb and fore-

finger.

To replace a bent needle, set needle adjusting screw

all the way forward.

Loosen needle chuck and slide out needle.

Insert new needle. Slide it forward with slight

pressure from index finger until the needle stops.

Do not push forward with great pressure, as the

needle may split the delicate paint tip and also dam-

age the needle point. To lock the needle in place

tighten needle chuck into needle adjusting screw.

Turn needle adjusting screw to desired spray pat-

tern.

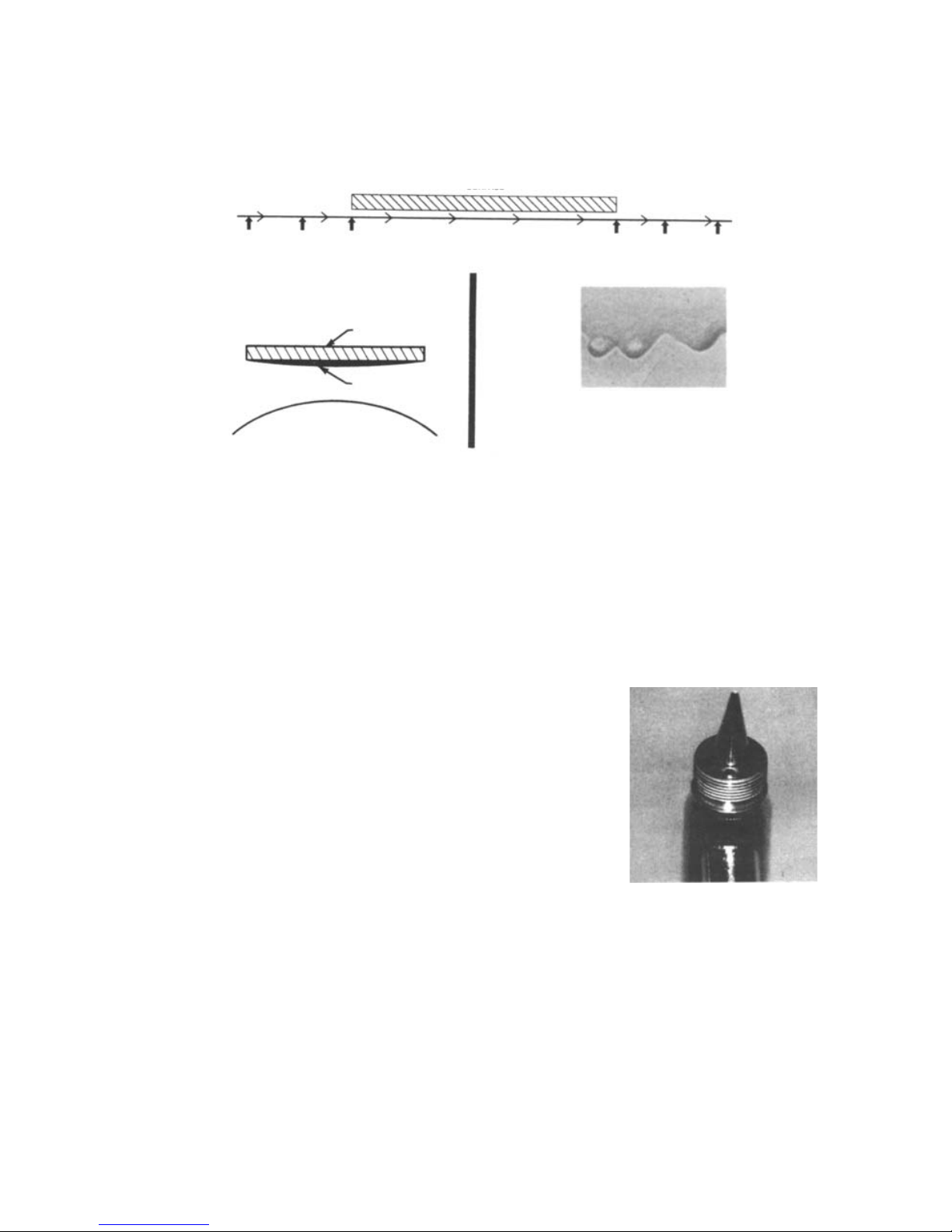

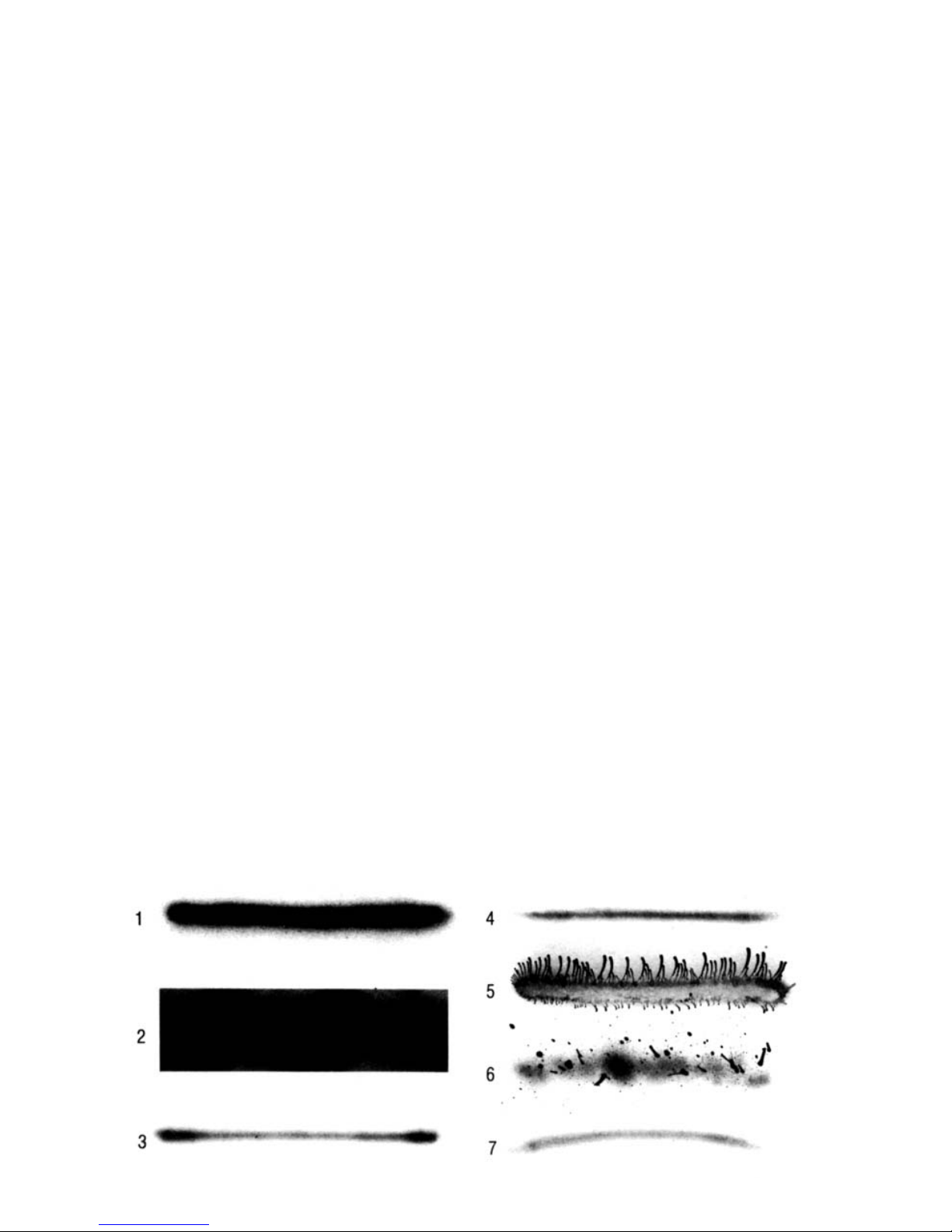

A bent needle will prevent you from airbrushing a

fine line and will cause an erratic direction of spray.

A bent tip does not always have to be discarded.

Place the needle on a firm surface at the angle of

the tip. Straighten the bent tip by running your fin-

gernail across it on the tabletop while you turn the

needle slowly. Run your fingernail from the body of

the needle outward towards the tip.

You can custom mix any color combination you

wish. REMEMBER: Paints must by compatible...that

is, mix enamels with enamels, lacquers, etc. Mix

thoroughly. Make sure paint is free of lumps...strain

if necessary. To help prevent your airbrush from

clogging, Badger offers a Fluid Filter (50-2018 sold

separately). The filter slides on and off the siphon

tube for quick and easy cleaning.

THINNING

Most jar paints are too heavy to spray. Enamels

should be thinned approximately 1 part paint to 1

pat thinner, and lacquers approximately 1 part paint

to 1 part thinner. TO thin automotive lacquers, con-

sult the spraying directions on the side of the paint

container.

WHEN USING LACQUER

Lacquer dries very quickly. For best results the

operation should be continuous, that is, air airbrush

should not be set down for more than a few

moments before resuming spray. Keep an extra

paint jar of thinner handy...remove lacquer jar,

attach jar of thinner and spray to clean out any lac-

quer that may dry in airbrush. Also refer to cleaning

instructions for additional information.

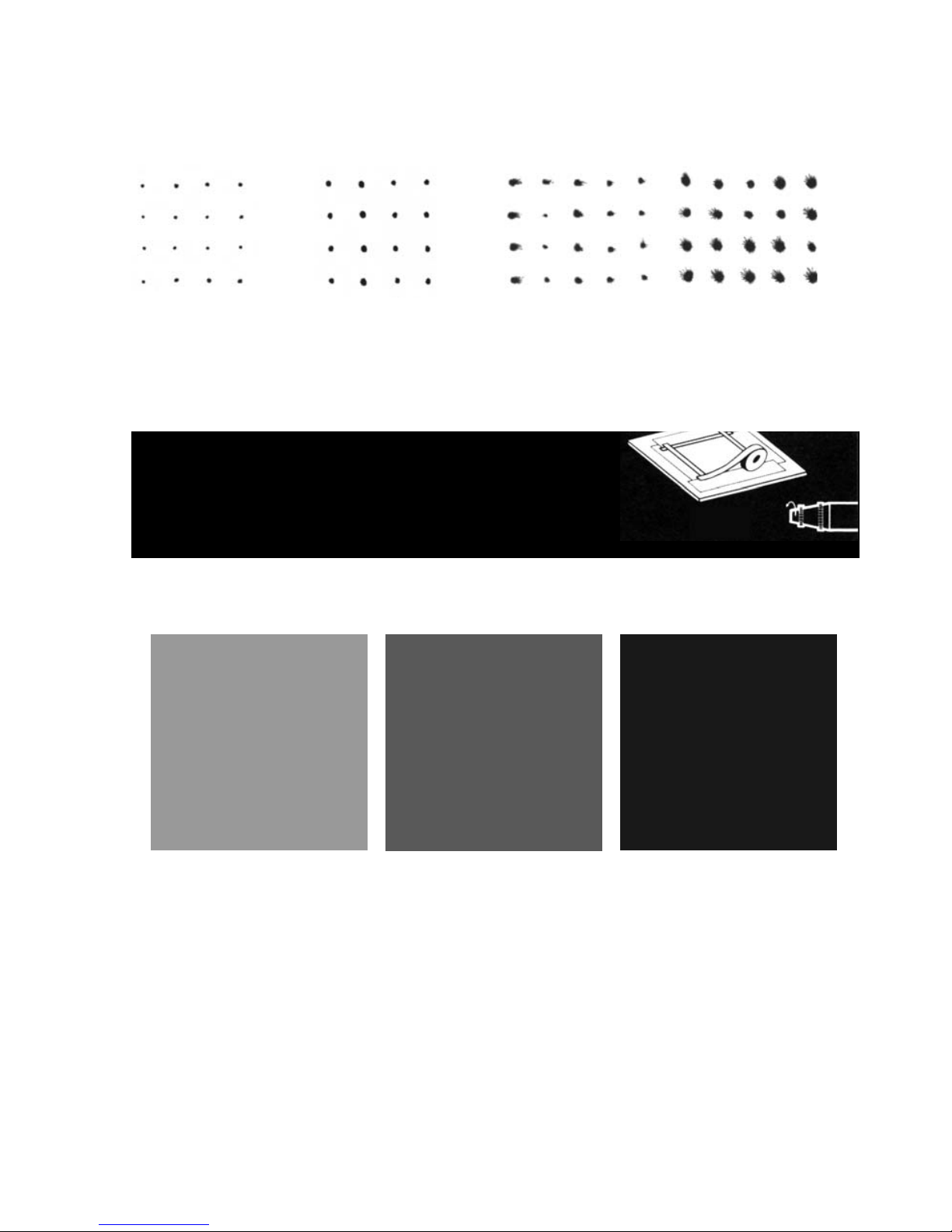

TO SPRAY

After mixing and thinning paint, fill paint jar about

2/3 full (or less). Attach jar of paint to airbrush, turn

air on and press trigger. Test your spray on old

newspaper or other material, make any necessary

spray adjustments, and get the “feel” of your air-

brush. (Be sure that paint or fumes cannot reach

any flame. Also make sure that there is adequate

ventilation).

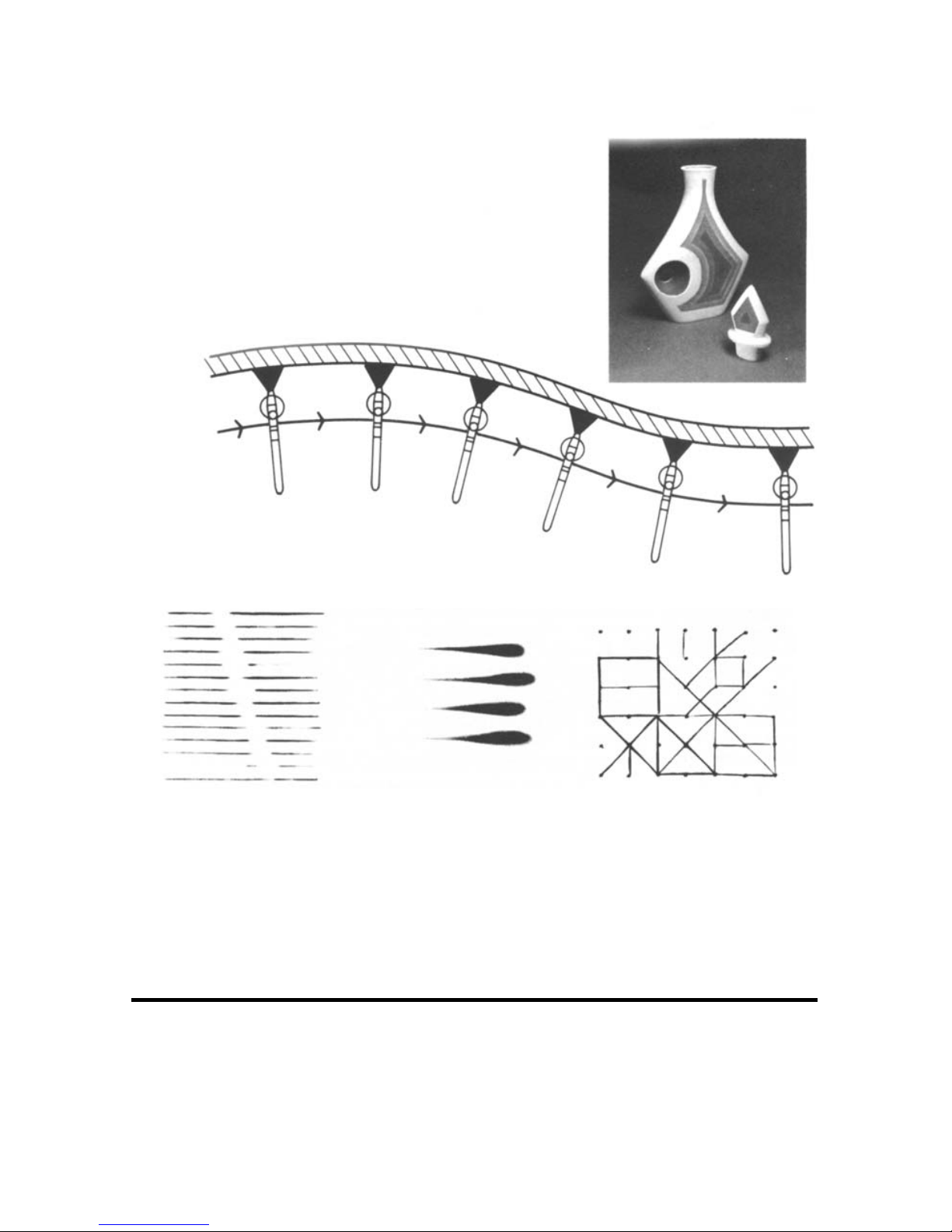

MANUFACTURERS NOTE

For larger jobs and prolonged spraying, a compressor or CO2tank is recommended. A 1/4˝ pipe thread fit-

ting (50-023 sold separately) is needed to adapt air-hose to air-supply. When using a “Bleeder Type” com-

pressor, a pipe thread fitting (50-0231 sold separately) must be used to prevent compressor from stalling

out or overheating when airbrush is not in use.

1.4˝ PIPE

ADAPTOR NO. 72 OR

1/32˝ DRILL