Startup

June 2021SGN-UM-00282-EN-05Page 10

Status: Com1 9/23/2008

File Options Tools

Program Values Board Values

Program Read Verify

Status: Idle Com Port 1

Pulse Output

High

Low

K-Factor

Pulse Width

150us

Auto

1s

500ms

100ms

25ms

1ms

Pulse Output

High

Low

K-Factor

Pulse Width

150us

Auto

1s

500ms

100ms

25ms

1ms

File Tools Version

Program

Read

Verify

Com Port

Blancett K-Factor Programming Software

Status: Com1 9/23/2008

File Options Tools

Program Values Board Values

Program Read Verify

Status: Idle Com Port 1

Pulse Output

High

Low

K-Factor

Pulse Width

150us

Auto

1s

500ms

100ms

25ms

1ms

Pulse Output

High

Low

K-Factor

Pulse Width

150us

Auto

1s

500ms

100ms

25ms

1ms

File Tools Version

Blancett K-Factor Programming Software

Com 1

Com 2

Com 3

Com 4

Com 5

Com 6

Com 7

Com 8

Com 9

Com 10

Com 11

Com 12

Com 13

Com 14

Com 15

Com 16

Program

Read

Verify

Com Port

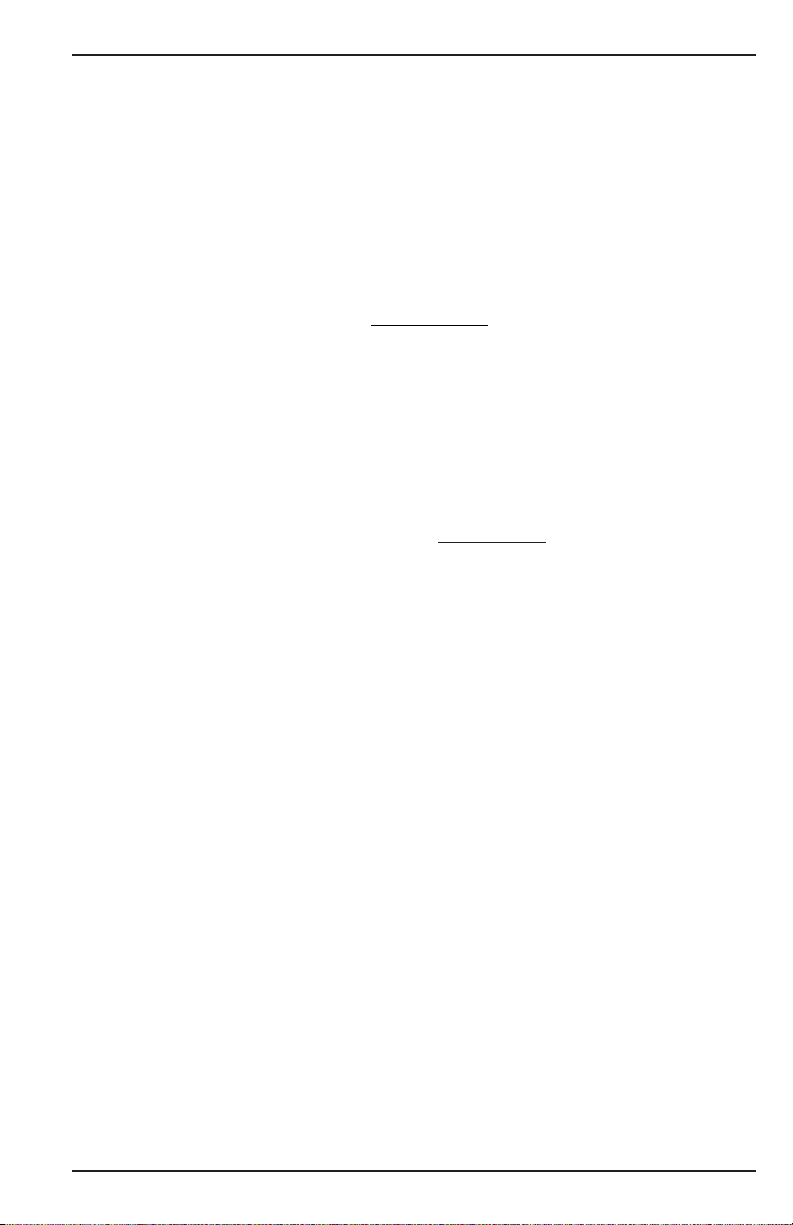

Figure 7: Tools drop down Figure 8: Com port menu drop down

If the Com port selected is invalid, the software shows the message ERROR –

Invalid Com Port when trying to program the board. If the incorrect Com port is

selected, or if there is a problem with the cable, the software shows the message

"No Response" after trying to program the board.

Setting the K-Factor

The K-factor is the ratio of input pulses per each output pulse, for example, if the

K-factor is set to 1, then each input pulse would yield one output pulse. The range

that the K-factor can be set to is 1…999,999,999. The K-factor is set by entering it

in the Program Values column of the software in the K-factor field.

Setting the Output Pulse Width

The output pulse width is the length of time the pulse remains active before

resetting to its original state. The K-factor scaler has a total of seven different pulse

widths. The Auto option does not restrain the output pulse to a specific length.

Instead, it varies and is dependent on output frequency. The higher the output

frequency, the shorter the pulse width output. The lower the frequency output,

the longer the pulse width output. This option turns off the Pulse Output selection

buttons because they do not apply in this mode.

Some end devices require the pulse to be a certain length or longer for proper

detection of each incoming pulse. For these devices, select a pulse width that is

long enough for the end device to recognize it.

The pulse width option is set by clicking the required pulse width radio button in

the Program Values column of the software.

Setting the Output Level Normally High or Normally Low

Most end devices are unaffected by this setting, but the K-factor scaler can invert

the output pulse level. This option is set by clicking the required pulse output

radio button in the Program Values column of the software.