Stationary VLA Batteries,

Installation and Operation Instructions

Page 6 of 17 www.baebatteriesusa.com Rev: 0219

4.0 UNPACKING-HANDLING

Single cells and multi-cell blocks may be received packed in individual Styrofoam

containers with shrink-wrap or packing cases, surrounded by foam, shrink-wrap and

attached to a wooden pallet. Carefully open the cases or carton to avoid possibly

damaging any of the cells or blocks.

NOTE: When removing the blocks or cells from the containers or cases always lift cells

from the bottom, never from the connectors or cell posts as this can damage cell

covers or post seals and void your warranty.

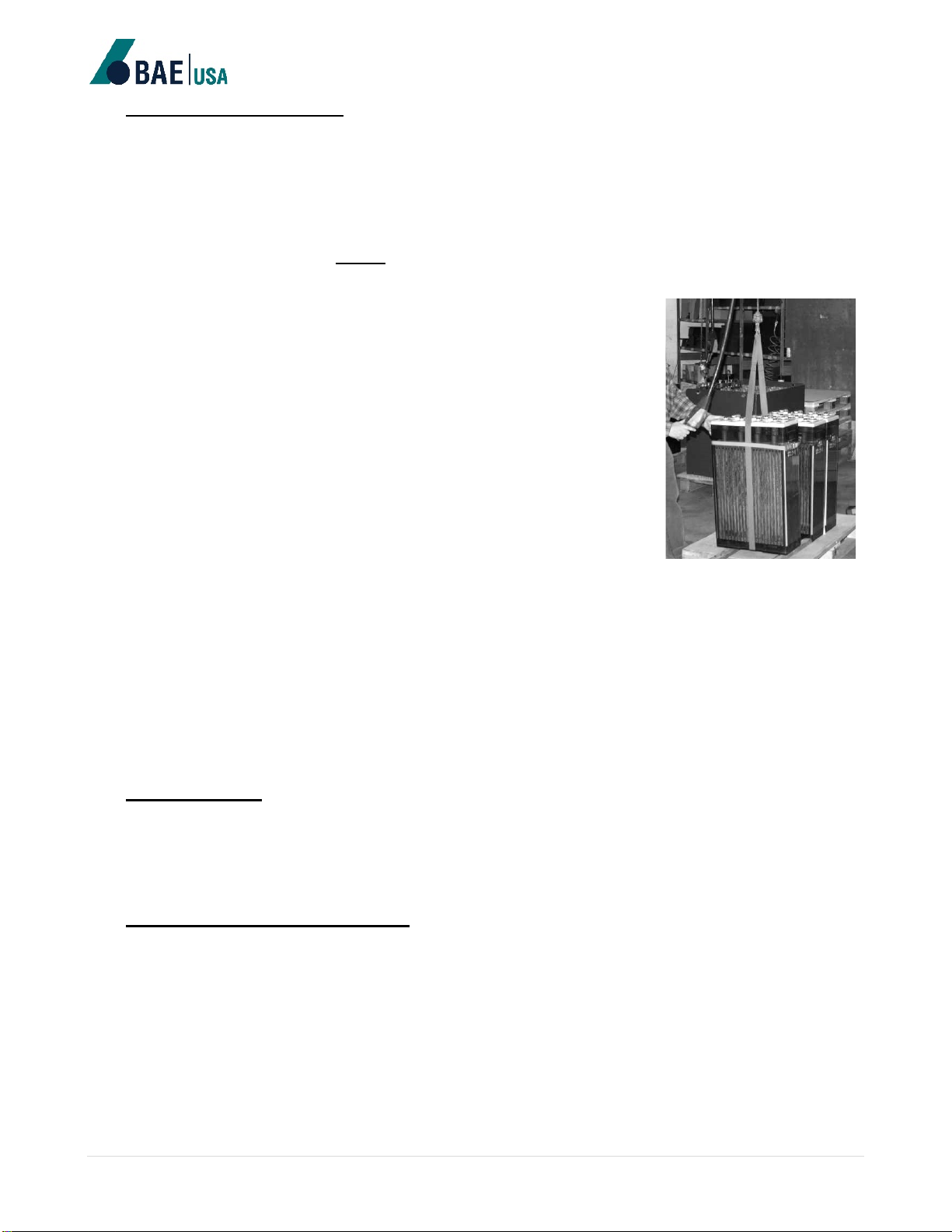

NOTE: A BAE lifting sling may be used on the larger capacity

cells and blocks - slip the lifting sling under the cell and

use the loops in the sling for hoisting the cell. Four

battery lift sizes are available based jar dimensions. .

•Small Block Lift Kit, L = 272 mm (10.7 in)

•Large Block Lift Kit, L = 385 mm (15.16 in)

•Small Cell Kit, H < 620 mm (24.4 in)

•Large Cell Kit, min: L x W x H, 145 x 205 x 700 mm

(5.71 x 8.07 x 27.56 in)

max: L x W x H, 220 x 580 x 855 mm

(8.66 x 22.83 x 33.66 in)

weight: 250 kg (551.1 lbs)

See the specific battery lifting sling operating instructions for details on use.

NOTE: A mechanical battery lift may also be used to move the cells.

If the cells were ordered wet (filled), immediately check the electrolyte level in each cell

or block. The electrolyte level should be between the maximum and minimum level lines

on the container. If the level is below the minimum line, check the container for damage.

If your visual inspection, after unpacking, indicates damaged posts, cell covers or jars, or

electrolyte levels are below the minimum line immediately contact BAE USA or your local

representative.

4.1 ACCESSORIES

When unpacking the cells, place the accessories along with the installation and operating

instructions in a safe location to avoid misplacement or loss. If you find any of the items

listed on the packing list are missing please contact BAE USA or your local

representative.

5.0 PRE-INSTALLATION PLANNING

We recommend batteries not be installed in battery rooms that are still under

construction; this avoids the risk of damage to the batteries during construction.

The installation of the individual cells is dependent on the size and type of cell and the

intended application of the battery. Standard designs provide for installation in battery

cabinets, conventional steel racks or seismic (earthquake resistant) racks.

For all installation options, the ideal designs should include acid-resistant coatings and

rail insulation to ensure that the required insulation between the rack and battery is

present over the life of the batteries.