6

5

11

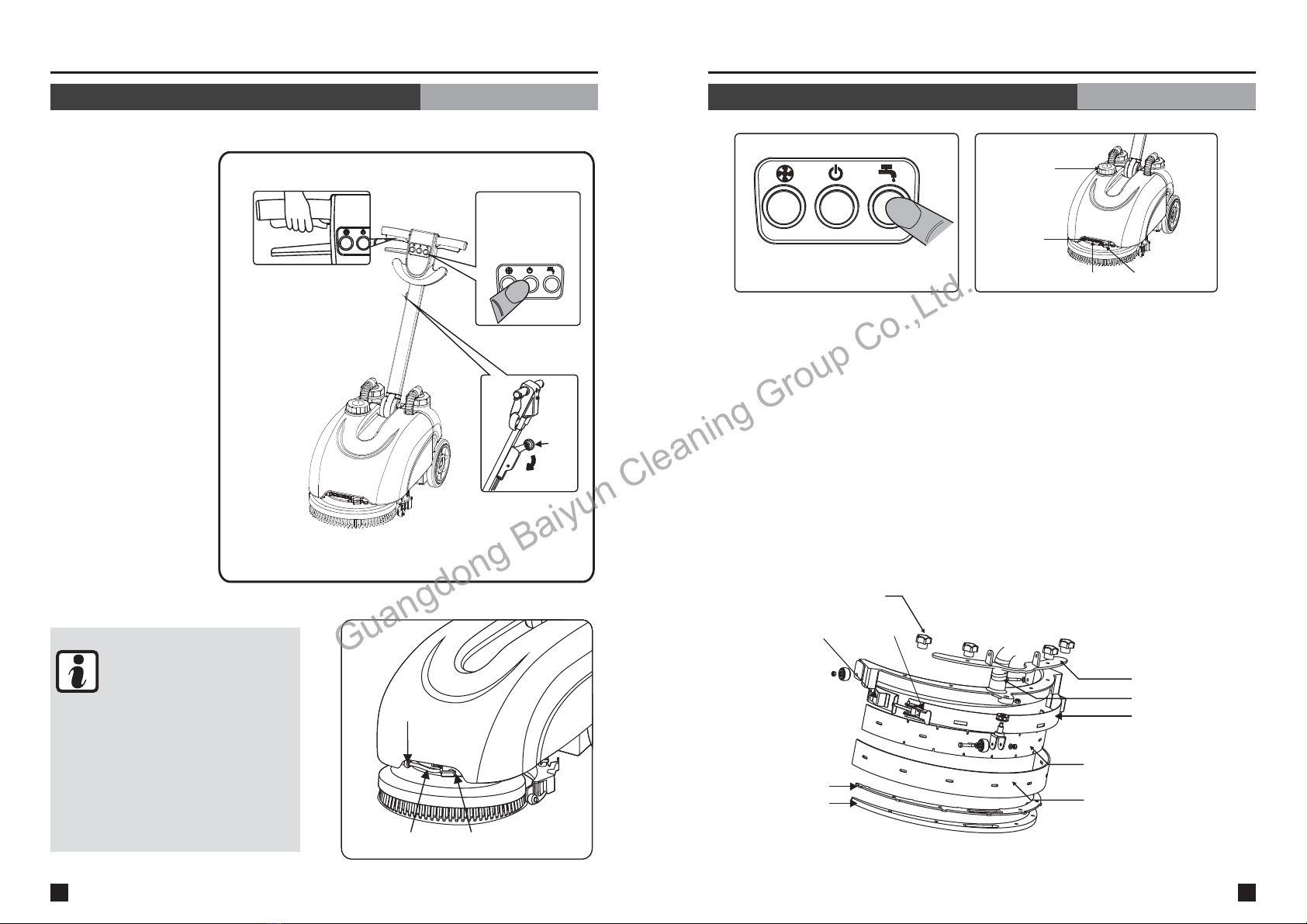

OPERATION INSTRUCTIONS

Operation steps

After the preparation work, operator can use the machine to begin the cleaning work.

c. Hold on the brush

motor switch a. Press the function

buttons

b. Put the squeegee

lever down

squeegee

lever

1 Check whether the sprinkling

button and the vacuum button

are turn off. Then switch on the

ON/OFF switch on the control

panel(fig.5-a), the machine will

in manual state.

.

2.Press the sprinkling button

on the control panel(fig.5-a),

the solenoid valve begins to

work, the machine starts

sprinkling water.

3.Put down the squeegee lever

to ensure that the squeegee

is totally touched with the floor

to work.

4.Hold on the brush motor

switches on both sides

(fig.5-c), the brush can

clean the floor.

5.After cleaning the work,

lift up the squeegee lever

and release the brush

motor switches. Then,

press the sprinkling button,

vacuum button, ON/OFF

switch to stop all cleaning

work.

Note

During the cleaning work, change the

water flow according to the condition

of the floor. The ball valve above the

brush cover can be used to adjust the

water flow. After the cleaning work,

pull the water pipe from quick connector

can discharge water in the solution tank

(fig.6).

Quick connector

Water pipe Ball valve

fig.6

MAINTENANCE GUIDE

Daily maintenance

Turn off the ON/OFF switch

fig.11

Solution

tank lid

Quick

connector

Water pipe Ball valve

fig.12

3.Maintain the squeegee

Remove, clean and air-dry the squeegee regularly to prolong the service life. The whole

squeegee assembly can be removed, to be cleaned and air-dry.

The procedure to remove the squeegee:

Star nuts

Triangle

clasp

Squeegee

clasp

Squeegee holder

Suction hose

Front squeegee

Rear squeegee

Upper inner pad

Lower inner pad

Retaining metal

strip assembly

①

②

③

④

Release the squeegee clasp to loosen the retaining metal strip assembly. Then pull the

two triangle clasps downwards to take out the retaining metal strip assembly.

After taking out the retaining metal strip assembly, the rear squeegee can be

removed.

Loosen the upper and lower inner pads and then the front and rear squeegee

can be removed. Check to confirm the wearing condition of the squeegee and

turn to an untouched side for use. Each squeegee has 4 sides for switching use.

Turn the two star nuts anticlockwise to remove the squeegee assembly.

Sprinkling switch

ON/OFF switch

Vacuum switch

Guangdong Baiyun Cleaning Group Co.,Ltd.