Operating instructions

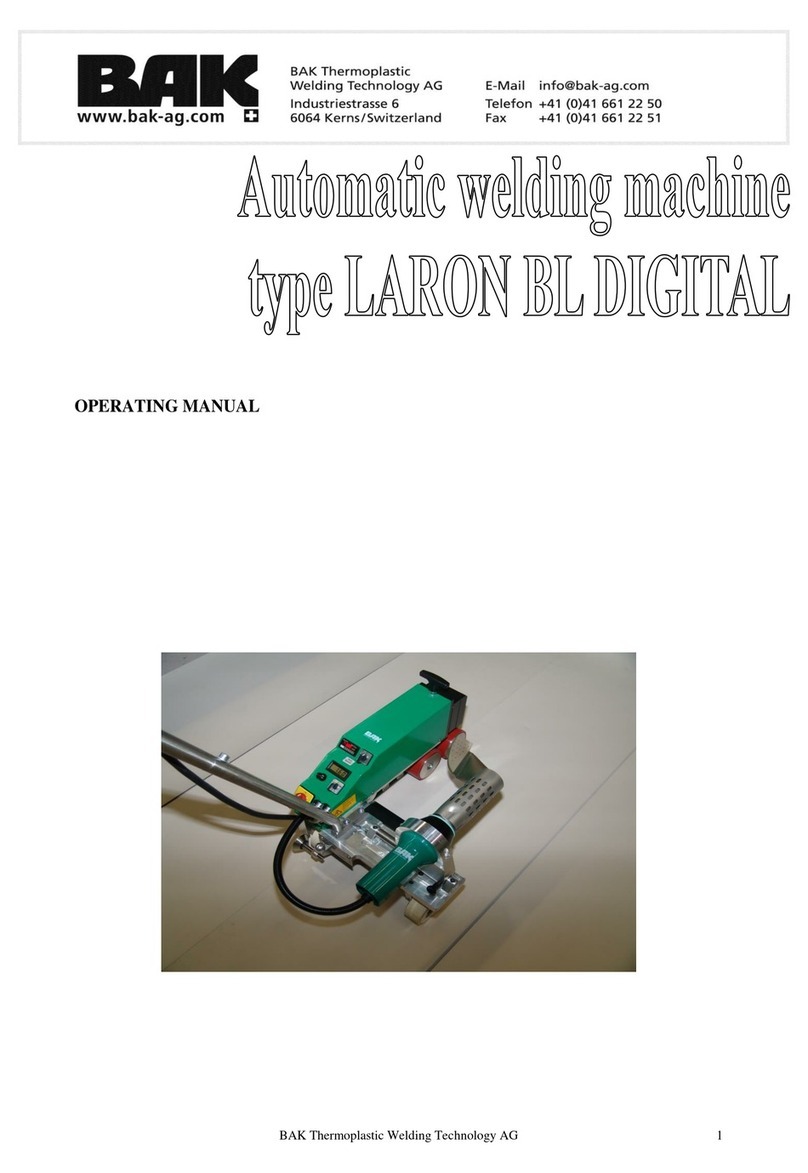

Automatic welding machine Laron

BAK Thermoplastic Welding Technology

3

Utilisation:

he Laron is an automatic welding machine for overlap welding to weld

geomembranes (geomembranes width 20mm or 40mm). he machine must only be

used to weld geomembranes (PE, PVC, PO, ECB, EPDM, CSPE and bitumen) at

the edge and uneven surfaces.

Automatic welding machines are manufactured according to the latest technology

and in compliance with safety requirements.

Any improper use may result in dangers for the operator or third parties or may

adversely affect machines and assets.

Only use the automatic welding machine if in technically perfect condition and for the

purposes for which they are intended while observing the operating instructions.

For the neglect or for damages resulting from it the manufacturer / supplier will not

accept any liability .

Any utilisation of the automatic welding machine, for other purposes than those for

which it is intended, is subject to the consent of the manufacturer / supplier.

Work on electrical parts of welding machine may only be performed by an electrical

engineer in compliance with electro-technical rules.

Indication of special risks:

All automatic welding machines may only be held and operated using the handles

provided for this purpose.

A risk of burning exists on all uncovered metal parts. Avoid contact with these parts

as they may achieve temperatures of up to 650°C.

Attention: Heat can reach combustible materials which are hidden.