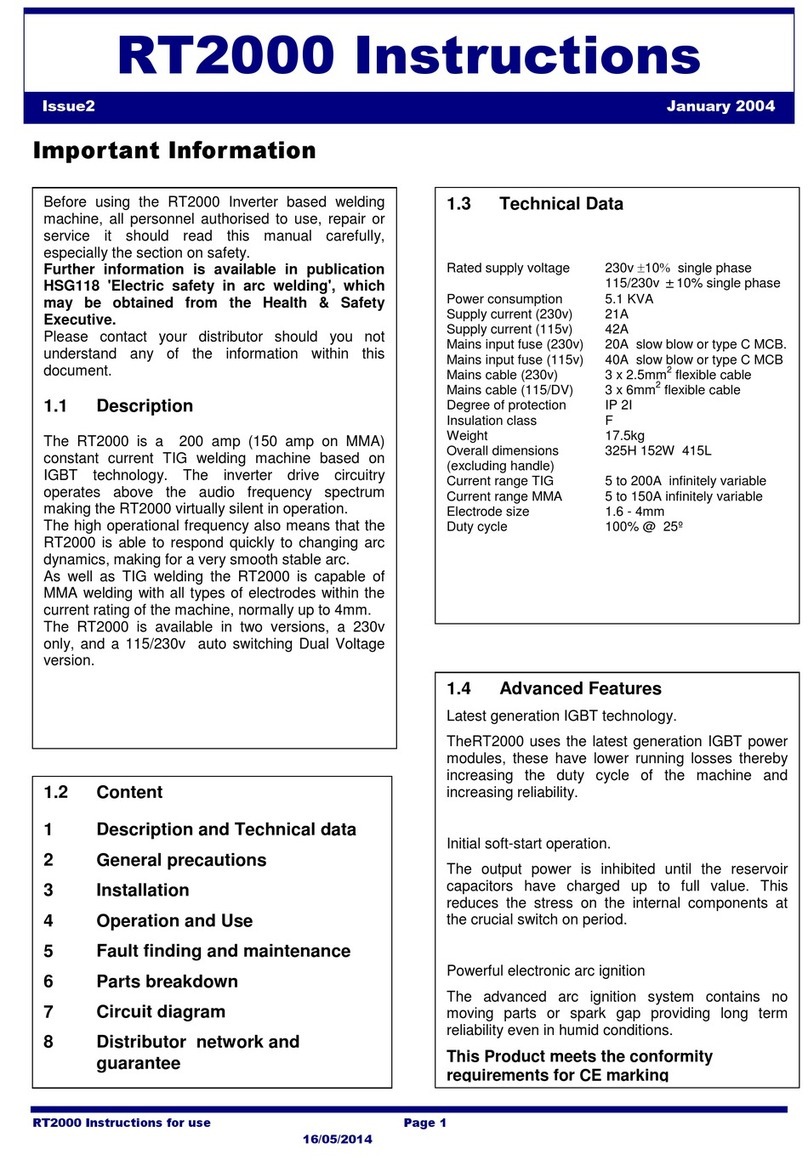

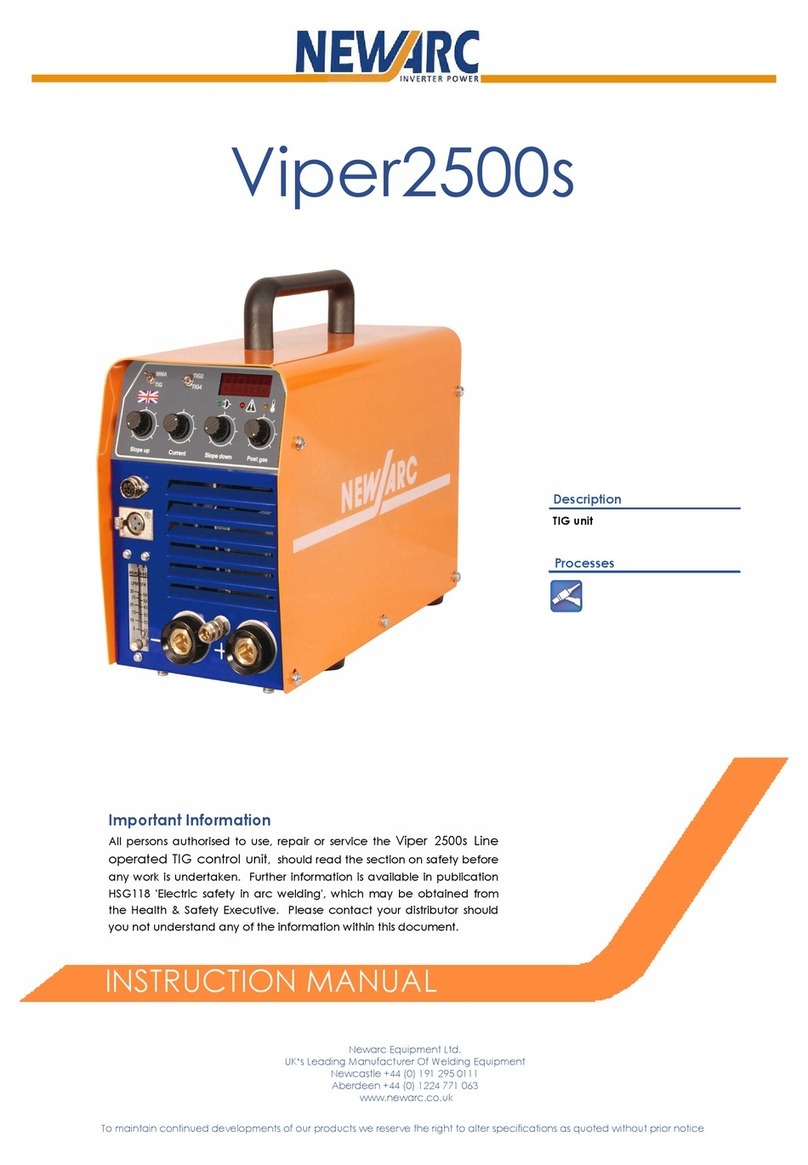

1. On-Off switch

2. Current control

3. Slope up control

4. Arc-force control

5. Digital display

6. Lift/Spark start selector switch

7. Thermal cut-out indicator

8. Power/Gas outlet connector

9. TIG torch switch connector

10. Slope down control

11. Mode switch

12. Remote control socket

13. Negative weld out connector.

4.2 Description of controls

1 On-Off switch

Switches the machine on and off. Upon switching on the

overload indicator will light and the machines output will be

inhibited, after 15 seconds the overload indicator will extin-

guish and the machine is ready for use.

Note: Post gas time. For a 5 seconds period after switching

on the post gas value is displayed as P# (The # value is the

set post-gas time) with the possibility to change the post-gas

time by repeatedly pressing the torch switch button. Every

torch switch press the post gas time is incremented by 1

second (from 0-30 seconds).

This setting is saved therefore it does not need re-setting

each time the machine is switched on.

2 Current control

Use this to set the output current of the RT2000.

3 Slope up control

With the slope up control set to minimum the RT2000 will

strike at the current set by the current control. With the slope

up control set to anywhere but minimum the RT2000 will

strike at 5A and then gradually increase the current to the

setting on the current control, the time this takes is deter-

mined by the position of the slope up control.

4 Arc-force control

Operates in MMA mode only. This control alters the welding

dynamics of the machine to facilitate welding with different

types of welding electrodes (e.g. general purpose, celulosic,

low hydrogen and iron powder). Turning towards maximum

will increase penetration at the expense of increased weld-

ing splatter, turning towards minimum will reduce penetra-

tion but the arc will be smoother and less fierce.

5 Digital display

Gives an accurate indication of the welding current.

Displays HU (High voltage) when HF spark start is activated.

Display the set value of post-gas P#. The display also displays

the setting values of slope up & slope down when been ad-

justed.

6 Lift/Spark start selector switch

Switches the machine into either 'HF start' or 'lift TIG' opera-

tion. In HF start the arc is initiated by a high voltage spark at

the Tungsten's tip. In lift TIG touch the Tungsten to the work-

piece, press the torch switch then lift the Tungsten to the

welding position, the arc will initiate.

7 Thermal cut-out indicator

Indicates that the thermal cut-out in the machine has oper-

ated. (see paragraph 5.1 in the fault finding and mainte-

nance section for possible reasons).

8 Power/Gas outlet connector.

For connection of a TIG torch with a combined power and

gas lead. If a TIG torch with a separate power lead and gas

hose is used, an adapter must be used to connect to this

outlet.

9 TIG torch switch connector.

For connecting the TIG torch switch lead.

10 Slope down control.

With the slope down control set to minimum the current will

shut down immediately the torch switch is released.

With the slope down control set to anywhere but minimum

and the torch switch released, the current will gradually de-

crease from the setting on the current control to 5 amps,

whereby the current will extinguish, the time this takes is de-

termined by the position of the slope down control.

11 Mode switch

This control switches the RT2000's welding mode.

MMA sets the machine in MMA mode.

TIG 2s sets the machine in 'normal' TIG mode, whereby press-

ing the TIG torch switch initiates the arc and releasing it will

extinguish the arc (at the end of any slope down period set).

TIG 4s sets the machine in 'latch' TIG mode, whereby pressing

the torch switch and releasing it initiates the arc, pressing and

releasing it again will extinguish the arc (at the end of any

slope down period set).

Note: Post gas time. When switching from MMA to TIG modes

For a 5 seconds period after switching modes the post gas

value is displayed as P# (The # value is the set post-gas time)

with the possibility to change the post-gas time by repeatedly

pressing the torch switch button. Every torch switch press the

post gas time is incremented by 1 second (from 0-30 sec-

onds).

This setting is saved therefore it does not need re-setting each

time the machine is switched on.

12 Remote control socket

For connecting external remote control units, these are the

RC300 remote control, the RPC300 pulse unit and the RFP300

foot pedal. There is no switch for remote operation, plugging

an external unit into the socket automatically selects remote

operation and disables the internal current control.

13 Negative weld out connector.

Main welding power output connector, negative polarity.

14 Positive weld out connector

1. On-O switch

output will be inhibited, after 15 seconds the overload indicator will extinguish and the machine ready for use.

seconds). This setting is saved therefore it does not need re-setting each time the machine is switched on.

2. Current control

Use this to set the output current of the RT2000.

3. Slope up control

With the slope up control set to minimum the RT2000 will strike at the current set by the current control. With

up control.