3Basic Knowledge

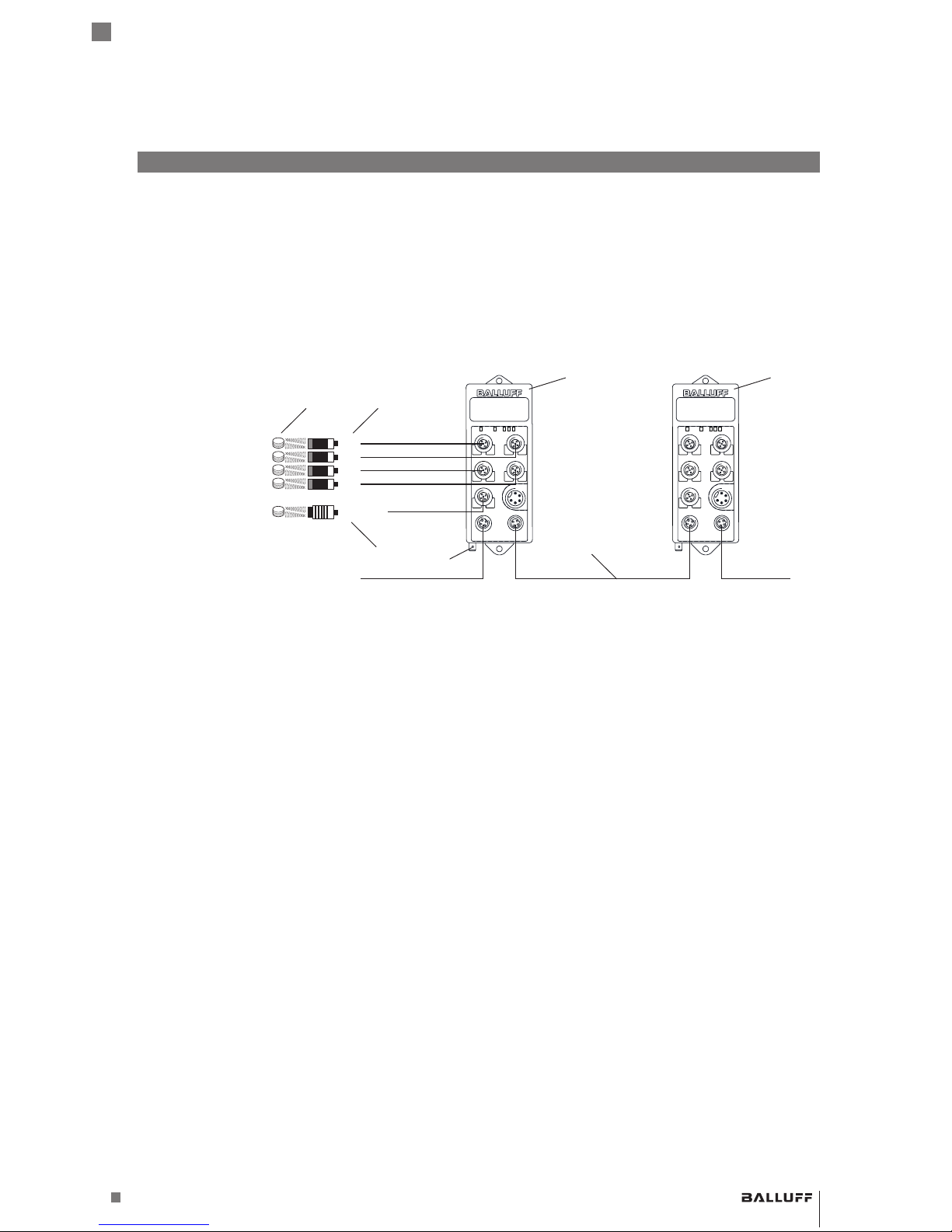

For BIS V-6108-048-C002, read/write heads in the BISVM-3 _ _, BISVL-3 _ _, and

BISVU-3 _ _ series can be connected to terminals H1...H4. BIS V-6108-048-C102 also

supports read/write heads in the BIS C-3 _ _ series (Adapter required).

Note

Read/write heads in the BISVU-3_ _ series are only supported with a device software

version of 3.0 or higher. Should the occasion arise, an update will be required.

Note

Device software as well as manuals with detailed information about the read/write

heads used are available at www.balluff.com.

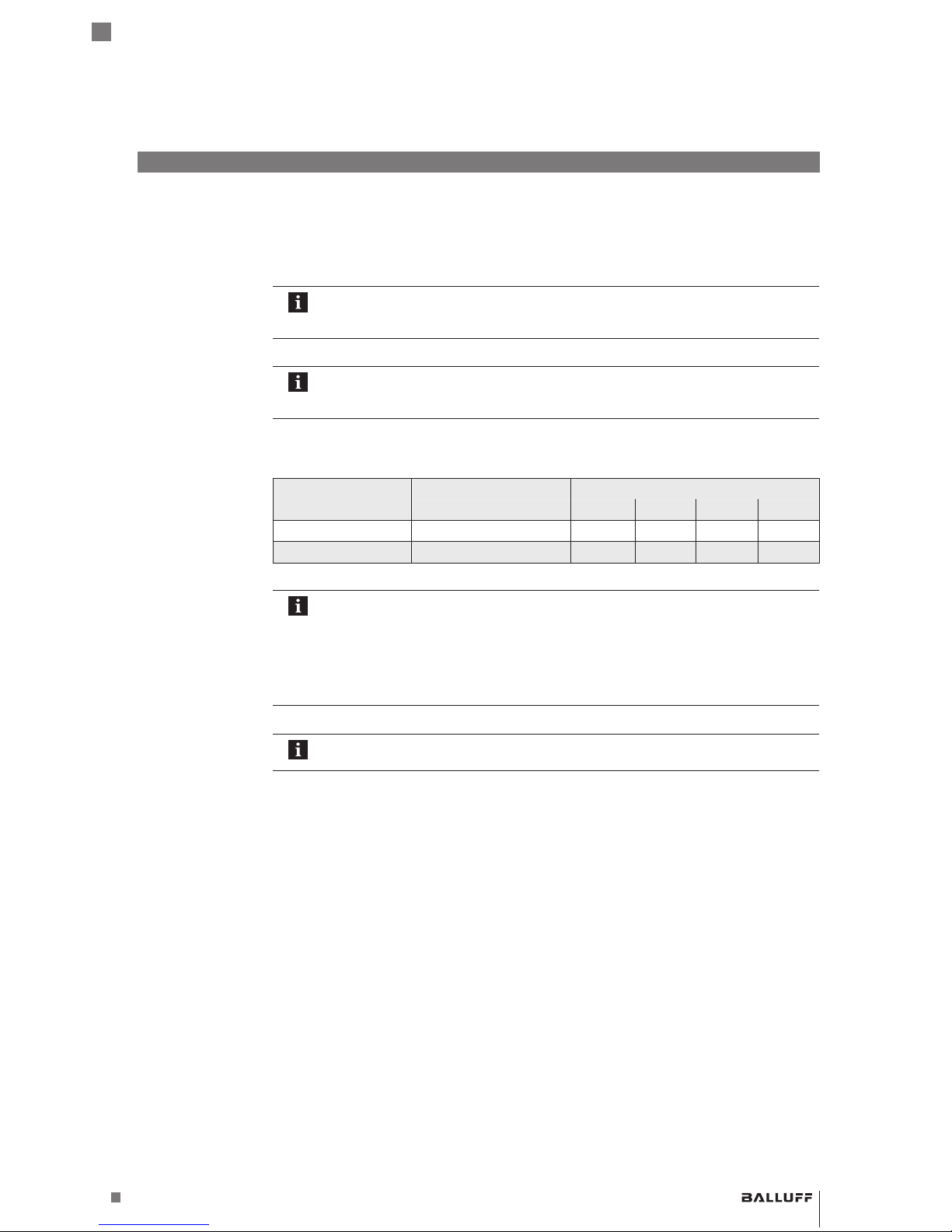

BISV processor units are available in different variants with respect to the supported read/write

heads. The following table shows the differences.

Processor Unit Available Connections Compatible Read/Write Heads

H1…H4 VM-3 _ _ VL-3 _ _ VU-3 _ _ C-3 _ _

BIS V-6108-048-C002 H1…H4 YES YES YES NO

BIS V-6108-048-C102 H1…H4 YES YES YES YES

Note

Only shielded cables are to be used for connecting read/write heads!

An adapter cable is required for connecting read/write heads in the BIS C-3_ _ series.

The maximum cable length for read/write heads in the BIS VM-3_ _, BISVL-3_ _,

and BISVU-3_ _ series is 50 m. For the BISC-3 _ _ series, the cable length is set at 1

m, 5 m, or 10 m plus the adapter depending on the design of the system.

Note

Visit www.balluff.com for more information on available software and accessories.

Open bus system for process and field communication in cell networks with few nodes and for

data communication in accordance with IEC61158/EN50173. Automation devices, such as

PLCs, PCs, operating and observation devices, sensors or actuators, can communicate using

this bus system. PROFINETIO is used in the BISV-6108.

3.5 Read/Write

Heads H1…H4

3.6 PROFINET