5

40 Rewind ™ Radial Winch

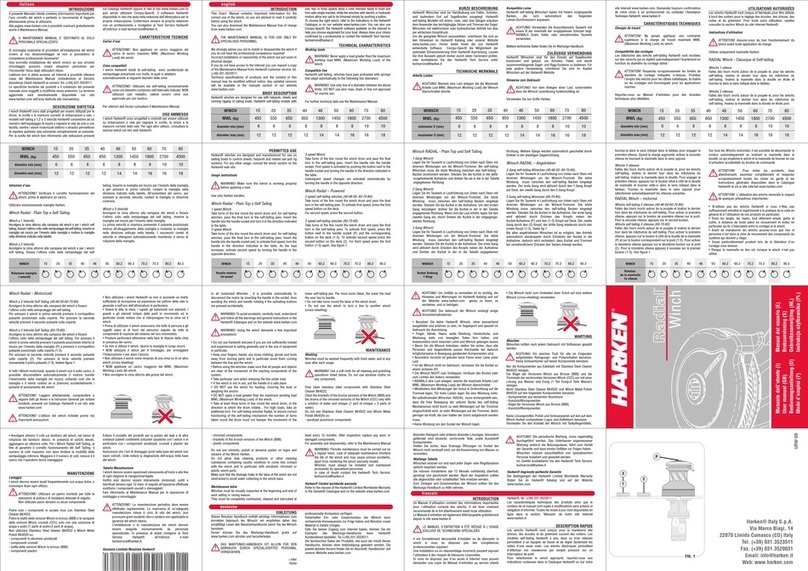

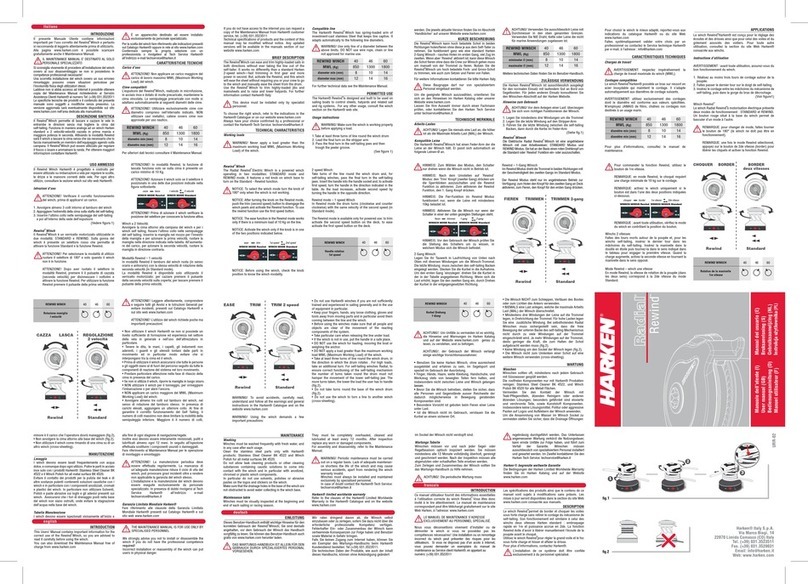

Installation and Maintenance Manual

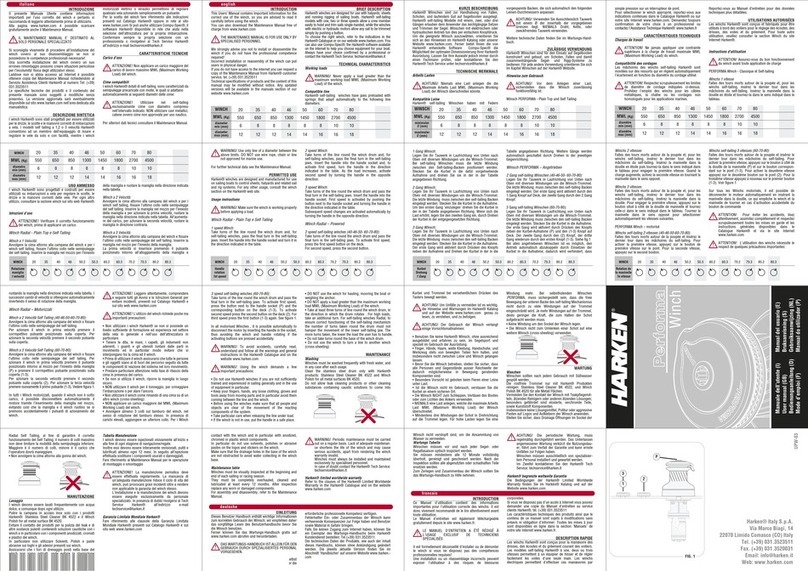

WARNING!

Failure to use the correct number and type of mounting fasteners

or failure to ensure the correct deck strength can result in the

winch pulling off the deck suddenly and unexpectedly during

high loads causing severe injury or death.

WARNING!

Verify the entry angle of the sheet. This must be 8° with tolerance

of ±2°, to avoid sheet overrides and damaging the winch or

making the winch inoperable leading to loss of control of the boat

which can lead to severe injury or death.

WARNING!

Mount the winch on the deck so that the nal drive gear is

positioned where the sheet enters the winch drum.

Incorrect position of drive gear can weaken winch leading to failure

which can cause an accident leading to severe injury or death.

NOTICE

For winch STA, STC and STCW versions only you can find

the icon on the skirt to identify the drive gear position.

After correctly positioning the nal drive gear with respect to the load, check that the motor,

gearing, electrical wiring and/or hydraulic pipes can be housed below decks. To help nd the

optimal compromise, remember that, to make the installation of the motor easier, it can be coupled

to the winch in different positions.

Once you have decided the correct mounting position for the winch on the deck and checked the

space available below deck, proceed with the installation.

The winch can be installed following one of the two procedures below (Procedure1 or Procedure 2).

Before starting the Installation procedure, set the knob in the following position:

final drive gear

SHEET

8°