Rioned UNICOM User manual

USER’S MANUAL

UNICOM

Edition: 01

Date: Tuesday 11 December 2012

RIONED

P.O. Box 5070

5004 EB Tilburg

The Netherlands

Telephone: +31 13 5479100

Internet: www.rioned.com

e-mail info@rioned.com

12/12 2

©Copyright 12/12 Rioned/RIOR B.V.Tilburg - Netherlands

All rights reserved. No part of this publication may be copied or published by means of printing, photocop-

ying, microfilm or otherwise without the prior written consent of RIONED. This restriction also holds for

the corresponding drawings and diagrams.

RIONED has the right to change parts at any time without any prior or direct warning to the client. Also,

the contents of this manual can be changed without any prior warning.

This manual is to be used only for this machine.

For extra information on adjustments, maintenance and repair, please contact the technical department of

your dealer.

12/12 3

Foreword.

This user’s manual is a manual for the professional user.

This user’s manual has the purpose to control the machine in a safety manner and must be saved with the

machine.

The photos and drawings help you understand the text easier.

First the user’s manual gives you an overview of the most important safety aspects. Then we explain how

the machine is built up and the global working of the machine.

Chapter “Technical specifications” gives you information about the working characteristics, performance

under normal use and construction specifications.

“Control” is the next chapter. This chapter explains how to use the machine systematically.

In the chapter “Maintenance”, the user can do small maintenance on the machine.

Chapter “Trouble shooting” has the purpose to solve simple defects.

With the “Exploded views” you can order original spare parts, are also useful for mounting, and disassemble

the machine.

Finally gives the chapter “Appendix” information about electrical and/or hydraulic connections.

12/12 4

12/12 5

TABLE OF CONTENTS

1 INTRODUCTION ...............................................................................................................7

1.1 Use...............................................................................................................................7

2 SECURITY...........................................................................................................................9

2.1 Instruction indications in this manual..........................................................................9

2.2 Description security measures.....................................................................................9

2.3 Personnel protection outfit ..........................................................................................9

2.4 Warnings......................................................................................................................9

2.5 Personnel qualification and education.......................................................................10

2.6 Danger that can occur if the security regulations aren’t observed ............................10

2.7 Working safely ..........................................................................................................10

2.8 Security regulations for the user and technical service.............................................10

2.9 Security regulations for maintenance, inspection, and mounting activities..............10

2.10 Making changes and fabricate spare parts.................................................................10

2.11 Improper use..............................................................................................................10

3 TECHNICAL SPECIFICATIONS ..................................................................................13

3.1 General ......................................................................................................................13

3.2 Engine........................................................................................................................13

3.3 Pump..........................................................................................................................15

3.4 Vacuum pump ...........................................................................................................15

3.5 Customer service.......................................................................................................15

4 CONSTRUCTION AND FUNCTIONING.....................................................................17

5 CONTROL.........................................................................................................................23

5.1 Before starting...........................................................................................................23

5.2 Hydraulic reel control................................................................................................24

5.3 Starting the engine.....................................................................................................25

5.4 Unclogging a drain....................................................................................................28

5.5 Cleaning a wall, terrace or floor................................................................................30

5.6 Stop working .............................................................................................................31

5.7 Spray gun with NW 5 hose........................................................................................31

5.8 Using the device during periods of frost ...................................................................31

5.9 Additional preparations when preparing for use:......................................................32

6 USING THE VACUUM DEVICE ...................................................................................33

6.1 Use.............................................................................................................................33

6.2 Before use:.................................................................................................................33

6.3 Fill the dirt water tank: ..............................................................................................33

6.4 Empty the dirt water tank:.........................................................................................34

7 STICKERS AND SYMBOLS...........................................................................................37

7.1 Pressure gauge...........................................................................................................39

7.2 Pressure regulator......................................................................................................39

7.3 Valve control.............................................................................................................39

7.4 Security sticker..........................................................................................................40

12/12 6

8 OPTIONS ...........................................................................................................................41

8.1 Hour counter..............................................................................................................41

8.2 Pulsator system..........................................................................................................41

8.3 Working lamp............................................................................................................41

8.4 Anti-freeze with anti freeze tank...............................................................................41

8.5 Radio remote control type Riomote ..........................................................................42

8.6 Hose guide.................................................................................................................43

8.7 Run dry protection.....................................................................................................44

9 MAINTENANCE...............................................................................................................45

9.1 Daily maintenance.....................................................................................................45

9.2 Weekly maintenance .................................................................................................45

9.3 Minor servicing .........................................................................................................45

9.4 Vacuum filter.............................................................................................................46

9.5 Vacuum blow off container.......................................................................................46

9.6 Hydraulic system.......................................................................................................47

9.7 Cleaning the vacuum pump.......................................................................................47

9.8 Maintenance vacuum pump.......................................................................................47

9.9 Cleaning the float ball (Siphon) ................................................................................48

9.10 Extensive periodical maintenance.............................................................................48

9.11 Maintenance scheme .................................................................................................48

10 TROUBLESHOOTING ....................................................................................................49

11 EXPLODED VIEWS AND PART LISTS.......................................................................51

11.1 Siphon........................................................................................................................52

11.2 Exploded view Pump P41(48L-180B). .....................................................................53

11.3 Exploded view Pump P45(75L-150B). .....................................................................54

11.4 Pressure regulator ULH 262......................................................................................55

12 APPENDIX.........................................................................................................................57

12.1 EC declaration Of Conformity For Machinery .........................................................57

12.2 Sales Managers..........................................................................................................58

12.3 Electric scheme..........................................................................................................59

12.4 Electric scheme Riomote...........................................................................................60

12.5 Hydraulic oil..............................................................................................................61

12.6 Dimensions................................................................................................................62

13 INDEX ................................................................................................................................63

12/12 7

1 INTRODUCTION

RIONED thanks you for your purchase of the RIONED drain and sewer-clearing machine. We rec-

ommend that you read this manual thoroughly and see that the machine is handled and maintained

in the proper manner. If your machine should give trouble and need servicing, when you want to

order parts, or if you have any questions, contact your RIONED dealer.

The machine is built by:

RIONED

P.O. Box 5070

5004 EB Tilburg

The Netherlands

Telephone: +31 13 5479100

Fax : +31 13 5479104

The Rioned high-pressure device has been especially designed and manufactured for cleaning

drains, walls, floors, and terraces with cold or hot water. For cleaning drains, special nozzles are in-

cluded in the delivery; for all other purposes, the spray gun, which is also included, can be used.

This manual contains all the necessary information concerning control and maintenance. If the de-

vice is positioned correctly, properly controlled, and regularly maintained, a warranty will be given

according to the general conditions of delivery. However, should it arise that the control and main-

tenance procedures are not diligently followed, the warranty will become invalid.

Use this machine only for cleaning drains, walls, floors and terraces with cold or hot water and to

drain liquid with or without pollution like sand, stones etc.

Use this machine only outside. If you want to work inside a building you have to ensure that there

is enough ventilation.

During the time that the weather conditions arebad, we recommend that you do not use the machine

(lightning)!

Authorised personnel may only use the machine.

The machine can not be used in an explosive environment.

Fill the clean water tank only with water.

It is strongly forbidden to drain flammable materials, chemicals, and elements with special regula-

tions.

In this manual you will find all necessary information concerning operations and maintaining your

machine. If handled properly, your machine is guaranteed according the general delivery conditions.

1.1 Use The integrated engine drives the high-pressure pump, the hydraulic pump, and the vacuum pump.

The high-pressure pump receives water from the water tank via the water filter and pressurises it.

The pressure can be continuously adjusted. The pressurised water leaves the machine via the high-

pressure hose on the reel.

The vacuum pump is connected to the vacuum tank. When this pump creates a vacuum, the tank

gets filled.

The hydraulic pump drives via a hydraulic system the hose reel.

12/12 8

12/12 9

2 SECURITY

Be responsible for other people when you are working with this machine.

This manual contains instructions for fundamental conditions that must be followed by use and

maintenance of this machine.

That is why it is necessary that authorised and qualified personnel must read the user's manual and

the user’s manual must always be available with the machine. Near the general regulations in this

chapter, you must also follow the security regulations in the other chapters.

2.1 Instruction

indications in this

manual

The in this manual containing security instructions, which are dangerous if they are not obeyed, are

marked with general security signs.

Security sign DIN 4844-W9.

2.2 Description

security measures • Emergency stop

The machine is equipped with an emergency stop. By operating this stop, the machine will stop im-

mediately. Do not use the button for normal stopping. Only use is when dangerous situations occur.

After use, turn the emergency stop in order to be able to start up again. Make sure the emergency

stop can always be reached.

• Over-pressure valve

Protects the pipe system and reservoir.

• Pressure regulator

The pressure regulator looks to it that the working pressure never gets to high. It functions like a

security valve.

• Security covers

This machine is equipped with several security covers over parts that are rotating. It is forbidden to

remove these security covers during operating this machine. You can only remove them if there is

maintenance on the machine. Stop the machine.

2.3 Personnel

protection outfit • Protection looking glasses

• Ear protector

• Gloves (Recommended)

• Waterproof clothe.

2.4 Warnings Open the side doors while operating the machine!

When working with the machine, keep grate inside the tool box free from obstacles!

Take care of not exceeding the maximum loading capacity of the vehicle by filling the tanks. Note

that the driver is responsible for this.

It is prohibited to drive with the water tank and vacuum tank full at the same time if the maximum

load weight of the vehicle is crossed!

12/12 10

It is strongly forbidden to spray on:

•humans

• animals

• Electrical components

Never block a control lever, unless this is mentioned.

Never let the high-pressure hose spray outside a sewer, drain or pipe.

Do not let the machine operate without supervision.

2.5 Personnel

qualification and

education

Personnel that use, maintain, and inspect the machine must have the right qualifications for this job.

Responsibility and authorisation of the personnel and the supervision on the personnel must be em-

bedded. If the knowledge is not present, the user must provide for the necessarily education.

2.6 Danger that

can occur if the

securityregulations

aren’t observed

If the security regulations are not observed, danger can occur for personnel and for the environment.

No amends are given if the regulations are not observed.

If the regulations are not observed, this can results in:

• Failure of important functions of the machine.

• Failure of prescribes methods for maintenance.

• Exposure of persons to dangers of electrical or mechanical failures

2.7 Working

safely The in this manual named security prescriptions, the national prescriptions to prevent accidents and

the internal labour, company and security prescriptions must be followed by the user.

2.8 Security

regulations for the

user and technical

service

• Protections of moving parts (for example couplings) may not be removed if the machine

is working.

• Leakage of dangerous mediums must disposed in a manner that there is no danger for the

personnel and environment. Statutory regulations must be followed.

• Danger caused by electricity must be excluded.

2.9 Security

regulations for

maintenance,

inspection, and

mounting activities

• The user sees to it that qualified technicians do all maintenance, inspection and mounting

activities. They must study the manual thoroughly.

• Maintenance may only be done when the machine is not functioning.

• The in the user’s manual mentioned handling to stop the machine must be notified.

• Directly after maintenance of the machine, all the security and protection facilities must

be functionally.

• Before starting the machine again, you must follow the instructions correctly.

2.10 Making

changes and

fabricate spare

parts

Changes to the machine are only permitted if Rioned has given written authorisation. The use of

original spare parts and accessories are for the safety necessary. Rioned is not responsible for inju-

ries or damages if other spare parts are used.

2.11 Improper use The security during working with the machine is only guaranteed if the use of the machine is con-

forming the user’s manual. The limits that are written in chapter “Technical Specifications” and

“Appendix” may never be overstepped.

If the machine does not work or give troubles, it is forbidden to work further with the machine. Tel-

ephone your dealer or the technical department of your dealer.

This manual contains all the necessary information concerning control and maintenance. If the de-

12/12 11

vice is positioned correctly, properly controlled, and regularly maintained, a warranty will be given

according to the general conditions of delivery. However, should it arise that the control and main-

tenance procedures are not diligently followed, the warranty will become invalid.

12/12 12

12/12 13

3 TECHNICAL SPECIFICATIONS

3.1 General

Year of constructions (month/year) : 12/12

Capacity vacuum tank : 1000 l

Capacity water tank : 500 l

Dimensions : see chapter 12.6 Dimensions page: 62

Length HP hose : 80 m

Diameter HP hose : ½” (NW13)

Length supply hose : 50 m

Diameter supply hose : 5/8” (NW16)

Length suction hose : ±30 m

Diameter suction hose : 2” (NW50)

Oil hydraulic circuit : HESTIA 46

Quantity : 5,5 l

Important! : Replace once a year!

Antifreeze : 43 litters

3.2 Engine

Description (symbol) Technical unit(SI unit)

Type : Honda GX690

Engine Type : Air-cooled, 4-Stroke, OHV

Bore x Stroke : 3.1" x 2.8" (78 x 72 mm)

Displacement : 42 cu in (688 cm3)

Compression Ratio : 9.3 : 1

Net Horsepower : 22.3 hp (16.6 kW)

Net Torque : 35.6 lbs ft (48.3 Nm)

PTO Shaft Rotation : Counterclockwise (from PTO shaft side)

Ignition System : Digital CDI with variable ignition timing

Starting System : Shift Type

Carburetor : 2-barrel, fuel cut solenoid, inner vent

Lubrication System : Full Pressure

Connecting Rod : Forged Steel

Governor System : Mechanical

Air Cleaner : Dual Element Type/Panel

Exhaust Emissions : Certified for use in all 50 states

Evaporative Emissions : Low permeation hose and purge joint provided

Battery (U,I) : 12 V, 45 A

Oil : 10W30 API/SF-CC or better

Oil Capacity : 2.2 L

Oil Filter : Automotive Spin-On Style

Dimensions (L x W x H) : 443 mm x 421 mm x 447 mm

Dry Weight : 45.7 kg

12/12 14

Type : Kubota V1505

Number of cylinder : 4

Bore x stroke (d x l) : 78 x 78,4 mm (3.07 x 3.09 in.)

Power (P) : 26,1 kW at 3000 min-1 DIN 70020

Fuel : Diesel

Cooling : Water cooled

Weight (m) : 110 kg

Battery (U,I) : 12 V, 45 A

Starter : 12 V x 1,2 kW

Oil : 10W30 API/SF-CC or better

Quantity : 4 l8.5 liq pt (UK), 7 pt (UK)

Normal coolant engine is protected to -28 °C

Special coolant engine is protected to -38 °C

For more information concerning the engine you can find it in the book delivered with this machine.

12/12 15

3.3 Pump

Description (symbol) Technical unit

Type : Speck P41

Number of plungers : 3

Number of valves : 6

Number of revolutions (n) : 1200 min-1

Maximum pressure (p) : See type plate on frame

Maximum output (V/t) : See type plate on frame

Oil : GX 80W90

Quantity (V) : 1 l

Weight (m) : 30 kg

Maximum water temperature (t,T) : 80 °C

Type : Speck P45

Maximum pressure (p) : See type plate on frame

Maximum output : See type plate on frame

Weight : 50 kg

Maximum water temperature : 55 °C / 131 °F(328,15 K)

Oil : GX 80W90

For more information concerning the pump, you can find it in the pump appendix delivered with this machine.

3.4 Vacuum pump

Type : MEC 5000

Oil : 15W30

Capacity Suction : -0,8 bar (relative)

Capacity Pressure : 0,49 bar (relative)

Quantity carter : 2,5 l

Oil : 15W30

Gear box : SAE 90

Type : Mannesmann SLS 54

Capacity : 290 m3/h

Capacity Suction : -0,8 bar (relative)

Capacity Pressure : 0,49 bar (relative)

Oil Summer Winter

: Essolub HDX 40Essolub HDX 30

: Esso-motor oil 40Esso-motor oil 30

: Shell Rotella SX 40Shell Rimula X 30

For more information see the vacuum pump enclosure

3.5 Customer service

When ordering spare parts it is recommended to give the following numbers:

Machine number : 10005002013128

Article number : 22110472000

Follow number : vo38396

12/12 16

12/12 17

4 CONSTRUCTION AND FUNCTIONING

The suction unit contains the following main parts:

1. High-pressure pump

2. Reel with suction hose

3. Water filter

4. Oil tank hydraulic system

5. Control box

6. Dirt water tank (Vacuum tank)

7. Sight glass / level indicator

8. Press valve

9. Suction valve

10. HP Hose on reel (HP =High pressure)

11. Hydraulic reel control

12. HP valve for HP hose on reel

13. Hook

14. Hose guide

15. Pressure gauge

16. Pressure regulator

17. Working lamp

18. Battery

19. Supply pipe water tank

20. Supply valve water filter

21. Syphon

22. Vacuum filter

23. Clear water tank

24. Engine

25. Drain valve “Vacuum tank”

26. Drain valve

27. Vacuum pump

28. Handle suction/pressure

29. Security valve

30. Vacuum meter/pressure gauge

31. Reel with supply hose

32. Valve supply reel

33. Pulsator on/off

34. Emergency stop

35. Vacuum blow off container

36. Receiver (radio remote control)

37. Charger (radio remote control)

38. Suction pipe

39. Suction hose storage reel

40. Supply valve Antifreeze

41. Antifreeze tank

Not included or visible

42. Orange light

43. Oil dropper vacuum pump (only MEC)

44. HP Hose hot water

45. Burner unit hot water

46. Bypass valve

47. Suction hose

48. Bypass valve

(vacuum tank - water tank)

49. HP valve for HP hose on swing arm

(Spool valve)

50. Inside filter

51. Fuel tank

52. Manhole clear water tank

53. Float ball protection

54. Cool tank vacuum pump

55. Oil tank vacuum pump

56. Connection circulation system

57. Choice valve

Hydraulic reel- or suction reel control

58. Engine start (keyhole)

59. Swing arm (Hydraulic)

60. Fuel tank (Heater)

61. Valve heater on/off

62. Hydraulic cover control

(Open/Close Cover)

63. Choice valve to use the hydraulic reel control

for the big reel or the small reel

Table of contents

Other Rioned Other manuals

Popular Other manuals by other brands

Weston

Weston 01-0201 instructions

ALORAIR

ALORAIR Ironmen28L-B Installation and operation manual

Pioneer

Pioneer MVH-X360BT owner's manual

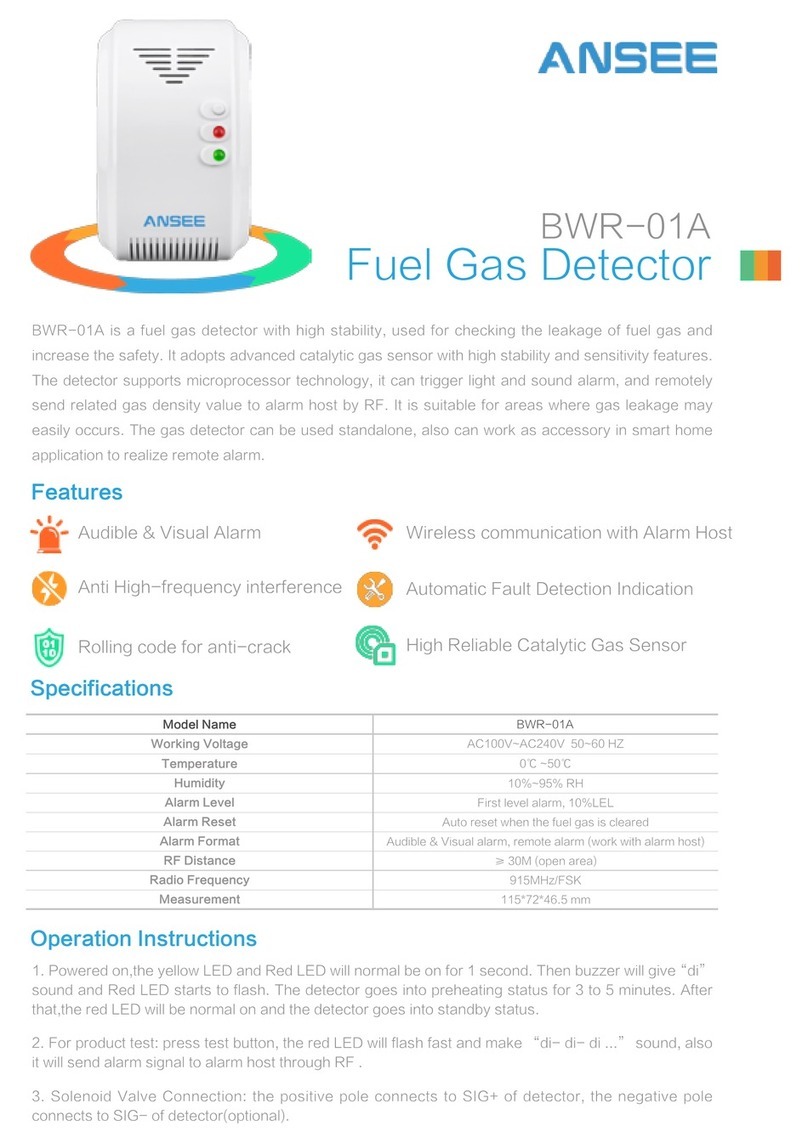

Ansee

Ansee BWR-01A Operation instructions

Tropic Marin

Tropic Marin SunaECO Series user guide

NRD

NRD Staticmaster P-2021 Series Installation, operation and maintanance manual