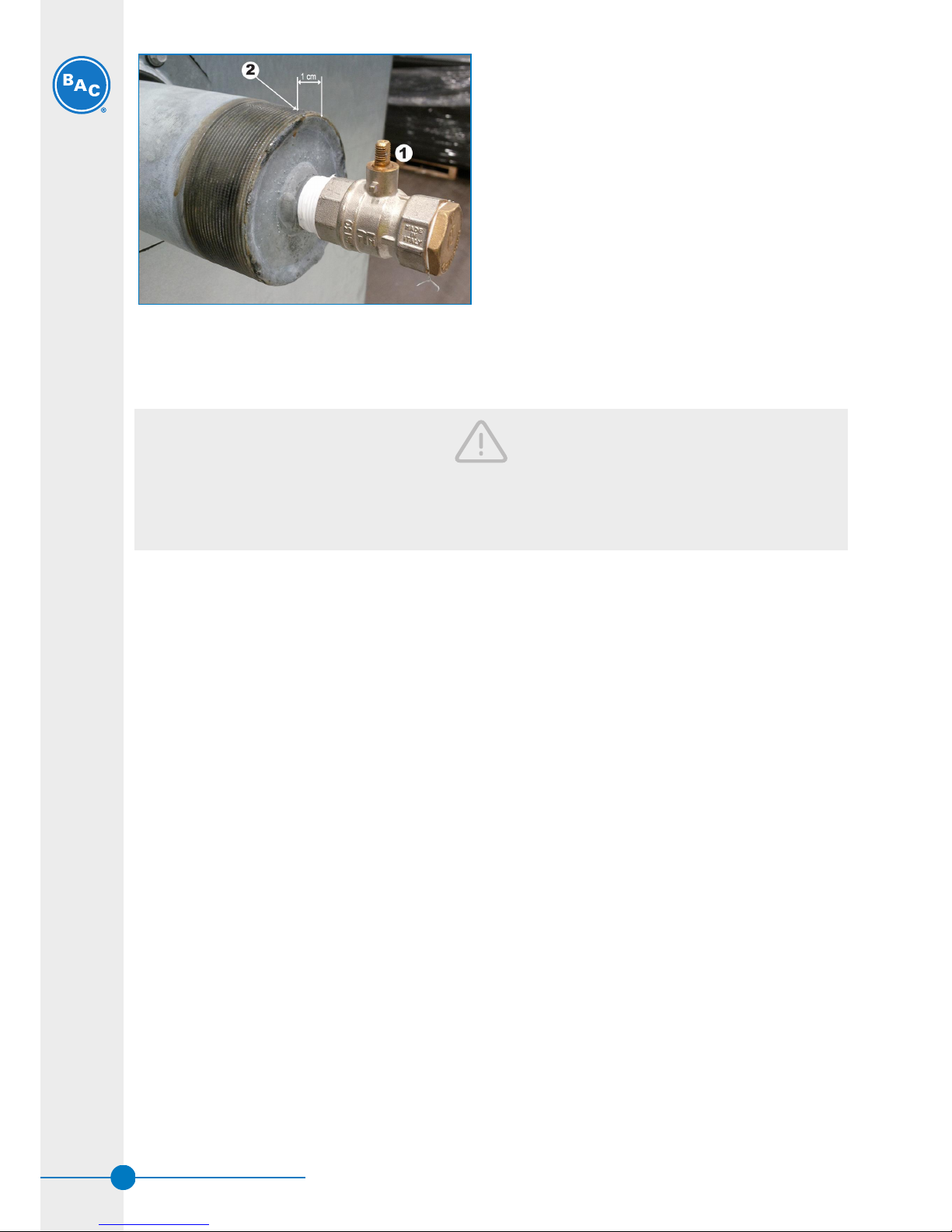

Threaded coil connection with pressure release valve on Ice Thermal Storage unit for Glycol execution.

1. Closed pressure release valve of upper coil connection.

2. After releasing the low pressure inert gas, cut coil connection here.

Caution

ONCE THE COIL IS NO LONGER PROTECTED BY THE INERT GAS, PROPER ACTIONS

AGAINST CORROSION MUST BE TAKEN ON SITE.

Freeze Protection

These products must be protected against damage and/or reduced effectiveness due to possible freeze-up by

mechanical and operational methods. Please refer to the BAC Product & Application Handbook or contact your

local BAC Balticare representative for recommended protection alternatives.

Safety Precautions

All electrical, mechanical and rotating machinery constitutes a potential hazard, particularly for those not familiar

with its design, construction and operation. Accordingly, adequate safeguards (including use of protective

enclosures where necessary) should be taken with this equipment both to safeguard the public (including minors)

from injury and to prevent damage to the equipment, its associated system and the premises.

If there is doubt about safe and proper rigging, installation, operation or maintenance procedures, contact the

equipment manufacturer or his representative for advice.

When working on operating equipment, be aware that some parts may have an elevated temperature. Any

operations on elevated level have to be executed with extra care to prevent accidents.

Air piping between air pump and TSU-C/D can have temperatures above 40°C. Insulate the piping if necessary to

prevent personal injury.

AUTHORIZED PERSONNEL

The operation, maintenance and repair of this equipment should be undertaken only by personnel authorized and

qualified to do so. All such personnel should be thoroughly familiar with the equipment, the associated systems

and controls and the procedures set forth in this and other relevant manuals. Proper care, personal protective

equipment, procedures and tools must be used in handling, lifting, installing, operating, maintaining and repairing

this equipment to prevent personal injury and/or property damage. Personnel must use personal protective

equipment where necessary (gloves, ear plugs, etc...)

W W W . B A L T I M O R E A I R C O I L . E U

6