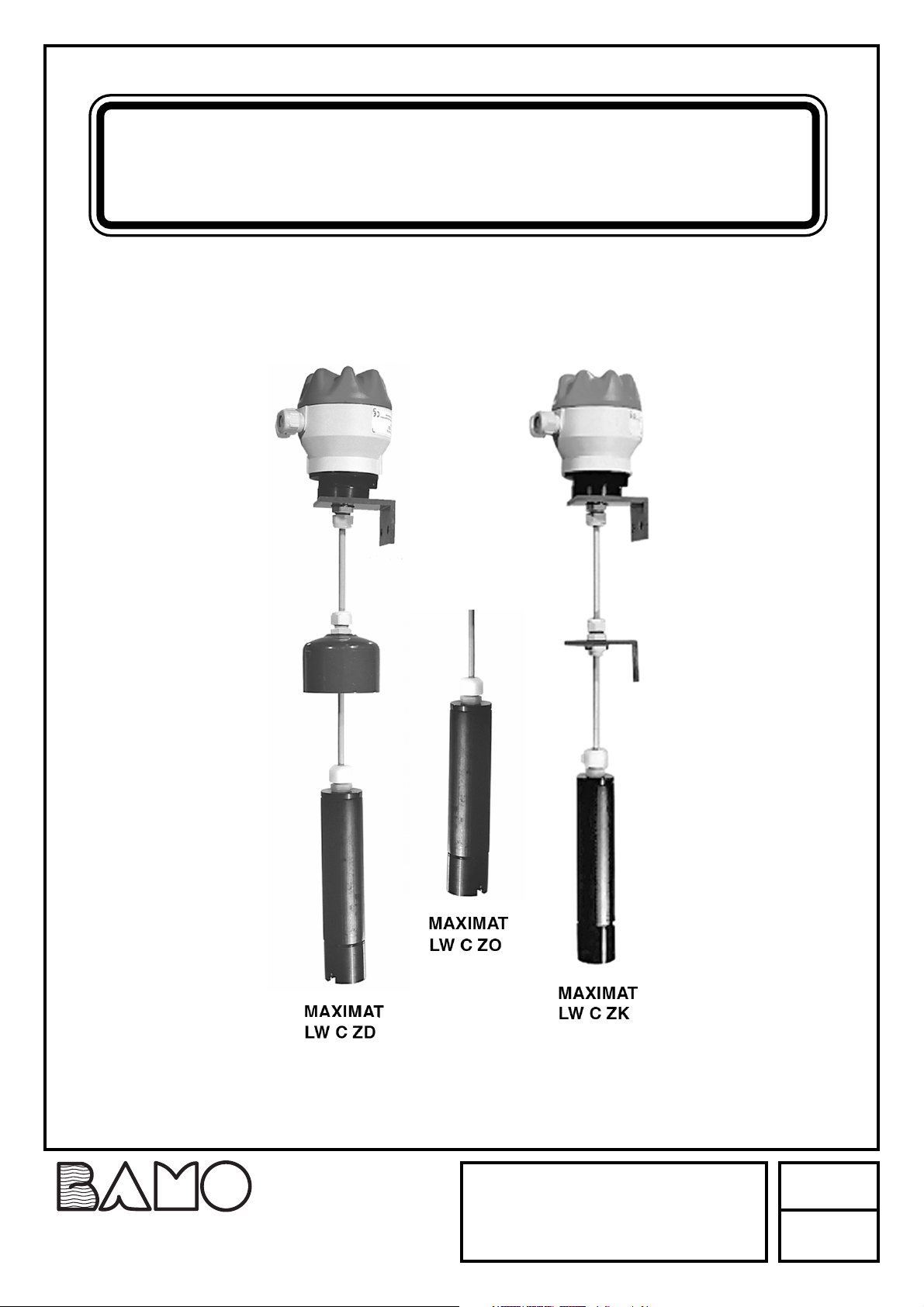

MAXIMAT LW C...

Detection sensor Glass carbon

Probe tube PE-HD (polyethylene)

Cap dia.63 mm (...CZD) PVC (polyvinyl chloride)

Bracket PVC (polyvinyl chloride)

Pg fitting PA (polyamide)

Seal / Pg fitting NBR (perbunan)

Measuring cable PVC (polyvinyl chloride)

MAXIMAT LW C25...

Detection sensor Glass carbon

Probe tube PE (polyethylene)

Cap dia. 32 mm(...CZD) PVC (polyvinyl chloride)

Bracket PVC (polyvinyl chloride)

Pg fitting PA (polyamide)

Seal / Pg fitting NBR (perbunan)

Measuring cable PVC (polyvinyl chloride)

INSTALLATION

The leakage sensor’s probe is suspended such that it hangs into the catch basin of the storage tank to be monitored.

The probe may make contact with the outside wall of the catch basin, or may stand on its floor.

The cable must be secured such that the probe is always positioned vertically.

The connector cable between the probe and the measuring transducer is pulled through the Pg fitting mounted to the bracket or the

cap until the portion of the cable inside the catch basin holds the probe in the vertical position.

When installed in a free-hanging manner, it must be assured that the connector cable is only pulled far enough through the

adjustor fitting to allow for a maximum clearance of 45 mm between the probe and the catch basin floor, so that the leakage

alarm is triggered at a maximum fill-level of 50 mm.

If the MAXIMAT LW CZ0 variant is used, other suitable mounting components must be used in an appropriate way.

MOUNTING EXAMPLES

Leakage sensor position

For applications involving storage tank catch

basins, the probe must be installed such that the

alarm signal is triggered at a fill-level of 50 mm

or less.

Catch basins, storage tank

The leakage probes are installed inside catch

basins. If the bottom of the probe is in contact with

the floor of the catch basin, the alarm signal is

triggered when the liquid reaches a fill-level of

approximately 5 mm.

555 M1 03 D 07-03-2007 Page 3

PERIODIC TESTING

The leakage probe must be tested for correct functioning at reasonable intervals, although not less than once a year. It is the

sole responsibility of the user to select the utilised test type, as well as a testing interval within the prescribed timeframe.

Testing must be performed which substantiates flawless functioning of the leakage sensor, and correct interaction with all

other associated components. This is assured by means of suitable simulation of a leak, or the physically measured effect

which causes triggering of the alarm signal. If correct functioning of the leakage sensor can be established by other means

(exclusion of function impairing errors), testing can be executed by simulating the appropriate output signal. Further details

concerning test methods are included, for example, in directive VDI / VDE 2180, page 4.

COMPONENT MATERIAL

In the event of a tank leak, the leakage sensor (probe and probe tube) comes into contact with the stored liquid, or vapours and

condensate resulting there for. For this reason, leakage sensor materials must be selected which are adequately resistant to the

liquid to be monitored.

Tank

Fastening angle

Cap with adjustable

thread joint

Catch basin

Sensor