D6T MEMS Thermal Sensors User’s Manual (A284) 2

1 Overview

This user manual describes the usage procedures, precautions, and other information regarding

D6T-series MEMS Thermal Sensors. This document also serves as a supplement to the product

catalog. Reference this document together with the product catalog when using this device.

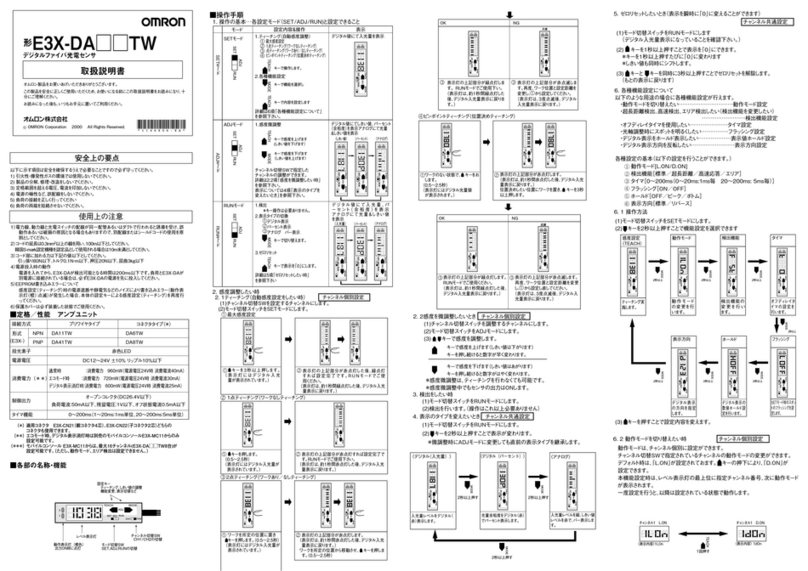

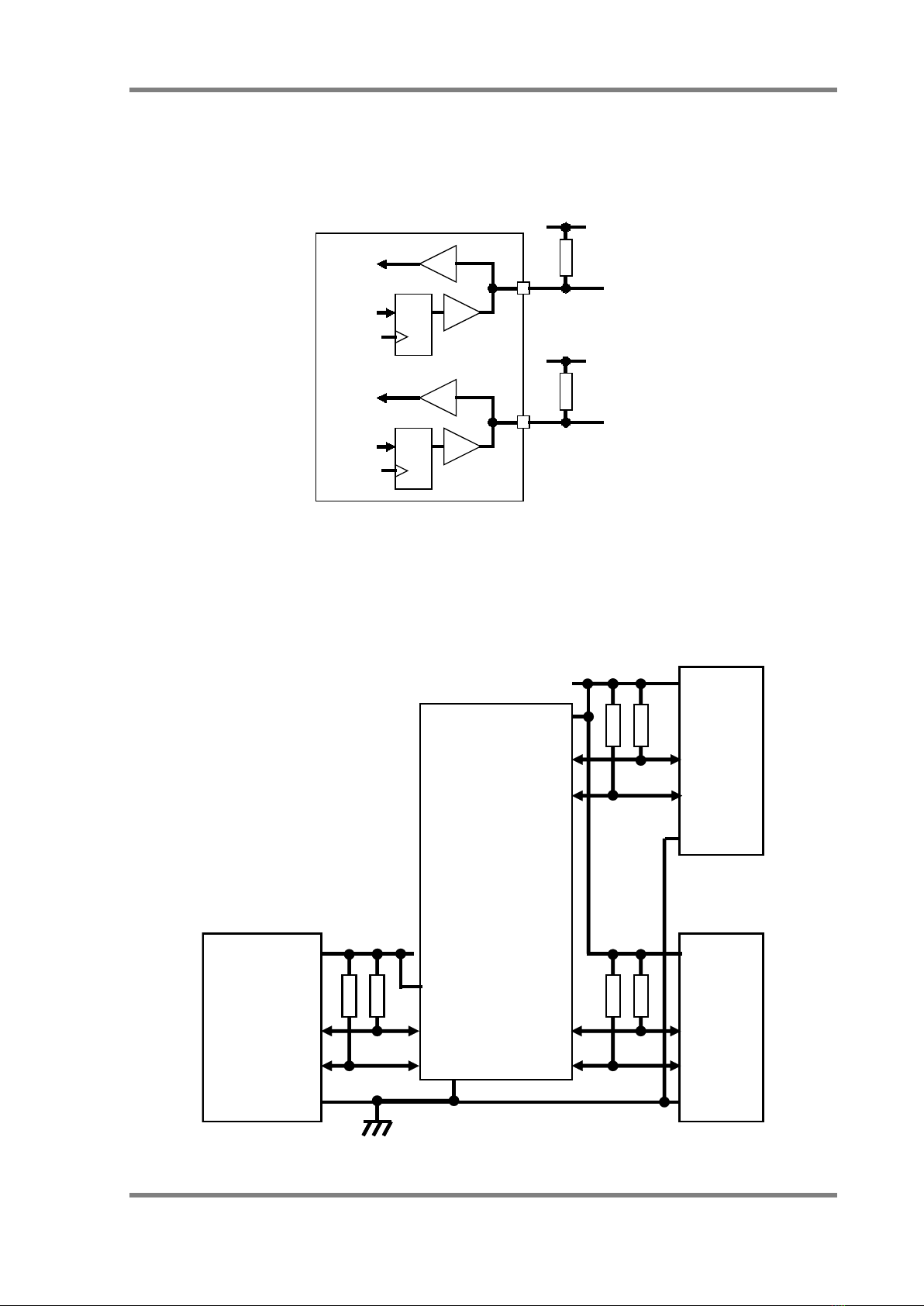

2 Structure (Part Configuration)

The D6T series of MEMS Thermal Sensors consists of a

small circuit board onto which a silicon lens, thermopile

sensor, specialized analog circuit, and logic circuit for

conversion to a digital temperature value are arranged.

This product only requires one connector to connect

these modules.

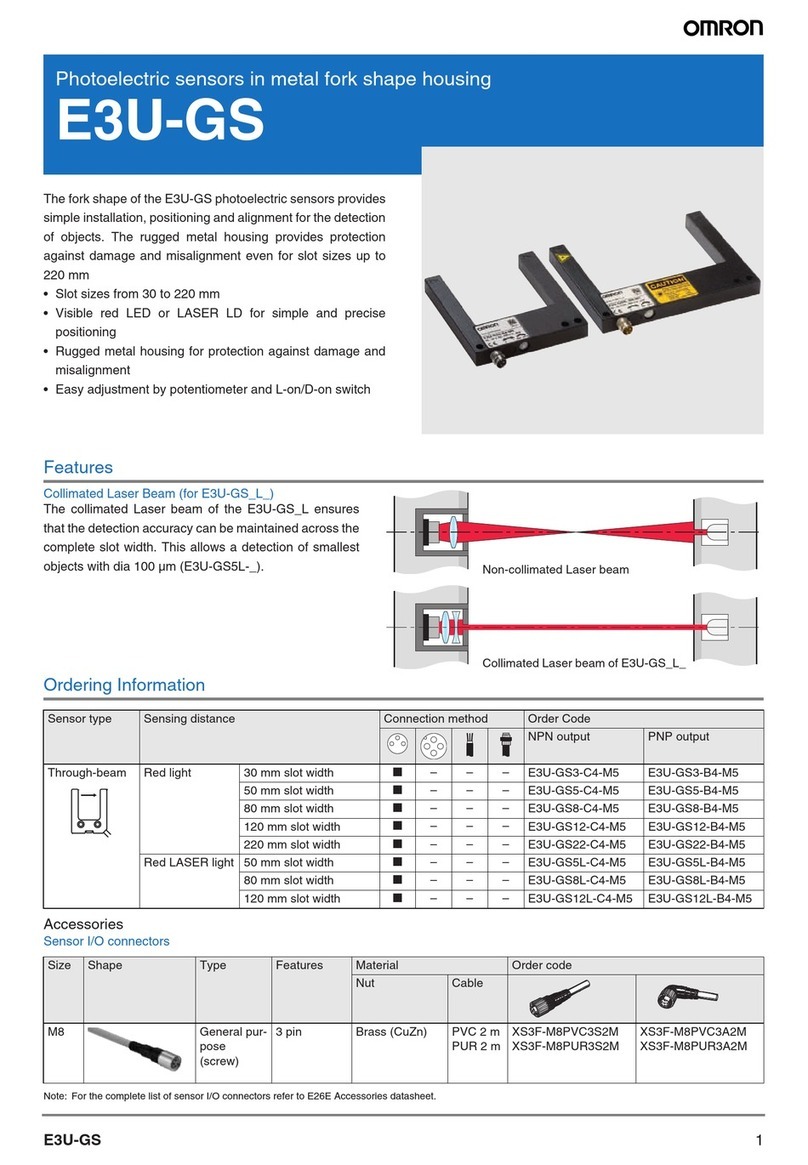

3 External Dimensions

This product features a circuit board size of 14 mm x 18 mm. An even more compact size of

11.6 mm x 12 mm is also available. Refer to the product catalog for more information on

mounting areas and positioning of the circuit board. Refer to Chapter 6 for more information on

compatible connectors.

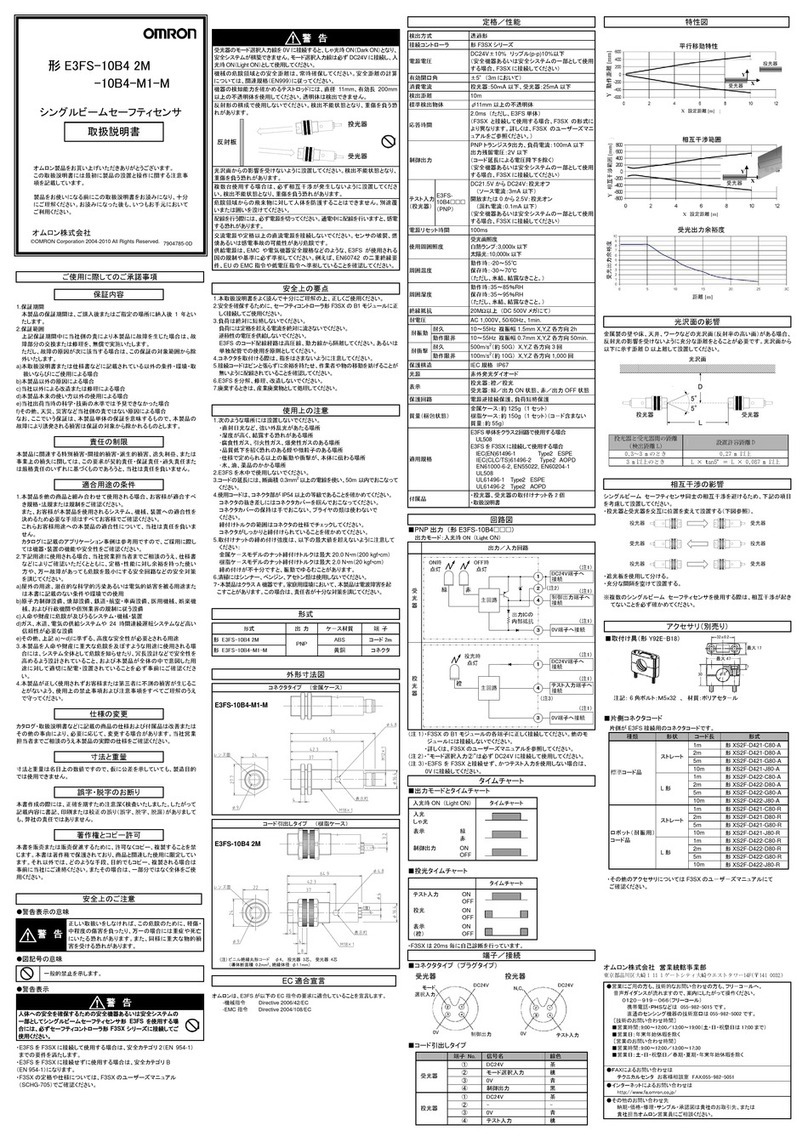

4 Principles of Operation

The following list describes an overview of the measuring

operation of the MEMS Thermal Sensors.

· The silicon lens focuses radiant heat (far-infrared

rays) emitted from objects onto the thermopile sensor

in the module. (*1)

· The thermopile sensor generates electromotive force

in accordance with the radiant energy (far-infrared

rays) focused on it.

· The values of this electromotive force and the internal

thermal sensor are measured. Then, the device

calculates the measured value (temperature of the

object) via an interpolation calculation that compares

the measured values with an internally stored lookup

table. (*2)

· The measured value is output via the I2C bus, and read

using a host system.

(*1) The D6T-1A-01/02 models use a silicon filter.

(*2) D6T-1A-01/D6T-1A-02/D6T-8L-09 use a temperature conversion circuit in the ASIC

to calculate measured values (temperatures of objects).

(Interior side)

Thermopile sensor

Silicon lens

(Back side)

I2C connector

Fig. 1. Exterior of Module (Reference)

Fig. 2. Module Configuration