NET R718PE02D User manual

Lidar Material Level Detection Sensor

R718PE02D

Lidar Material Level

Detection Sensor

R718PE02D

User Manual

Copyright© Netvox Technology Co., Ltd.

This document contains proprietary technical information which is the property of NETVOX Technology. It shall be maintained in strict

confidence and shall not be disclosed to other parties, in whole or in part, without written permission of NETVOX Technology. The

specifications are subject to change without prior notice.

1

Table of Contents

1. Introduction ...............................................................................................2

2. Appearance ................................................................................................2

3. Features......................................................................................................3

4. Set up Instruction.......................................................................................3

4.1 On/Off.................................................................................................3

4.2 Network Joining.................................................................................3

4.3 Function Key......................................................................................4

4.4 Sleeping Mode....................................................................................4

5 Data Report.................................................................................................4

5.1 Example of ReportDataCmd..............................................................5

5.2 Example of ConfigureCmd................................................................6

5.3 Example of General Calibration Configuration.................................9

5.4 Set/GetSensorAlarmThresholdCmd ................................................10

6. Application...............................................................................................12

7. Installation ...............................................................................................13

7.1 Precautions for sensor:.....................................................................13

8. Important Maintenance Instruction .........................................................14

2

1. Introduction

R718PE02D is a wireless communication device for Netvox Class C device based on LoRaWAN open protocol. It is a wireless

communication device for the material level detection industry that uses LiDAR radar for single-point ranging. Based on the ToF (Time

of Flight) schematic, the R718PE02D provides stable, accurate, and reliable ranging performance by optimizing the optical system and

built-in algorithms. It is not easily affected by the surface state of the detected object, and the ranging performance can reach up to 25m.

The product is equipped with a unique dust-removal wiper structure. The radar-driven dust-removal wiper can complete the dust removal

operation of the optical mirror, so it can maintain the accuracy of distance measurement in an environment with severe dust pollution and

dust accumulation. The R718PE02D body and the LiDAR sensor communicate through the UART serial communication and transmit

the detected data to other devices for display through the wireless network. It adopts a wireless communication method that conforms to

the LoRaTM protocol standard.

LoRa Wireless Technology:

LoRa is a wireless communication technology dedicated to long distance and low power consumption. Compared with other

communication methods, LoRa spread spectrum modulation method greatly increases to expand the communication distance. Widely

used in long-distance, low-data wireless communications. For example, automatic meter reading, building automation equipment,

wireless security systems, and industrial monitoring. The main features include small size, low power consumption, transmission

distance, anti-interference ability, and so on.

LoRaWAN:

LoRaWAN uses LoRa technology to define end-to-end standard specifications to ensure interoperability between devices and

gateways from different manufacturers.

2. Appearance

Indicator

Function Key

LiDAR Sensor

Dust-Removal Wiper

3

3. Features

⚫SX1276 wireless communication module

⚫Powered by 5V DC

⚫IP30 rating

⚫Lidar material level detection with dust removal wiper

⚫Compatible with LoRaWANTM Class C device

⚫Frequency hopping spread spectrum technology

⚫Configuration parameters can be configured through third-party software platforms, data can be read and alarms can be set via SMS

text and email (optional)

⚫Available third-party platforms: Actility/ThingPark, TTN, MyDevices/Cayenne

4. Set up Instruction

4.1 On/Off

Power on

5V DC power supply

Turn on

Connect the power supply

Turn off

Disconnect the power supply

Restart

Press the function key for 5 seconds until the green indicator flashes once.

Release the function key and the indicator will flash 10 times.

Back to factory setting

Press the function key for 10 seconds until the green indicator flashes 20 times

Note

1. When user disconnects the power supply; the device should be off by default.

2. On/off interval is suggested to be about 10 seconds to avoid the interference of capacitor

inductance and other energy storage components.

3. 10 seconds after power on, the device will be in engineering test mode.

4.2 Network Joining

Never joined the network

Turn on the device to search the network to join.

The green indicator remains on for 5 seconds: Success

The green indicator remains off: Fail

Had joined the network

(without factory resetting)

Turn on the device to search the previous network to join.

The green indicator remains on for 5 seconds: Success

The green indicator remains off: Fail

Fail to join the Network

Check the device verification information on the gateway or consult your platform server

provider.

4

4.3 Function Key

Press and hold for 5 seconds

Restart

The green indicator flashes 10 times: Success

The green indicator remains off: Fail

Press and hold for 10 seconds

Factory resetting and restart

The green indicator flashes 20 times: Success

The green indicator remains off: Fail

Press once

The device is in the network: green indicator flashes once and sends a report

The device is not in the network: green indicator remains off

4.4 Sleeping Mode

The device is on and in the

network

Sleeping period: Min Interval

When the report change exceeds setting value or the state changes, the device would send a

data report according to Min Interval.

The device is on but not in the

network

Disconnect the power supply when the device is not in use.

Check the device verification information on the gateway

5 Data Report

After power on, the device will immediately send a version packet report and an attribute packet report.

The device sends data according to the default configuration before any other configuration.

Default:

Max Interval = 0x0384 (900s)

Min Interval = 0x0384 (900s) (detect the material level and voltage at every Min Interval)

reportchange: batteryvoltagechange ---- 0x01 (0.1V)

distancechange ---- 0x012C (300mm)

The interval of the data reports might vary due to the firmware.

R718PE02D default Max Interval = 15min and Min Interval = 15min. (The intervals could be set based on customers’ demands.)

R718PE02D reports the distance between sensor and material, the percentage of the material level, and the ranging range.

Note: 1. The dust removal wiper will automatically wipe once when the device report cycle is reached or when the button is

pressed.

2. The blind zone distance of the sensor is ≤ 0.1m.

Please refer to the Netvox LoRaWAN Application Command and http://www.netvox.com.cn:8888/cmddoc for devices’ data

analysis.

5

Tips

1. Battery Voltage:

If the battery is equal to 0x00, it means that the device is powered by a DC power supply.

2. Version Packet:

When Report Type=0x00 is the version packet, such as 01D5000A00201705030000, the firmware version is 2017.05.03.

3. Data Packet:

When Report Type=0x01 is data packet; If the device data exceeds 11 bytes or there are shared data packets, the Report

Type will have different values.

5.1 Example of ReportDataCmd

FPort: 0x06

Bytes

1

1

1

Var(Fix=8 Bytes)

Version

DeviceType

ReportType

NetvoxPayLoadData

Version–1 Byte –0x01——the Version of NetvoxLoRaWAN Application Command Version

DeviceType–1 Byte –DeviceType of Device

The DeviceType is listed in Netvox LoRaWAN Application DeviceType doc

ReportType –1 Byte –the presentation of the NetvoxPayLoadData, according the DeviceType

NetvoxPayLoadData–Var (Fixed =8bytes)

Device

Devive

Type

Report

Type

NetvoxPayloadData

R718PE02D

0xD5

0x00

SoftwareVersion(1

Byte)

Eg.0x0A-V1.0

HardwareVersion

(1 Byte)

DateCode(4 Byte)

eg 0x20170503

Reserved

(2 Byte)

0x01

Battery

(1Byte,

unit:0.1V)

Status

(1Byte,0x01_On

0x00_Off)

Distance

(2Bytes,

Unit:1mm)

FillLevel

(1Byte,Unit:1%)

SensorStrength

(2Bytes)

CapBattery

(1Byte, unit:0.1V)

Only the battery version

is supported)

0x02

Battery

(1Byte,

unit:0.1V)

ThresholdAlarm(1Byte,

Bit0_Low Distance Alarm,

Bit1_High Distance Alarm,

Bit2_ Low FillLevel Alarm,

Bit3_ High FillLevel Alarm,

Bit4-7:Reserved)

Reserved(6Bytes,fixed 0x00)

6

Example of Uplink1: 01D50100000C1226105700 (FillMaxDistance: 2000mm, DeadZoneDistance: 0mm)

1st byte (01): Version

2nd byte (D5): DeviceType 0xD5 -R718PE02D

3rd byte (01): ReportType

4th byte (00): DC power supply

5th byte (00): Status -OFF

6th-7thbyte (0C12): Distance –3090mm 0C12(Hex) = 3090(Dec), 3090*1mm = 3090mm

8th byte (26): FillLevel –38% 26(Hex) = 38 (Dec), 38*1% = 38%

9th –10th byte (1057): SensorStrength –1057(Hex) = 4183 (Dec)

11th byte (00): Reserved

Example of uplink2: 01D5020001000000000000

1st byte (01): Version

2nd byte (D5): DeviceType 0xD5 -R718PE02D

3rd byte (02): ReportType

4th byte (00): DC power supply

5th byte (01): ThresholdAlarm 3090mm < 4000mm (LowThreshold) //0x01 = 0000 0001 (bin)

6th-11th byte (000000000000): Reserved

5.2 Example of ConfigureCmd

Fport: 0x07

Bytes

1

1

Var (Fix =9 Bytes)

CmdID

DeviceType

NetvoxPayLoadData

CmdID–1 byte

DeviceType–1 byte –Device Type of Device

NetvoxPayLoadData–Var bytes (Max=9bytes)

Description

Device

CmdI

D

Device

Type

NetvoxPayLoadData

ConfigReportReq

R718PE02D

0x01

0xD5

MinTime

(2bytes

Unit:s)

MaxTime

(2bytes

Unit:s)

BatteryChange

(1byte

Unit:0.1v)

DistanceChange

(2byte

Unit:1mm)

Reserved

(2Bytes,

Fixed0x00)

ConfigReportRsp

0x81

Status(0x00_success)

Reserved (8Bytes,Fixed 0x00)

ReadConfigRepor

tReq

0x02

Reserved (9Bytes,Fixed 0x00)

Bit 0 = 1

7

ReadConfigRepor

tRsp

0x82

MinTime

(2bytes

Unit:s)

MaxTime

(2bytes

Unit:s)

BatteryChange

(1byte

Unit:0.1v)

DistanceChange

(2byte

Unit:1mm)

Reserved

(2Bytes,Fixed0x

00)

SetOnDistanceThr

esholdRreq

0x03

OnDistanceThreshold(2byte Unit:1mm)

Reserved (7Bytes,Fixed 0x00)

SetOnDistanceThr

esholdRrsp

0x83

Status(0x00_success)

Reserved (8Bytes,Fixed 0x00)

GetOnDistanceTh

resholdRreq

0x04

Reserved (9Bytes,Fixed 0x00)

GetOnDistanceTh

resholdRrsp

0x84

OnDistanceThreshold(2byte Unit:1mm)

Reserved (7Bytes,Fixed 0x00)

SetFillMaxDistan

ceReq

0x05

FillMaxDistance (2byte Unit:1mm)

Reserved (7Bytes,Fixed 0x00)

SetFillMaxDistan

ceRsp

0x85

Status(0x00_success)

Reserved (8Bytes,Fixed 0x00)

GetFillMaxDistan

ceReq

0x06

Reserved (9Bytes,Fixed 0x00)

GetFillMaxDistan

ceRsp

0x86

FillMaxDistance (2byte Unit:1mm)

Reserved (7Bytes,Fixed 0x00)

SetDeadZoneDist

anceReq(REMAI

N Lastconfig

when resetfac)

0x0B

DeadZoneDistance (2byte Unit:1mm)

Reserved (7Bytes,Fixed 0x00)

SetDeadZoneDist

anceRsp(REMAI

N Lastconfig

when resetfac)

0x8B

Status(0x00_success)

GetDeadZone

DistanceReq

0x0C

Reserved (9Bytes,Fixed 0x00)

GetDeadZone

DistanceRsp

0x8C

DeadZoneDistance (2byte Unit:1mm)

Reserved (7Bytes,Fixed 0x00)

8

(1) Configure R718PE02D report parameters:

MinTime = 1h (3600s, 0x0E10), MaxTime = 1h (3600s, 0x0E10), BatteryChange = 0v (0x00), DistanceChange = 500mm (0x01F4)

Downlink: 01D50E100E100001F40000

Response:

81D5000000000000000000 (configuration success)

81D5010000000000000000 (configuration failure)

(2) Read Configuration:

Downlink: 02D5000000000000000000

Response:

82D50E100E100001F40000 (device current parameter)

(3) Configure R718PE02D report parameter:

FillMaxDistance = 5000mm (0x1388)

Downlink: 05D5138800000000000000

Response:

85D5000000000000000000

(4) Read device parameter:

FillMaxDistance = 5000mm (0x1388)

Downlink: 06D5000000000000000000

Response:

86D5138800000000000000

(5) SetDeadZoneDistance://When restoring factory settings, the last set value will be retained.

Downlink: 0BD5006400000000000000 // Set the device detection dead zone distance to 100mm (0x64).

Response:

8BD5000000000000000000

(6) GetDeadZoneDistance:

Downlink: 0CD5000000000000000000

Response:

8CD5006400000000000000 // Get the device detection dead zone distance of 100mm (0x64).

9

5.3 Example of General Calibration Configuration

FPort: 0x0E

Description

Cmd

ID

SensorType

PayLoad(Fix =9 Bytes)

SetGlobalCalibrateReq

0x01

See below

Channel

(1Byte)

0_Channel1

1_Channel2,etc

Multiplier

(2bytes,

Unsigned)

Divisor

(2bytes,

Unsigned)

DeltValue

(2bytes,

Signed)

Reserved

(2Bytes,

Fixed 0x00)

SetGlobalCalibrateRsp

0x81

Channel (1Byte)

0_Channel1

1_Channel2,etc

Status(1Byte,0x00_success)

Reserved

(7Bytes,

Fixed 0x00)

GetGlobalCalibrateReq

0x02

Channel (1Byte)

0_Channel1

1_Channel2,etc

Reserved

(8Bytes,

Fixed 0x00)

GetGlobalCalibrateRsp

0x82

Channel

(1Byte)

0_Channel1

1_Channel2,etc

Multiplier

(2bytes,

Unsigned)

Divisor

(2bytes,

Unsigned)

DeltValue

(2bytes,

Signed)

Reserved

(2Bytes,

Fixed 0x00)

ClearGlobalCalibrateReq

0x03

Reserved 10Bytes,Fixed 0x00)

ClearGlobalCalibrateRsp

0x83

Status(1Byte,0x00_success)

Reserved (9Bytes,Fixed 0x00)

SensorType = 0x36 Channel = 0x00 // The distance sensor channel fixed value of the device is 00

(When restoring factory settings, the last set value will be retained.)

Multiplier =0x0001 Divisor = 0x0001 DeltValue = 0x0064

Assuming that the original value of the uploaded Distance is 1000mm, and the calibration is increased by 100mm, the uploaded value

is 1100mm.

(1) SetGlobalCalibrateReq:

Downlink: 0136000001000100640000

Response: 8136000000000000000000

(2) GetGlobalCalibrateReq:

Downlink: 0236000000000000000000

Response: 8236000001000100640000

Assuming that the original value of the uploaded Distance is 1000mm, and the calibration is reduced by 100mm, the uploaded value is

900mm

10

(3) SetGlobalCalibrateReq: Calibration reduced by 100mm, Multiplier =0x0001, Divisor = 0x0001, DeltValue = 0xFF9C

Downlink: 01360000010001FF9C0000

Response: 8136000000000000000000

(4) GetGlobalCalibrateReq:

Downlink: 0236000000000000000000

Response: 82360000010001FF9C0000

(5) Clear the calibration value: The uploaded value is back to 1000mm.

ClearGlobalCalibrateReq:

Downlink: 0300000000000000000000

Response: 8300000000000000000000

5.4 Set/GetSensorAlarmThresholdCmd

Fport:0x10

CmdDescriptor

CmdID

(1Byte)

Payload (10Bytes)

SetSensorAlarm

ThresholdReq

0x01

Channel

(1Byte,

0x00_Channel1,

0x01_Chanel2,

0x02_Channel3,etc)

SensorType

(1Byte,

0x00_Disable ALL

SensorthresholdSet

0x2F_ Distance,

0x30_ FillLevel,

SensorHighThreshold

(4Bytes, Unit:same as

reportdata in fport6,

0Xffffffff_DISALBLEr

HighThreshold)

SensorLowThreshold

(4Bytes,Unit:same as

reportdata in fport6,

0Xffffffff_DISALBLErHigh

Threshold)

SetSensorAlarm

ThresholdRsp

0x81

Status

(0x00_success)

Reserved (9Bytes,Fixed 0x00)

GetSensorAlarm

ThresholdReq

0x02

Channel

(1Byte,

0x00_Channel1,

0x01_Chanel2,

0x02_Channel3,etc)

SensorType

(1Byte,

Same as the

SetSensorAlarmThresh

oldReq’s SensorType)

Reserved (8Bytes,Fixed 0x00)

GetSensorAlarm

ThresholdRsp

0x82

Channel

(1Byte,

0x00_Channel1,

0x01_Chanel2,

0x02_Channel3,etc)

SensorType

(1Byte,

Same as the

SetSensorAlarmThresh

oldReq’s SensorType)

SensorHighThreshold

(4Bytes,Unit:same as

reportdata in fport6,

0Xffffffff_DISALBLEr

HighThreshold)

SensorLowThreshold

(4Bytes,Unit:same as

reportdata in fport6,

0Xffffffff_DISALBLErHigh

Threshold)

11

Channel - 1 byte

0x00_Distance

0x01_FillLevel // When restoring factory settings, the last set value will be retained.

(1) SetSensorAlarmThresholdReq: (Set the Distance high threshold to 5m and the low threshold to 4m)

Downlink: 01002F0000138800000FA0 //1388Hex = 5000Dec, 5000*0.001m = 5m; FA0Hex = 4000Dec 4000*0.001m = 4m

Response: 8100000000000000000000

(2) GetSensorAlarmThresholdReq:

Downlink: 02002F0000000000000000

Response: 82002F0000138800000FA0

(3) Clear all sensor thresholds. (Configure the Sensor Type to 0)

Downlink: 0100000000000000000000

Response: 8100000000000000000000

12

6. Application

In the case of detecting the material level of the barn, the device is installed on the top of the barn, and the device is powered on after

fixing. The device collects the distance between the material level and the sensor and the percentage of the material level in the barn at

regular intervals.

H: The height of the barn (this value can be set with the payload command; the “fillmaxdistance” in payload means H)

D: The distance between the device and the material (this value is “distance” in uplinks)

L: The material level (this value can be calculated by the “distance” in uplink and “fillmaxdistance” in payload)

Calculation: L = fillmaxdistacnce –distance

d: The DeadZoneDeistance set by the device (the distance that cannot be detected by the actual device)

FillLevel: The percentage of the material level in the barn. (Status = 0)

The value of the total height of the barn can be set through commands according to the specific scene.

Illustration 1 Illustration 2

FillLevel = ((H - D) / H) * 100% FillLevel = ((H - D) / H-d) * 100%

Note:

The ranging range of the device is:

90% reflectivity, 0Klux 0.1m~25m; 10% reflectivity, 0Klux 0.1m~12m;

90% reflectivity, 100Klux 0.1m~25m; 10% reflectivity, 100Klux 0.1m~12m

The calculate method of material level percentage of

DeadZoneDistance can be set.

13

7. Installation

7.1 Precautions for sensor:

1. When installing the sensor, it is recommended to use M2.5 round head Phillips screws for installation.

Please remove the protective film of the optical lens before use. The lens of front panel of LiDAR cannot be covered. Please keep

it clean. The surface of optical lens is the ranging zero of LiDAR.

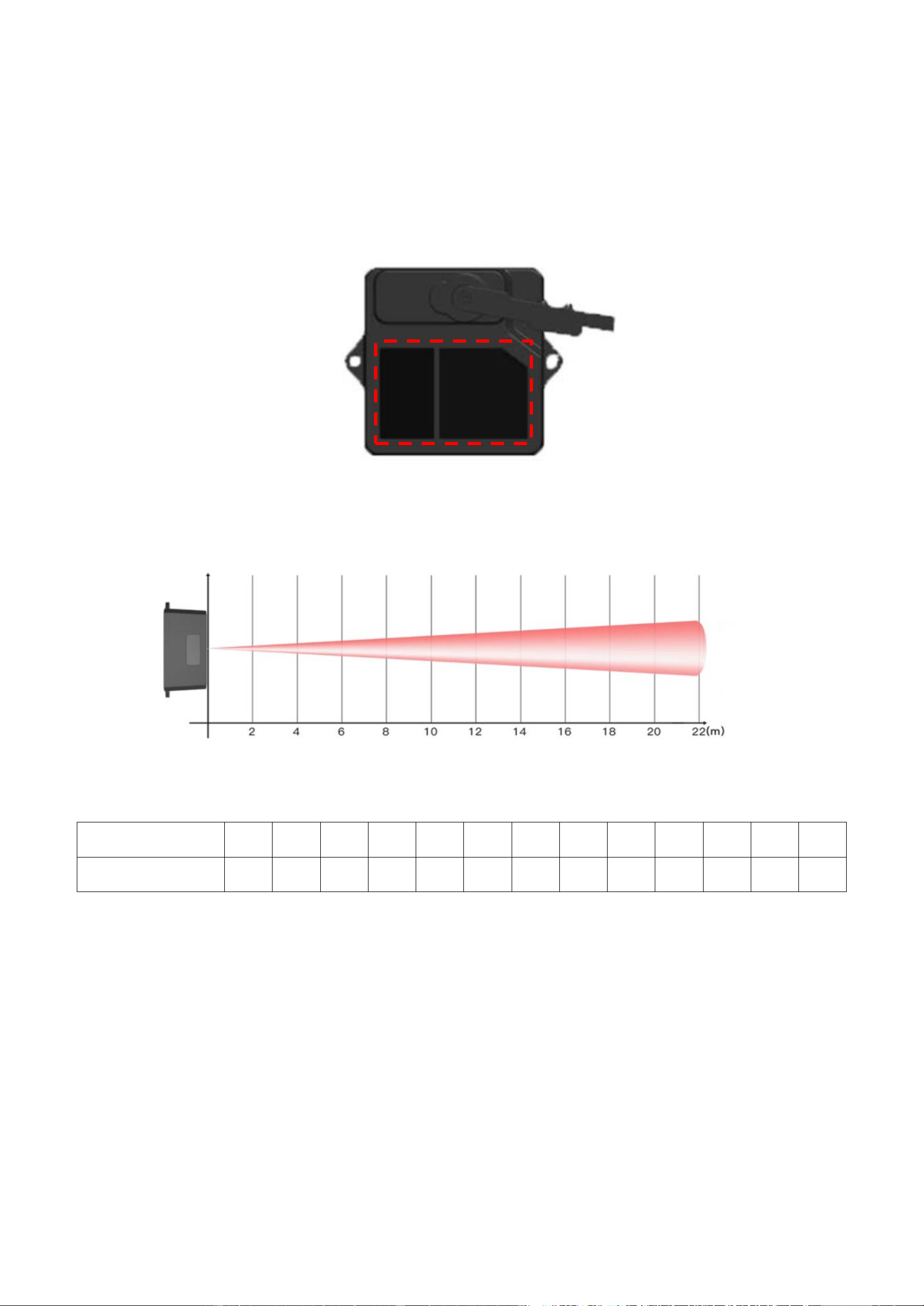

2. The detection angle of the sensor is 3°. At different distances, the size of light spot, namely the edge length of the detection range,

is different.

The spot size at different distances

3. Side length of the detection range at different distances (the detection range is a square)

Distance (m)

1

2

3

4

5

6

7

8

9

10

15

20

22

Spot Size (cm)

5

10

16

21

26

31

37

42

47

52

79

105

115

Spot Size at Different Distances

Note: The side length of the detected target object should be greater than the side length of the detection range of the sensor. When

the side length of the detected object is smaller than the side length of the detection range, the effective range of the radar

will be reduced. When detecting a slope, the sensor can be placed in the middle of the slope.

4. Maintenance and Cleaning

⚫Before/after turning on the device, please check the exposed window mirror and check whether the optical components are dirty,

if dirty, please clean it in time.

⚫The optical components should be cleaned regularly because the device will be placed and operated in a harsh environment.

14

⚫Before cleaning, please turn off the device first, and use a soft cloth to gently wipe the window in the same direction, avoiding

repeated wiping back and forth, which may cause damage to the window mirror.

⚫Do not use alcohol to clean the window mirror as it may be damaged.

⚫Do not disassemble the dust-removal wiper, which may easily cause device failure.

⚫When the steering gear shaft is blocked by dust, the steering gear may be damaged due to increased resistance. It is

recommended to clean the shaft regularly.

8. Important Maintenance Instruction

Kindly pay attention to the following in order to achieve the best maintenance of the product:

•Do not use or store the device in dusty or dirty environments to prevent damage to parts and electronic components.

•Do not store the device in high temperatures. This may shorten the lifespan of electronic components, damage batteries, and deform

plastic parts.

•Do not store the device in cold temperatures. Moisture may damage circuit boards as the temperatures rise.

•Do not throw or cause other unnecessary shocks to the device. This may damage internal circuits and delicate components.

•Do not clean the device with strong chemicals, detergents, or strong detergents.

•Do not apply the device with paint. This may block detachable parts and cause malfunction.

The instructions are applied to your device, battery, and accessories.

If any device is not working properly or has been damaged, please send it to the nearest authorized service provider for service.

Table of contents

Popular Accessories manuals by other brands

Vadsbo

Vadsbo Sensor Narrow installation manual

Awaiba

Awaiba Dragster V3-8K-3.5 Calibration manual

Fisher Scientific

Fisher Scientific Isotemp 500 Series instruction manual

cozee home

cozee home 806335 instruction manual

BITO

BITO PROflow Instructions for assembly and use

IFM Electronic

IFM Electronic PB7 operating instructions