B&C LR3D-14 User manual

Technical Manual

for

Model No. LR3D-14 and LR3D-28

Linear Regulator

With Over-Voltage Protection, Low-Voltage Sensing,

And Field-Adjustable Charging Voltage

Including:

Installation Instructions;

Troubleshooting Guide; and

Instructions for Continued Airworthiness

B & C Specialty Products

P.O. Box B

Newton, KS 67114

(316) 283-8000

bandc.com

LR3D-TM, Rev. IR (5/13/2020)

LR3D Technical Manual Preface

Rev. IR (5/13/2020)

B&C Specialty Products Page i

bandc.com

INDEX

Name

INTRODUCTION

INSTALLATION

OPERATION

TROUBLESHOOTING

WIRING DIAGRAM

INSTRUCTIONS FOR

CONTINUED

AIRWORTHINESS

Section

A

B

C

D

E

F

NOTE

The LR3D-14 and LR3D-28 Linear Regulators are not STC’d or PMA’d

and are intended for installation in amateur-built aircraft only.

LR3D Technical Manual Section A

Rev. IR (5/13/2020) Introduction

B&C Specialty Products Page A - 1

bandc.com

INTRODUCTION

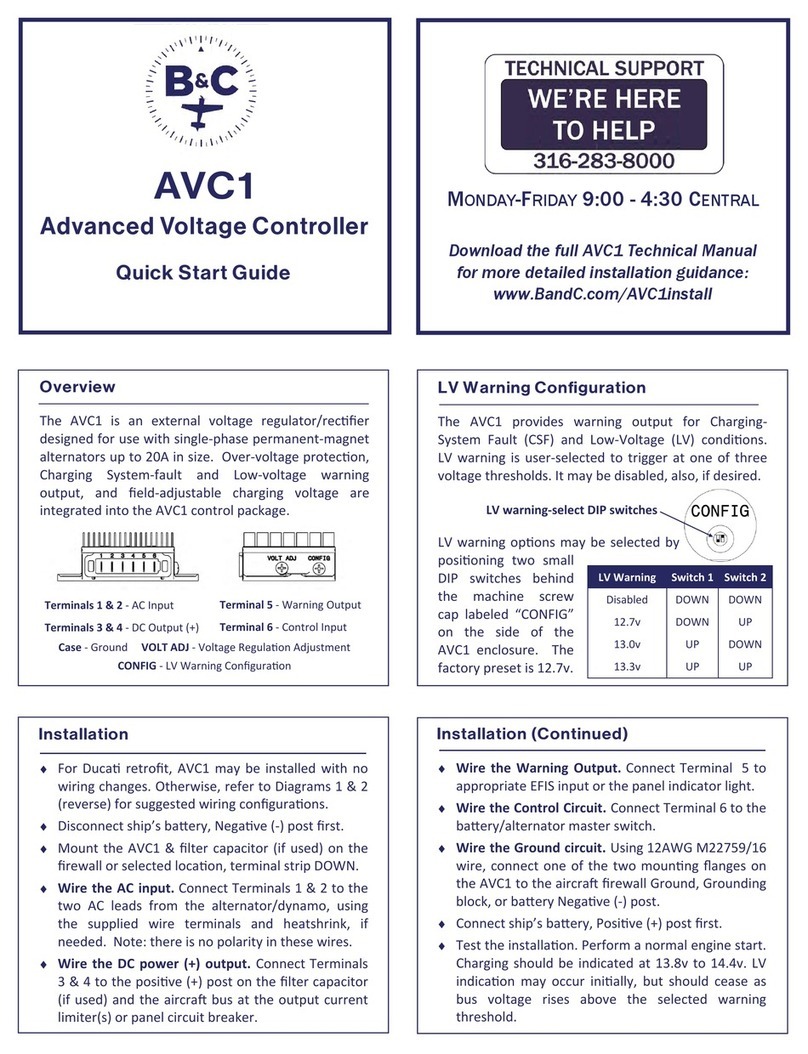

The LR3D is an external alternator controller (regulator) designed for use with B-type, wound-

field alternators. Over-voltage (OV) protection, Low-Voltage (LV) warning output, and field-

adjustable charging voltage are integrated into the LR3D control package.

OVERVIEW

1 - Battery Temp input (optional)

2 - Over-Voltage Test input (optional)

3 - Bus Voltage Sense input

4 - Field output

5 - Low-Voltage Warning output

6 - Bus Field Supply input

7 - Ground input

Case Ground & Voltage Adjust (not shown)

Terminal 1 – This input, when used with the optional temperature probe, will enable the LR3D to

automatically adjust the alternator output voltage as the temperature of the battery terminal

changes. Because the ideal charging voltage for a battery is dependent on battery temperature,

some operators may desire a higher charging voltage during winter operations and a lower

charging voltage during summer operations. While this can be accomplished by manually

adjusting the voltage regulator, the intent of this feature is to make the adjustment occur

automatically from one season to the next. In practice, the vast majority of installations do not see

a wide enough swing in battery temperature to justify the added expense and complexity of the

temperature probe.

Terminal 2 - This input is used to verify the function of the crowbar OV protection circuit in the

LR3D. If aircraft bus voltage is momentarily applied to this terminal, the LR3D will interpret it

as an OV event and will trigger the crowbar circuit, causing the 5A Alternator Field circuit

breaker to open just as it would for an actual OV condition. This test may be performed during

the annual condition inspection of the aircraft using a jumper wire or test lead. Fixed wiring of

this feature is uncommon and not recommended.

LR3D Technical Manual Section A

Rev. IR (5/13/2020) Introduction

B&C Specialty Products Page A - 2

bandc.com

Terminal 3 - This input is used by the LR3D to accurately sense the bus voltage for the purpose of

voltage regulation and low voltage warning. If no bus voltage is provided to this input, the

regulator will not operate.

Terminal 4 - This output provides the alternator field excitation and connects to the field terminal

of the alternator. Field fault protection is provided within the LR3D to protect the LR3D if a fault

occurs on the field wire or alternator field winding. In the event of excessive field current, the

LR3D will current-limit this output and trigger the OV crowbar circuit to open the 5A alternator

field circuit breaker. The LR3D cannot be used with alternators requiring 4A or more field

current.

Terminal 5 - This output should be connected to the ground side of a warning indicator. The other

side of the warning indicator should be connected to aircraft power and can potentially be added

to another appropriate system circuit breaker if circuit breaker space is limited. The LR3D is

compatible with both incandescent and LED warning indicators and provides a pulsing ground to

the warning indicator when the low voltage warning is active. Care should be taken to use a

warning indicator that does not exceed 250mA to avoid damaging the lamp-driver circuit within

the LR3D. Do NOT connect aircraft bus voltage directly to terminal 5 and do NOT use a plain

LED without a current-limiting resistor.

Terminal 6 - This input is connected to the aircraft bus by means of a 5A circuit breaker and an

alternator switch. Field current is sourced from this input; voltage sense for OV protection is also

provided from this input. If the crowbar OV circuit is triggered due to an actual OV event, a field

fault, or a manual OV test, the LR3D internally connects this terminal to ground, causing the 5A

alternator field circuit breaker to open.

Terminal 7 - This input is connected to aircraft ground. The ground path must be capable of

providing a connection with less than 0.5 Ohms of resistance between terminal 7 on the LR3D

and the battery negative (-) terminal.

Case Ground - This redundant input is connected to aircraft ground, and should be totally

independent from the wiring associated with the terminal 7 input. The ground path must be

capable of providing a connection with less than 0.5 Ohms of resistance between the threaded

Case Ground post on the LR3D and the battery negative (-) terminal.

Voltage Adjustment - This precision potentiometer, covered by a round black cap, permits

plus/minus user adjustment of the LR3D output voltage set-point (see below, “System Function”).

SYSTEM FUNCTION

The LR3D is pre-set to control alternator output voltage at 14.4V (or 28.8v on the LR3D-28). If

voltage adjustment is desired, this may be accomplished by accessing the adjustment

potentiometer located behind the round black cap on the side of the LR3D enclosure. Each full

LR3D Technical Manual Section A

Rev. IR (5/13/2020) Introduction

B&C Specialty Products Page A - 3

bandc.com

turn of the potentiometer will adjust the voltage by approximately 0.2V on the LR3D-14 and

0.4V on the LR3D-28 (clockwise to increase, counterclockwise to decrease). The available

range of adjustment is approximately 11.0V-16.0V (LR3D-14) and 22.0V-32.0V (LR3D-28).

Use a handheld digital voltmeter at the battery to confirm any field adjustment.

In normal operation the Low-Voltage (LV) warning light will not be illuminated. The light may

flash in response to low engine RPM and high bus load, however; or it may flash to indicate an

emerging problem in the charging system.

The integrated Over-Voltage (OV) protection is set at a non-adjustable 16.25V (± 0.25V) on the

LR3D-14, and 32.5V (± 0.5V) on the LR3D-28. When triggered, this protective response will

cause the 5A field supply circuit breaker to open, thereby depriving the alternator of excitation

voltage and causing it to drop off-line. The alternator will remain off-line until power is restored

to the circuit by manually closing the 5A circuit breaker.

The LV warning light will begin to flash when the voltage sensed at terminal 3 drops to

approximately 12.7V and below (LR3D-14), or 25V and below (LR3D-28). The warning light

will cease flashing if/when the sensed voltage rises above these thresholds.

PARTS LIST

The following parts are supplied with the LR3D-14 and LR3D-28:

Qty. Part No. Description

1 LR3D-14 or LR3D-28 Alternator Controller (Regulator)

8 S814R6 Terminal, Ring, 18-22AWG

1 S888-1-4 (14v) or S888-2-4 (28v) Warning Lamp, Yellow

The following parts may be needed but are not supplied:

Qty. Part No. Description

1 L-40, LX60, BC410-H, BC462-H (or equal) Alternator

1 CB2 Circuit Breaker, 2A

1 CB5 Circuit Breaker, 5A

1 S700-2-3 Switch, Toggle

NOTE

The pre-set charging voltage of the LR3D should be suitable for most

12V & 24V Sealed Lead Acid (SLA) batteries. Electrical systems

using legacy “Flooded” batteries, or Lithium (LiFePO4or similar)

batteries, may require field adjustment. Consult the documentation

provided by the manufacturer to ensure adequate battery performance

and service life.

LR3D Technical Manual Section A

Rev. IR (5/13/2020) Introduction

B&C Specialty Products Page A - 4

bandc.com

AR M22759/16-18-9 Wire, 18 AWG, White, Tefzel

AR M22759/16-22-9 Wire, 22 AWG, White, Tefzel

2 AN4-4A Bolt

4 AN960-416L Flat washer

2 AN365-428A Locking nut

The above items are available individually, or as part of an installation kit (P/N: LR-INSTALL),

from B&C Specialty Products, bandc.com, phone: 316-283-8000.

CHANGE IN WEIGHT AND BALANCE

The LR3D Controller weighs a nominal 0.6 lbs. Variations in airframe station references for all

aircraft affected by this kit preclude including pre-calculated weight and balance data in this

manual. Weight of electrical accessories and hardware will vary for each individual installation.

The installer is responsible for ensuring that aircraft weight and balance are correct.

LR3D Technical Manual Section B

Rev. IR (5/13/2020) Installation

B&C Specialty Products Page B - 1

bandc.com

INSTALLATION

Preparation

Step 1. Refer to applicable service manual instructions; remove and retain engine cowl.

Disconnect ship’s battery, Negative (-) terminal first.

Step 2. Refer to applicable service manual instruction; remove existing regulator.

Step 3. Select a suitable location to mount the LR3D. Mounting on the pilot’s side of the

firewall or inside the cabin near the panel, terminal strip down, is preferred (linear

controllers are electrically “quiet” and create little or no noise when properly installed

and grounded).

NOTE

Take care to choose a mounting location that will protect the LR3D

from heat, vibration, and water.

LR3D Technical Manual Section B

Rev. IR (5/13/2020) Installation

B&C Specialty Products Page B - 2

bandc.com

Step 4. Select a suitable location to mount the low voltage warning light in your instrument

panel. An incandescent light has been included with the LR3D; however, an LED

indicator (user supplied) may be substituted, if desired. The warning light should be

positioned within the pilots' peripheral vision — generally, a 45-degree angle in front

of the pilot. A panel location away from direct sunlight is preferred.

Step 5. Select a suitable panel location to mount the 2A and 5A circuit breakers. A panel

location within the pilot’s field of vision and reach is recommended.

Step 6. Select a suitable panel location to mount the alternator field switch. A panel location

immediately adjacent to the ship’s battery master is recommended, if practicable.

Regulator Installation

Step 7. Mount the LR3D to the firewall or selected location, terminal strip down. On a metal

firewall, AN4-4A bolts, AN960-416L flat washers, and AN365-428A locking nuts,

will be adequate to secure the regulator.

Step 8. Wire the LR3D sense and field supply circuits using M22759/16 Tefzel wire and the

supplied S814R6 ring terminals, according to the wiring diagram on page E-1.

Step 9. Wire the LR3D to ground using M22759/16 Tefzel wire and the supplied S814R6 ring

terminals, according to the wiring diagram on page E-1. Be certain to establish ground

connections to both terminal #7 and the threaded ground stud located below the

terminal strip.

Step 10. Wire the 2A and 5A circuit breakers and alternator field switch using M22759/16

Tefzel wire, according to the wiring diagram on page E-1.

NOTE

The LR3D senses bus voltage through terminal #3. If the low voltage

warning light is not desired, terminal #5 may be left unconnected; but

terminal #3 must still be connected to the bus through a fuse or circuit

breaker. If terminal #3 is not connected to power, the LR3D will not

work. “Jumpering” terminal #3 to terminal #6 is not recommended.

NOTE

This step is important for all airframes, and crucial for composite

aircraft. The LR3D obtains a redundant connection to ground through

the threaded stud. A jumper between terminal #7 and the ground stud

will compromise redundancy. Ground connections must be totally

independent and not rely on common fasteners. Select 18AWG wire

(or larger) and ring terminals for these connections.

LR3D Technical Manual Section B

Rev. IR (5/13/2020) Installation

B&C Specialty Products Page B - 3

bandc.com

Step 11. Wire the S888-1-4 warning light (or alternate indicator) using M22759/16 Tefzel wire,

according to the wiring diagram on page E-1. Place heatshrink (supplied) over each

wire for the warning light base, solder the wires onto the base terminals, and shrink the

heatshrink over the connection.

Step 12. Connect ship’s battery, Negative (-) terminal last, and replace engine cowl.

Step 13. Test the installation as follows —

A. Low-voltage indication: turn the battery master switch ON, and observe the

warning light. Depending on the condition of the battery, this light may or may

not flash. If it does not begin flashing, turn on the landing light or the nav lights

to lower the battery voltage sufficiently to make the warning light start to flash

(typically between 12.5 and 13.0 volts on LR3D-14; or 24.5 and 25.5 volts on

LR3D-28).

B. Over-voltage protection: with the battery master switch ON, turn the alternator

field switch ON. Touch a jumper wire momentarily between terminal #2 and

terminal #6; this should cause the 5A field circuit breaker to open (thus

confirming the function of the OV protection circuit). Failure of the field breaker

to open is cause for investigation.

C. System charging: start the engine according to normal procedure. With the

engine running and the battery master switch ON, turn the alternator field switch

ON. An increase in bus voltage to 14 to 14.4 volts (or 28 to 28.8 volts) should be

observed, depending on the electrical load, engine RPM, and type of alternator

(refer to the supporting documents for the alternator to determine the RPM at

which measurable output may be expected). The low-voltage warning light

should no longer flash.

Step 14. Update ship’s weight and balance, pilot operating handbook and maintenance records.

Tips for a Successful Installation

1. Avoid deviating from the installation instructions and wiring diagram. The LR3D has been

designed to integrate into your aircraft electrical system in a specific way, with separate bus

connections for “sense” and “control”. Similarly, the LR3D also requires other associated

NOTE

If panel space is limited, a 2A in-line fuse may be substituted for the

2A circuit breaker associated with terminal #5. The 5A circuit breaker

associated with terminal #6 MUST be used. Connecting terminal #6

directly to the bus or using PTC thermistors (sometimes called “solid-

state breakers”) will damage the LR3D if there is an OV condition.

LR3D Technical Manual Section B

Rev. IR (5/13/2020) Installation

B&C Specialty Products Page B - 4

bandc.com

components, such as circuit breakers and an alternator field switch, which meet certain

specifications. These connections and associated components are vital to proper system

function.

2. Use time-proven components in your installation. Our technical staff has found that a

reliable installation is often made or broken by the associated parts used to install the

LR3D. Here are several specific choices that can help you avoid trouble:

• Select a “toggle-type” rather than a “rocker-type” switch for the alternator field

switch. Our tear-down analysis of the internals of each type has shown that the

mechanical properties and basic materials used in a simple toggle switch will

provide superior service over time. Avoid “split-rocker” switches in particular –

though popular and found on many aircraft, these can be a common source of

reliability woes as they accumulate time in service.

• Select KLIXON or Mechanical Products circuit breakers, both of which are widely-

used in general aviation. These well-constructed, single-purpose devices are

reasonably economical, and will serve you well over time. Avoid combination

“switch-circuit breakers” (another common source of reliability issues).

• Use nylon pre-insulated ring terminals (supplied), and crimp these with the correct

tool. Route wiring along existing harnesses, where they exist, and secure with

nylon wire ties. Ensure that all wiring is tied away from chafe points and clear of

all flight control mechanisms throughout the entire range of control movements.

Use a 5-lb pull test to check crimped connections; verify the terminal is crimped on

the wire, not the insulation.

• Ensure the integrity of your alternator field connector (plug) and associated wiring.

The LR3D connects to the alternator by means of a single wire; an intermittent

connection at the alternator will result in erratic – and unstable – operation.

LR3D Technical Manual Section C

Rev. IR (5/13/2020) Operation

B&C Specialty Products Page C - 1

bandc.com

OPERATION OF THE LR3D

Start-Up

Turn ON battery/alternator master switch(s). Perform a normal engine start. Proceed with other

pre-flight procedures. Note: there is no significant difference between turning the alternator ON

before or after engine start.

In-Flight

Bus voltage in flight will normally be maintained between 14.0V and 14.4V with the LR3D-14,

or between 28.0V and 28.8V with the LR3D-28, unless the regulation set-points have been re-

adjusted in the field. Bus voltage below these set-points can also be present if bus load exceeds

alternator capacity, if excessive voltage drop exists in the regulator wiring or associated

components, or if there has been a failure at some point in the charging system.

Low-Voltage (LV) warning indication will become active when bus voltage drops below the

factory-set LV threshold (see Section A, “System Function”). Indication will be in the form of a

flashing warning light if the supplied indicator has been used in your installation. This warning

indication will persist until the LV condition ceases.

Over-Voltage (OV) protection and warning indication will become active when bus voltage

rises above the factory-set OV threshold (see Section A, “System Function”). The LR3D will

shut down the charging system, followed shortly thereafter by LV warning indication as the bus

voltage drops below the LV threshold in response to continuing loads. Indication will again be

in the form of a flashing warning light, this time in conjunction with an open 5A field supply

circuit breaker. While a manual reset of this 5A circuit breaker may be attempted, should the

OV condition continue the protective OV response will persist, keeping the charging system off-

line until the root condition is corrected.

Shutdown

Perform a normal engine shutdown. Turn OFF battery/alternator master switch.

LR3D Technical Manual Section D

Rev. IR (5/13/2020) Troubleshooting

B&C Specialty Products Page D - 1

bandc.com

TROUBLESHOOTING

Refer to the wiring diagram found on page E-1 and use a high impedance (preferably digital)

volt/ohmmeter (DVM) to make the following checks. Please note that the engine should not be

running, the mags should be OFF, and there should be no auxiliary power applied to the aircraft

electrical system.

1. Turn all switches OFF. Use the lowest resistance scale on the DVM. Check resistance

between the battery negative (-) terminal and both pin 7 of the regulator and the engine

case. Measurements over 0.5 Ohm to either would be cause for investigation; should this

be detected, check the engine ground strap, battery ground strap, and regulator ground

wire(s) for loose or contaminated connections, broken conductors or bad crimp joints. If

these measurements are less than 0.5 Ohm, any of these three points may be used as ground

reference (-) for the measurements that follow.

Resistance from battery to pin 7:_____Ohms; from battery to engine case:_____ Ohms

2. Turn ON the battery master and alternator field switches. Measure the voltage on the

battery bus and on pin 3 of the regulator. The voltages should be equal within 0.2 volts. A

difference of greater than 0.2 volts may be caused by using a circuit breaker as the source

for pin 3 that supplies another device of considerable load. Change to a breaker dedicated

to pin 3. It is recommended that pin 3 NOT be jumpered to pin 6. If pin 3 has no voltage,

the regulator will not operate and low voltage warning will be lost.

Bus voltage:_______ volts Pin 3 voltage:________volts

3. Measure the voltage on pin 6 of the regulator. It should be within 0.5 volts of the bus

voltage. A difference of greater than 0.5 volts may be caused by poor contacts in the field

breaker or field switch, or poor crimp joints/loose screw terminals in the wiring between

the bus and pin 6. Absence of voltage on pin 6 will prevent the regulator from operating.

Pin 6 voltage:_________volts

4. Check the voltage on pin 4 of the regulator. If the bus voltage is 13.0V or less, the pin 4

voltage should be approximately 1.2 volts less than the voltage on pin 6. A difference of

significantly less than 1.2V between pins 4 and 6 may indicate an open field circuit from

pin 4 through the alternator windings to ground. Voltage differences significantly greater

than the above could indicate a bad regulator unless the bus voltage is greater than 13.0V.

Systems with batteries that have a high resting voltage (such as LiFePO4batteries) may

have a lower voltage on pin 4. An ideal pin 4 voltage would be approximately 10.9 to 11.4

volts on a 12.6 volt bus and 23.5 to 24.0 volts on a 25.2 volt bus.

Pin 4 voltage:________volts

5. Move to the engine compartment. Measure the field voltage at the alternator as follows –

LR3D Technical Manual Section D

Rev. IR (5/13/2020) Troubleshooting

B&C Specialty Products Page D - 2

bandc.com

L-40, BC410-H, and BC425-H Alternators: Use a thin probe or small gage

wire wrapped around the probe to reach through the connector body and

measure the voltage at either field connector terminal coming out of the

alternator. Do not disconnect the field connector for this measurement.

LX60, BC460-H, and BC462-H Alternators: Turn OFF the battery and

alternator master switches. Disconnect the field connector from the

alternator. Use an 18 AWG jumper with an alligator-clip (or fashion an 18

AWG jumper wire) approximately 6” in length to temporarily link either

active field connector terminal with the corresponding male blade coming

out of the alternator. Turn ON the battery and alternator switches. Use

DVM probe to measure voltage at the alligator clip. Turn OFF battery and

alternator master switches, remove jumper, and reinstall field connector.

Observed voltage in the above should measure within 0.5 volts of the measurement on pin

4 of the regulator. A lack of voltage may indicate an open circuit between pin 4 of the

regulator and the field terminal, or a damaged/failed regulator.

If an open field circuit is suspected, the battery and alternator master switches may be

turned OFF, the alternator field connector removed, and a resistance measurement made

between the connector and pin 4 of the regulator. Look for near 0 Ohms. Field resistance

of the alternator may also be checked at this time by measuring from either male field

terminal blade to alternator case; typically, this should measure between 3 and 10 Ohms.

Values other than these may indicate a broken field wire, or heavily worn alternator

brushes and slip rings (respectively).

Field terminal voltage:_______volts Alternator field resistance:_______Ohms

6. With the switches ON, check the voltage between the alternator output post (or “B”-lead)

and ground. It should be battery voltage. If not, check the wiring between the alternator

“B”-lead and the battery positive (+) terminal. Look for loose or contaminated

connections, broken wires, or an open breaker or fuse.

Alternator “B”-lead voltage:______volts

7. If all of the voltages in the first 6 steps are close to the value specified, the charging system

should be operative. If not, check for a broken or loose alternator belt or broken alternator

drive coupling (if so equipped). It is also possible on some installations that the engine

speed will have to be near run-up RPM or more for the system to provide useable output.

Intermittent problems are the hardest to find. In composite aircraft a common root cause is poor

system grounds; metal aircraft can exhibit this defect, also, if proper system grounding is not a

priority.

Noise problems can also be challenging. To manage system noise problems, consider the

following:

LR3D Technical Manual Section D

Rev. IR (5/13/2020) Troubleshooting

B&C Specialty Products Page D - 3

bandc.com

• Correct (or prevent) noise problems by using a unitized grounding system, such as a

“ground block.” This averts small voltage differences between different ground points

— a common source of electrical noise (and erratic behavior in associated devices).

• The battery acts as a noise filter in the system. Poor connections to the battery, or a

battery in the initial stages of failing, can add to or even cause noise problems.

• Shielding of low-level audio leads (especially microphone leads or headset leads) is a

necessity. Sometimes the shields in the cables can separate from repeated flexing; so a

check of shield continuity with an ohmmeter may prove illuminating.

• Wire routing is important. Separate noise-carrying conductors (like “P”-leads) from

other wiring. Avoid running noisy wiring parallel to other wiring in the same bundle.

• Stop the noise at its source. Once the noise is “loose,” it can be difficult to filter it out

of all affected systems. Try to locate the offending item and correct the problem at that

point. Switching off the alternator, the mags (first one then the other), or any other

electrical equipment that generates noise should help to find the offender.

B&C is always ready to assist our customers with technical problems during construction and

thereafter. The safety of our friends and reliability of our products are top priority. If this guide

has not solved your problem, please feel free to contact us –

Phone: 316-283-8000 (Monday – Friday, 9:00am to 4:30pm Central time)

LR3D Technical Manual Section E

Rev. IR (5/13/2020) Wiring Diagram

B&C Specialty Products Page E - 1

bandc.com

LR3D Technical Manual Section F

Rev. IR (5/13/2020) Instructions for Continued Airworthiness

B&C Specialty Products Page F - 1

bandc.com

INSTRUCTIONS FOR CONTINUED AIRWORTHINESS

The B&C LR3D-14 and LR3D-28 regulators require no recurrent maintenance and have an

indefinite service life. At each annual condition inspection, check the regulator externally for

security of mounting, tightness of terminal screws, and chafing or breakage of wiring. Perform

an operational check to determine that the regulator maintains the aircraft electrical bus at its

approximate set point as loads are added and removed (at high loads, cruise RPM may be

required).

Failure due to broken wires or damaged connectors may be corrected in the field using repair

procedures complying with the latest revision of AC43.13-xx. Use only nylon-insulated PIDG

wire terminals and M22759/16 Tefzel wire for repairs to the LR3D connecting harness. All

repairs to the LR3D are by factory service or replacement only.

Field adjustment of the regulated voltage may be accomplished by accessing the precision

adjustment potentiometer located under the round black cap on the side of the LR3D enclosure.

A small flat-blade screwdriver may be used for the adjustment; clockwise rotation increases the

set voltage at a rate of 0.2V per full turn (LR3D-14) or 0.4V per full turn (LR3C-28).

The integrated Over-Voltage (OV) protection function is set at a non-adjustable 16.25V (±

0.25V) on the LR3D-14, and 32.5V (± 0.5V) on the LR3D-28. A 5A circuit breaker or fast-

acting fuse is required between the aircraft bus and pin 6 of the LR3D for this functionality to

operate.

The Low-Voltage (LV) warning output is fixed and non-adjustable, and will activate between

12.7V and below (LR3D-14), or 25V and below (LR3D-28).

INSTALLATION OF THIS UNIT ON A TYPE-CERTIFICATED AIRCRAFT

MUST BE ACCOMPANIED BY AN STC OR BY A ONE-TIME FIELD APPROVAL

This manual suits for next models

1

Table of contents

Other B&C Controllers manuals

Popular Controllers manuals by other brands

Siemens

Siemens GAMMA wave GE 561/01 Technical product information

Ewellix

Ewellix CAHB-2 Series Installation, operation and maintenance manual

hager

hager WUT09 manual

ModelCraft

ModelCraft 550 operating instructions

RKC INSTRUMENT

RKC INSTRUMENT FB900 Series installation manual

Emerson

Emerson dixell XW60K Installation and operating instructions