Contents

Introduction.................................................................................................................................................... 5

Introduction to the User Guide..................................................................................................................... 5

Where to Get Help ........................................................................................................................................ 5

Safety ............................................................................................................................................................. 5

General Safety Considerations...................................................................................................................... 5

Safety Symbol Index...................................................................................................................................... 6

Specific Safety Considerations ...................................................................................................................... 6

Dymax UV Light-Curing General Safety Considerations................................................................................ 6

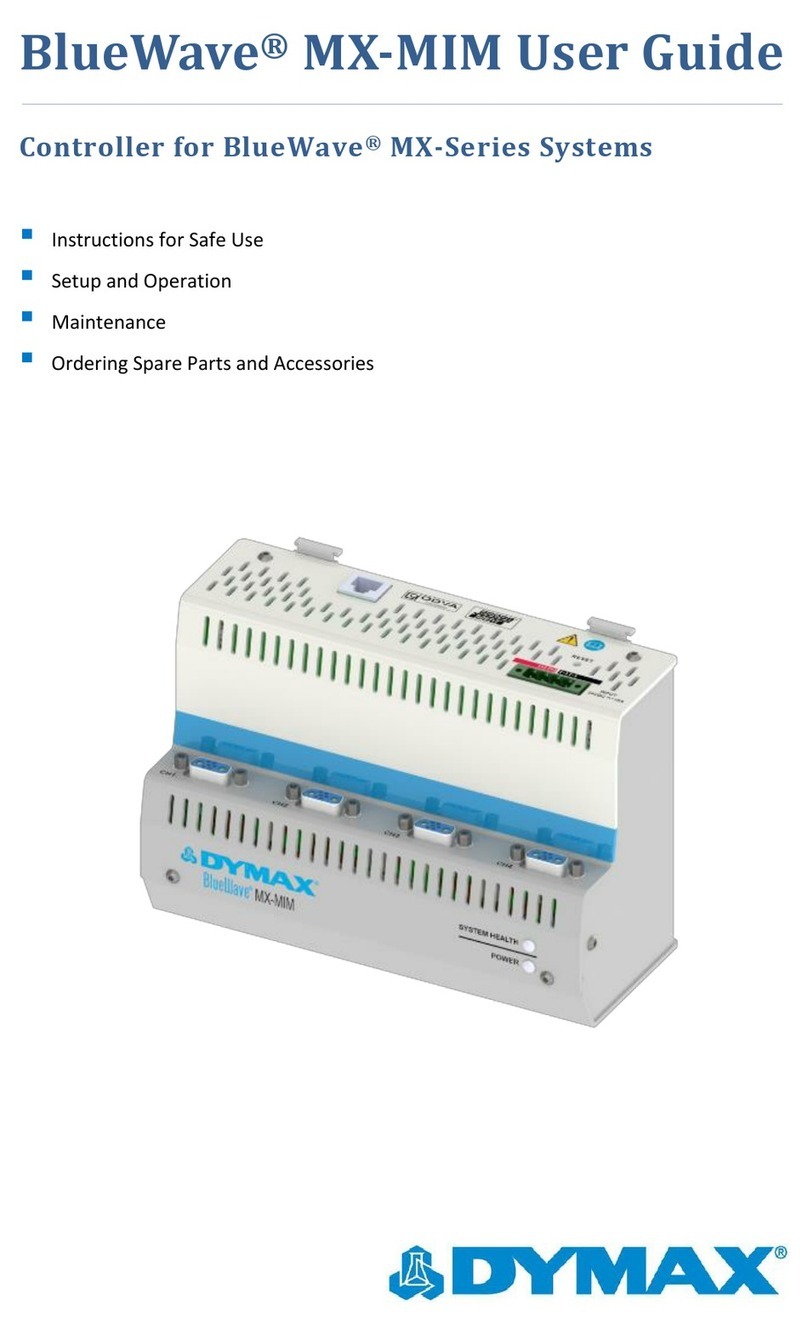

Product Overview ........................................................................................................................................... 8

Description of BlueWave MX-Series Multichannel Controller ...................................................................... 8

Features & Benefits..................................................................................................................................... 10

Control Panels ............................................................................................................................................. 11

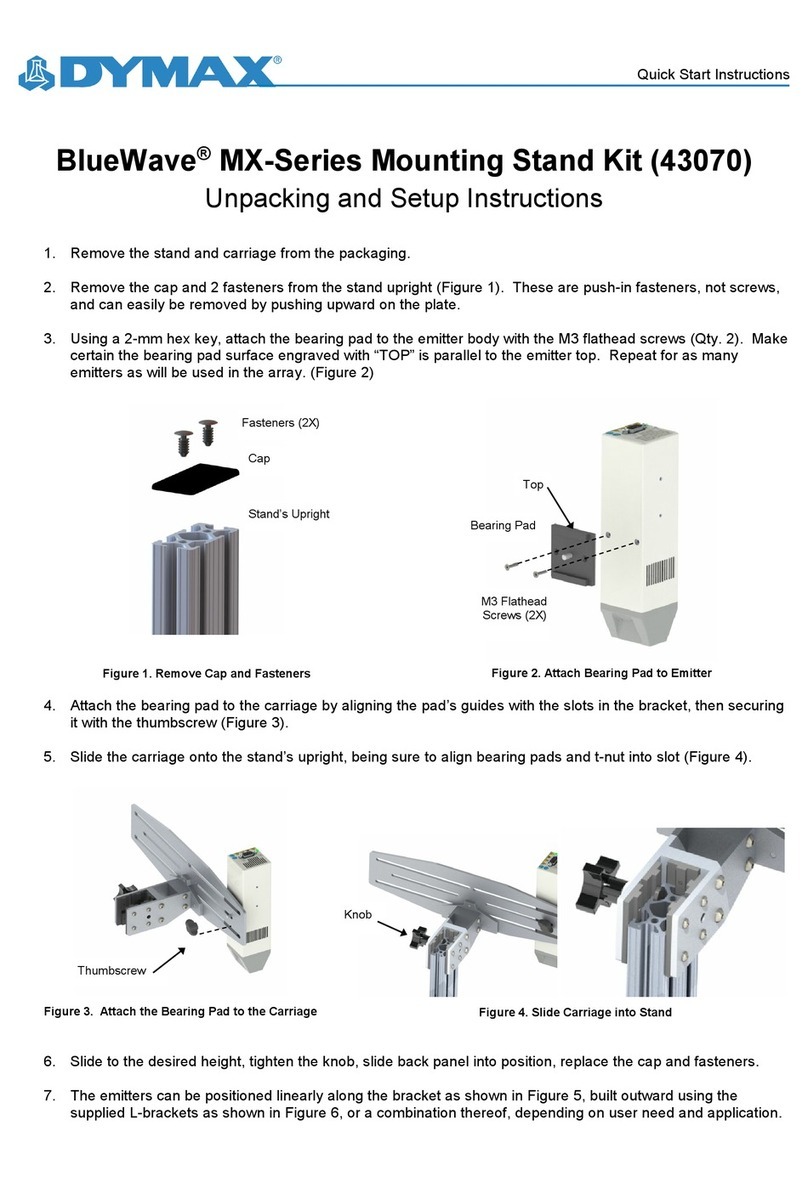

Unpacking..................................................................................................................................................... 13

Unpacking and Inspecting Your Shipment .................................................................................................. 13

Parts Included ............................................................................................................................................. 13

System Setup ................................................................................................................................................ 14

System Connections .................................................................................................................................... 14

Modes of Operation ..................................................................................................................................... 15

Manual Mode.............................................................................................................................................. 15

Timed Mode................................................................................................................................................ 15

PLC (Programmable Logic Controller) Operation........................................................................................ 15

Input/Output Interface ............................................................................................................................... 16

Examples of PLC Wiring............................................................................................................................... 18

Examples of Master interlock / System Health Wiring ............................................................................... 20

Operation ..................................................................................................................................................... 21

Admin Screen .............................................................................................................................................. 21

Touch Screen Interface ............................................................................................................................... 21

Irradiation ................................................................................................................................................... 24

Loading and Saving Programs ..................................................................................................................... 25

System Screens ............................................................................................................................................. 25

System Information..................................................................................................................................... 25

Curing Time Screen ..................................................................................................................................... 26

Power Level Screen ..................................................................................................................................... 26

Cure Delay Screen ....................................................................................................................................... 27

Production Screen....................................................................................................................................... 28

PLC Screen................................................................................................................................................... 28

Program Screen........................................................................................................................................... 29

Program Name Screen ................................................................................................................................ 29

Settings Screen............................................................................................................................................ 30

User Screen ................................................................................................................................................. 30

New Password Screen................................................................................................................................. 31