PKT-GD/GS-IM-DE-B-EN-09-19 Rev.0 9

Use head protection!

Wear suitable head protection

during transport.

Use protective clothing!

Wear suitable protective clothing

during commissioning, mainte-

nance and troubleshooting.

Use hand protection!

Wear suitable hand protection

during transport, commissioning,

maintenance and troubleshooting.

2.6 Personnel qualification

Only trained or instructed personnel who

has known and understood the operating

instructions as well as the possible dangers

of the rotary actuator is allowed to work with

the rotary actuator. The responsibility of the

personnel for operation, maintenance and

repair must be clearly defined by the oper-

ator.

Personnel to be trained, instructed or un-

dergoing training may work on the rotary

actuator only under the constant supervi-

sion of an experienced person.

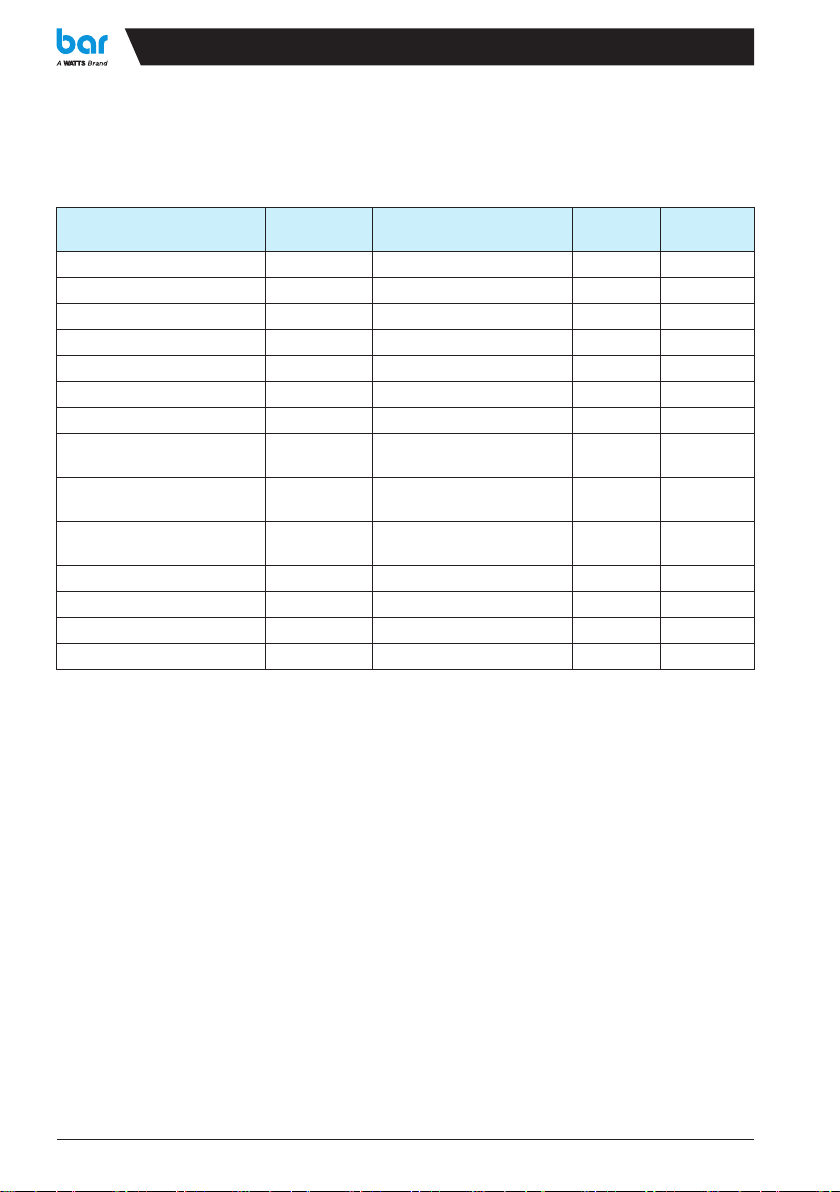

The individual activities on the rotary actua-

tor require different personnel qualifications

which are listed in the following table. The

different qualifications are characterized by

the following skills and knowledge:

• Instructed persons must operate the rotary actuator and be able to detect possible

damage and dangers on the rotary actuator.

• Instructed persons with technical training must also be aware of the dangers of han-

dling pressurized equipment, hot and cold surfaces, harmful and hazardous materials

and the process of installing and removing the valves in a process line, the specific and

potential risks of the process and the most important safety regulations.

• Trained electricians must read and understand electrical circuit diagrams, commission,

put electric machines into operation, service and maintain them, wire switch and control

cabinets, install control software, ensure the functionality of electrical components and

identify potential hazards in handling electrical and electronic systems.

• Trained pneumatic specialists must read and understand pneumatic circuit diagrams,

put pneumatic systems into operation, service and maintain them, disconnect and

connect pneumatic hoses, ensure the proper functioning of pneumatic components,

assess the work performed on the pneumatic system and identify potential hazards.