Becker & Hickl DCC-100 User manual

1

Becker & Hickl GmbH March 2005 Printer HP 4500 PS

Intelligent Measurement

and Control Systems

DCC-100

Detector Control Module

PCI compatible detector control module for single photon counting experiments

- Power supply and gain control for Hamamatsu H7422, H5783 or H5773 modules

- Gain control for Hamamatsu R3809U MCP via FuG power supplies

- Overload shutdown of detectors in conjunction with bh HFAC-26 preamps

- Power supply for thermoelectric coolers, particularly for H7422

- Short circuit protected +12V, +5V and -5V power supply for preamps and detectors

- Software switched +12V, +5V and -5V power supply outputs for detector on/off control

- High current digital outputs for shutter and filter control

- PCI card, software for Windows 95, 98, 2000 and NT

'Tel. +49 / 30 / 787 56 32

FAX +49 / 30 / 787 57 34

http://www.becker-hickl.com

2

Contents

Introduction..............................................................................................................................................................3

Structure of the DCC-100 ........................................................................................................................................3

Detector control blocks .......................................................................................................................................3

High Current Switch Block .................................................................................................................................4

Power supply for thermoelectric cooler...............................................................................................................4

Applications.............................................................................................................................................................5

Controlling H5783 and H5773 photosensor modules..........................................................................................5

Controlling the H7422 and H8632 ......................................................................................................................5

Controlling an R3809U MCP PMT.....................................................................................................................6

Controlling PMH-100 detectors ..........................................................................................................................6

Controlling Shutters.............................................................................................................................................7

Installation................................................................................................................................................................8

Requirements to the Computer............................................................................................................................8

Installation of the DCC-100 Software .................................................................................................................8

Software Update..................................................................................................................................................8

Update from the Web .....................................................................................................................................8

Installation of the DCC-100 Module...................................................................................................................9

Shutdown of High Current Switches...............................................................................................................9

Software.................................................................................................................................................................10

Startup Panel .....................................................................................................................................................10

Main Panel.........................................................................................................................................................10

Power-On State.............................................................................................................................................10

State after Software Start..............................................................................................................................10

Controls for Power Outputs and Detector Gain............................................................................................11

Detector Overload ........................................................................................................................................11

High Current Switches..................................................................................................................................12

Disable Output Function...............................................................................................................................12

Cooler Control..............................................................................................................................................12

Saving and Loading the Setup...........................................................................................................................12

Pin Assignment ......................................................................................................................................................13

Specification...........................................................................................................................................................14

Index ......................................................................................................................................................................15

3

Introduction

The DCC-100 module is used to control detectors in conjunction with bh photon counters. It

can be used to control the gain of the Hamamatsu H7422, H5783, H6783 or similar

photosensor modules by software. The gain of MCPs and PMTs can be controlled via the FuG

HCN-14 high voltage power supply. In conjunction with bh preamplifiers, overload shutdown

of the detectors can be achieved. Furthermore, the DCC-100 delivers the current for

thermoelectric coolers, e.g. for the Hamamatsu H7422. High current digital outputs are

available for shutter or filter control. The DCC-100 is a PCI module for IBM compatible

computers. It works under Windows 95, 98, 2000 and NT.

Structure of the DCC-100

The block diagram of the DCC-100 is shown in the figure below.

+12V

Short Protection

on/off

Short Protection

Short Protection

+5V

-5V

on/off

Overload

Flip-Flop

+12V

+5V

-5V

0..0.9V

0..10V

/OVLD

on/off

Vcont

reset

shdn

shdn

Connector 1

+12V

on/off

+5V

-5V

on/off

Overload

Flip-Flop

+12V

+5V

-5V

0..0.9V

0..10V

/OVLD

on/off

Vcont

reset

shdn

shdn

Connector 3

+12V

on/off

+5V

-5V

on/off

+12V

+5V

-5V

on/off

Power Switches

on/off

Connector 2

shdn shdn

Peltier Power

Supply

0..5V 0..2A

Pel+

Pel-

Vpel

Ipel

on/off

Jumper

Detector Control Detector ControlPower Switches

DCC-100 Block Diagram

12 bit DAC 12 bit DAC

Detector GainDetector Gain

Short Protection

Short Protection

Short Protection

Short Protection

Short Protection

Short Protection

The DCC-100 contains two detector control blocks and one general purpose power switch

block.

Detector control blocks

The detector control blocks contain power supply outputs for detectors, a digital-to-analog

converter (DAC) for detector gain control, and an overload shutdown circuit.

The power supply outputs are short-circuit-protected and deliver +12 V, +5 V and -5 V. The

outputs can be switched on an off by software.

A 12 bit DAC is used to control the gain of the detector. It delivers the 0 to +1.0 V control

voltage required for Hamamatsu photosensor modules (H7422, H5783, H5773 etc.) and a

0 to +10 V control voltage for FuG high voltage power supplies.

Both detector control blocks have a detector overload shutdown function. The shutdown

function works in conjunction with bh HFAC-26 preamplifiers. If the preamplifier detects an

overload condition it sends an active low overload signal (/ovld) to the DCC-100. This signal

sets the overload flip-flop which shuts down the detector control voltage and the +12 V

detector power supply. Furthermore, it can be used to deactivate the switches in the power

switch block (see below).

One of the detector control blocks contains a power supply for thermoelectric coolers.

4

High Current Switch Block

The high current switch block contains power supply outputs for detectors and preamplifiers

and eight high-current MOSFET switches to operate shutters, motors or magnetic actuators.

The power supply outputs are short-circuit-protected and deliver +12 V, +5 V and -5 V. The

outputs can be switched on an off by software.

The MOSFET switches are able to switch currents up to 2A and voltages up to 20V. One side

of each switch is connected to ground, the other side is available at the output connector. The

switches are not short circuit protected.

The high current switches can be shut down (i.e. set into the non-conducting state) by one or

both overload signals from the detector control blocks. The configuration is set by jumpers on

the DCC-100 board, see ‘Configuration of Power Switch Shutdown’.

Power supply for thermoelectric cooler

Power supply for thermoelectric coolers is available at connector 3. The output delivers up to

5 V and 2 A. Both voltage and current can be selected by software. The device automatically

controls either the output voltage or the output current. Voltage control is active as long as the

current through the load is smaller than the current limit set by the software. When the current

through the load reaches the current limit the device automatically switches to current control.

A block diagram is shown in the figure below.

Switching

Regulator

+12V

from PC

feedback -

+

reference

'current'

reference

'voltage'

PEL+

PEL-

Cooler

+

-

0.25 Ohm

Power supply for cooler

R1

R2 R3

A1

D1

A switching regulator is used to generate the supply current for the cooler. The cooling current

flows through the sensing resistor R3. As long as the voltage at R3 is smaller than the

reference voltage at A1 (‘current’ reference) A1 is inactive and the switching regulator works

as a normal voltage stabiliser. If the voltage at R3 exceeds the reference voltage at A1, the

amplifier becomes active, and, via D1, overwrites the feedback voltage of the switching

regulator. This causes the regulator to reduce the output voltage until the voltage at R3 equals

the reference of A1.

Please note that the current control can work only if the cooling current flows back into the

’PEL-‘ pin of the DCC-100. Therefore make sure that the ‘-‘ side of the cooler is not

connected to ground. Moreover, make sure that you don’t reverse the ’PEL+‘ and ’PEL-‘

lines. This would heat the detector instead of cooling it and probably result in severe damage

of the detector assembly.

5

Applications

Some applications of the DCC-100 are described below.

Controlling H5783 and H5773 photosensor modules

The H5783 and the H5773 are high speed miniature PMT

modules of Hamamatsu. The modules contain a small

photomultiplier along with high voltage generator. The

resolution in the TCSPC (time-correlated single photon

counting) mode is typically 150 to 200 ps. The H5783

comes in various cathode versions for the wavelength

range up to 820 nm. The H5783 can be controlled in a

similar way as the H7422. The connections are shown in

the figure right. A HFAC-26-10 preamplifier with a

10 µA overload threshold is used to amplify the single

photon pulses and to send an overload signal to the

DCC-100.

A second H5783 can be controlled separately via connector 1. In this case the power supply

for both HFAC amplifiers should be taken from connector 2.

Don’t connect or disconnect the signal cable from the detector to the preamplifier when the

detector is switched on. This can destroy the amplifier. Make sure that the +12 V at connector

2 is switched on. Otherwise the HFAC does not work, and the overload protection is inactive.

Controlling the H7422 and H8632

The H7422 is a high speed, high sensitivity PMT

module of Hamamatsu. It contains a GaAs

photomultiplier along with a thermoelectric

cooler and a high voltage generator. The

resolution in the TCSPC (time-correlated single

photon counting) mode is typically 250 ps. The

H7422 comes in different cathode versions for the

wavelength range up to 900 nm. The H8632 is

available for the wavelength range up to 1100nm.

The recommended connection to the DCC-100 is

shown in the figure right. The detector is

connected to ‘Connector 3’ of the DCC-100. The

DCC-100 delivers the +12 V operating voltage, the 0 to 1.0 V gain control voltage, and the

current for the thermoelectric cooler.

The output signal of the PMT is amplified by the HFAC-26-1 preamplifier. The single photon

pulses at the output of the amplifier have a few 100 mV amplitude and are used to trigger the

CFD input of a bh TCSPC module (SPC-300 through SPC-730, see manual at www.becker-

hickl.de).

The HFAC-26-1 amplifier monitors the output current of the H7422. If an average current of

1 uA is exceeded the /ovld signal of the HFAC-26 goes to ‘low’. This sets the overload

flip-flop in the DCC, and the gain control voltage and the +12 V at connector 3 are shut down.

Notice: The H7422 has its own overload shutdown. The H7422 may shut down if the gain

control voltage changes at a rate faster than 10 V/s. The changing rate of the gain control

to SPC module

CFD in

HFAC-26-10

PMTOut

/ovld

+12V

Gain Cont 0..0.9V

+12V

DCC

H5783P

Power supply and gain control of H5783

with overload shutdown

+12V

1

2gnd

3

gnd

to SPC module

CFD in

HFAC-26-1

PMTOut

/ovld

+12V

Gain Cont 0..0.9V

Peltier +

Peltier -

Fan

+12V

DCC

H7422

Power supply and gain control of H7422

with overload shutdown

+12V

1

gnd

2

3

gnd

6

voltage in the DCC-100 is kept below the critical value. If the H7422 shuts down internally

for whatever reason, it can only be re-activated by cycling the +12 V operating voltage.

Don’t connect or disconnect the signal cable from the detector to the preamplifier when the

detector is switched on. This can destroy the amplifier. Make sure that the +12 V at

connector 2 is switched on. Otherwise the HFAC does not work, and the overload protection

is inactive.

Controlling an R3809U MCP PMT

The Hamamatsu R3809U is the fastest photon counting detector currently available. It uses a

microchannel plate for electron multiplication. In the TCSPC mode a time resolution of less

than 30 ps (fwhm) can be achieved. MCP PMTs are extremely sensitive to overload. Because

the microchannels are continuously destroyed by sputtering the lifetime of the detector is

limited. The degradation effect is not noticeable under normal operating conditions. However,

overloading the detector can rapidly exhaust the residual lifetime. Therefore, MCP PMTs

should always be operated with overload protection, or at least with an overload indicator.

The figure right shows how an R3809U MCP can be

operated with overload protection. An FuG HCN-14-

3500 is used as an high voltage power supply for the

R3809U. The HCN-14 is available with a 0 to 10 V

control input. The high voltage is proportional to the

control voltage. Therefore, the detector operating

voltage can be controlled by the DCC-100 and be shut

down on overload.

For overload detection, the HFAC-26-01 preamplifier

- with an overload threshold of 0.1 µA - is used.

Notice: Please observe the usual safety rules when

working with high voltage. Make sure that there is a

reliable ground connection between the detector and

the HV power supply. Don’t use broken cables, loose

connectors or cables with insufficient insulation.

Don’t connect or disconnect the signal cable from the detector to the preamplifier when the

detector is switched on. This can destroy the amplifier. Make sure that you connected all

ground connections. Missing ground connections can result in high voltage instability or

unreliable overload shutdown.

Make sure that the +12 V at connector 2 is switched on. Otherwise the HFAC does not work,

and the overload protection is inactive.

Controlling PMH-100 detectors

The PMH-100 of bh is an easy to use detector head that

contains a Hamamatsu photosensor module, a

preamplifier, and an optical and acoustical overload

indicator. due to its compact design it has an excellent

noise immunity and a TCSPC time resolution of 140ps to

200ps (fwhm of system response).

Since there is no overload signal available from the PMH-

100 it cannot be automatically shut down on overload. Up

to three detectors can, however, switched on and off via

the DCC-100. By connecting the detectors to a bh SPC

module via a HRT-41 or HRT-81 router the signals of all

to SPC module

CFD in

HFAC-26-01

MCP Out

/ovld

HV Cont 0..10V

+12V

DCC

Overload shutdown for R3809U MCP

R3809U

HV

gnd

/ovld

HCN

FuG

gnd

DCC

Switching on/off PMH-100 detectors

+12V switchable

+12V switchable

to SPC, CFD

PMH-100

PMH-100

PMH-100

+12V switchable

gnd

gnd

gnd

HRT-41

Routing

Module

1

2

3

7

detectors can be recorded simultaneously. Or, by switching only one detector on, the desired

detector can be selected for measurement. The configuration is exceptionally useful for laser

scanning microscopes which normally use several detectors in different light paths.

Controlling Shutters

Shutters or other actuators can be controlled

via the high current switches of connector 2.

The switches can operate a voltage up to 20 V

and up to 2 A. The power supply for the

external load can be taken from connector 2 if

a current of 100 mA at +12 V or 200 mA at

+5 V is not exceeded. For higher currents an

external power supply must be used.

Since shutters and other magnetic devices are

inductive loads a flyback diode must be

connected across the load. For supply voltage

up to 12 V a resistor can be connected in series

with the flyback diode to achieve a faster turn-

off time. The value of the resistor should be

about the DC resistance of the actuator or

shutter coil.

The switches can automatically be shut down (i.e. set into the non-conducting state) when an

overload condition occurs at connector 1 or connector 3. Which of the overload inputs is used

for shutdown can be selected by jumpers on the DCC-100 board, see ‘Shutdown of High

Current Switches’.

Sometimes it is required to lock a shutter in the

‘closed’ state as long as a potential overload

condition persists. An example is a microscope

with a mercury or halogen lamp. When the

lamp is on, opening the shutter must be

inhibited. A solution is shown in the figure

right. The photodiode detects the light from the

lamp, and the amplifier sends an ‘/ovld’ to the

DCC-100. The signal can be connected parallel

to the /ovld from the amplifier.

As long as the lamp is on, /ovld remains ‘low’

and the shutter cannot be opened. This gives

additional safety against detector damage.

It must, however, be pointed out that an

absolute safety against detector damage cannot

be achieved in this way. If the lamp is switched on when the shutter is open it takes a few

milliseconds until the overload is detected and the shutter closes. This can be enough to cause

severe detector damage. Therefore, the best way is always an mechanical interlock so that the

lamp path is closed when the detection path is opened.

DCC

b0 Out

+12V

+12V

b1 Out

Shutter

Filter

Actuator

1

2

3

+12 to +20V

to switch

<+12V

to switch

Controlling shutters and filters

DCC

1

-

+

10p

100M

1k

BC850 AD820

BPW34

/ovld

+12V

b0

Photodiode

in front of

shutter

3

2

HFAC26

+12V

shutter

Detector

Photodiode

light path

off-closed

/ovld

Locking a shutter in a potential overload situation

8

Installation

Requirements to the Computer

The computer must be a Pentium PC with a graphics card of 1024 by 628 resolution or more.

There must be enough free PCI slots to insert the required number of DCC-100 modules.

Although computer speed is usually not an issue for the DCC-100 we recommend a computer

with a speed of at least 300 MHz.

Installation of the DCC-100 Software

The installation of the DCC-100 Standard Software is simple - start setup.exe from the

installation disk.

You can install the software also from the Becker & Hickl web site, e.g. if you want to

upgrade your system with a new computer and a new DCC software version has been released

in the meantime. In this case proceed as described under ‘Update from the Web’.

The DCC software is based on 'LabWindows/CVI' of National Instruments. Therefore the so-

called 'CVI Run-Time Engine' is required to run the DCC software. The 'Run-Time Engine'

contains the library functions of LabWindows CVI and is loaded together with the DCC

software. The installation routine suggests a special directory to install the Run-Time Engine.

If the required version of the Run-Time Engine is already installed for another application, it

is detected by the installation program and shared with the existing LabWindows CVI

applications.

Software Update

If you install a new DCC software version over an older one only the files are copied which

have a newer date. This, to a certain extend, avoids overwriting setup files such as auto.set

(the last system settings). Consequently, you cannot install an older software version in place

of a newer one. If you want to do this (normally there is no reason why you should), run the

‘Uninstall’ program before installing.

Update from the Web

The latest software versions are available from the Becker & Hickl web site. Open

www.becker-hickl.de, and click on ‘Software’.

9

Click on ‘Download’, ‘Windows 95/98/NT/2000’. Choose the DCC-100 software and get a

ZIP file containing the complete installation. Unpack this file into a directory of your choice

and start setup.exe. The installation will run as usual.

For a new software version we recommend also to download the corresponding manual. Click

on ‘Literature’, ‘Manuals’ and download the PDF file. Please see also under ‘Applications’ to

find notes about typical applications of the DCC in conjunction with bh photon counters.

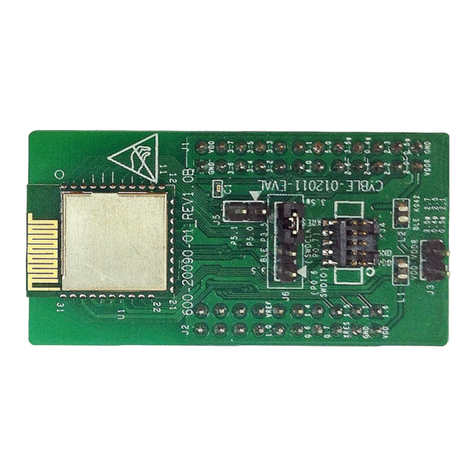

Installation of the DCC-100 Module

To install the DCC-100, switch off the computer and insert the DCC module(s). To avoid

damage due to electrostatic discharge we recommend to touch the module at the metallic back

shield. Then touch a metallic part of the computer with the other hand. Then insert the module

into a free slot of the computer.

The DCC-100 has a PCI interface. Windows has a list of PCI devices, and on the start of the

system it automatically assigns the required hardware resources to the components of this list.

When the computer is started first time with the DCC inserted Windows detects the DCC and

updates the list of hardware components. Therefore it may ask for driver information from a

disk. Although this information is not actually required for the DCC you should select the

driver information file from the driver disk delivered with the module.

If you don’t have the driver disk, please download the driver file from www.becker-hickl.com

or www.becker-hickl.de, ‘Software’, ‘Windows 95/98/NT/2000’ ‘Device drivers for bh

modules’.

Shutdown of High Current Switches

The high current switches can be shut down (i.e. set into the

non-conducting state) by one or both overload signals from the

detector control blocks. The configuration is set by jumpers on

the DCC-100 board. The location of the jumpers is shown in

the figure below.

If the jumpers ‘SHDN1’ or ‘SHDN3’ are set the high current

switches are deactivated when an active ‘/overload’ signal is

detected at connector 1 or connector 3, respectively. If both

jumpers are set the switches are deactivated by both

‘/overload’ signals.

To operate the peltier cooling unit of an H7422 or PMC-

100 detector the jumper next to the output connector must

be removed (opened). Please make sure that the jumper at

the connector which is NOT attached to an H7422 (PMC-

100 ) is closed if only one detector is used. NEVER

CLOSE BOTH JUMPERS SIMULTANEOUSLY.

Please note: If two H7422 ( PMC-100 ) detectors are

operated simultaneously the cooling units of both

detectors are supplied in a series connection. As a

consequence the sliders to control the coolers are used in

common.

DCC

1

2

3

Remove jumper

when connecting a

H7422 or PMC-100

Close jumper ONLY if

J1

J3

J1 is removed !

to connector 1

10

Software

Startup Panel

The DCC standard software is able to control up to four DCC-100 modules. The startup

window is shown in the figure below.

The installed modules are marked as ‘In use’ and

shown with their serial number, PCI address and

slot number. When the startup window appears,

click on ‘OK’ to open the main window of the DCC

software.

The software runs a simple hardware test when it

initialises the modules. If an error is found, a

message ‘Hardware Errors Found’ is given and the

corresponding module is marked red. In case of non-

fatal hardware errors you can start the main window

by selecting ‘Hardware Mode’ in the ‘Change

Mode’ panel. Please note that this feature is

intended for trouble shooting and repair rather than for normal use.

Main Panel

The main panel is shown in the figure right. The

panel contains the controls for the power supply

outputs, the high current switches, and for the peltier

cooling.

Power-On State

Before the software takes control over the DCC the

DCC control registers are in an undefined state. To

avoid that the detectors are activated and possibly

operated at a too high gain, after power-on the

detector overload flip-flops are in the ‘Overload

Shutdown’ state. That means, the +12V and the

detector control voltages at connector 1 and 3 are

shut down. If the jumpers for the shutdown of the

high current switches are set also the switches are in

the ‘off’ state.

When the DCC software starts, it loads the previously

used parameters into the DCC registers.

State after Software Start

When the DCC software starts, it automatically reloads the

settings of the last use. These setting are saved an a file

‘auto.set’ which is updated every time when you exit the DCC

software.

After a software start, the DCC outputs are activated only if

the ‘Enable Outputs on Startup’ option is switched on. ‘Enable

Outputs on Startup’ can be switched on and off under

‘Parameters’, see figure right. We recommend to use the

Startup Panel

DCC main panel after power-on. ‘Enable

Outputs on Startup’ is switched off.

‘Enable Outputs on Startup’ option

11

automatic enable only if detector damage or any hazard due to high voltage is reliably

excluded.

If the outputs are disabled they can be enabled via the ‘Enable Outputs’ button at the bottom

of the main panel.

Controls for Power Outputs and Detector Gain

The main panel is structured into ‘Connector 1’,

‘Connector 2’, ‘Connector 3’, and ‘Cooling’. To

switch on or off one of the output signals click on

the corresponding button. The detector gain

control signals are changed by dragging the

vertical bars or by typing in a value between 0 and

100%. Please note, that the Gain / HV signals

control the high voltage of the detectors.

Therefore, the detector gain is not proportional to

the control signal. For PMTs and MCPs the

relation is approximately

GAIN = Vcontrol n

with n ranging from 2.5 to 5. Therefore, the

relation is highly nonlinear, and the PMT gain

varies over several orders of magnitude. Don’t be

surprised that photon counting works only at a HV

setting close to the maximum.

Detector Overload

If a PMT overload is detected the ‘OVLD’ light of

the corresponding connector turns on and a

warning (flashing ‘!’) is issued. At the same time

the detector control signal and the +12 V at the

corresponding connector are shut down. You can

also disable the high current switches on overload,

e.g. to close shutters. To disable the switches from

the overload flip-flops of connector 1 or 2 jumpers

on the DCC board have to be set.

To switch on the detector(s) after an overload

shutdown, click on the ‘RESET OVLD’ button.

Make sure that the overload has been removed

before you reset the detectors.

Safety note: Please make sure that you don’t

exceed the maximum values for your detector(s).

Particularly, if you control a HV power supply,

make sure that it is safe to turn on or increase the

voltage. Although the DCC-100 contains some

safety features, such as detector shutdown at

power-on or overload, it cannot be made safe in terms of operator errors, such as turning on

HV power supplies with open or wrong connected output cables, or exceeding the maximum

operating voltage for a given detector. bh will not take responsibility for accidents or detector

damage resulting from setting or loading values exceeding maximum values for a given

experiment setup.

DCC main panel, detectors activated

DCC main panel, after overload

12

High Current Switches

The high current switches can be switched on and off independently by the control buttons

under ‘Connector 2’. All switches can be disabled (i.e. switched into the non-conducting state)

be the ‘Disable Outputs’ button.

The high current switches can be shut down (i.e. set into the non-conducting state) by one or

both overload signals from the detector control blocks. The configuration is set by jumpers on

the DCC-100 board, see ‘Installation’, ‘Shutdown of High Current Switches’.

If the high current switches have been deactivated by detector overload they must be explicitly

switched on after the overload condition is removed.

Disable Output Function

The power supply outputs, the detector gain signals and the high current switches can be

disabled and enabled by the ‘Disable Output’ or ‘Enable Output’ button. You can

automatically disable all outputs at the start of the software to bring the system in a safe state

before you switch on the detectors. The ‘Disable on Start’ function can be switched on and off

under ‘Parameters’.

Cooler Control

The cooling current can be switched on and off by clicking on the ‘ON’ button. To control the

cooling power, you can set an output voltage and an output current. Of course, setting voltage

and current in an electrical circuit simultaneously is impossible. The cooling power supply

works in a way that the voltage at the output is controlled as long as the specified current is

not reached. When the specified current is reached current control takes over and the current is

controlled. In other words, the cooling is controlled in way that neither the selected voltage

nor the selected current is exceeded. Current control is indicated by the ‘Curr Lmt’ light.

Saving and Loading the Setup

To load or to save the DCC setup, click on

‘Main’ in the menu bar and select ‘Save’ or

‘Load’. The ‘Save’ and ‘Load’ menus are

shown below.

When you save a setup you first have to enter

a file name or to select a file name by

clicking into the ‘file name’ field. There you

can also change to other directories or drives.

A history of file names is available via the

‘’ button right of the file name.

Then you can - but need not - type in the

operator name, a company name, and a

description for what your setup is.

13

Loading a setup file works in a similar way.

Click on the ‘file name’ field and select the

correct setup file. In the ‘File Info’ field you

will see the information typed in when the

file was saved. If it is the right file, click on

‘Load’.

Note: Please make sure that you load the

right file for your experiment setup.

Although the DCC-100 contains some safety

features, such as detector shutdown at power-on or overload, it cannot be made safe in terms

of operator errors, such as turning on HV power supplies with open or wrong connected

output cables, or exceeding the maximum operating voltage for a given detector. bh will not

take responsibility for accidents or detector damage resulting from setting or loading values

exceeding maximum values for a given experiment setup.

Pin Assignment

Connector 1

15pin HD-SubD

Pin Signal

1 +5V out switchable

2

3

4

5 GND

6 -5V out switchable

7

8

9

10 +12V out switchable, ovld sdwn

11 -12V out

12 0...+10V HV cont., ovld sdwn

13 0...+1.0V gain cont., ovld sdwn

14 /OVLD1 input

15 GND

Connector 2

15pin HD-SubD

Pin Signal

1 +5V out switchable

2 Bit0 open drain out

3 Bit1 open drain out

4 Bit2 open drain out

5 GND

6 -5V out switchable

7 Bit3 open drain out

8 Bit4 open drain out

9 Bit5 open drain out

10 +12V out switchable

11 -12V out

12 Bit6 open drain out

13 Bit7 open drain out

14

15 GND

Connector 3

15pin HD-SubD

Pin Signal

1 +5V out switchable

2 Peltier +

3 Peltier +

4 Peltier +

5 GND

6 -5V out switchable

7 Peltier -

8 Peltier -

9 Peltier -

10 +12V out, switchable, ovld sdwn

11 -12V out

12 0...+10V HV cont., ovld sdwn

13 0...+1.0V gain cont., ovld sdwn

14 /OVLD3 input

15 GND

14

Specification

Power Supply Outputs (Connectors 1 to 3)

Max. Current at +12 V 100 mA

Short Circuit Current +12 V 50 mA 1)

Time from /OVLD to disable +12V 10 ms 2)

Output current in disabled state, +12 V < 0.5 mA

Max. Current at +5 V 200 mA

Short Circuit Current +5 V 60 mA 1)

Output current in disabled state, +5 V < 0.5 mA

Max. Current at -5 V 200 mA

Short Circuit Current -5 V 60 mA 1)

Output current in disabled state, -5 V < 0.5 mA

Max. Current at -12 V total 120 mA, single output 60 mA

Short Circuit Current -12 V No short protection. Don’t short longer than 1s

1) Foldback Characteristics, don’t short several outputs simultaneously for more than 20s

2) Connectors 1 and 3 only. 250 load, time from +12V to +6V output voltage.

Detector Gain Control (Connectors 1 and 3)

Resolution 12 bit

Voltage Range Pin 12 0 to +10 V

Load at Pin 12 min. 1 k

Output Resistance at Pin 12 100

Voltage Range Pin 13 0 to +1.0 V

Load at Pin 13 min. 1 k

Output Resistance at Pin 13 100

Output Time Constant 100 ms

Overload Shutdown

Overload inputs at connector 1 and 3 TTL, active Low, Pull-up resistor 10 k

Overload Reset By Software and at Power-ON

High Current Switches (Connector 2)

Typical ‘On’ Resistance, 25°C 70 m

Max. Switch Current, Single Switch 2 A

Max. Switch Current, Sum of all Switches 5 A3)

Max. turn-off Voltage at Switch 20 V

Turn-on and turn-off transition time, Load 10 100 ns

Disable on /OVLD if configured by jumpers

Disable Transition Time < 1 us

Time from /OVLD to Disable < 2 us

3) Both GND pins used

Supply for Thermoelectric Coolers (Connector 3)

Output Voltage 0 to 5 V

Output Current 0 to 2 A

Resolution of Output Voltage and Current 12 bit

Output Resistance 0.4 4)

Output Capacitance 300 uF

Output Ripple < 5 mV

4) All pins parallel

PC Interface

Dimensions 160 mm x 106 mm x 15 mm

Interface / Connector PCI

Register Access I/O only

Supply Current, +5V, No Load, typ. value 0.6 A

Supply Current, +5V, Maximum Load, typ. value 1.2 A

Supply Current, +12V, No Load, typ. value 0.2 A

Supply Current, +12V, Maximum Load, typ. value 1.6 A

15

Index

/ovld signal 5

Block Diagram of DCC-100 3

Computer, Requirements for DCC 8

Connectors, Pin Assignment 13

Controls, for Cooling 12

Controls, for Detector Gain 11

Controls, for High Current Switches 12

Controls, for Power Outputs 11

Cooler Control 4, 12

Cooling Current 4, 12

Cooling Voltage 4, 12

Current Limit Light 12

CVI Run-Time Engine 8

Detector Control 3

Detector Control Blocks 3

Detector Control Blocks, Overload Shutdown 3

Detector Control Signal 3

Detector Control, DAC 3

Detector Gain 11

Detector Overload 11

Detector Shutdown 11

Device Drivers 9

Disable on Start Function 12

Disable Outputs Button 12

Disable Outputs Function 12

Download, Manual 9

Download, Software 8

Driver Disk 9

Driver, for DCC-100 Module 9

Enable Outputs Button 12

Enable, outputs on startup 11

File, Save and Load 12

Flyback Diode 7

Gain Control Signal 5

H5773 5

H5783 5

H7422 5

H8632 5

Hardware Test 10

HCN-14-3500 6

HFAC-26 Preamplifier 5, 6

High Current Switches 4, 7

High Current Switches, Controls, for 12

High Current Switches, shutdown 4, 9

High Voltage Power Supply 6

High Voltage, Safety Rules 6

HRT-41 7

HRT-81 7

Inductive Load 7

Installation, of DCC Module 9

Installation, of DCC Software 8

Installation, of DCC-100 Driver 9

LabWindows/CVI 8

Load Setup 12

Main Panel 10

Manual, Download 9

Manual, pdf File 9

MCP 6

MCP, Lifetime 6

MCP, Overload 6

MCP, Power Supply 6

Microchannel Plate 6

Outputs, enable on startup 11

Overload Flip-Flop 3

Overload Light 11

Overload Shutdown 3, 10, 11

Overload Shutdown, via HFAC-26 Preamp 3, 5, 6

Overload Signal 3, 5

PEL+ and PEL- pins 4

Peltier Control 4, 12

Peltier Current 4, 12

Peltier Voltage 4, 12

Pin Assignment, of Connectors 13

PMH-100 6

Power Outputs, Switching ON/Off 11

Power Supply, for High Current Switches 7

Power Supply, for MCP 6

Power Supply, High Voltage 6

Power-On, State after 10

Preamplifier 5, 6

Preamplifier, for H5783 and H5773 5

Preamplifier, for H7422 5

Preamplifier, for MCP 6

R3809U 6

Reset, after Detector Shutdown 11

Router 7

Safety Notes 4, 6, 11, 13

Safety Notes, Cooler 4

Safety Notes, High Voltage 6

Save Setup 12

Setup, Load 12

Setup, Save 12

setup.exe 8

Shutdown, at Power-On 10

Shutdown, H7422 5

Shutdown, of Detectors 3, 11

Shutdown, of high current switches 4, 7, 9, 12

Shutter, Locking 7

Shutters 7

Software Start, State after 10

Software, for DCC-100 10

Software, Installation 8

Software, Update 8

Software, Update from the Web 8

Specification 14

Startup Panel 10

Structure of DCC-100 3

Thermoelectric Coolers 4

Table of contents

Popular Control Unit manuals by other brands

Siemens

Siemens SIPROTEC 4 7XT71 Series manual

WEG

WEG CFW500 Series Installation, configuration and operations guide

dehn

dehn Blitzductor BXT ML4 BD EX 24 installation instructions

Allen-Bradley

Allen-Bradley ArmorBlock Series Wiring diagrams

National Instruments

National Instruments NI 9474 Getting started

Honeywell

Honeywell DR 300 installation instructions