1640-IN-026-A-00 Page 2 of 10

1.0 INTRODUCTION

The Society of the Plastic Industry, Inc. has established a

standard communication protocol (SPI) that provides a plat-

form for instrumentation manufactured by different compa-

niestocommunicatetogetheronthesameRS-485localarea

network.

TheSPIAuxiliaryEquipmentInterfacemodule(71-946-X)will

allow the MACO®4000, 5000 and 6000 Series controllers to

communicate (via SPI protocol) with auxiliary equipment

typically found in plastic molding, extruding or blowmolding

facilities, including mold temperature controllers, hot runner

controllers,chillers,dryers, additive feeders andmeltpumps.

A maximum of 32 separate devices can be connected to a

MACO on the same SPI auxiliary interface module. With this

interfacethestandardfeaturesoftheMACOcontrollerswould

beutilized, such as recipestorage (allowing fast setup times)

RLDinterface capabilitywithouttheneedfor extensivewiring

to the Sequence inputs/outputs Statistical Process Control

(SPC) of auxiliary equipment parameters.

The SPI Auxiliary Equipment Interface module is pre-config-

ured to communicate with SPI compatible auxiliary equip-

ment. The end user or OEM needs no programming skill, or

knowledge of the intricacies of the SPI protocol. You simply

need to know what SPI compatible devices being used and

the quantity you wish to communicate with. The user needs

a working knowledge of Barber-Colman OptiGrafix and RLD

programming software.

The SPI Auxiliary module will communicate with any device

listed in the current, released version 3.01a of the SPI Phase

I protocol (also listed in section 3.1 of this document). It will

communicate at a user selectable baud rate of 1200, 2400,

4800, 9600, and 19.2K. Every "required" command, as de-

fined by the protocol, for the devices listed are supported in

this release of firmware.

2.0 SETUP INSTRUCTIONS

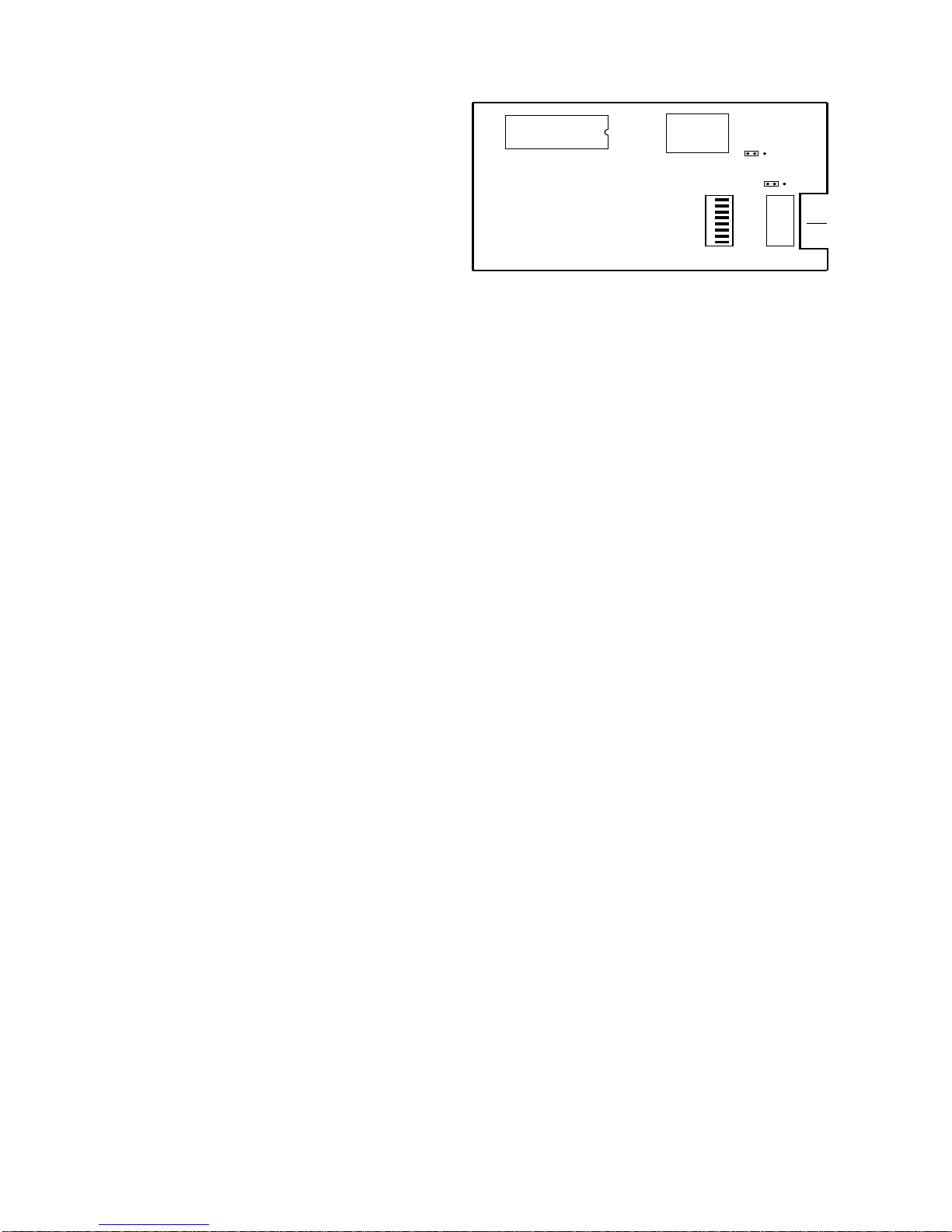

2.1 Board Location

TheSPIAuxiliarymodulemaybeplacedinslot1,2,or3ofthe

communicationsmotherboard(A-13408-1).Thecommunica-

tions motherboard must be installed in primary chassis 1 in a

slotwhichhasacontroldatabusconnector;thisisthemiddle

connector on the back-plane of the MACO controllers. You

may only have one (1) RS-485 SPI Module per system.

The SPI Auxiliary Equipment module can be used with data

handler version V20.75 or newer.

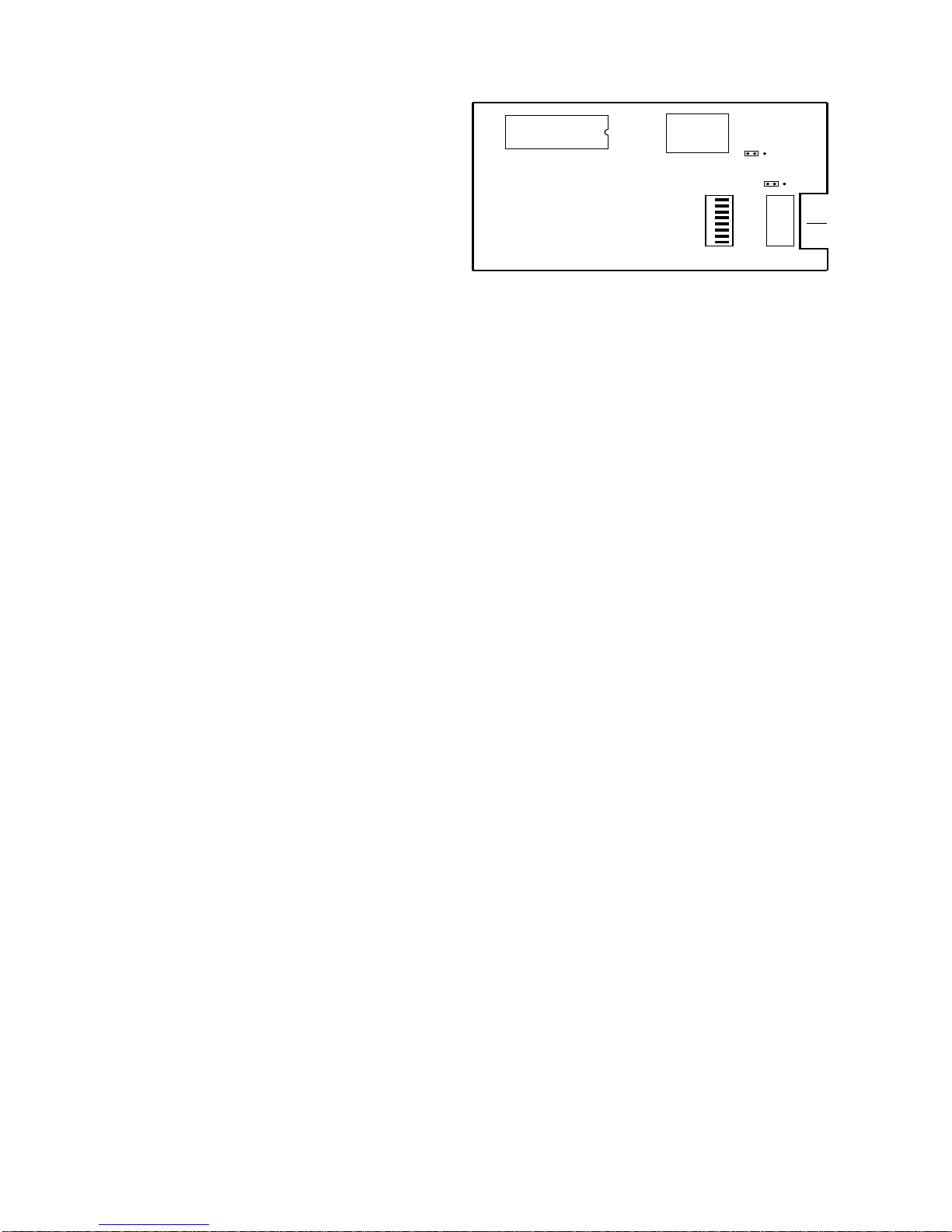

2.2 Jumpers and Switches

There are two hardware jumpers that have to be manual set

before installing the SPI Auxiliary module (daughterboard)

onto the communications motherboard A-13408-1XX.

Jumpers J1 and J2 are to be in the "IN" position, see Figure

2.2. These jumpers connect the bus termination resistors to

the Data(+) and Data(-) terminals.

SHIELD

ISOCOM

DATA

DATA

4

3

2

1

ON OFF

S1

8

7

6

5

4

3

2

1

IN OUT

J1

U10

A-13404-2

RS-485 COMMUNICATIONS

T1

IN OUT

J2

Figure 2.2 SPI Auxiliary Interface module.

2.3 Node Address

ThenodeaddressswitchS1ontheSPIAuxiliarymoduleisnot

used.

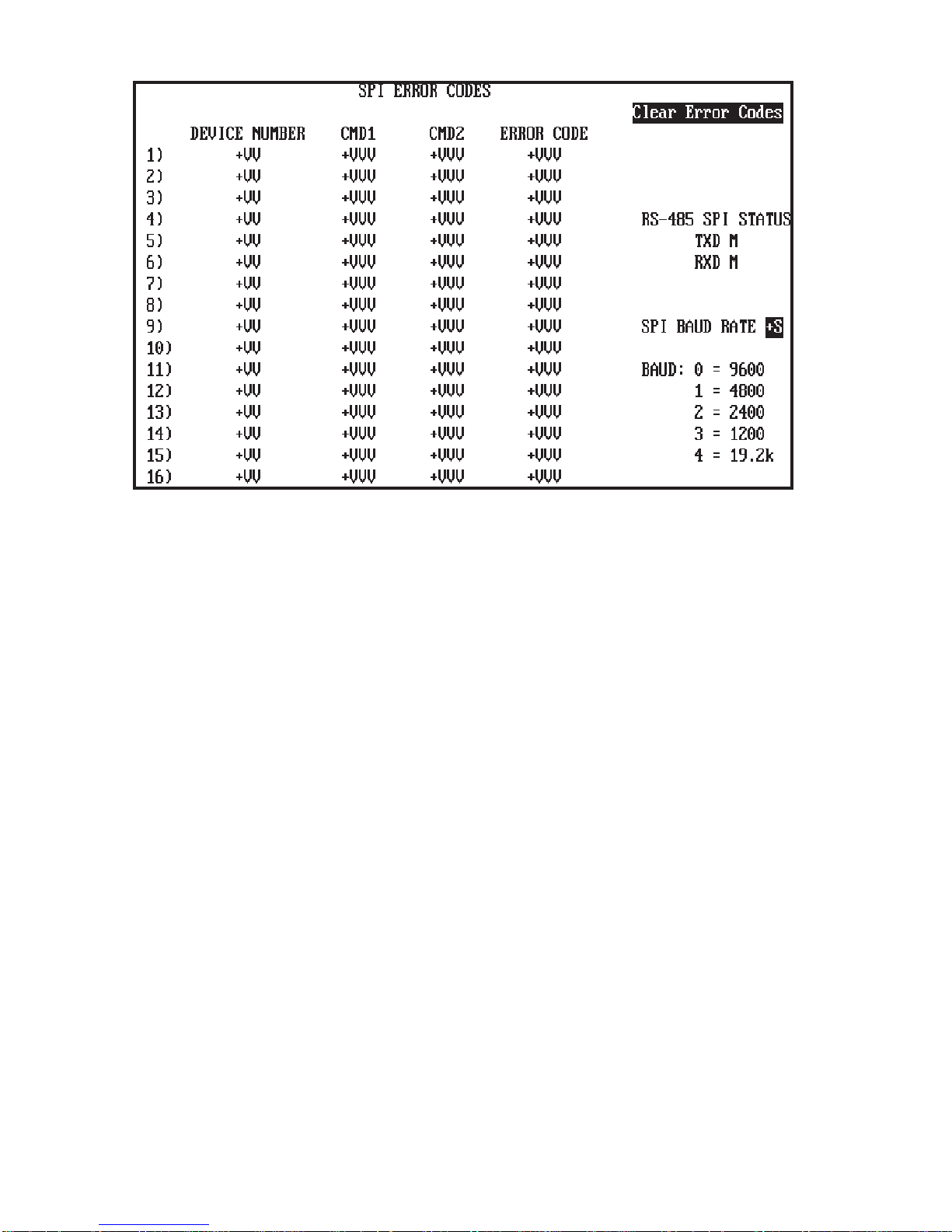

2.4 MACO SERIAL COMMUNICATION SETUP

TheMACOserialcommunicationssetupscreen(figure2.4)is

used for setting baud rates and enabling communications.

This controller can have as many as three separate external

devices connected for use with serial communications.

Daughterboards purchased for the communications

motherboard determine what type of device can be con-

nected. The COMM setpoints correspond to daughterboard

locations on the motherboard:

COMM 1 bottom slot.

COMM 2 middle slot.

COMM 3 upper slot.

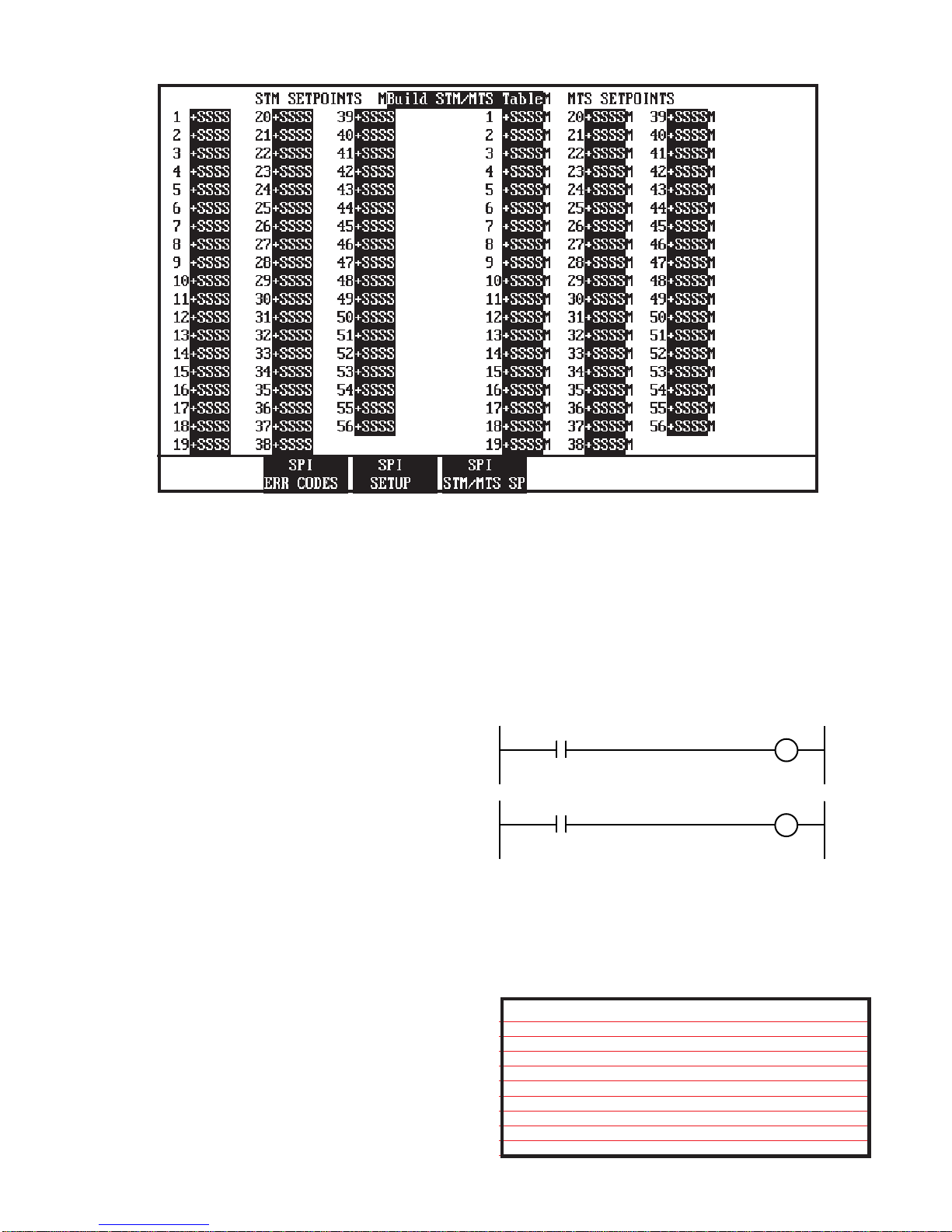

2.4.1 Modfiles and Sample Screens

The diskette SA-00064-01X-0-00 is provided. It contains the

modfiles and sample SPI screens that will be required by the

MACO and OptiGrafix programming software. Preform the

followingstepstoinstallthesefilesontoyouruserapplication.

A. Copy the two modfiles; to copy the modfiles place

the diskette into floppy drive and copy to your exist-

ing modfile directory.

Example: Copy A:\modfiles\*.* C:\modfiles.

B. Using the OptiGrafix screen editor copy the SPI

samplescreensfromthediskette(A:\ADB0001name

of application to copy from) to your user application

on the hard drive using the Application ...

Utilities...Copy from ... Screens Feature.

2.4.2 COMM Setpoints

Examine the Module Information Screen to determine which

communicationsboardsarepresentandthenenterasetpoint

foreachdaughterboard,seeFigure2.4.COMM1,2or3may

be an RS-485 device (a setpoint of 0 to enable SPI commu-

nications) and COMM 1, 2 or 3 may be an RS-232 device (a

setpoint of 0, 1 or 2). Note that only one of EACH DEVICE is

allowed (i.e., can’t have two RS-232 printers or two RS-232

PCs, etc.). Al other information on this screen (Figure 2.4) is

for RS-232 communications.