Bard HI-BOY Guide

I

u

THE

WALL

MOUN'PM

HI-BOY

COMBINATION

GASIELECTRIC

USER'S

INFORMATION

MANUAL

BARD

MANUFACTURING

COMPANY

Bryan,

Ohlo

43506

WARNING:

If

the

information

in

this

manual

is

not

followed

exactly,

a

fire

or

explosion

may

result

causing

property

damage,

persond

injury

or

loss

of

life.

*

Do

not

#tom

or

use

gasoline

or

other

flammable

vapors

and

liquids

in

the

vicinity

of

this

or

any

other

appliance.

*

WHAT

TO

DO

IF

YOU

SMELL

GAS

Do

not

try

to

light

any

appiiiace

Do

not

touch

any

electrical

switch;

do

not

use

any

phone

in

your

building.

Immediately

call

your

gas

supplier

from

a

neighbor's

pbone.

Follow

the

gas

supplier's

instructions.

If

you

cannot

mch

your

gas

supplier,

call

the

fire

department.

*

Installation

and

scrvice

must

be

performed

by

a

qualified

inatdler,

service

agency

or

tbe

gas

supplier.

1

Since

1914..Mrmng,

.heed

just

as

plumed.

Manual:

2100-148

Rw.

H

Supersedes:

Rev.

G

File:

Volume

111,

Tab

20

Date:

November

1995

3

General

The warnings shown on the cover of this manual and the

information on the following pages are very important

and should be fully read and understood by the operator

of this equipment. Please take the few minutes necessary

to completely read this booklet, and if there are any

questions when you are through, ask your installer to

review them with you. Please retain this booklet for

future reference.

Rating Plate Information

Record the manufacturer’s name, unit model number

and serial number below. These are on your unit rating

plate. Record installation date, which is important for

warranty purposes.

Also fill in the installer’s name, address and telephone

number. This will be handy if you have questions later.

Some companies install an identification tag on units

they install or service. If not, ask for the information.

Your Unit Information

Unit Type ____________________________________

Manufacturer’s Name __________________________

Model Number ________________________________

Serial Number ________________________________

Date Installed _________________________________

Installer/Service _______________________________

Address ______________________________________

City/State/Zip Code ____________________________

Telephone Number _____________________________

IMPORTANT SAFETY PRECAUTIONS

A. Signal Words

Years of safe, dependable service, are assured when

you understand and follow all safety precautions.

Remember: Your unit contains flames, gas, electric-

ity, rotating parts and metal edges.

Signal words “Warning” and “Caution” alert you to

potential hazards.

“Warning” alerts you to situations that could cause

series injury or property damage.

“Caution” alerts you to situations that could cause

minor or moderate injury.

B. Safety Precautions

These are some of our most important safety

precautions; others are throughout this manual.

Please read and follow them.

1. Gas and Combustion Products

Warning

Any condition that will allow gas or combustion

products to enter unit area can cause nausea, asphyxia-

tion or fire resulting in damage, injury

or death.

Natural gas and propane (LP) gas have characteris-

tic odors. When your unit is operating correctly, you

should not smell any unfamiliar odor. Normally,

burning gas with air produces combustion products

which contain carbon dioxide, oxygen and water

vapor.

Aldehydes have a strong pungent, acrid smell that

can cause nausea.

Carbon monoxide is tasteless, colorless and odor-

less. It can cause headaches, flu-like symptoms or

nausea. We refer to all these symptoms as nausea in

this manual. It can also cause death by asphyxiation.

Warning

Any unfamiliar smell can alert you to presence

of gas or aldehydes. If you detect any unfamiliar

odor call service technician.

Warning

Do not block or cover combustion openings in the

unit door. Blocking or covering these openings

could cause nausea, asphyxiation or fire resulting

in damage, injury or death.

Warning

A loud noise may mean faulty burner ignition. If

your unit makes a loud noise, turn it off. If you

don’t turn your unit off, it could cause fire or an

explosion, resulting in damage, injury or death.

2. Storage and Use of Flammable, Corrosive and

Combustible Products Near Your Unit.

4

Important

Should overheating occur, or the gas supply fail

to shut off, shut off the manual gas valve to the

unit before shutting off the electrical supply.

FIGURE 1

FIGURE 2

FIGURE 3

AIR FILTERS

It is the user’s responsibility to check the condition of

the air filters on at least a monthly basis when the unit is

in use and to clean or replace whenever it is necessary.

Permanent Type Filter (usually foam type) are washable.

Use a solution of soapy water, followed by a rinse in

clear water and then dried by tapping the frame against a

solid object.

Never operate the unit without proper filters in place.

Never substitute a throwaway (fiberglass) for a perma-

nent (foam) type.

Return air filter size is 20 x 30 x 1 (throwaway) and is

serviceable from the left side of the unit as shown in

Figure 2.

Fresh air filter size is 4 x 26 x 1/2 and is a permanent

type filter, refer to Figure 2 for service location.

AIR CONDITIONING START UP

PROCEDURE CRANKCASE HEATERS

Single and three phase models have an insertion well-

type heater located in the lower section of the compres-

sor housing. This is a self-regulating type heater that

draws only enough power to maintain the compressor at

a safe temperature.

Some form of crankcase heat is essential to prevent

liquid refrigerant from migrating to the compressor,

causing oil pump out on compressor start-up and

possible valve failure due to compressing a liquid.

The decal in Figure 4 is affixed to all outdoor units

detailing start-up procedures. This is very important.

Please read carefully.

FIGURE 4

Warning

Never store or use flammable liquids or vapors

near or on your unit. These include gasoline,

kerosene, cigarette lighter fluid, cleaning fluids,

solvents, paint thinners or painting compounds.

Flammable vapors can travel great distances

before igniting. Flammables could cause fires or

explosions and result in damage, injury or death.

Warning

Never store or use anything near or on your unit

that can produce vapors that are corrosive to gas-

fired appliances. Vapors from products containing

chlorines, fluorines, bromines and iodines can

cause vent system or heat exchanger failure.

Examples of such products are spray or aerosol

containers, detergents, bleaches, cat litter, waxes,

adhesives, solvents and other cleaning compounds.

Vent system or heat exchanger failure could cause

nausea, asphyxiation or fire, resulting in damage.

CLEARANCES

There are certain minimum installation clearances from

the unit cabinet and sheet metal plenum attached to the

unit to any combustible materials. These clearances for

each model are shown on the unit rating plate (located

on the right side) and are the responsibility of the

installer during the installation of the appliance.

It is the user’s responsibility to make sure these clear-

ances are always maintained thereafter. Additionally, a

minimum of 30 inches for serviceability is required from

the right side of all models.

COMBUSTION AND VENTILATING AIR

It is the responsibility of the user to assure that the

important flow of combustion and ventilating air is not

obstructed from reaching the unit.

Do not block or obstruct air openings on the unit.

LIGHTING AND SHUTDOWN

INSTRUCTIONS

Refer to Figure 3 for general location of components

referenced in the following “Lighting and Shutdown

Instructions.” These components are located behind the

“Burner Access Door”.

5

IMPORTANT

THESE PROCEDURES MUST BE FOLLOWED

AT INITIAL START-UP AND AT ANY TIME

POWER HAS BEEN REMOVED FOR 12

HOURS OR LONGER.

TO PREVENT COMPRESSOR DAMAGE

WHICH MAY RESULT FROM THE PRESENCE

OF LIQUID REFRIGERANT IN THE

COMPRESSOR CRANKCASE.

1. MAKE CERTAIN THE ROOM THERMOSTAT IS IN

THE "OFF" POSITION (THE COMPRESSOR IS

NOT TO OPERATE).

2. APPLY POWER BY CLOSING THE SYSTEM

DISCONNECT SWITCH. THIS ENERGIZES THE

COMPRESSOR HEATER WHICH EVAPORATES

THE LIQUID REFRIGERANT IN THE CRANKCASE.

3. ALLOW 4 HOURS OR 60 MINUTES PER POUND

OF REFRIGERANT IN THE SYSTEM AS NOTED

ON THE UNIT RATING PLATE, WHICHEVER IS

GREATER.

4. AFTER PROPERLY ELAPSED TIME, THE

THERMOSTAT MAY BE SET TO OPERATE THE

COMPRSSOR.

5. EXCEPT AS REQUIRED FOR SAFETY WHILE

SERVICING--DO NOT OPEN SYSTEM

DISCONNECT SWITCH.

7961-061

CIRCULATION BLOWER CONTROL

INITIAL START UP

When electrical power is first supplied to the unit, the

low speed blower relay will automatically energize and

the indoor motor will run for one minute. This run in

period will only occur during initial power up or when

the power supply is interrupted.

HEATING OPERATION

One minute after main burner ignition, the circulating

blower will start on low speed. Following termination of

the heating cycle, a two minute delay will keep the

circulating blower running. Any major deviations from

these times should be reported to your service agency.

COOLING OPERATION

Immediately upon a call for cooling, the circulating

blower will be energized on high speed. At the end of the

cooling cycle, the compressor will stop and the circulat-

ing blower will continue to run for one minute.

MAINTENANCE INSTRUCTIONS

The unit should be inspected annually by a qualified

service agency.

Routine inspection and maintenance procedures are the

responsibility of the owner/user and are outlined below.

ROUTINE MAINTENANCE

Air Filters—Check the condition at least monthly when

the unit is in use, and replace (throwaway, fiberglass

type) or clean (permanent, foam type) as necessary.

Reference Figure 2.

Lubrication Requirements—The indoor circulating air

blower motor and outdoor circulating air fan motor are

permanently lubricated and require no re-oiling. The

combustion air blower motor should be re-oiled once a

year with 3-4 drops SAE20 motor oil.

Warning—Turn off electrical power supply to prevent

injury from moving parts or electric shock.

ROUTINE INSPECTION

Inspect the physical support of the unit annually to make

sure it is securely fastened to the building. Also look for

any obvious signs of deterioration.

Inspect the pilot and main burner adjustment at the

beginning of each heating season. Refer to Figure 5 and

Figure 6 for general guidelines. Call qualified service

agency for any adjustments.

Inspect the vent terminal for any obvious deterioration

and to make sure it is free and clear of any obstructions.

REPLACEMENT PARTS

Replacement parts for the gas/electric units are available

through local distributors.

A replacement parts list manual is supplied with each

unit. When ordering parts or making inquiries pertain-

ing to any of the units covered by these instructions, it is

very important to always supply the complete model

number and serial number of the unit. This is necessary

to assure that the correct parts (or an approved alternte

part) are issued to the service agency.

FIGURE 5

6

FIGURE 6

Observe the main burners in operation. The flame

should be mostly “blue” with possibly a little orange (not

yellow) at the tips of the flames. The flames should be in

the center of the heat exchanger compartments and not

impinging on the heat exchanger surfaces themselves.

Observe the fire until the blower starts (there is a normal

delay period until the heat exchanger warms up). There

should be no change in the size or shape of the flame. If

there is any wavering or blowing of the flame on blower

start-up, it is an indicattion of a possible leak in the heat

exchanger.

FRESH AIR DAMPER ASSEMBLY

The fresh air damper assembly is shipped in the return

air chamber accessed from the back of the unit. Remove

the shipping screws and damper assembly. Attach the

damper assembly to the blower service door as shown in

Figure 2. The damper assembly includes a permanent

filter that can be easily removed for cleaning. See Figure

3.

The damper blade is shipped in the full open position

allowing the maximum amount of fresh air at all times.

If no fresh air is desired or if barometric operation (blade

opens when blower starts) is desired, remove and

reinsert the plastic canoe clips as shown in Figure 7.

All capacity, efficiency and cost of operation information

as required for Department of Energy “Energyguide”

Fact Sheets is based upon the fresh air blank-off plate

(BOP-1A) in place and is recommended for maximum

energy efficiency. The blank-off plate is available upon

request from the factory and is installed in place of the

fresh air damper shipped with each unit.

FIGURE 7

FILTER

A one inch throw away filter is supplied with each unit

taped to the back of the unit. This filter is installed by

removing the filter service door located on the left side

and sliding the filter into position, as shown in Figure 3.

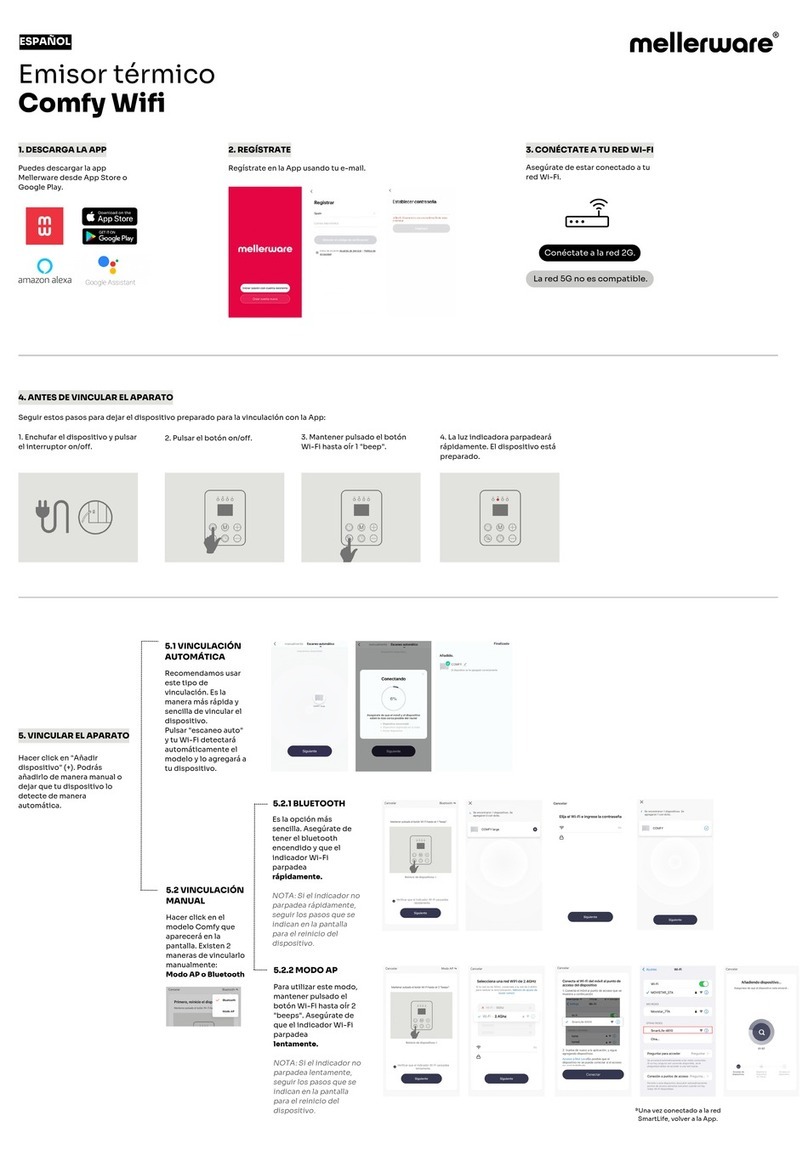

Table of contents

Popular Heater manuals by other brands

Saunatec

Saunatec 1106-105 Installation and operating instructions

Westinghouse

Westinghouse WSHUT02 instruction manual

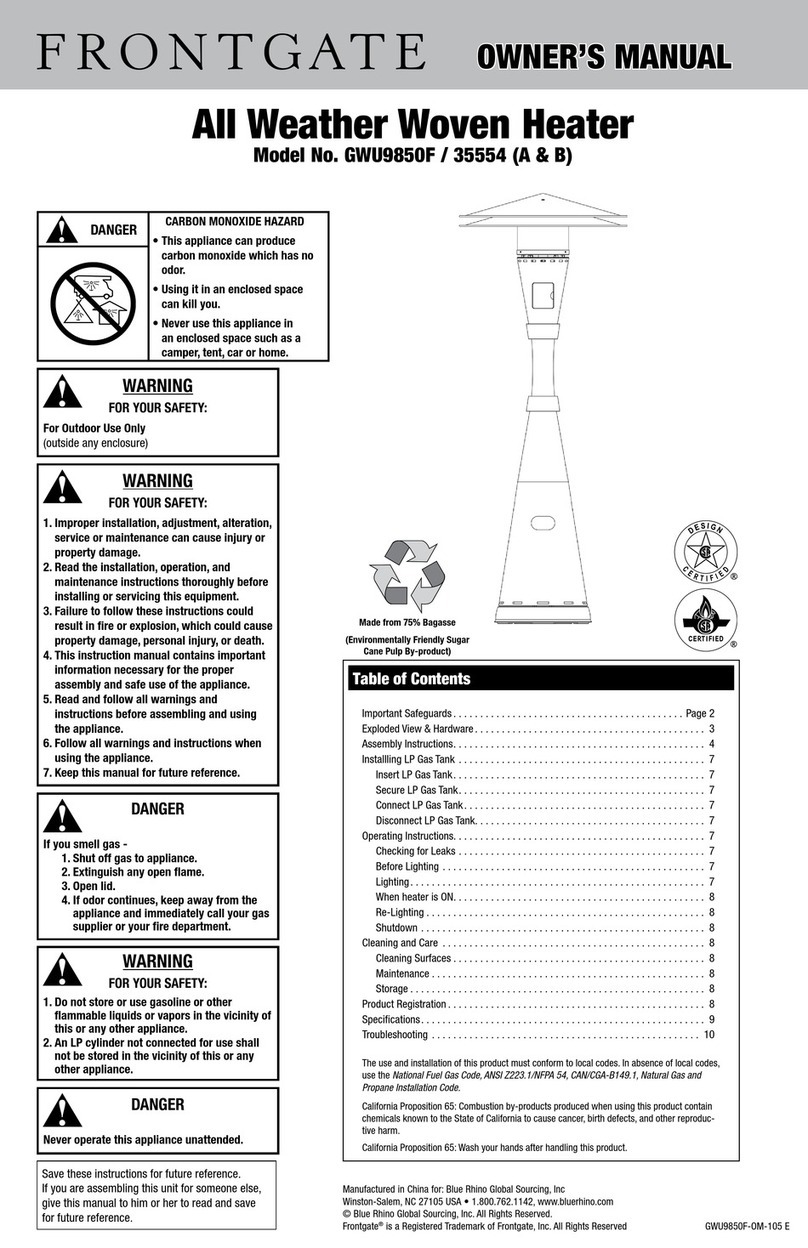

Frontgate

Frontgate GWU9850F / 35554A owner's manual

Campingaz

Campingaz Comfort Heat IR Instructions for use

THERMOFAN

THERMOFAN TF1000 installation guide

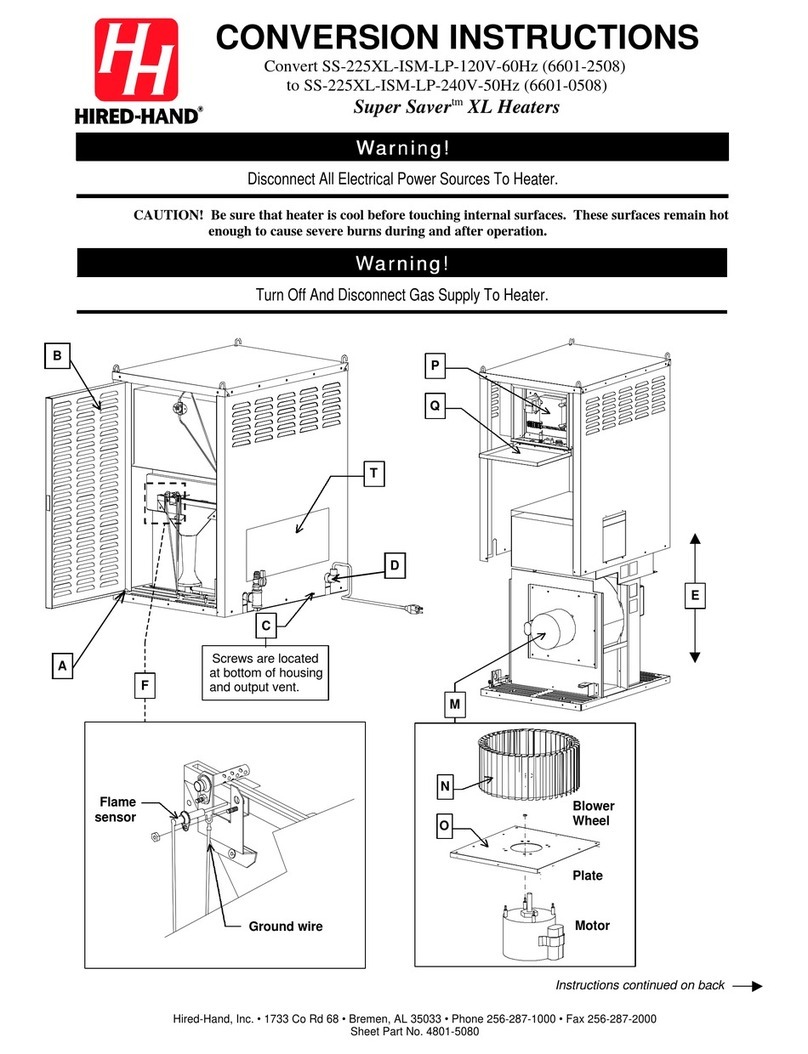

HIRED-HAND

HIRED-HAND Super Saver XL Conversion instructions

winkler

winkler WOCP operating instructions

EOS

EOS Zeus HD Installation and operating instructions

Royal Sovereign

Royal Sovereign PRO HWS-480 owner's manual

TEFAL

TEFAL Excel Aqua Plus manual

Consort

Consort PSL050/SS Installation & Control Guide

Dimplex

Dimplex RPX075N Installation and operating instructions