BARGAM AT Biturbo Series User manual

1

MAINTENANCE & USE OPERATOR’S MANUAL

TRAILED SPRAYERS

AT Biturbo , AT Pneus , AT , AT Vigne ,

AT Fruits , Turbo AT, Super AT Biturbo,

Super AT, AET

MOUNTED SP

RA

YE

R

AP PNEUS, AP70 , AP50 , Turbo AP45 , Turbo AP45 flex , Turbo AP35

LOW VOLUME SPRAYERS mod. : “PNEUS”

SPRAYERS WITH DIRECTIONAL CANNON HEAD mod. : “FLEX”

WEED KILLING AND SPRAY GROUP :mod: AP for weed killing booms,spray

booms , electric sprayers

CAREFULLY

READ

THE

INSTRUCTIONS

BEFORE

START

USING

THE

EQUIPMENT

Via della Cooperazione,20- 40026 Imola (BO) ITALY

Tel. +39(0542)648511 Fax +39(0542)640539

www.bargam.com - e-mail: sales@bargam.com

2

DIMENSIONS AND WEIGHTS TABLE

MODEL

C

APA

C

I

T

Y

L

T

W

I

D

TH

M

M

L

E

N

G

H

T

M

M

H

EI

G

H

T

M

M

W

E

I

G

H

T

K

G

AT 660

600

1100

2300

1160

550

AT 1100 1000 1150 3080 1195 690

AT 1650 1500 1350 3140 1500 750

AT 2200 2000 1400 3600 1400 780

AT 3300 3000 1800 4000 1500 930

AET 660 600 1100 2300 1160 440

AET 1100 1000 1150 3080 1195 550

AET 1650 1500 1350 3140 1500 750

AET 2200 2000 1400 3600 1400 780

AT PNEUS 660 600 1100 2300 1100 440

AT PNEUS 1100 1000 1150 3080 1150 550

AT PNEUS 1650 1500 1350 3140 1350 690

AT PNEUS 2200 2000 1400 3600 1400 780

AT BITURBO 1100 1000 1150 3580 1200 600

AT BITURBO 1650 1500 1350 3640 1500 740

AT BITURBO 2200 2000 1400 4100 1400 800

AT BITURBO 2200 2000 1400 4100 1400 830

AT BITURBO 3300 3000 1700 4500 1500 980

AT FRUITS 1100 1000 1150 3080 2150 570

AT FRUITS 1650 1500 1350 3140 2150 690

AT FRUITS 2200 2000 1400 3600 2200 780

AT FRUITS 3300 3000 1700 4000 2800 930

AT VIGNE 660 600 1100 2300 1160 440

AT VIGNE 1100 1000 1150 3080 1195 550

AP70 330 300 1000 1235 1070 207

AP70 440 400 1000 1235 1200 227

AP70 440 400 1000 1235 1200 237

AP70 660 600 1410 1260 1220 247

AP70 660 600 1410 1260 1220 247

AP70 880 800 1410 1260 1430 267

AP70 1100 1000 1410 1260 1590 300

AP50 220 200 1000 1235 910 193

AP50 330 300 1000 1235 1070 203

AP50 440 400 1000 1235 1200 228

TURBO AP45 440 400 1300 1000 1200 341

TURBO AP45 660 600 1420 1410 1220 423

TURBO AP45 880 800 1420 1410 1430 435

TURBO AP45 1100 1000 1420 1410 1590 443

TURBO AP35 330 300 1210 1000 1150 262

TURBO AP35 440 400 1210 1000 1300 276

TURBO AP35 660 600 1260 1410 1350 290

TURBO AP45 FLEX 440 400 1550 1400 1900 444

TURBO AP45 FLEX 660 600 1550 1400 1900 526

TURBO AP45 FLEX 880 800 1550 1400 1900 538

TURBO AP45 FLEX 1100 1000 1550 1400 1900 546

SUPER AT BITURBO 2200 2000 1600 3800 2300 1030

SUPER AT BITURBO 3300 3000 2400 4200 2400 1180

SUPER AT 2200 2000 1600 3800 2300 980

SUPER AT 3300 3000 2400 4200 2400 1130

TURBO AT 1100 1000 1150 3080 1195 700

TURBO AT 1650 1500 1350 3140 1500 820

TURBO AT 2200 2000 1400 3600 1400 910

TURBO AT 3300 3000 1700 4000 1500 1060

AP PNEUS 330 300 1000 1400 1070 207

AP PNEUS 440 400 1000 1400 1200 227

AP PNEUS 660 600 1410 1400 1220 247

3

INTRODUCTION

This manual describes the performances and the operations with necessary instructions

for proper use and periodic maintenance of the equipment.

This manual is divided into chapters for an easy consultancy.

The information contained in this manual is intended for a professional user, who must

have specific knowledge about how to use the machine and must be authorized and

trained.

We recommend the use of original spare parts and accessories. Not original parts could

invalidate the warranty, might be dangerous and might reduce the life duration and the

performance of the machine.

In case of transfer or sale this manual must always be delivered with the machine. If it is

damaged

or

los

t, a copy can be asked the supplier or previous owner. The manual is

considered as part of the equipment.

GENERAL WARRANTY CONDITIONS:

a) To the extent the following provisions, the Seller warrants solely to Buyer that the goods

sold are free from defects on material, design, manufacture and assembly in relation to the

level of technical development at the time of construction. This undertaking is limited to

defects that occur during the period of 12 months from the date of the delivery .

b) Ending the standard warranty (12 months), the term of the same effect may be delayed

up to a maximum of six months by BARGAM S.p.A. to the Buyer , if the produced goods

are not immediately sold. In this case, the warranty starts from the moment that the Buyer

delivers the equipment to the third parts (Purchaser). The Buyer must inform BARGAM

S.p.A. that the equipment was sold to the end-users .This obligation is considered fulfilled

when the Buyer sends to BARGAM S.p.A. the warranty

dra

ft that can

be

f

ound

on the

web site “www.progroup.it " completed in any part. In any case, the guarantee

provided by BARGAM S.p.A. is valid and effective ever and only for the Buyer and cannot

be relied on by t

he

la

t

es

t.

c) BARGAM S.p.A. does not guarantee services and / or workmanship of engines

mechanisms and diesel equipment, electrical and thermal (but not limited to tires, fuel

injection system, engine, differential axle, bearings, hydraulic shares, ...) sold

individually or simply assembled by the Seller. In this case the warranty is limited to the

warranty period given by the OEM and contained in the technical documentation

provided by BARGAM S.p.A. to the Buyer upon delivery. Buyer declares his

acknowledge and acceptation

o

f t

he

guarantees issued by these manufacturers.

4

d) The warranty will be valid if the claims and / or defect will be sent within 8 days in

writing form to the manufacturer .

e) The Purchaser shall be waived in any case by the warranty:

-If the vices and / or defects depend on normal wear and tear of the property;

-If the goods delivered is subjected to improper use or use higher than expected from the

contract and the documentation provided with the products;

-If the defects are derived from an assemblage made by the Purchaser that is not in

accordance with the instructions contained onto the manual "Instructions for Use";

-If it does not perform periodic maintenance procedures and strictly in accordance with the

schedule proposed by the Seller;

-If, in the event of any faults and defects, repair and / or replacement of defective parts is

not addressed to the Seller;

-If it does not meet the deadlines of payments.

f) The guarantee provided by BARGAM S.P.A. consists solely of the repair and / or

free replacement of parts and / or parts that present defects and / or defects, with the

express exclusion of the guarantees contained in Articles. 1490, 1492, 1497, 1512 of the

Italian Collection of rules and, as well as the

aliud

pro

alio and the obligation to

indemnify any direct or indirect, immediate or mediate, resulting from defects and

/ or defects themselves. No other recognition will be made as security for labour,

transportation, various interventions, etc.., insofar as they are considered part of the

trade discount granted.

g) The Buyer must send back the defective goods to the BARGAM S.p.A. and the latter

may choose whether the repairing or replacement thereof options. The bonds are

considered the BARGAM S.p.A. fulfilled by

delivery

t

o

Purchaser of the repaired or

replaced goods.

h) In the event that the BARGAM S.p.A. send products to replace the defective ones

before the receipt of the latter, the buyer must return the tainted products to the

Producer within 15 days of receipt of those substitutes. The goods become the property of

the producer itself. If the Purchaser, except as writing authorized by BARGAM S.p.A.,

does not return the defective products within the mentioned period shall be required to pay

the replacing of the products

i)The costs and risks of shipping the defective product from Buyer's premises to the

headquarters of the BARGAM S.p.A. and the cost of repairs made outside of

establishments BARGAM S.p.A., will be borne by Buyer. Similarly, even the return

cost and the risks of transporting the goods repaired or replaced from the BARGAM

S.p.A. will be at purchaser costs.

5

TABLE OF CONTENTS

1 ABOUT THIS MANUAL

1.1 UPDATING THE MANUAL

1.2 COPYRIGHT

1.3 CE MARKING PLATE

1.4 INFORMATION ON THE MACHINE

1.4.1 INTENDED USE

1.4.2 DESCRIPTION

1.5 STORAGE

1.6 FIRST USE OR USE AFTER LONG PERIOD

1.7 DISASSEMBLING

1.8 SAFETY AND ACCIDENT PREVENTION

1.8.1 PESTICIDES

1.8.2 FIRE-FIGHTING MEASURES

1.9 SAFETY SIGNS

1.9.1 LOCATION OF THE MACHINE PICTOGRAMS

1.9.2 DESCRIPTION OF PICTOGRAMS

2 TRANSPORT AND HANDLING

3 TRANSPORT ON PUBLIC ROAD (only for approved machine)

4 OPERATION OF THE MACHINE

4.1 HYDRAULIC SYSTEM

4.1.1 MAIN TANK

4.1.2 CIRCUIT CLEANING TANK

4.1.3 HAND WASHING TANK

4.1.4 SUCTION FILTER & “3 WAY”GATE

4.1.5 PUMP

4.1.6 HIGH PRESSURE FILTER

4.1.7 MIXERS

4.1.8 CONTROL UNIT

4.1.9 DISTRIBUTORS

4.1.10 NOZZLES

4.2 PNEUMATIC SYSTEM

4.2.1 IMPELLER

4.2.2 GEAR BOX

4.3 WORKING ADJUSTMENTS

4.3.1 ORIENTATION OF THE AIR FLOW

4.3.2 SETTING PRESSURE HYDRAULIC SYSTEM OF WORK

4.4 CRITERIAS FOR CHOOSING & ADJUSTING THE WATER FLOW

4.4.1 SPRAYERS WITH AXIAL FAN

4.4.2 SPRAYERS WITH FAN GUN

4.4.3 LOW VOLUME SPRAYERS

4.4.4 GROUPS AND SPRAY HERBICIDE: HERBICIDE BOOMS, LANCES, ELECTRIC IRRORATOR

4.5 CALIBRATION OF MACHINE

4.5.1 MAX LIMIT OF CONCENTRATION OF PLANT PROTECTION PRODUCT USED

4.5.2 INTENSITY 'OF COVERAGE

4.5.3 INDEX LEAF COVERAGE

4.5.4 DEGREE OF SPRAYING

4.5.5 MINIMIZE THE DISPERSIONS

4.5.6 EFFECTIVENESS AND NOZZLE ORIENTATION

4.5.7 ORIENTATION AND EFFECTIVENESS OF AIR OUTLETS

4.6 MIXING

5 CORRECT OPERATION OF THE MACHINE

5.1 CLEANING FILTERS

5.2 CHECKING OF PROGRESS’SPEED

5.3 OPERATE IN ENVIRONMENTAL GOOD CONDITION NELLE CORRETTE CONDIZIONI AMBIENTALI

5.4 CHECKING OF THE GEARBOX OIL LEVEL

5.5 CHECKING OF THE RESERVOIR LEVEL

5.6 CHECKING OF MANOMETER

6 CONNECTION TO THE MACHINE

6.1 CONNECTION OF THE MACHINE TO THE TRACTOR

6.2 DISCONNECTION OF THE MACHINE FROM THE TRACTOR

7 MAINTENANCE

7.1 OPERATOR’S MAINTENANCE OPERATION

7.2 GREASING

7.3 CHECK OF OIL LEVEL : GEARBOX

7.4 REPLACEMENT OF OIL ON GEARBOX

7.5 CHECKING OF TURBINE

7.6 CHECKING OF THE NOZZLES

7.7 CHECKING OF THE FILTERS

8 TABLE OF SCHEDULED MAINTENANCE

9 TABLE OF TROUBLES RESEARCH

10 SPARE PARTS

6

1 ABOUT THIS MANUAL

This manual is an integral part of the machine and must accompany it in

case of resale and until its demolition.

In case of loss or damage of this Manual please request a copy to the manufacturer (IMA.

IT S.p.A. via Gambellara 10 Imola BO ) or retailer ( )

insert name and address of the retailer

This manual should be translated into the language of the country where the machine is

sold .

On equipment are suitable some pictograms which have to be maintained in a perfect

condition and replaced when they are no longer legible by the operator.

The presence of this symbol means to pay close attention to the item

described

It would be possible that some devices described in this manual are missing on your

machine, depending on fittings and/or market features based on machine destination.

1.1 UPDATING THE MANUAL

The information, descriptions and illustrations in this manual reflect the state of the art

when

machine

has

been commercialised .

The manufacturer reserves the right to make, at any time, any changes to the machines

for technical or commercial reasons. These changes do not require at manufacturer to act

on sold equipment to update it or to consider it inadequate.

Any additions that the manufacturer deems appropriate to provide, it need to be stored

together with the manual and has to be considered an integral part of it.

1.2 COPYRIGHT

The copyright of this manual belongs to the manufacturer. This manual contains text,

drawings and technical illustrations that cannot be disclosed to third parties or transmitted,

in whole or in part, without the written permission of the manufacturer of the machine.

10

1.3 CE PLATE

The CE plate is positioned in front of the machine near the drawbar (if trailed model) or

positioned t

o

t

he

3 Point Hitch (if mounted model)

It indicates:

- Brand of the manufacturer

- Company name and address of

manufacturer

- Type and model of equipment

- Weight

- Serial identification number

- Year of construction

1.4 INFORMATION ON THE MACHINE

1.4.1 INTENDED USES

The machine "sprayers " is designed exclusively for the distribution of pesticides .

The sprayers are machines intended for pesticide, fungicides and others phytochemical

treatments.

Their function is to spray the mixture in aqueous solution and conveys it to the crop , made

by nozzles

and

air

flow, produced by a fan, that brings the drops on the leaves.

The machine should be operated by a single operator inside the cab of the tractor.

The operator using the machine must be familiar with all the instructions contained in this

manual.

The machine has been designed and built to operate outdoors, because its performance is

affected by the weather conditions.

The machine "sprayer" described in this manual complies with the European directive

200642CE and subsequent modifications and integrations and therefor it is equipped with

CE mark.

Every different use of the machine is considered unauthorized and

dangerous.

11

1.4.2 DESCRIPTION

The Fan air sprayers are popular: the liquid is brought out of the tank, using a pump to the

nozzle where it is hit by a strong air current speed produced by a fan (centrifugal or axial).

For optimal spraying the air flow should be smoothed e.g. against-propellers or conveyors.

The quantity of product depends on the number and extent of the nozzles.

In this way it will reach a diameter of droplets between 100 and 300 microns.

The machine consists of:

-Mounted Frame to connecting to the tractor rear lifting arms (for mounted unit models ).

-Frame with drawbar to connecting the rear hitch of the tractor (for trailed models).

-Main polyethylene Tank (4.1.1)

-Polyethylene system washing tank (4.1.2)

-Polyethylene hand-washing tank (4.1.3)

-Suction Filter (4.1.4)

-Pump (4.1.5)

-High pressure Filter (only trailed Models) (4.1.6)

-Control unit (Par 4.1.9)

-Nozzles (Par 4.1.10)

-Axial or centrifugal impeller (4.2)

1.5 STORAGE

If the machine is stored for long periods it is necessary to store it in a place protected

against atmospheric agents and protect it to avoid damage.

Verify that the storage temperature is between

0

°C and 50°c.

Do not place the machine on the ground sloped or excessively saggy.

The machine is designed to be parked safely on compact soil with slopes of up to 8.5°.

In order t

o

prepare

the machine for the storage it is necessary to proceed to a thorough

cleaning of the tank and hydraulic circuit with the same procedure used at the end of

treatment..

In addition , it’s necessary to:

completely empty the water circuit to avoid damage caused by frost.

Mix with clean water a liquid anti-freeze to protect not only the pump but also all

components in contact with the liquid (command groups, Jet holder and filters).

Remove and clean the filters and nozzles which must be kept in a secure

environment

by

weathering.

cancel the pressure inside the hydro-pneumatic compensator of the pump

Grease the moving metal parts.

Repaint all surfaces that could rust, where necessary..

place the machine in a ventilated place sheltered from rain and Sun..

12

1.6 START UP OR RESTART AFTER LONG PERIOD OF INACTIVITY

Before using the machine for the first time or after a long period of inactivity you must do

the following:

check that the machine does not present any damage.

Check that the machine is correctly mounted in its entirely.

Check the mechanical parts, which must be in good condition and not rusted..

Check that the suction filter and tank inside are clean and free of residues.

Check that the connections are mounted correctly by following the basic schema.

check that the tube straps are tight correctly as all fittings and connections..

ensure that the gear box is suitably replenished of lubricant

check that the fan is free to rotate and that the box is not deformed by blows

received

during

transport..

check and, if necessary, restore the oil level of the pump.

Grease transmissions and mechanical joints.

Ensure the presence and functionality of protective devices.

check the status of the pump and the hydraulic compensating.

make sure that all the nozzles are in good condition, with no obvious signs of wear

and fouling.

check the status of all hoses and replace them if necessary.

check tightness of all bolts of the machine.

Remove the cardan shaft from the machine and lubricate it.

1.7 SCRAPPING

In case of scrapping the machine must be disposed in adapted landfills according to the

current legislation.

Before scrapping it is necessary to separate the plastic or rubber parts, electrical and

electronic material.

Before scrapping the equipment thoroughly washing inside and out. Unloading of washing

compounds

in

t

he

environment without precautions is banned due to groundwater

pollution.

Recover any waste oil and dispose of it in the special collection centers.

used oil must be properly recovered and must not be dispersed in the

environment, because, according to the current regulations, is classified

as hazardous waste

a

nd i

t

should be awarded to special collection

centers.

For the collection of waste oil, it is mandatory to consult the local norms of Oils residual.

The parties constituted only by plastic, aluminum, steel, can be recycled.

13

1.8 SAFETY AND ACCIDENT PREVENTION REGULATIONS

A correct use of the machine, a scrupulous compliance with the rules listed here

and the strict enforcement of all precautions to prevent dangerous situations, will

prevent risks of accidents or injury, a better and longer work of machine and

minimise failures.

The BARGAM S.p.A. declines all and every responsibility objective and subjective

when the behavioral norms described on this manual are not applied

Machine is not suitable to be used in sectors other than agriculture.

Machine must be used by a single operator inside the cab of the tractor.

A different use from the one specified is considered improper.

Machine must only be used by authorized, trained and properly trained operator.

The operator after reading and assimilating the instructions contained in this

manual must get adequate preparation on the proper use of the machine and must

be in possession of driving license. Please remember to contact the manufacturer

in case of doubt about the use of the machine and on the interpretation of this

manual.

The manual must be always closed to be easily consulted to verify the operating

cycle. If it is lost or damaged you must request to BARGAM S.p.A. a copy.

The operator must be ensured that, during the operation no person or animals are

within working range. Never operates the machine near any people standing

closed or transiting within the working area of machine.

Do not use the machine if you are tired, ill or under the influence of

alcohol, medicines or drugs..

This machine is usually used during the day, if it is requested, exceptionally, to

use it at night or in reduced visibility condition it should be used with lighting

system of the tractor or an auxiliary lighting system mounted onto equipment .

Any arbitrary modification made at this machine indemnifies and keep indemnified

BARGAM S.p.A. from any liability for damages or injury which may result to

operators, third parties and things.

Verify carefully the machine before each start up.

BARGAM S.p.A. cannot cover any improper use which can cause a potential danger

The signs applied to the machine provides important notices, their full

compliance are important for your safety.

Be sure all safety pictograms are legible. Clean and replace them if necessary

with new labels.

before using the machine make sure that all safety devices are placed correctly in

place and in good condition; If you experience failures or damages to replace

them immediately..

Before go down from the tractor and before every maintenance operation actuate

the parking brake, stop the engine and remove the ignition key from the

dashboard

Staff should use the safety equipment and personal protective equipment during

the use and maintenance of the machine.

It is recommended that the machine operator not to wear clothing that can give

rise to snagging.

It is necessary that the operator is equipped with suitable dust mask for

respiratory protection.

14

During working operations the operator must have sufficient visibility on areas

deemed dangerous so it makes sense to keep clean and in very good condition

mirrors that is equipped with the tractor..

Machine must not be left unattended with the engine of the tractor in motion or

ignition key inserted.

keep the machine clean from foreign matter (debris, tools, miscellaneous items) that

could damage the functioning or cause damage to the operator.

When the machine is stopped on sloping ground, use the parking brake and locking

wedges supplied with the machine.

do not operate on muddy soil, sandy or saggy..

check the state of art of the hydraulic hoses. In case of deterioration (or at least

every year) is recommended to replace them.

Do not use controls unit or hydraulic hoses as handholds. These components are

mobile and do not offer stable support.

Any modification of the machine art may cause security issues. In this case the user

will be solely responsible for any accidents.

It is strictly prohibited to remove or tamper with the safety devices..

Be sure of the good condition of the pictograms. If the pictograms are damaged must

be replaced with other to require to the original manufacturer and replaced in the

position indicated by the use and maintenance manual (section 1.9.1)

Normally, the machines are not designed for road use. Road traffic is allowed if the

machine is equipped with special accessories (e.g. self-reflective signs, flashing

lights, rear lights, etc ...) and when connected to tractors which comply with country

regulations.

In case of circulation on public roads, be sure you the tank is free of any chemical

inside it.

Before travelling on public roads, put the machine in transport position, in

accordance with the manufacturer's indications.

It is strictly prohibited the transport of persons on the machine.

The coupling of the machine to the tractor, shall be exclusively performed on

attachment points provided for this purpose in accordance with the safety

regulations in force.

Before connecting the machine make sure the weight of the front axle of the tractor is

sufficient. The laying of the ballast masses must be made on the supports provided for

this purpose in accordance with the rules of the manufacturer of the tractor. The load

on the front axle of the tractor, must not be less than 20% of the sum of the kerb

weight of the tractor and the operator.

pay attention to the risk of unintentional contact of parts of the machine with the

high voltage airlines.

Perform the turns prudently, taking into account the overhang, the length, the height

and weight of the machine.

Do not use a PTO shaft without adequate protections in accordance with legal

requirements.

Do not transit, stay or work between the tractor and the machine.

15

before starting the tractor's engine, make sure all controls are in neutral position

before you engage the PTO, check that the fan protection network is present and

well fixed and that the gearbox is in neutral position.

Keep always clean the area of movement of the impeller, removing foreign objects

both outside and inside the security network.

do not commute with the impeller running outside of those necessary for spraying

pay attention for any person or animal is closer to the fan when this is running.

After the PTO disengagement, moving elements can still turn a few seconds. Do not

approach until it stops.

1.8.1 PLANT PROTECTION PRODUCTS

Spraying is a delicate operation and involves substantial risk of contamination of people,

animals and the environment. It is very important to treat the functionality of all the parts of

sprayer;

The operator is always the subject more exposed to chemicals used and must work using

all measures necessary for his safety;

It is important to operate under the right weather conditions and inquire about the weather

for the entire period of application;

measure accurately the doses of pesticides to enter in the main tank;

Make sure that the chemicals used are compatible with the materials of construction of the

atomizer;

Never leave chemicals in the tank for more than a few hours;

Carefully follow the rules of detention and use of plant protection products on the market

and ensure that people and animals cannot touch them;

Before each treatment, thoroughly wash the containers of chemical liquid/powders

Do not use the machine without water tank for hand washing or if the same is not

completely fill up;

It is advisable to clean the machine at the same place in which you perform the fills or in a

square where the waters are collected in a pit for disposal;

Avoid uncontrolled discharge of mixing waste on streams, sewers and public areas;

16

1.8.2 FIRE-FIGHTING MEASURES

The machine is built with wide use of materials derived from petroleum, moreover, the

presence of various types of oil and chemical residues make them potentially flammable

Keep on the tractor's

-board

an

extinguisher of adequate capacity and provide periodic

recharge. The hand fire extinguisher use is reserved to staff able to use it.

It is recommended that the operators staff is aware of the major technics of operations in

case of fire;

All fuels and most of the lubricants and hydraulic fluids are flammable;

Do not smoke when refuelling or restore fluid level, do not make supplies near an open

flame, do not transfer the fuel;;

Never use gasoline, solvents or other flammable or toxic fluids for cleaning mechanical

parts: use approved commercial solvents that are non-toxic and non-flammable;

Do not perform welding operations near reservoirs, pipes, tanks, electrical wires or

inflammable materials;

In case of welding protect with suitable screens flammable parts.

1.9 SAFETY SIGNS

Make sure of the good condition of the pictograms. If the pictograms are damaged must be

replaced with other required by the original manufacturer and placed in the position

indicated by the use and maintenance manual.

Make sure the safety pictograms are legible. Clean it using a cloth, soap and water.

.1.9.1 LOCATION OF PICTOGRAMS ON THE MACHINE

On mounted sprayers, safety pictograms are

located laterally on main tank

.

On trailed sprayers, the adhesives are

placed near the drawbar.

17

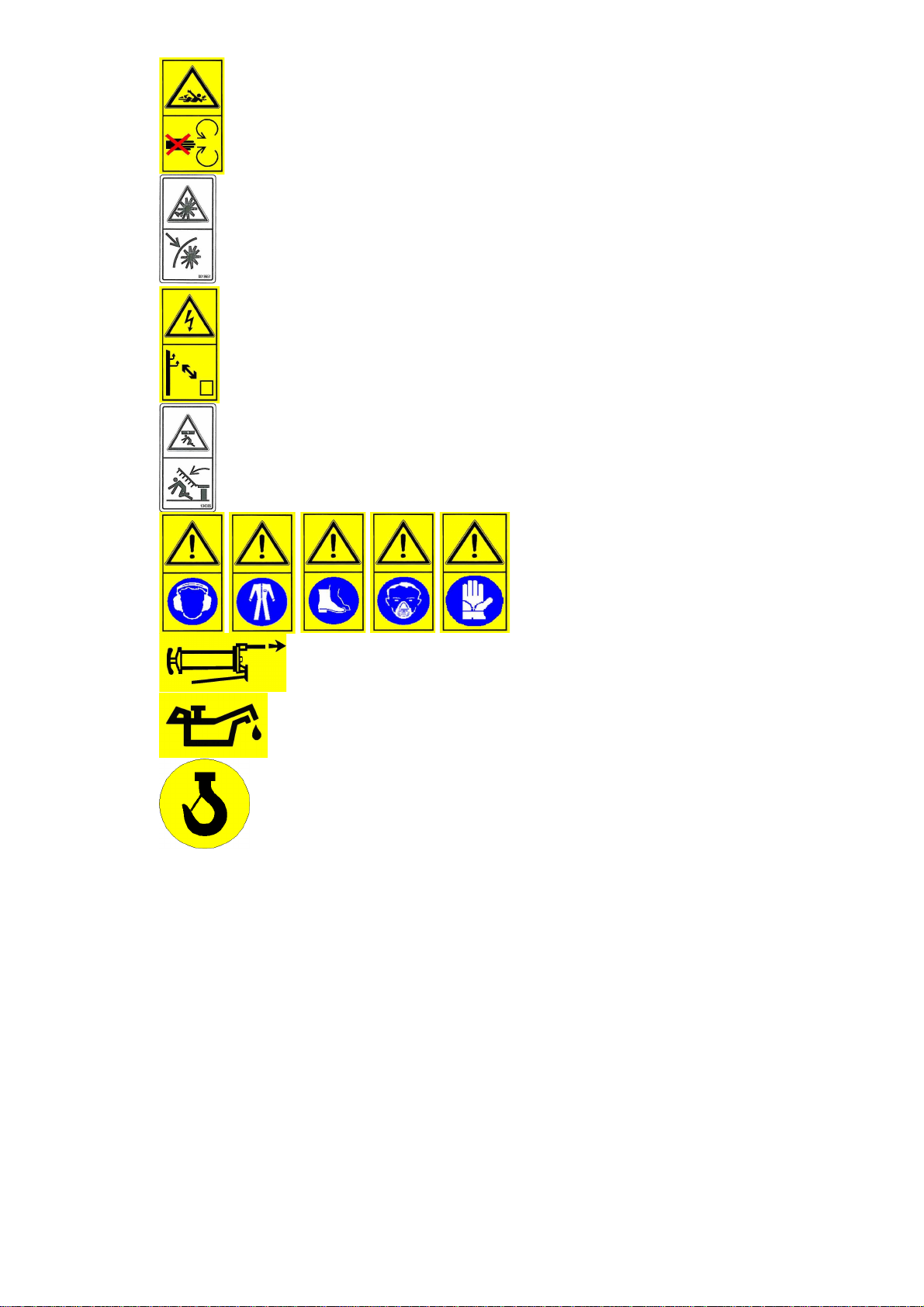

1.9.2 DESCRIPTION OF PICTOGRAMS

1 CAUTION : adjustment operations and

maintenance must be carried out after

reading the user's manual, with the

machine stopped and off key.

2. CAUTION -DANGER of fluids under

pressure. Read the manual before

intervening and in case of injury, seek

medical advice.

3. CAUTION-DANGER this machine must

be used by a single operator.

4. CAUTION-do not climb or get carried

by the machine.

5. WARNING -danger of shearing..

6. WARNING -DANGER poisonous

products to touch and aspirate..

7. WARNING -DANGER maximum

working pressure.

8. ATTENTION-DANGER do not

introduce yourself in the tank.

9. CAUTION –danger -tube pressure,

refer to the owner's manual

18

10. WARNING -danger of entanglement

and dragging. Do not bring your hands to

the transmission shaft in motion.

11. WARNING -DANGER rotating parts.

12 CAUTION-danger of electrocution.

During use of the machine pay maximum

attention to overhead power lines.

13. WARNING –crushing hazard -do not

stand below the machine arms

14. Use required personal

protective equipment ..

15. GREASING POINTS

16. OIL TANK

17. LIFTING POINT

19

2 HANDLING AND TRANSPORT

Place the maximum attention to safety during the loading and unloading operations which

must be carried out by qualified personnel ( truck operators, etc.).

When lifting the machine it is important to use the appropriate lifting eyes indicated by

pictograms..

The presence of this sticker on the machine indicates a:

ATTACHMENT POINT FOR LIFTING HOOK

To transport the machine, it’s important to use a means crafted.in power and size,

3 TRANSIT ON HIGHWAY (only for homologated machines )

case you need to follow a highway ,it's necessary to abide yourself strictly

to the rules of the road taking particular care with any requirement noted in

the booklet of the machine and the choice of appropriate speed. The firs

step during the circulation is to install any optional light bars, self-

reflecting signs etc ....

It is mandatory to provide the machine of flashing yellow light..

The weight of the modified machine changes the stability of the whole tractor-atomizer,

influencing the ability of steering and braking, for this reason it is necessary to proceed at

moderate speed.

4 MACHINE OPERATION

Make sure that during the work, all parts of the machine work regularly.

Point out that most of the accidents and damages that may occur during

use of the machine are caused by the loosening of the fastening

elements.

As in the first phase of the life of the machine is produced an overall settlement of all

mechanical and hydraulic connections ,it is essential to carry out the controls of the

machine with maximum accuracy.

Before using the machine make sure that within the range of the machine there are no

people or animals.

Make sure that no person or animal are in near of ventilators when this is running.

The machine must be used by a single operator inside the cab of the tractor.

It is absolutely forbidden to remove and/or change the protections on the machine..

20

Do not use the machine when tired, ill or under the influence of medication, drugs or

alcohol..

Before using the machine it is necessary to learn the layout of controls and operation..

Pay attention to the risk of unintentional contact of parts of the machine with the high

voltage airlines.

4.1 PLUMBING

4.1.1 MAIN TANK

The main tank has various capacities. To fill the water tank use only indirectly open

waters or just free-fall from water conductor.

You can fill the tank through the pump using the pick-up filter (p. 4.1.4)

The tank is equipped with a graduated band that brings transparency to the exact

quantity

o

f

liquid

inside. The detection has to be made in flat area .

All filling systems provided by BARGAM S.P.A. are preventing pollution and

regurgitation of liquid inside the tank

4.1.2 WASHING- SYSTEM CIRCUIT TANK

All mounted and trailed sprayers are equipped as per CE directive

n

°2004/108 of

circuit-washing tank to cleaning the whole machine (suction pump delivery, nozzles).

The tank must be filled only by clean water.

To use the circuit-washing tank for cleaning it is enough to turn the 3-way gate valve on

CIRCUIT-WASHING TANK position and operate the pump for 10 min.

When done, it's necessary to eliminate waste in defined places where they cannot

cause harm to people or to the environment.

Use different active ingredients on various crops to avoid damage .We recommend to

add to each washing liquid 2 kg of soda for every 100 liters of water.

4.1.3 HAND-WASHING TANK

For the cleaning of the operator, when using the machine or when it is necessary, is

installed a tank of variable capacity according to the main tank. The clean water tank

for hand washing has to be filled only by clean water.

Do not drink for any reason the liquid inside!

21

4.1.4 SUCTION GATE AND 3 WAYS VALVE

The inlet filter allow to fill

the tank from external

sources (wells, streams,

etc..).Filters assembled on

equipment have 50 mesh

cartridges of 0.3 –0.4 mm

(pos. 3).

The filter must be frequently

checked while with a good

cleaning of these you get a

smooth operation of the

machine.(§:7.7)

If the liquid used in the treatment has

many impurities, it is good practice to

clean them each

tank’s filling. Always remember do not

clean the filter with the pump on and to

wear appropriate safety clothing. Before removing the filter cap (POS.

7) make sure that the same is isolated from the pipe by turning the

appropriate gate valve or the 3 -way diverter. After washing the cartridge

replace the cover reconnecting it to the circuit.

To use the suction filter:

remove the throttle valve on the bottom of the suction strainer (POS. 8)

tighten the rubber door fitting the bottom filter thread (POS. 7)

connect the rubber pipe from 6 yards with floating filter on

place the pressure regulator on exhaust position

action the pump

check the water level in the tank

switch off the pump and disconnect the tube from the suction filter

“3 WAY GATE VALVE

The 3-way gate valve permits to direct, inside the loop, the liquid in various directions

- During spraying in the field the level

should be placed in position 1.

- During the filling phase from wells or from

the external tanks, it can take any position.

- During the tank and circuit washing (at

the end of each treatment, chemical liquid

change or when it has required for the

periodic maintenance ), the lever must be

placed in position 3.

22

4.1. 5 PUMP

A pump is installed on the machine

according to the models .The pump manual

is enclosed to t

his

manual

. We recommend

to read both carefully . Be very careful with

the data reported by the manufacturer.

The pump can be identified from the data

plate applied on it; the main data of

pressure and f

low

are

easy to find. Normally

the pump must not exceed 550 rpm; a

number of major tours does not improve

performance but compromise the life and

safety of the equipment. On the pump there

is a safety valve calibrated to prevent the

over pressure . Do not tamper with this

valve for any reason and do not block the hose connected to it.

4.1.6 HIGH PRESSURE FILTER ( ONLY TRAILED MODELS)

The high pressure filter consists of a PVC body

(Det. 1.4) with two inputs and two outputs (item

8) (38 ".1/2").It also has a drain valve (POS. 6).

Inside there is a filter cartridge (POS. 3) which

has the task of collect any impurities presented

inside the circuit.

The high pressure filter should be cleaned following

the procedures outlined in chapter: routine

maintenance. (See § 7.7)

4.1.7 AGITATORS

Agitators are Venturi tubes supplied by the

pump through a manual valve that must be

always opened to allow the

wave of product before, during and after

treatment. The agitators valve shall be closed

only during system washing with clean

wa

t

er

f

rom

holding tank maintenance

23

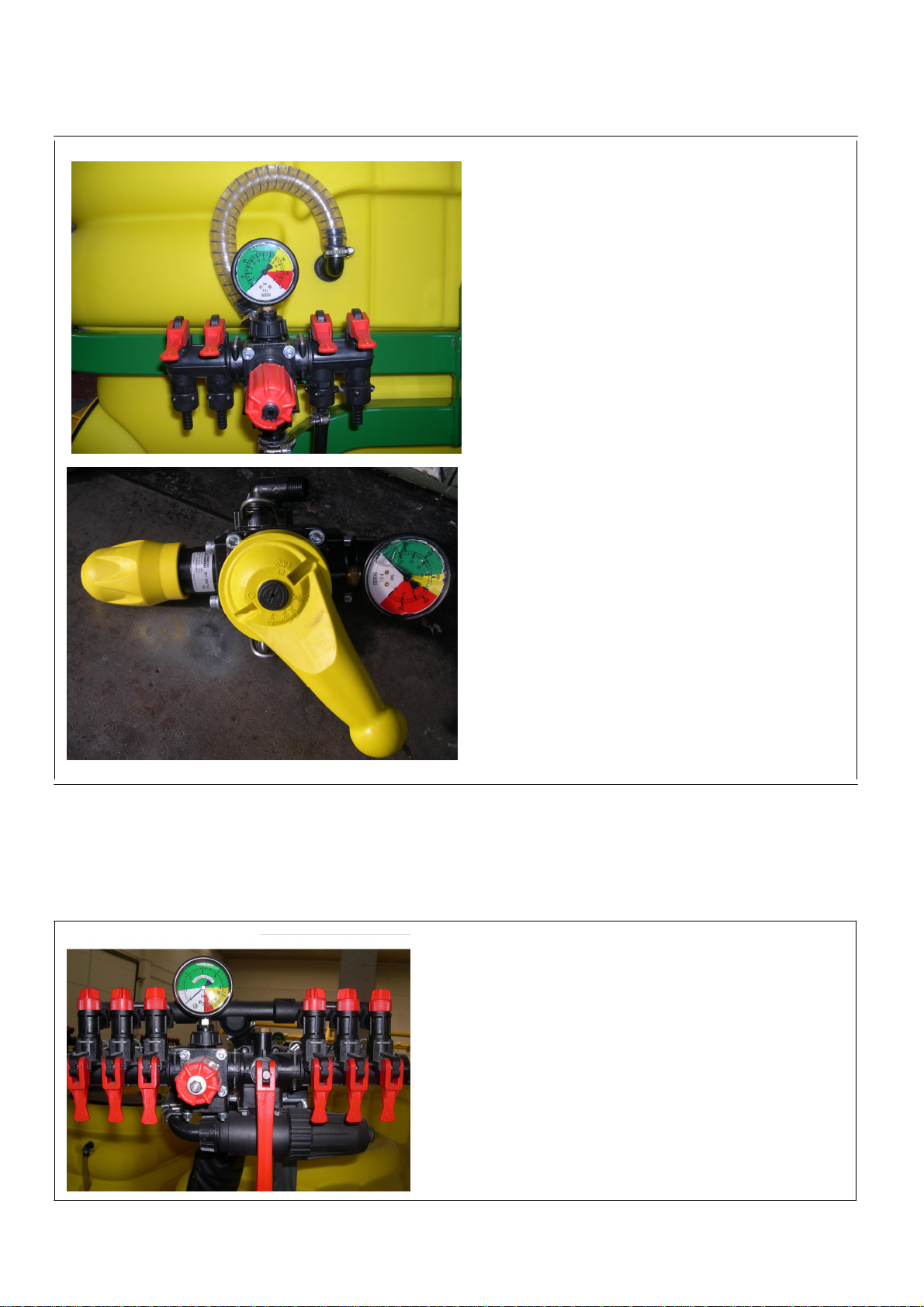

4.1.8 CONTROL UNIT

The control unit consists of a pressure

regulator (R), and a distributor (D).

At the pressure regulator is installed a

manometer (M) which allows to view the

pressure within the circuit. Using the

regulator it is possible to adjust (depending

on the number, the type of nozzles,

processing speed and other parameters), on

pressure operation of the machine .

In case of anomalies in the circuit, which

can generate strong pressure safety, it

intervenes a safety valve calibrated

according to models.

Pressure regulators may be manual

(mounted on the atomizer fig 1, or

tractors (model BYMATIC fig 2) or

electric (with control panel placed in the

cabin), in the latter case it is provided a

distance gauge fitted with a separator

because for security reasons it's not

possible to bring liquids in pressure in

the signal box. If the tractor is equipped

with a sealed cabin it is compulsory to

use electric controls.

Also for this device is attached related

manual.

4.1.9 DISTRIBUTORS

The Distributor (D) consists of gate valves or

cocks which convey the fluid in various directions.

M

D

R

FIG 1

R

D

M

This manual suits for next models

67

Table of contents