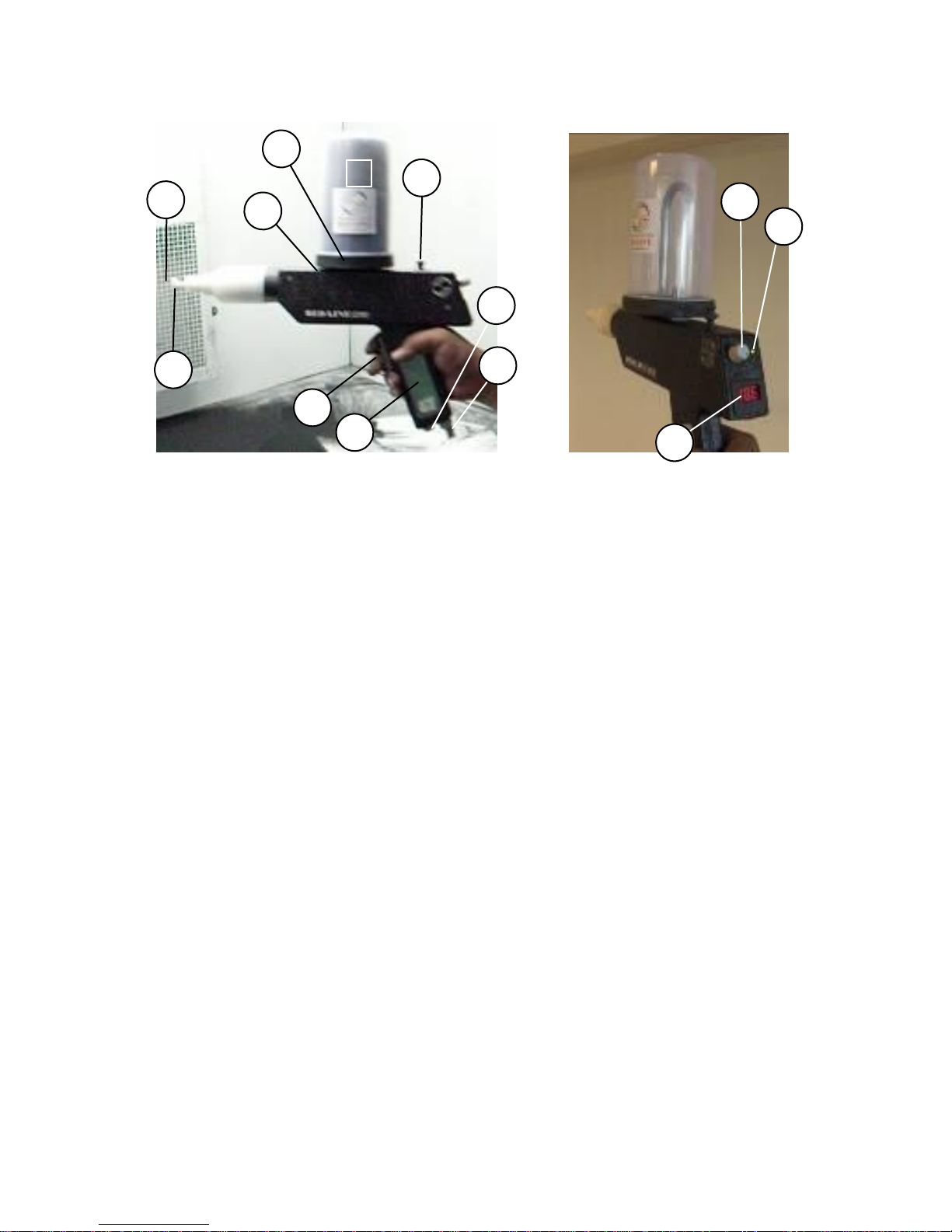

Operations:

1. Hang the article(s) to be coated in the spray booth or in a safe

enclosure, ensuring that they are properly earthed (grounded).

2. Switch ON the mains power switch to the machine from the wall

power outlet. The indicator (if provided) on the wall-mounting power

adaptor should light up.

3. Switch on the compressed air supply to the machine and set the

pressure at around 20 - 30 psi.

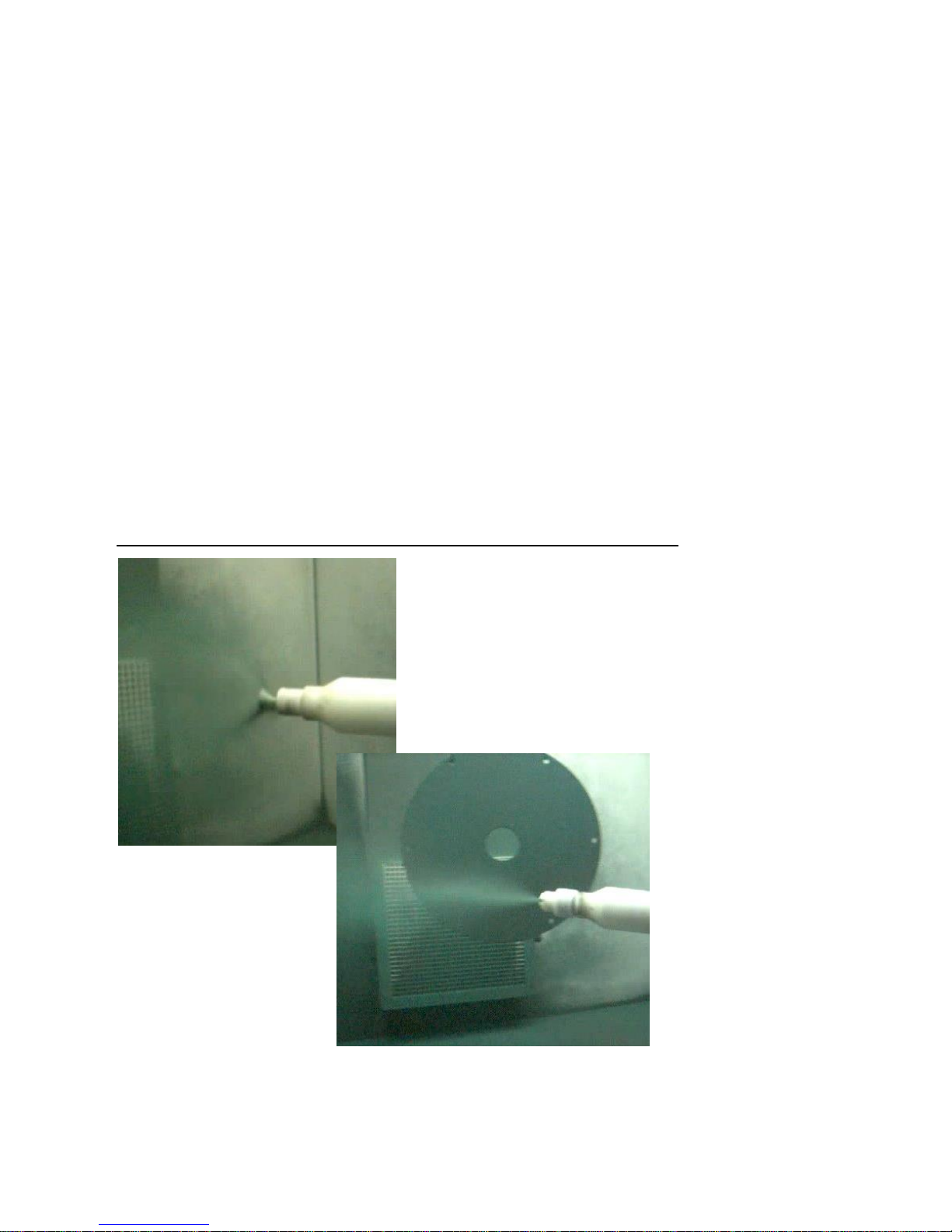

4. Point the gun into the booth towards the grounded articles to be

coated and press the trigger on the spray gun. The indicator at the

back of the gun (yellow) should light up. The Digital Meter will

indicate the (nominal) charging voltage available at the tip of the

gun. Turn the kV controller knob (at the back of the gun) clockwise

to increase the charging voltage to the max –approx 100kV. The

range available is approx from 20kV to 100kV. Turn the flow

controller clockwise till you achieve powder flow at a rate and

density of satisfaction to you.

5. Keeping the nozzle of the gun about 10 to 20 cms (4” to 8”) from the

articles being coated, spray powder in smooth horizontal arm

sweeps. Ensure that the part to be coated is completely coated with

powder. Excessive coating may lead to unwanted and unnecessary

thicker coats.

6. Releasing the trigger of the gun switches OFF the powder flow as

well as shuts down the electronics used to generate and control the

high voltage. Please note that your powder spray gun may still

hold electrostatic charge. To prevent any accidents, please touch

the charging tip to a ground point to discharge any residual

electrostatic charge.

7. Place the coated article in the oven which has been preheated to

the required temperature (350 - 390oF / 180 - 200oC). Check the

curing time with the powder manufacturer (this information may be

available on the powder carton or from the powder supplier). Keep

the article in the oven for the desired time. At the end of the curing

period, switch off the oven, open the door of the oven, allow the

parts to cool and remove them. Please note under-curing or over-

curing (temperature or time) could give you unwanted results.

8. Your part is ready, duly powder-coated.