BarlowTyrie 9111210 User manual

BARLOW TYRIE

quality since 1920

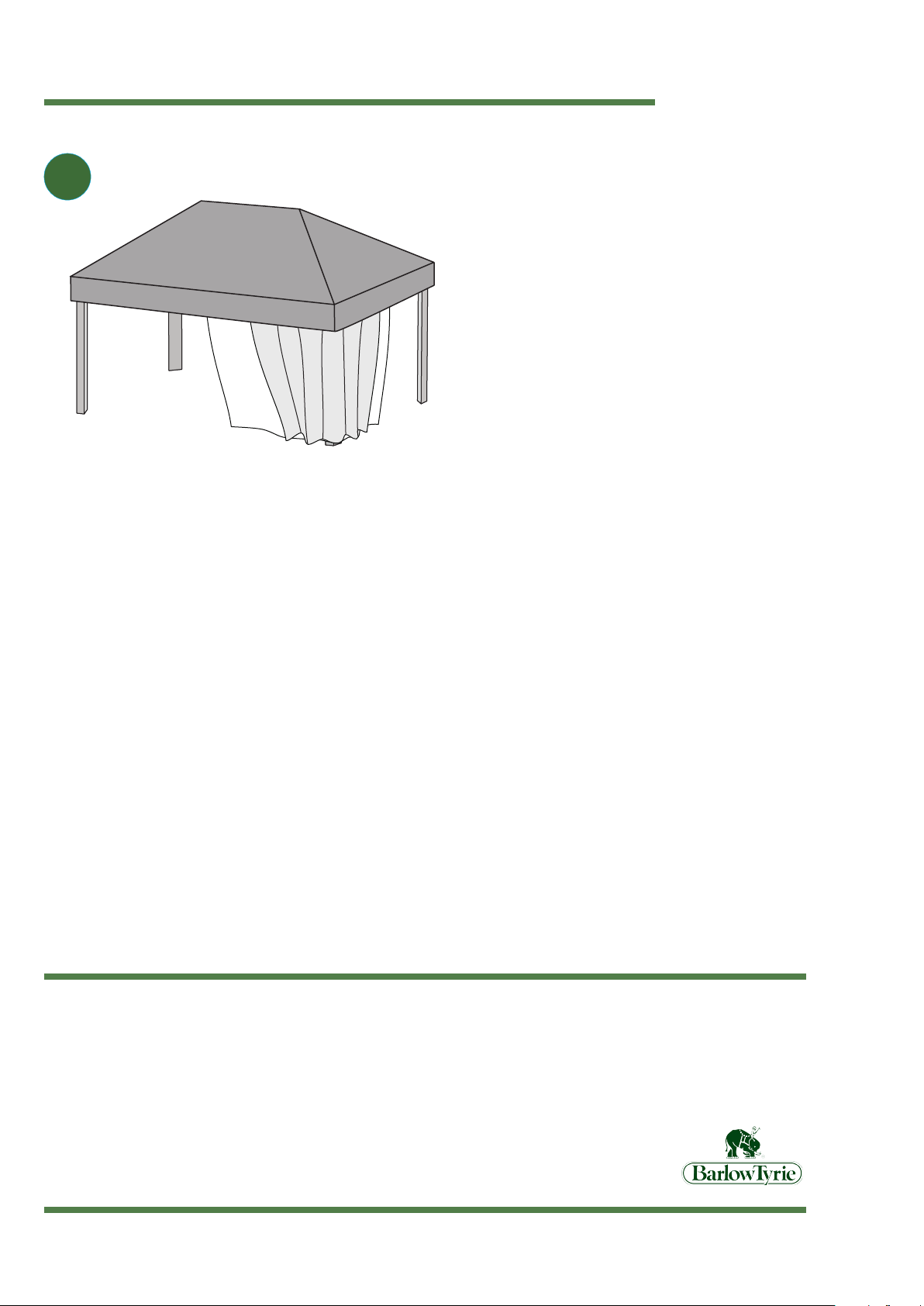

3.66 x 4.5m - 12’ x 15’ Pavilion Shelter with Double Rail Beams

Ref: 9011215

Step by Step Assembly Instructions

Pavilions

Before you begin

These installation instructions will lead you through the process of installing your new pavilion.

The installation of the pavilion requires special attention to certain detail. Before you begin you

should:

Check your order Make sure the contents of the carton match the product numbers on your

order. Contact your dealer if there are any damaged, missing or incorrect parts.

Pay attention to safety Because of the size and weight of certain parts, installation is

recommended with no fewer than two people. Always maintain a clean, organized work area.

Make sure you have the right tools and materials Barlow Tyrie supplies the appropriate

fasteners upon request through your dealer for anchoring the pavilion securely to the ground.

If you are unsure about the required anchoring system best suited for your pavilion consult your

dealer for the proper fastening method.

Review entire installation guide This step gives you the opportunity to contact your dealer to

answer any questions before you begin.

Assembly requirements

Two people Spirit level

Hand drill Screwdriver set

Step ladder Long nose pliers

Spanners Rubber hammer

Tape measure

www.teak.com Page 1 of 16

Step by Step Assembly Instructions

3.66 x 3m - 12’ x 10’ Pavilion with Cabrio Folding Roof

Product Ref: 9111210

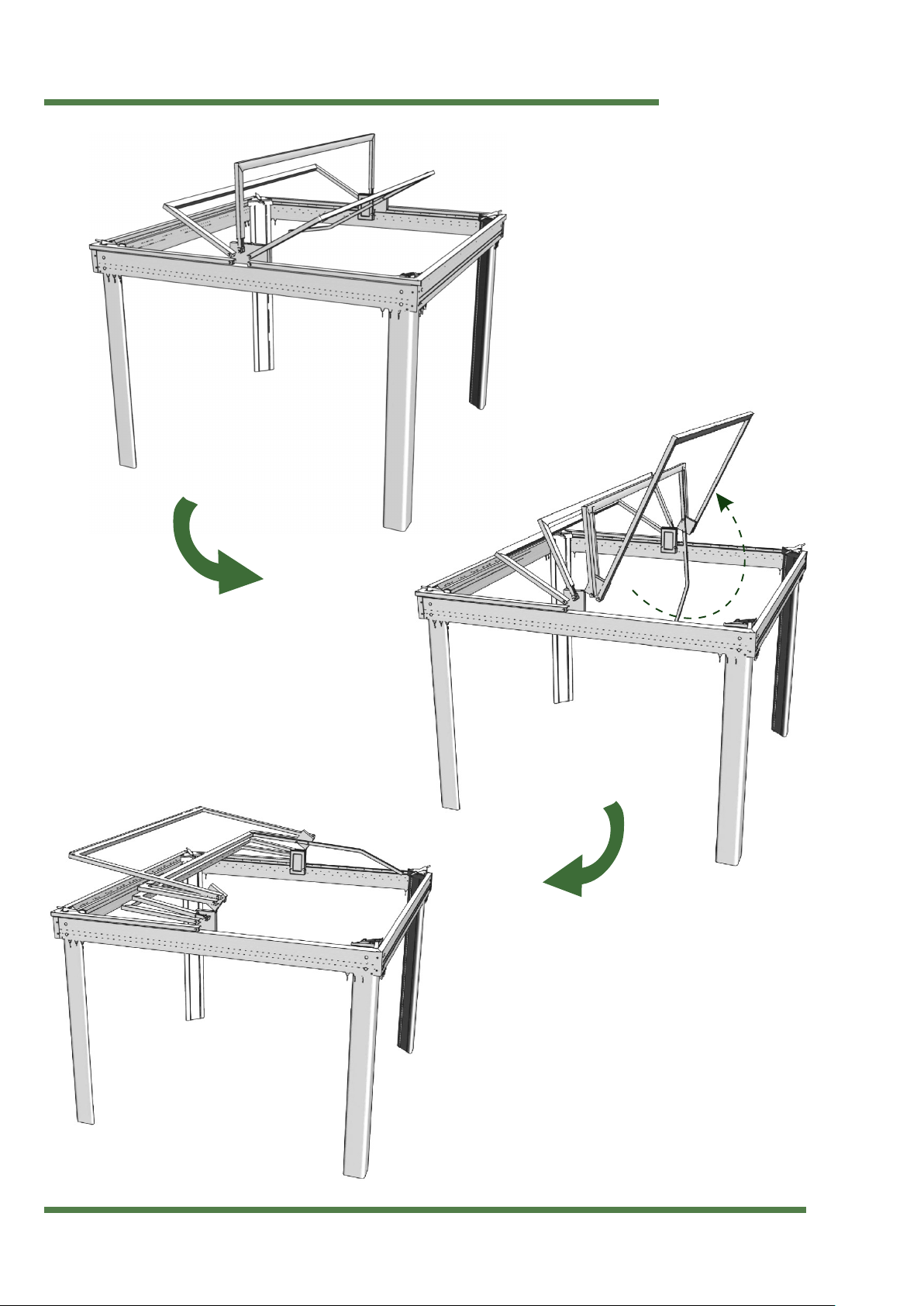

Assembly overview

BARLOW TYRIE

quality since 1920

www.teak.com Page 2 of 16

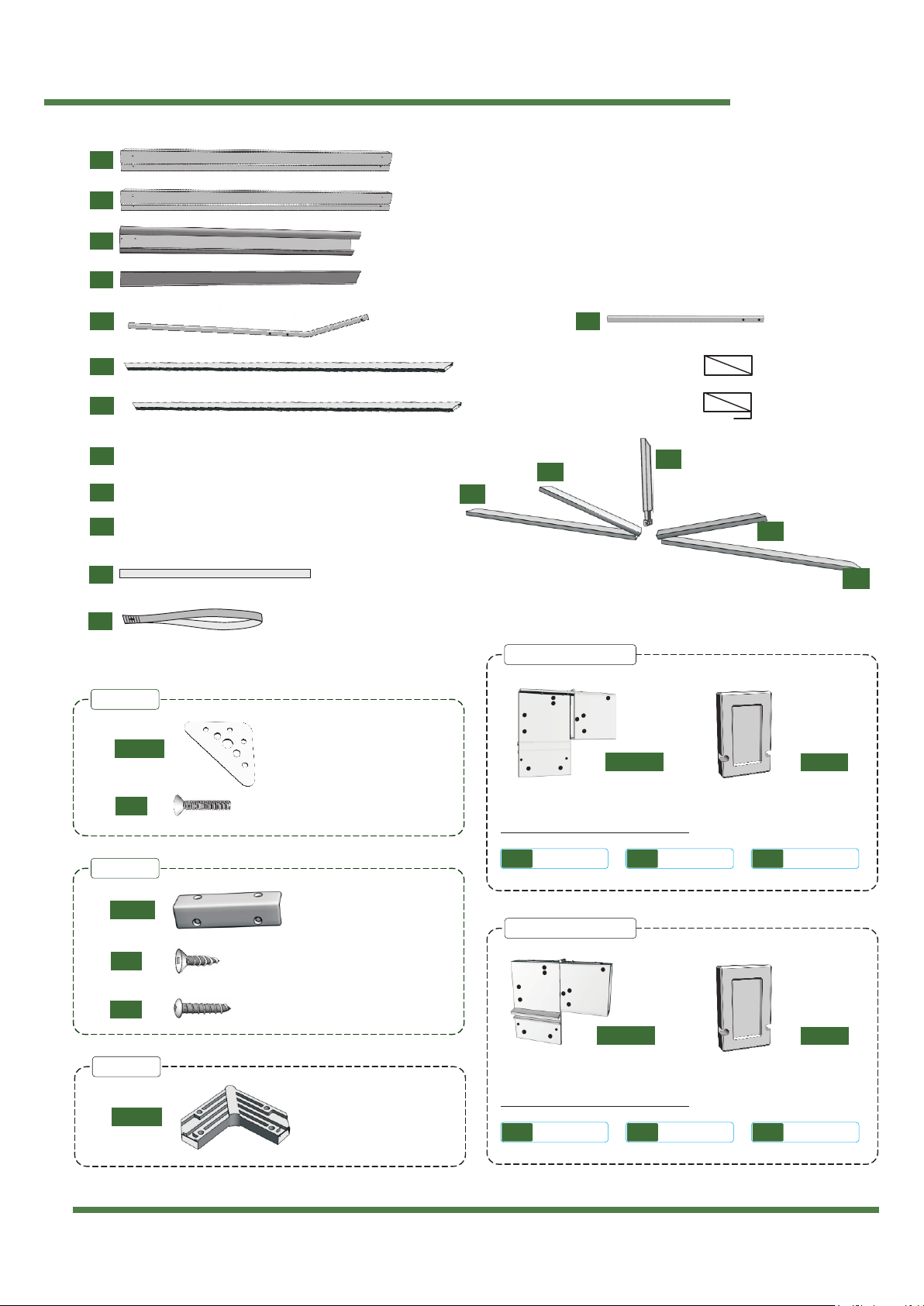

Part list

BARLOW TYRIE

quality since 1920

www.teak.com Page 3 of 16

2x B1

1x L1

3x T1

2x T2

4x T3

T3

T3

T4

T4

T5

4x T4

2x T5

4x R1

1x R2

2x B2

4x P1

4x P2

Lower Truss with 5/16” dia hole about pivot point

MiddleTruss with 5/16” dia hole about pivot point

Center Truss with plastic spring slide insert

Lever Arm Strap

Flat Bar Roof Trusses

1x

1x

1x

1x

1x

1x

Post End Plate

Inlcudes the following sub kits:

Inlcudes the following sub kits:

16x 002

4x AL005

Roof Hinge

Roof Hinge

1x KC.02L

1x KC.02R

1x PL005

1x PL005

Roof Hinge Cover

Roof Hinge Cover

Plastic Corner Bracket

4x K4.01

8x 025

16x 015

Plastic Corner Insert

10x PL007

KC.01

KC.04-A

KC.05

KC.03 (RHS KIT)

KC.02 (LHS KIT)

SKC.03-1 SKC.03-2 SKC.03-3

SKC.03-3SKC.03-2

SKC.03-1

Beam 3 mtrs 10 feet (roof hinge side)

Beam 3.66 mtrs 12 feet (transverse side)

Triangular Corner Post

Corner Post Cover

Full Length Lever Arm 1x L2 Dummy Lever Arm

Transverse Roof Support (no grove)

Transverse Roof Support (with grove)

Cross-Sectional View

Cross-Sectional View

Plate Screw 1/4” x 13/4”

Metal Screw #10 - 3/4”

Metal Screw #8 - 3/4”

Part list

BARLOW TYRIE

quality since 1920

www.teak.com Page 4 of 16

1/4” dia Nylon Bushing

Nylon Lock Nut - 1/4”-20

Plastic Finishing Hole Cap

Hinge Box Side Cover

Lever Arm Fork

Fork Installation Guide

Lever End

Cover

16x 002

4x PL014

2x PL01 1

1x PL012

2x PL010 2x PL013

4x PL016

4x PL07 4x PL015

1/4” Flat Washer

1x 002

2x 020

2x 018

1x 005

1x 010

2x 016

#8 Square Head Screwdriver Bit

#10 Square Head Screwdriver Bit

Pulleys included with curtains

PL101

20x R3 Velcro Strips

Carriage Bolt - 5/16” x 2”

5/16” Flat Washer

16x 003

16x 007

16x 012 5/16” Nylon Lock Nut

5/16” Nylon Lock Nut

Nylon Bushing - 5/16”

5/16” Flat Washer

5x 012

10x 006

5x 004

10x 019

2x

Tab Washer 1/4”-20

Roof Hinge Cover Screw #10-3/8”

1/4” Flat Washer

1/4” Lock Washer

Hex Bolt - 1/4”-20 x 5/8”

2x 008

2x 001

2x

2x 005

2x 014

2x 026

2x

Nylon Bushing - 5/16”

Carriage Bolt - 5/16”x 2”

5/16” Flat Washer

5/16” Lock Washer

5/16” Nut

2x 011

2x 009

2x 003

4x 006

2x 019

SKC.03-1

SKC.03-2

SKC.03-3

KC.07

KC.06

KIT - 08

MISC

Hex Bolt - 5/16” x 31/4”

Cover Screw - 1/4” x 13/4”

Strap Screw - 1/4” x 13/4”

Self-tapping Screw - #12 x 13/4”

BARLOW TYRIE

quality since 1920

www.teak.com Page 5 of 16

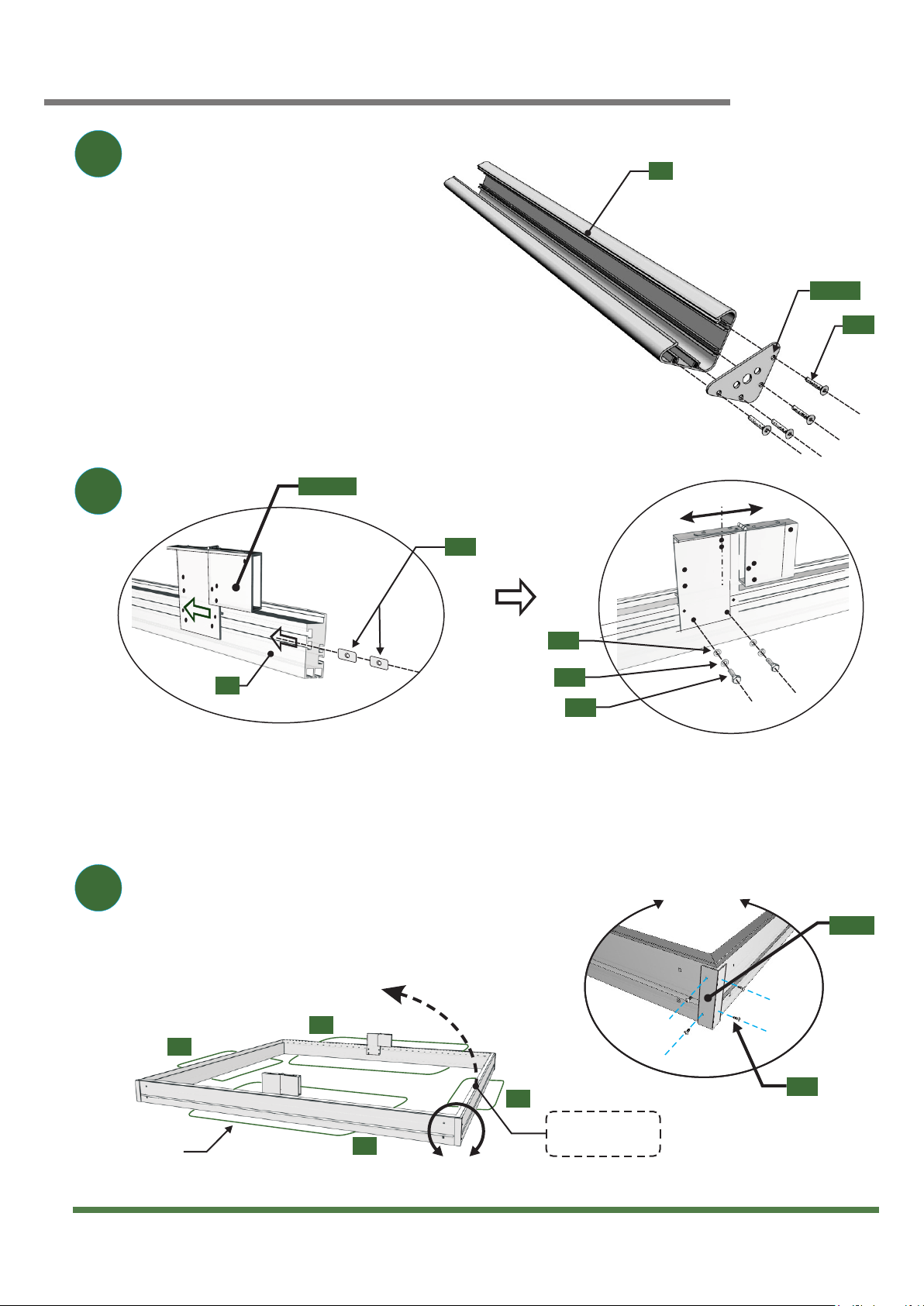

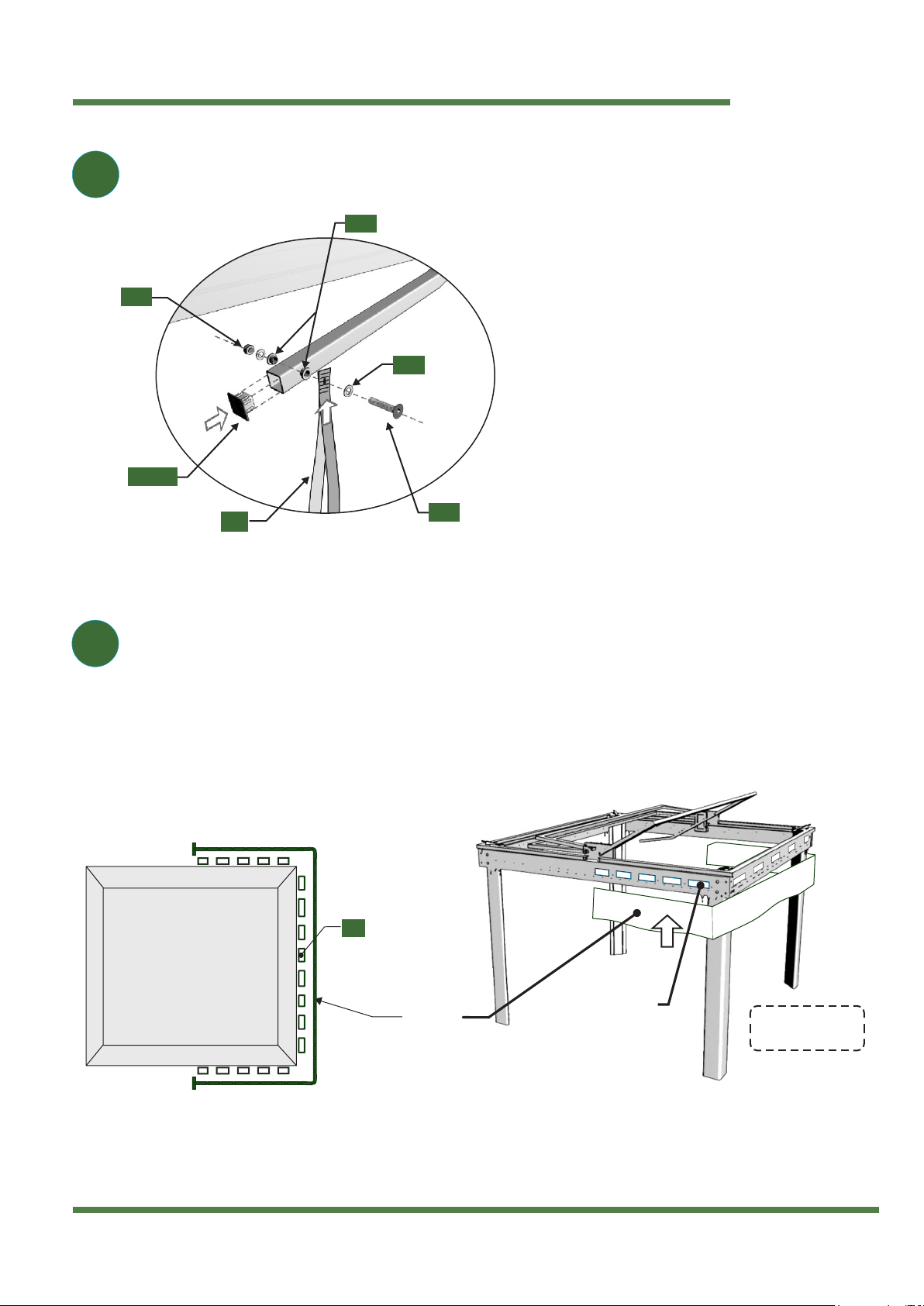

Getting started

3

2

1

P1

AL005

002

Roof will open

from this side

Cardboard

B1

B1

B1

B2

B2

KC.02L

A-A

001

005

014

008

View A-A

015

K4.01

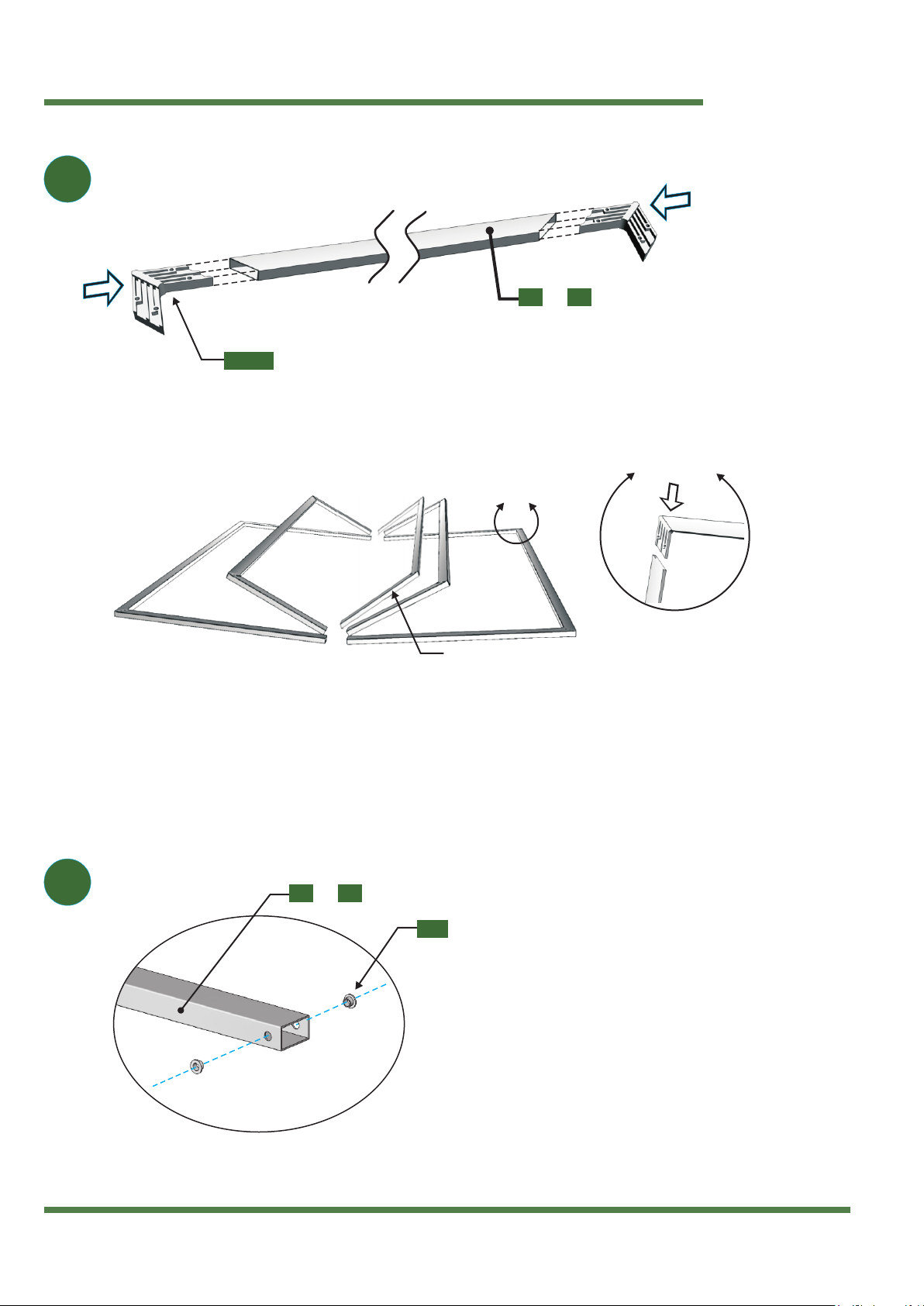

Secure the base plates (AL005)to the bottom of each

of the aluminium corner posts (P1)using metal bolts (002)

as shown in the diagram. (Repeat step for all four corner

posts.)

Install the two roof hinges on the beams (B1)by first inserting two tab nuts into the bottom interior groove of both

beams. Then slide the tab nuts till the mid section of the beams. Install the roof hinges on both beams using bolts

and washers shown in the above right hand side diagram. LIGHTLY TIGHTEN BOLTS. The hinge will be centered and

bolts will be tighten in step 6.

On a flat surface, assemble all the beams together by fixing the

aluminum corner bracket (K4.01)at each corner, using the metal

scews (015)supplied, as shown in the diagram. You may use

pieces of the cardboard box to protect the frame from scratches.

Assembling the roof

BARLOW TYRIE

quality since 1920

www.teak.com Page 6 of 16

5

4

T1 T2

&

T3 T4

&

Use a Rubber

Hammer

Nylon Bushing

Roof Truss Ends

View A-A

Use a Rubber

Hammer

MiddleTruss Assembly

A-A

PL007

019

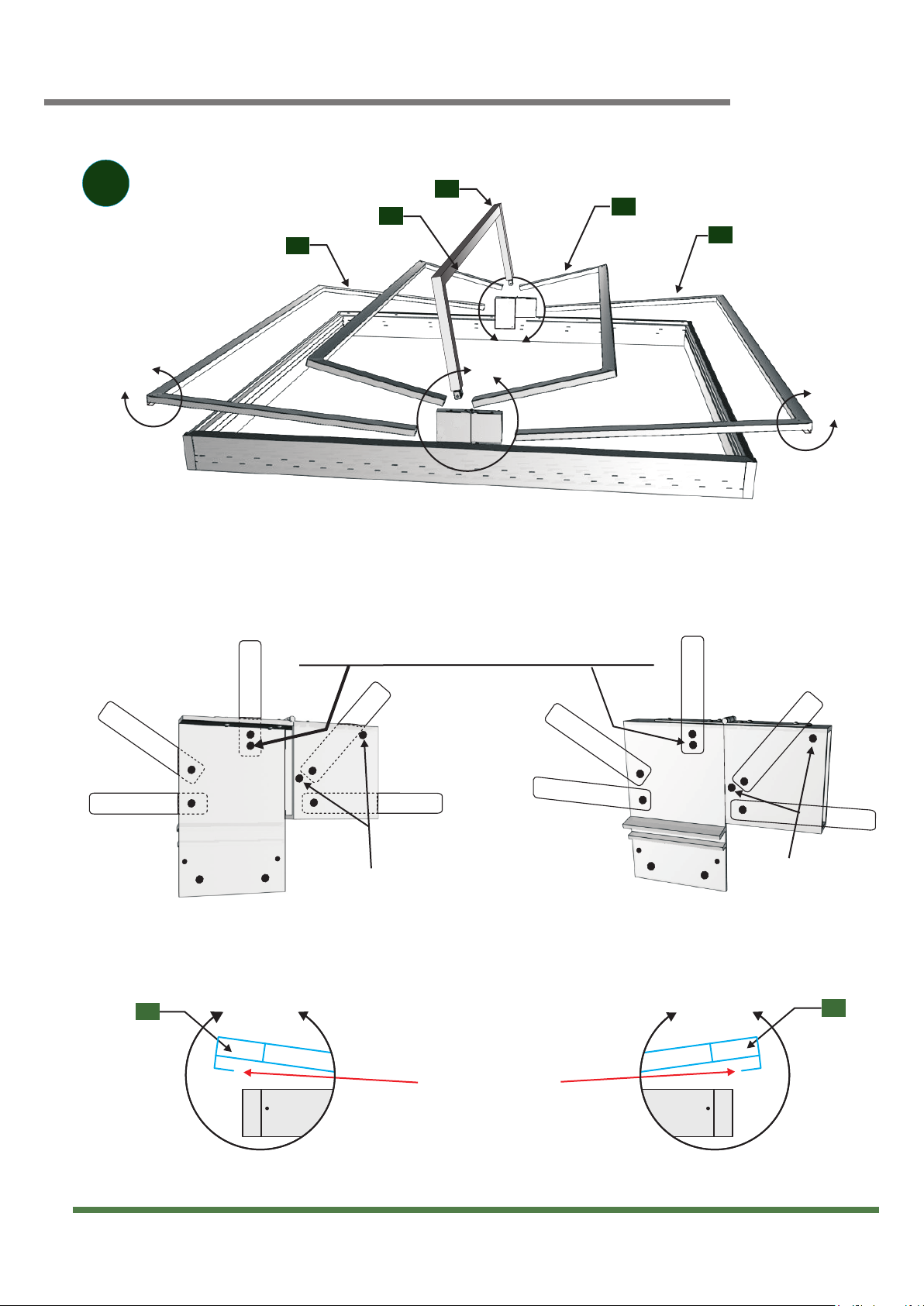

Install the plastic corner inserts (PL007)at each end of the transverse

roof supports (T1)and (T2)as shown in the figure above.You will need a

rubber hammer to insert them properly

Complete the assembly by inserting the trusses (T3), (T4)and (T5)at each end of the

transverse roof supports as shown in the figure above. Again you will need a rubber

hammer to insert them properly.

On each end of the roof truss assemblies (T3)and (T4)

install two plastic bushings as shown in the diagram

BARLOW TYRIE

quality since 1920

www.teak.com Page 7 of 16

Assembling the roof framework

6

B-B

View C-CView B-B

Install the middle plastic stub truss on The

upper hole can be used in time if more pressure needs to

be exerted by the middle truss onto the roof fabric.

the lower hole.

Lay the trusses on top of the beam assembly in the order and orientation shown by the

diagram above. Consult views B-B, C-C, D-D and E-E for specific detail. Then turn to the

next page for a description on how to fix each trusses to the hinges.

E-E

D-D

Transverse

Groove Should be

Facing Downwards

Support

T2

T2

T3

T3

T4

T5

T4

View D-D View E-E

C-C

Holes used for

Lever Arm

and Dummy

Lever Arm

(see Step 9)

Holes used for Lever Arm

and Dummy Lever Arm

(see Step 9)

Assembling the roof framwork

BARLOW TYRIE

quality since 1920

www.teak.com Page 8 of 16

F-F F-F

Transverse Support

Groove Facing

Downwards

Tighten Bolts

(repeat on other side)

Center Hinge Assembly

View B-B

(Hardware Installation)

View B-B

(TOP VIEW)

See Through

View

View F-F

004

006

002

006

KC.02L

014

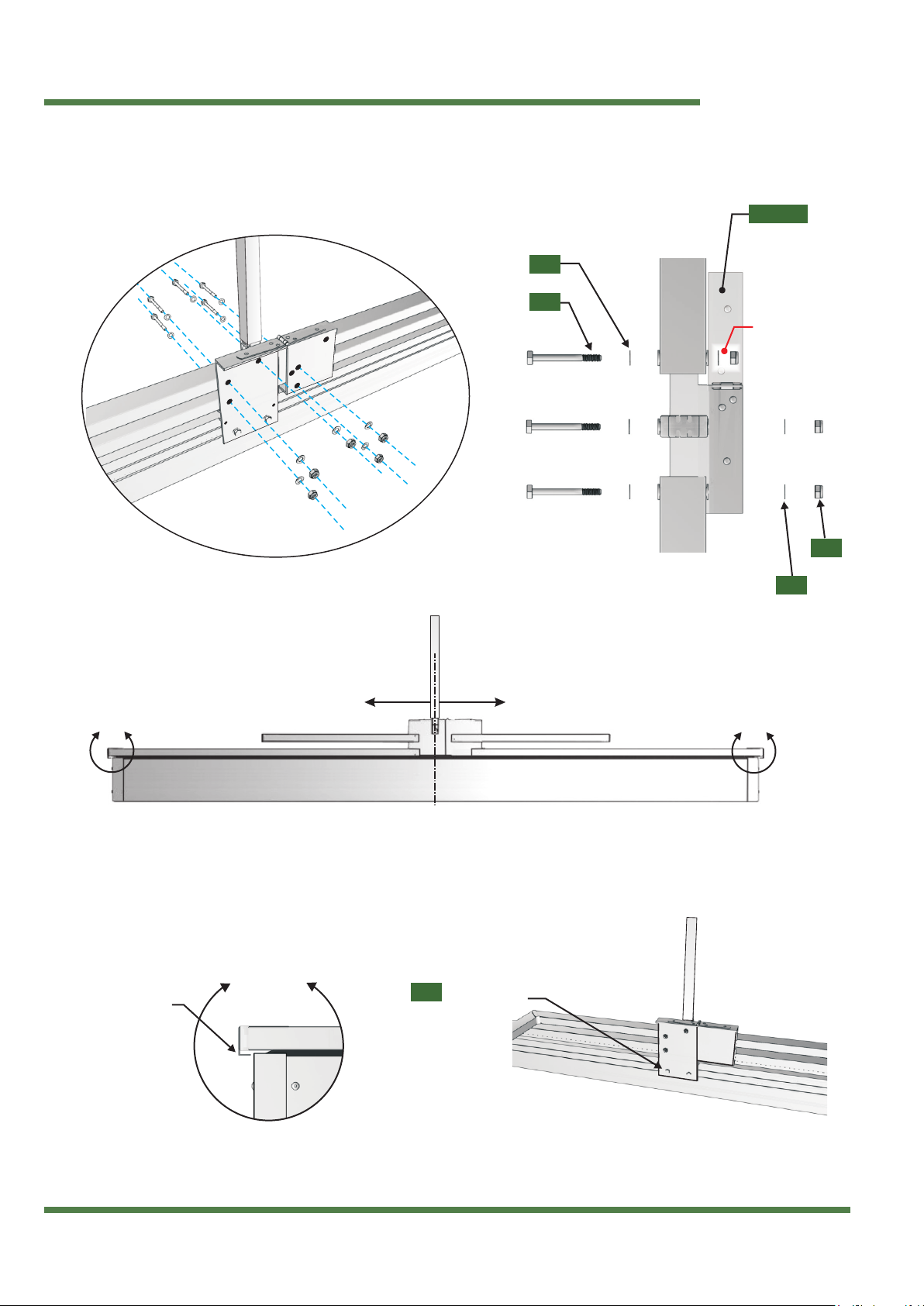

Install the trusses on the hinge using hardware shown in views B-B.

Notice that only one side is shown. Repeat this step on the other hinge.

Once the trusses have been fixed properly to each hinge, center the roof assembly

by allowing the protruding groove of (T2)to extend just beyond the edge of beam

(B2)(see view F-F). Then tighten the hinge bolts as shown in the bottom right diagram.

Installing the corner posts

BARLOW TYRIE

quality since 1920

www.teak.com Page 9 of 16

View G-G View G-G

(TOP VIEW)

Flat Washer

007

Lock-Nut

012

003

003

7

Top View

G-G

P1

P1

P2

P2

P2

Locking

Key

Assembly

KC-07

002

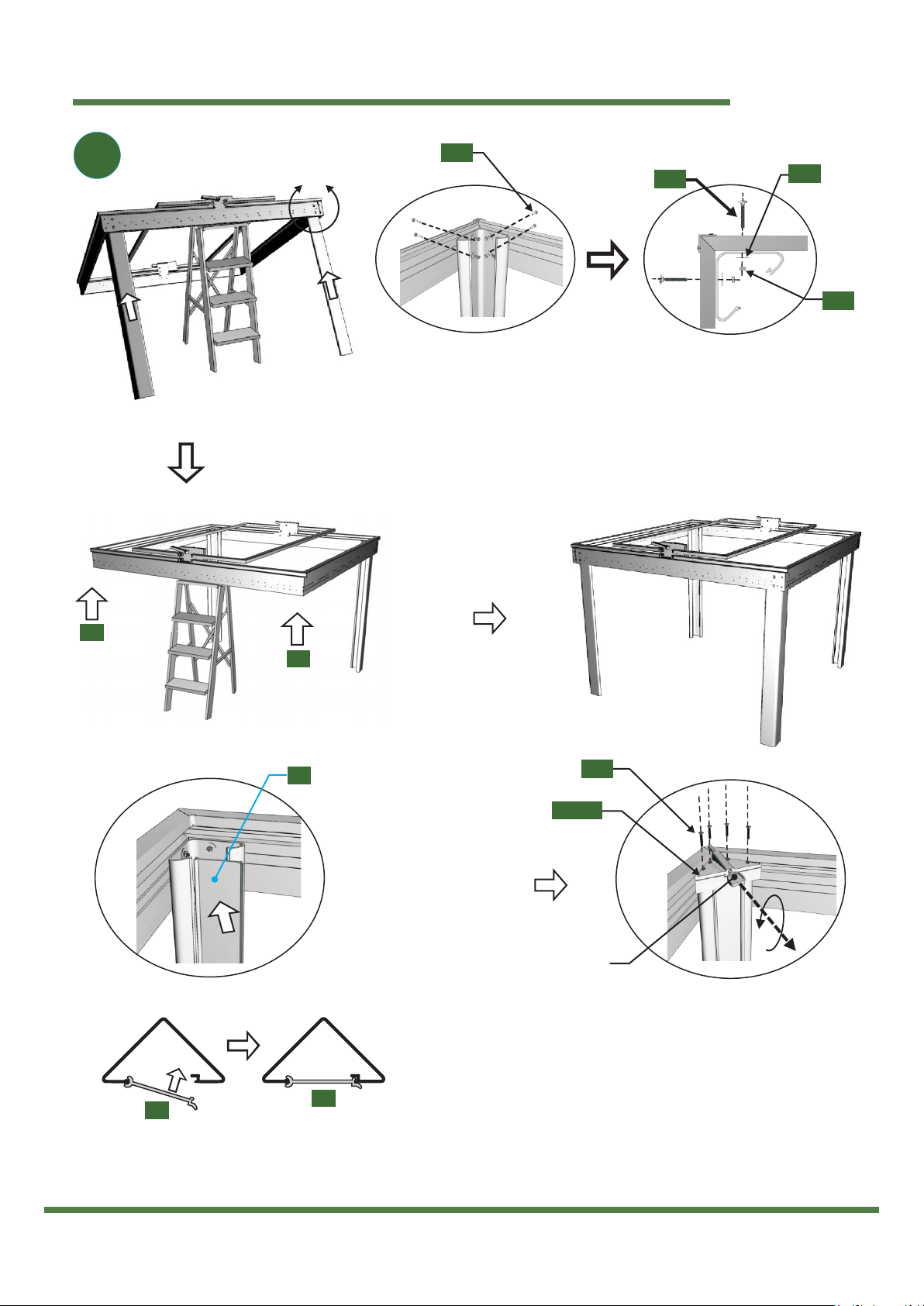

Attach one of the four corner posts (P1)to each corner of the structure using

hardware shown in the top right diagrams. This step may require a second

person or a ladder to lift the roof assembly in order to fix all four corner posts

(P1). See diagrams below for further assembly steps.

To complete the

post assembly, snap

together the corner

post (P1)and

corner post covers

(P2). Repeat step

for each corner.

Then fasten the top cover assembly (KC.07)on top of

each corner post (P1)DO NOT OVER TIGHTEN SCREWS.

The locking key can be in the unlocked position or

removed from the cover assembly by turning then

pulling it.

Anchoring the pavilion

BARLOW TYRIE

quality since 1920

www.teak.com Page 10 of 16

8

Make sure the structure is well aligned and levelled with the floor

as shown in the diagram below. Consult the section below for

recommendations on the type of anchorage required for fixing

the structure on the floor.

level

Ground Fixing

WOOD

OPTION A

WOOD DECK/FLOOR

Requirements:

8 (2 per plates) of each

- 5/16" x 2" wood screws

- 5/16" washers

CONCRETE

SOIL

OPTION B

CONCRETE/CEMENT FLOOR

The Permo Lock anchoring system is the recommended

method that offers a strong permanent solution for

anchoring your shelter and to protect it against the

wind. See next page for instructions on how to install this

anchor

C1

C2

C3

Remaining holes in

plate (AL005) are used

for xing the structure

on the oor

W

L

D

Distances W, L, and D are calculated

from centre to centre of plates (AL005)

Requirements:

8 (2 per plate) of each

- 3/8” x 11/2” expansion anchor

* use 1/2” cement drillm bit

Dimensions inches (cm)

W 111 (282)

L 138 (350)

D 177 (450)

C1 79 (200)

C2 114 (290)

C3 144 (366)

Anchoring the pavilion

BARLOW TYRIE

quality since 1920

www.teak.com Page11 of 16

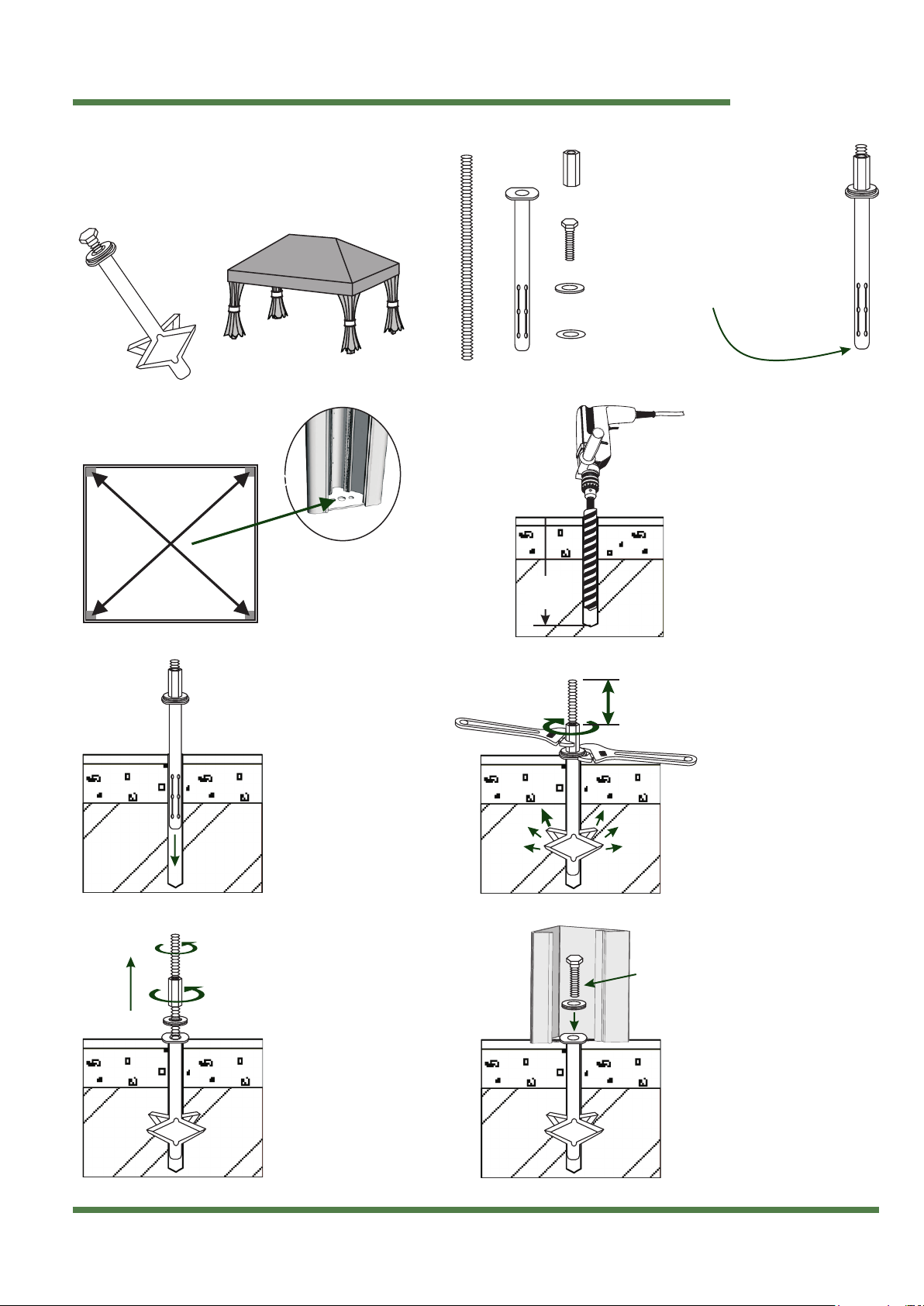

Top View

3-1/4” (8.2cm)

Permo

®Lock Anchoring System

Insert the assembled

Permo Lock anchor

into the drilled hole

Unscrew the coupling

and rod completley

from the xed Permo

Lock anchor and

remove the two

washers

Place the corner of the structure

over the anchor and ax it using

the supplied ½” bolt and washers.

Grease the threads of the bolt

Screw in the coupling nut without

turning the rod and anchor.

The maximum opening of the

Permo Lock anchor occurs when

the rod extends 3¾” (8.2cm)

above the coupling nut

Drill a 1” x 19¾” (2.5cm x 50cm)

hole at each marked location

using a percussion drill with a

diamond tip masonry drill bit

Apply grease on threads

19¾”

(50cm)

x4

lock washer

x4

washer

x1

rod

x4

bolt

x1

coupling

x4

anchor

Position your assembled

structure on the chosen

location then mark the

center of each corner plate

Packaging Contents

One Permo Lock anchor comes

preassembled and ready to use

as shown on the right. Verify that

the rod end is ush with the end

of the anchor.

Final frame assembly

BARLOW TYRIE

quality since 1920

www.teak.com Page 12 of 16

H-H

I-I

9

View H-H

(step a)

View H-H

(step b)

Remove the guide

after installing the fork.

View H-H

(step c)

L1

L1

T4

View I-I

(TOP VIEW)

See

Through

View

Install the Plastic Finishing Cap

L1

10

016

006

011

009

019

003

026 020

PL01 1

PL01 1

PL005

PL010

PL012

KC.02L

Install the plastic fork on the (T4)truss assembly on the opening side. Locate the proper

position of the fork by using the fork installation guide as shown in views H-H. Then use the

self tapping screw (016)to fix the fork on the transverse truss member. Then insert the end

of the lever arm on the fork and fix the lever using hardware shown in view I-I. Repeat step

on other side for the dummy lever arm.

To complete the roof hinge mechanism, install the

plastic hinge cover (PL005)over the roof hinge using

screws (026).Then install side cover (PL010)and the

hole cap (020). Repeat step on both sides.

Final frame assembly

BARLOW TYRIE

quality since 1920

www.teak.com Page 13 of 16

12

R2

11

Velcro Strip

(top groove)

16” apart

Valance

TOP VIEW

Velcro Strip

(top groove) Roof will open

from this side

R3

002

005

010

018

PL013

Insert velcro strips at every 16” in the top groove of the beams. Then fix the

valance to the velcro strips (R3). Start from one end of the valance and

work your way around the frame assembly. See adjacent diagrams for detail.

Install the lever strap on the end of the lever arm

using hardware shown in the left diagram.

Then install the plastic cap (PL013)on the end

of both the lever and dummy lever arm.

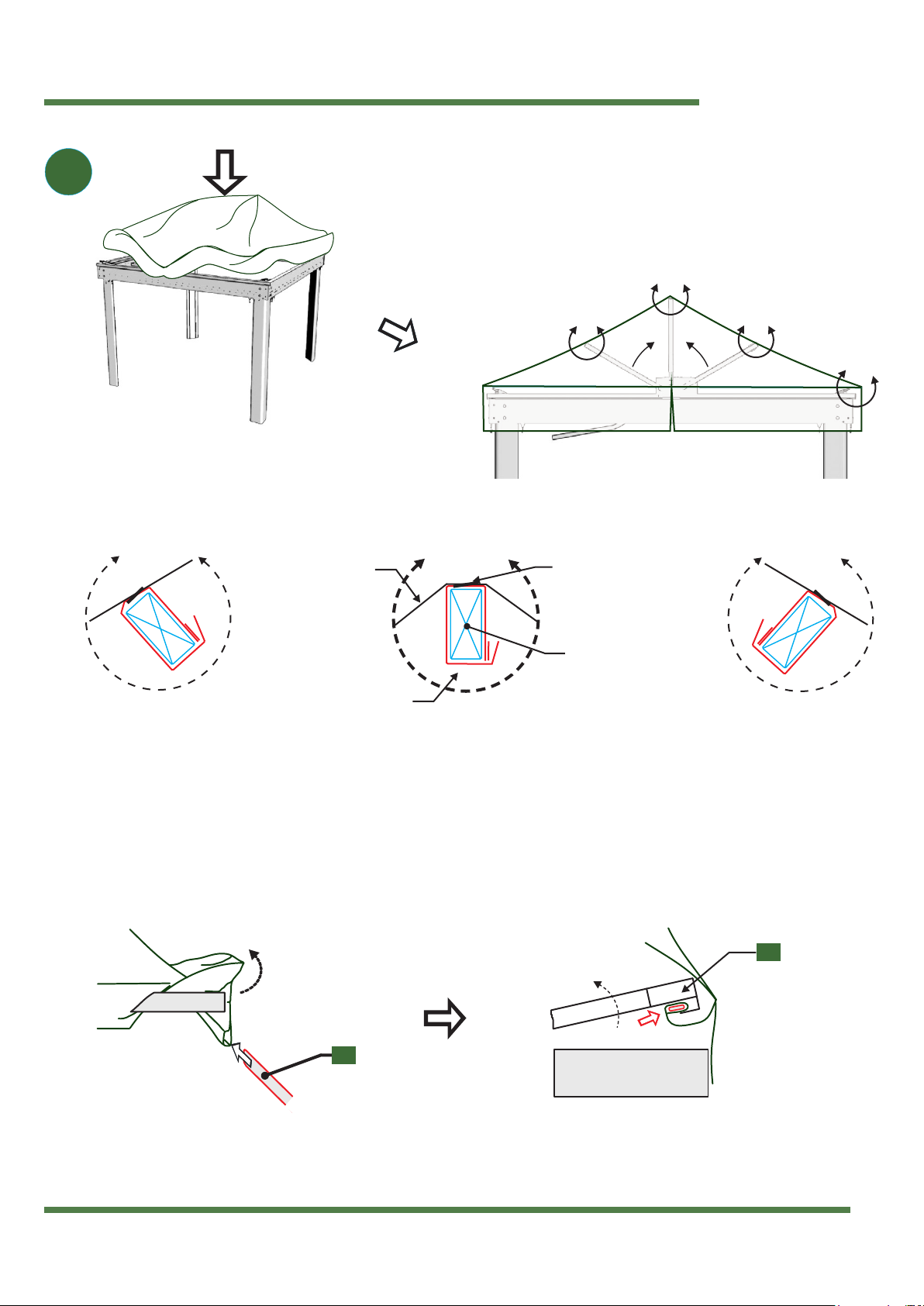

Installing the roof fabric

BARLOW TYRIE

quality since 1920

www.teak.com Page 14 of 16

SIDE VIEW

J-J

K-K

M-M

L-L

13

View L-L

View K-K View J-J

Roof Support

Velcro Strip

Roof Fabric Weld Line

View M-M

(Step a)

Insert a flat bar on each

end of the pocket

View M-M

(Step b)

R1

T2

The next step will give instructions on how to fix the roof cover to the frame assembly. Slide the flat bars

(R1)in the pocket of the fabric as shown in View M-M.Then raise the truss assembly and push the flat bar

and fabric into the groove of the transverse truss (T2). Then fix the velcro strip around the 2 roof supports

(T4). Note that the velcro should be fitted around the support as shown in views K-K (left hand side

support) and L-L (right hand side support). Then raise the middle roof support (T5)in its upright position

and fix the velcro around it as shown in view J-J.

Install the roof fabric cover over the frame assembly

with roof trusses down. Make sure that all 4 corners

of the roof fabric are aligned properly.

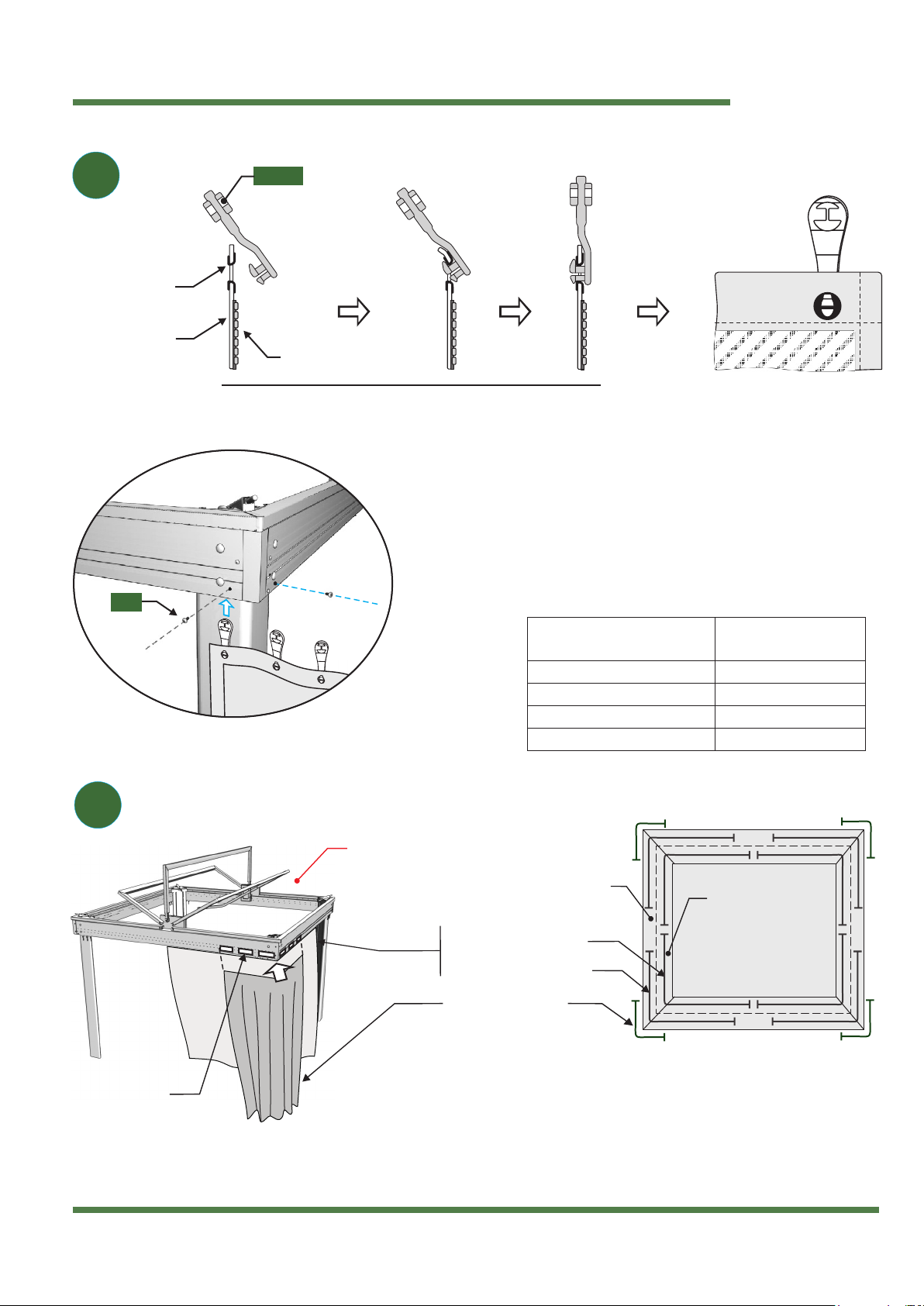

Installing the curtains

BARLOW TYRIE

quality since 1920

www.teak.com Page 15 of 16

15

14

025

outside rail

curtains on outside rail

decorative curtains

(installed using velcro strips

on bottom beam groove)

inside rail

curtains on inside rail TOP VIEW

Velcro Strips

Bottom Groove

16” apart

Profile View

Zipper

(Interior Side)

Metallic

Eyelet

Curtain

(Exterior Side)

Curtain

Exterior Side

Plastic Pulley Snap Pulley

in place

PL101

Roof fabric and valence

not shown for clarity

Install plastic pulleys (PL101)by snapping them in each metallic

curtain eyelet. Use long nose pliers to facilitate this operation.

Pulleys should be facing towards the curtain side on which the

zipper is located (see above steps). Then install each curtain

sections into the provided beam slots as shown by left hand

diagram. After installing all pulleys, block the access with the

screws (025)as shown in the diagram. Repeat step for each

corner. See next step (15) for curtain installation example

Curtain Type Rail

Decorative curtains Inner or Outer

Mosquito curtains Inner

Acrylic curtains Outer

Plastic curtains Inner or Outer

The decorative curtains are installed using velcro strips (R3)inserted

16” apart in the bottom groove of the beams similarly to the valance

in step 13. If you have purchased optional curtains (mesh netting,

transparent plastic or acrylic fabric) install them on the inside or

outside rail of the beams.

Installing the curtains

BARLOW TYRIE

quality since 1920

www.teak.com Page 16 of 16

Ref 3412

Barlow Tyrie Limited

Braintree

Essex CM7 2RN England

t: + 44 (0)1376 557 600

f: + 44 (0)870 460 1100

Barlow Tyrie Inc

1263 Glen Avenue Suite 230

Moorestown

NJ 08057 - 8101 USA

t: + 1 856 273 7878

f: + 1 856 273 9199

15 Install the decorative curtains on the iterior or exterior

rail of the beams (B1)and (B2). If you have purchased

optional curtains (mosquito netting, transparent plastic or

acrylic fabric) install them on the inside rail of the beams.

Table of contents

Other BarlowTyrie Patio Furniture manuals

Popular Patio Furniture manuals by other brands

GB

GB 5 Piece Ottoman Set instruction manual

Sunjoy

Sunjoy L-UB381PCM-50C manual

Patio Premier

Patio Premier Caspian 203016 instruction manual

Costway

Costway PATIOJOY OP70682 user manual

Doppler

Doppler Goliath 5x5 Assembly instructions and user guide

JAYDEN CREATION

JAYDEN CREATION HOUFC0185 Assembly instruction