Barnant Company 689-0010 User manual

OPERATING MANUAL

TEMPERATURE

CONTROLLER R/S

(ADVANCED MODEL)

689-0010

689-0015

Barnant Company

28W092 Commercial Avenue

Barrington, Illinois U.S.A. 60010-2392

(847) 381-7050

(847) 381-7053 (Fax)

800-637-3739

www.barnant.com

e-mail: bar[email protected]

A-1299-0610

Edition 04

Barnant-cover.p65 10/8/01, 9:42 AM1

EU Declaration of Conformity

Name of Apparatus: Temperature Controller

Model Number: 689-0015

Description of Apparatus: Deluxe Process Temperature

Controller, 15A output.

Barnant Company declares that the above model is in

conformity to the following harmonized standards and directives:

Applicable Applicable Manufacturer’s

Directives Specifications Report Number

73/23/EEC EN61010-1/A2:1995 TR9755

93/68/EEC EN61010-2-010:1995

89/336/EEC EN61326-1/A1:1998 TR9756

92/31/EEC

93/68/EEC

The last two digits of the year in which the current

configuration of the above models were assessed per

the Low Voltage Directive is: 00.

Manufacturer: Barnant Company Division

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010-2392

USA

Tel: 847-381-7050

Manufacturer’s Signature:

James W. Doll Date

Vice President, Engineering

3 October, 2000

i

TABLE OF CONTENTS

Title Page

WARNINGS AND CAUTIONS................................................................1

INTRODUCTION....................................................................................2

APPLICATION DATA ..............................................................................3

DESCRIPTION.......................................................................................3

GENERAL.........................................................................................3

CONTROL PANEL DESCRIPTION ..................................................4

Vacuum Fluorescent Readout......................................................4

UP, DOWN, LEFT Arrows ............................................................4

MENU Key ...................................................................................5

SET Key.......................................................................................5

ALARM Key..................................................................................5

TUNE Key ....................................................................................5

RUN/STOP Key............................................................................5

HEAT, COOL, TUNE LED Annunciators ......................................5

How To Use This Product.............................................................6

INSTALLATION ......................................................................................7

INITIAL HARDWARE SETUP ...........................................................7

SETUP PROCEDURE ......................................................................9

Sensor Types ...............................................................................9

Thermocouple.......................................................................10

Thermistor ............................................................................10

Platinum RTD........................................................................10

Temperature Scale .....................................................................11

Alarm Selections ........................................................................11

Process Alarms.....................................................................13

Process HI ............................................................................13

Process LO ........................................................................... 14

Process HILO ....................................................................... 15

Deviation Alarms...................................................................15

Deviation LO .........................................................................16

Deviation HI ..........................................................................16

Deviation HILO......................................................................17

Deviation Band......................................................................18

Alarm Hysteresis...................................................................19

Audible Alarms ...........................................................................19

Advanced Set-Up .......................................................................20

Sensor Calibrate ........................................................................20

Over Temp Stop ......................................................................... 21

Loop Break Stop ........................................................................ 21

ii

TABLE OF CONTENTS (Continued)

Title Page

Control Action ............................................................................22

Control Mode .............................................................................22

Control Mode On/Off.............................................................23

PID - Proportional Band, Integral and Derivative ..................23

AUTO Tune ........................................................................... 23

Proportional Band ............................................................24

Integral Time ....................................................................24

Derivative Rate ................................................................ 25

Ramp and Soak ....................................................................25

Assured Soak ..................................................................26

Segment Definition ..........................................................26

Control Parameters (CP) .................................................27

Cycle Time ................................................................................. 27

Run Time.................................................................................... 27

Recorder Output ........................................................................28

Serial Baud ................................................................................28

Power Up Control ....................................................................... 28

OPERATION ........................................................................................30

CONTROL MODE...........................................................................30

RAMP AND SOAK MODE .............................................................. 31

TROUBLESHOOTING AND MAINTENANCE .....................................32

TROUBLESHOOTING ....................................................................32

CALIBRATION ................................................................................ 32

MAINTENANCE/CLEANING........................................................... 32

SPECIFICATIONS ...............................................................................33

INPUTS...........................................................................................34

OUTPUTS.......................................................................................35

WARRANTY.........................................................................................36

PRODUCT RETURN............................................................................36

TECHNICAL ASSISTANCE ................................................................. 36

APPENDIX A - SETUP MODE .......................................................... A-1

APPENDIX B - ERROR MESSAGES/CORRECTIVE ACTION ......... B-1

ACCESSORIES ...................................................................BACK PAGE

1

SAFETY PRECAUTIONS

DANGER: There are no user-serviceable parts in this

instrument.Do not remove cover,as high voltages

exist inside the unit.Refer servicing to your dealer.

DANGER: If thermocouples are at a high voltage, this volt-

age will be present at other points inside the unit.

DANGER: For continued fire protection, replace fuse only

with a fuse of the specified current, voltage, and

type. Remove power cord from wall socket before

checking or replacing a fuse. High voltages exist

on fuse terminals.

WARNING: To avoid electric shock, the power cord protective

grounding conductor must be connected to

earth-ground.

WARNING: Install an independent temperature limit control

protection system where a fault condition could

result in fire or other hazard. Failure to install

such a system could result in injury to personnel

or damage to property.

IBM - Reg TM International Business Machines Corp.

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries.

2

INTRODUCTION

This manual provides information for installing and operating the Tempera-

ture Controller R/S (advanced model).

Refer to Figure 1 for a view of the front panel of theTemperature Controller R/

S.Refer to Figures 2 and 3 for a view of the back panels of the 115V or 230

V versions.

FIGURE 1. TEMPERATURE CONTROLLER R/S

FIGURE 2.TEMPERATURE CONTROLLER R/S, BACK PANEL

(115 V MODEL)

3

FIGURE 3.TEMPERATURE CONTROLLER R/S, BACK PANEL

(230 V MODEL)

APPLICATION DATA

Applications for the Temperature Controller R/S include heating and cooling

of solids, liquids, and gases. For all applications, there are certain set-up

operations that should be made carefully to assure optimum and safe perfor-

mance.Thepowerandtypeof heater, thepositioning ofthesensor,theamount

of thermal insulation, the flash point of the heated material and the many

controller set-up menu options are among the many variables to be consid-

ered in setting up the controller.

One of the most important of these considerations is the heater sizing.A heater

thatis too lowpoweredmaynot beableto raise or even maintain the material at

the desired set point.A heater that is too high powered will not maintain precise

temperature control and may be unsafe. Because of the many system vari-

ables, optimum heater sizing must be determined experimentally; however, an

approximation can be made through a few calculations.These calculations are

included in the software program included with the unit.

DESCRIPTION

GENERAL

The Temperature Controller R/S is designed to maintain a constant, pre-set

process temperature. It uses a temperature sensor to detect the temperature

of the process.Using a microprocessor software algorithm, it adjusts a heater

or cooler by varying the output duty cycle.TheTemperature Controller R/S is a

single-loop controller intended for laboratory or industrial applications.The unit

can control loads of up to 15 amperes (A).

TheTemperature Controller R/S is housed in a rectangular metal enclosure,

with plastic bezels on the front and back. All connections are made on the

rear of the unit. The display and keypad are on the front. A bail bar, or tilt

stand, is used to elevate the front display panel for easy viewing and opera-

4

tion.Theunitcanalsobemountedinapanelwith the use of an optional panel

mount kit. A two-line, 16-character, 14-segment vacuum fluorescent display

is used for display of operating, setup, and alarm parameters.

A number of accessories can be used with this deluxe model of theTempera-

tureController, including various types of temperaturesensors,heating units,

cooling units (such as fans or pumps), remote alarms, and recorders.

One of several additional R/S model features (not available in the standard

models) is “Ramp and Soak,” which uses a timed sequence pre-set user

temperature set points.

The unit also has RS-232-C Serial Communications, so that it can be set up

and controlled by a computer. An IBM®-compatible PC (personal computer)

diskisincludedwiththeR/Scontroller,alongwithaseparateoperator'smanual.

It can be used to set up the controller and perform logging and other func-

tions.For advanced users, a serial communications specification is included

on disk for customized programming.

CONTROL PANEL DESCRIPTION

Refer to Figure 4 and the following paragraphs.

Indicator

Lights

Readout Display LEFT Arrow

UP and

DOWN

Arrows

Alarm LED

Function Control Keys

FIGURE 4. FRONT PANEL DISPLAYS

Vacuum Fluorescent Readout

The vacuum fluorescent readout displays operation and setup parameters.

Alarm conditions are also displayed.

UP, DOWN, LEFT Arrows

The UP and DOWN arrow keys will increment or decrement the current val-

ues of displayed (blinking) numerals or enable you to scroll through a list

where multiple-choice parameters are offered. The LEFT arrow key allows

5

you to change default numeric settings by moving the blinking cursor left to

the next most significant digit.When you have reached the most significant

digit (furthest left), the LEFT arrow key will move the flashing cursor back to

the least significant digit (furthest right).

MENU Key

The MENU key allows you to access all of the user-configurable setup pa-

rameters of the Temperature Controller. Pressing the MENU key will scroll

through the parameter options, using the arrow keys to change those param-

eters. Refer to the Setup Procedures section for additional information on

each parameter.

SET Key

The SET key allows you to change the control setpoint (SP), using the arrow

keys. Pressing the SET key again will exit the setpoint mode. In the Ramp

and Soak mode, the SET key will toggle the display between setpoint and run

time remaining. Refer to the Operation section for additional information on

changing the setpoint.

ALARM Key

TheALARMkeyenablesyoutoacknowledgetemperature control alarm con-

ditions and silence the audible alarm.Pressing the ALARM key will erase any

alarm messages on the display and stop the ALARM from flashing. If the

alarm condition is still present, the ALARM LED will remain on until the PV

(process variable) is out of the alarm condition. If manual Reset mode is

selected in setup, the ALARM key will also de-energize the alarm relay.

Refer to Setup Procedures section for additional information on setting the

appropriate alarms.

TUNE Key

The TUNE key will start an AUTO tune cycle. Heat (or cooling) is automati-

cally applied to determine PID values. AUTO tuning must be enabled in the

setup mode for this key to function. Refer to the AUTO Tuning section for

additional information on this setting.

NOTE: When the TUNE key is pressed, the output is turned full on three

times for a period of time and overshoot of the setpoint will occur.

Do not use the AUTO tune feature if this would have an adverse

affect on your process.

RUN/STOP Key

Pressing this key when the Temperature Controller is stopped will start the

control process and activate the load, if required.Pressing this key when the

Temperature Controller is running will cause it to stop.

6

HEAT, COOL, TUNE LED Annunciators

These three indicators will light to indicate Temperature Controller functions.

The green HEAT light will turn on when power is being applied to the heater

output.The green COOL light will turn on when theTemperature Controller is in

the cooling mode and power is applied to the cooler output.The yellow TUNE

light will turn on when the Temperature Controller is in the AUTO tuning mode.

How to Use this Product

Here is a summary of the steps required to setup and operate the Tempera-

ture Controller R/S.

1. Install the unit.

Setup your process.

Plug the Controller power cord to an AC outlet, turn unit on.

Plug the heater (or cooler) into the Controller rear panel and install in

your process.

Connect a sensor to the rear panel (thermocouple, RTD or thermistor)

and install in your process.

Optional installation connections:

Connect a recorder to the recorder contacts on the rear panel.

Connectanexternalalarmtothealarmoutputconnectionontherearpanel.

Connect a serial cable between the Controller RS232 connector and a

PC and follow the instructions for setup in the separate PC program op-

erator manual.

2. Setup the operating parameters. Press MENU and follow the interactive

setup selections. If your setup is the same as the factory set defaults,

this step is not necessary.However, each of the setup options should be

checked for desired or proper setting.

Set sensor type that was connected.

Select temperature scale.

Set alarms, if desired.

Calibrate system, if better accuracy is desired.

Set safety stops (over temperature and loop break).

Select control action and mode desired (PID, on/off or Ramp/Soak).

Setup recorder output temperatures, if a recorder is connected.

Set baud rate for serial connection, if a PC is connected.

3. Set the run temperature and begin controlling.

Press the SET key and enter the desired setpoint temperature.

Press TUNE if autotune is selected in setup and you want to automati-

cally determine the PID settings.

Press the RUN/STOP key to begin temperature control.

The setpoint (SP) temperature and the actual temperature (or process

variable, PV) are displayed.

Press ALARM to acknowledge an alarm condition.

7

INSTALLATION

INITIAL HARDWARE SETUP

1. Remove controller from packaging.Keep all packing material until proper

operation has been verified.

2. Use the "bail" bar (or tilt-stand) at the bottom of the unit to adjust position

for easy viewing of front panel.

Caution: To avoid electric shock, the power cord pro-

tective grounding conductor must be con-

nected to earth-ground.

Caution: Install an independent temperature limit con-

trol protection system where a fault condition

could result in fire or other hazard. Failure to

install such a system could result in injury to

personnel or damage to property.

3. Plug the unit in to a correctly rated AC outlet and turn on the power using

the ON/OFF switch on the back panel. Refer to Figure 5.

FIGURE 5. 115 V BACK PANEL

3 Wire RTD

Probe Jack

Thermistor

Probe Jack

Heater/Cooler

Output Fuse ON/OFF

Switch

Main

Power

Fuse

Heater Cord

Cable Connection

Recorder Output

Isolated 4-20 mA

RS-232-C Serial

Connector

Mini-ANSI Thermocouple

Jack (500 ohm Max

Load Resistance)

115 V

8

Line Cord

Connection

Heater Cord

Cable Connection

Recorder Output

Isolated 4-20 mA

RS-232C Serial

Connector

Mini-ANSI Thermocouple

Jack (500 ohm Max

Load Resistance)

Heater/Cooler

Output Fuse

Thermistor

Probe Jack

3 Wire RTD

Probe Jack

ON/OFF

Switch

Main

Power

Fuse

230 V

FIGURE 5. 230 V BACK PANEL

4. Connect one of the three types of sensors to the unit (refer to Accesso-

ries section for a listing of compatible probes).

5. Connect the heater or cooler (maximum of 15 A) to the unit.

6. Install the PC (personal computer) cable to the RS-232-C serial commu-

nications terminal, if desired. Refer to your PC hardware guide for PC

connections.

7. The following charts show the required connections for interfacing to an

IBM-compatible computer with either a 9-pin or 25-pin plug.The cables

listed in the Accessories section are properly wired for use.

Temperature

Controller Computer Computer

DB-9 DB-9 DB-25

Pin 2 Pin 3 Pin 2

Pin 3 Pin 2 Pin 3

Pin 5 Pin 5 Pin 7

RS-232-C Connection Chart

NOTE: The serial data format is full duplex, 1 start bit, 8 data bits, no

parity, and 1 stop bit.The baud rate is user-selected.

9

8. Recorder output and alarm output devices may be installed on the tem-

perature controller (refer to Figure 5). The 4/20mA recorder output is

designed for a left positive (+) and a right negative (-) connection.Alarm

output is designed for a left–NO (normally open), center–COM (com-

mon), and right–NC (normally closed) connector.

SETUP PROCEDURE

NOTES: a. At any time during the setup procedure, you may return to

the previous screen by pressing and holding down the LEFT

arrow key and then pressing the MENU key.

b. For experienced operators, a flow chart may be used for set-

up. Refer to Appendix A.

c. The setup mode can only be entered when the Temperature

Controller is stopped.

1. Set the ON/OFF switch on the rear panel to ON.The LEDs will light and

all segments will light temporarily as a check of the display.

2. After the diagnostics are complete, the Temperature Controller will dis-

play the unit identification screen (refer to Figure 6).

TEMPERATURE

CONTROLLER

FIGURE 6. UNIT IDENTIFICATION SCREEN

This screen will be displayed for a few seconds.The unit will automati-

cally progress to the RUN screen.

3. Press MENU once to begin the setup process.

Sensor Types

1. To select a sensor type, press the DOWN arrow key.The following

screen will appear, with the default, or last selected, sensor indi-

cated (refer to Figure 7).

SENSOR TYPE

THERMOCOUPLE

FIGURE 7. SENSOR TYPE SELECTION SCREEN

10

2. Press the DOWNarrowkeytoselectoneofthethreesensortypes,

which are described as follows:

Thermocouple

1. To select a thermocouple type, press the MENU key (refer to Figure 8).

2. The screen will display the last thermocouple selected. To chose an-

other thermocouple type, press the DOWN arrow key to move forward

or, if passing a desired selection, the UP arrow key to move backward.

Thermocouple selections include: K, J, E, B, T, S, R, and N.

3. Select the thermocouple type by pressing the MENU key. To ensure

proper operation, be sure that the correct thermocouple type is con-

nected at the thermocouple jack before running the program.

THERMOCOUPLE

TYPE J

FIGURE 8.THERMOCOUPLE SELECTION SCREEN

Thermistor

1. The second sensor type available is the thermistor.Press the MENU key

at the SENSOR TYPE - THERMISTOR screen to display the following

screen (refer to Figure 9).

2. Use the UP or DOWN arrow key to chose either YSI 400 or YSI 700

thermistors.

3. After selecting the correct thermistor, press the MENU key.

THERMISTOR

YSI 400

FIGURE 9.THERMISTOR SELECTION SCREEN

11

Platinum RTD

1. The Platinum RTD is the third sensor type that can be selected. Press

the MENU key at the SENSOR TYPE - PLATINUM RTD screen and the

following screen will appear (refer to Figure 10).

2. SelecteitherAlpha .003850orAlpha.003916.SelectanAlphaof0.003850

(default setting) for all probes listed in the Accessories section.

3. After selecting the platinum RTD type, press the MENU key to advance

to Temperature Scale selection.

100 OHM RTD

ALPHA .003850

FIGURE 10. PLATINUM RTD SELECTION SCREEN

Temperature Scale

1. After pressing the MENU key in the SENSOR-TYPE screen, the

program will progress to theTemperature Scale selection.TheTem-

perature scale selection has five temperature scales from which to

choose: Celsius(°C),Fahrenheit(°F), Reaumur(°R'), Rankine (°R),

or Kelvin (K). Refer to Figure 11.

2. Press theDOWNarrowkeyto switchtoa desired temperaturescale.

Press the MENU key to select the appropriate scale.

TEMP SCALE

FAHRENHEIT °F

FIGURE 11.TEMPERATURE SCALE SELECTION SCREEN

12

Alarm Selections

1. Alarms will activate only when the Temperature Controller is in the RUN

mode. When an alarm occurs, the alarm relay will energize, the alarm

LED will flash, the audible alarm will sound intermittently and the display

will flash the type of alarm.There are three possible alarm mode selec-

tions: MANUAL RESET, AUTO RESET, or OFF. Refer to Figure 12.

2. If you select ALARM SETPOINTS - OFF, no process or deviation alarms

will actuate.Both AUTO RESET and MANUAL RESET will result in alarms

actuating. If you select AUTO RESET, the relay will automatically shut off

when the PV temperature falls out of the alarm setpoint temperature. For

MANUAL RESET, the alarm relay is turned off when the ALARM key is

pressed. The alarm LED remains on until the alarm condition clears. For

both AUTO and MANUAL, the flashing message and the audible alarm are

turned off.

3. The first Alarm screen will display ALARM SETPOINTS - MANUAL RE-

SET. Refer to Figure 13.

ALARM SETPOINTS

MANUAL RESET

FIGURE 13. ALARM SETPOINTS MANUAL RESET SCREEN

4. To go to the Auto Reset Screen, press the DOWN arrow key. Refer to

Figure 14.

ALARM SETPOINTS

[SELECTIONS]

FIGURE 12. ALARM SETPOINTS SELECTION SCREEN

ALARM SETPOINTS

AUTO RESET

FIGURE 14. ALARM SETPOINTS AUTO RESET SCREEN

13

5. To select an automatic alarm reset, press the MENU key when the Auto

Reset screen is blinking.

6. To go to the Alarms Off Screen, press the DOWN arrow key. Refer to

Figure 15. If selected, refer to Alarms Auto Reset procedure, below.

ALARM SETPOINTS

OFF

FIGURE 15. ALARM SETPOINT OFF SCREEN

7. To select alarms off, press the MENU key when the ALARMS - OFF

screen is blinking.

8. After alarm selection, press the MENU key to move on to Alarm Hyster-

esis.After setting Alarm Hysteresis, press the MENU key again to move

on to the Audible Alarm screen.

Process Alarms

Process alarms are absolute values.These values remain the same no mat-

ter what the setpoint temperature is set to. For example: if the operator sets

an alarm to trigger at 60 degrees Celsius and the SP (setpoint) temperature

is set at 55 degrees Celsius, the alarm will trigger at 60 degrees.If the opera-

tor resets the SP temperature to 57 degrees, then the process alarm value

will stay at the already set 60 degrees.

There are three types of process alarms: PROCESS HI, PROCESS LO, and

PROCESS HILO. Refer to the following paragraphs for more information.

Process HI

1. Process HI is a fixed value and will not change if the SP temperature

value is changed. It activates the alarm when the PV temperature ex-

ceeds the set alarm temperature.Refer to Figure 16.If the Control Action

is set to COOL and the PV temperature exceeds the alarm temperature

when the RUN key is pressed, the alarm will not be activated. The PV

temperature must first fall below the alarm temperature before the high

alarm is enabled.This allows for normal system startup without activat-

ing the alarm.

ALARM MODE

PROCESS - HI

FIGURE 16. PROCESS HI SCREEN

14

2. Select the PROCESS - HI screen by pressing the MENU key.The follow-

ing screen will appear (refer to Figure 17). Set the Process HI tempera-

ture by using the arrow keys.

PROCESS ALARM

HI XXXXX °F

FIGURE 17. PROCESS HI SETTINGS SCREEN

Process LO

1. Process LO is a fixed value and will not change if the SP temperature

value is changed.It activates the alarm when the PV temperature drops

below the alarm temperature.Refer to Figure 18.If the Control Action is

set to HEAT and the PV temperature is below the alarm temperature

when the RUN key is pressed, the alarm will not be activated. The PV

temperature must first rise above the alarm setpoint before the low alarm

is enabled.This allows for normal system startup without activating the

alarm.

ALARM MODE

PROCESS - LO

FIGURE 18. PROCESS LO SCREEN

2.Select the PROCESS - LO screen by pressing the MENU key. The fol-

lowing screen will appear (refer to Figure 19). Set the Process LO tem-

perature by using the arrow keys.

PROCESS ALARM

LO 000XX °F

FIGURE 19. PROCESS LO SETTINGS SCREEN

15

Process HILO

1. Process HILO is afixedvalue(afixedhigh and a fixedlowalarm setpoint)

and will not change if the SP temperature value is changed.The purpose

for process HILO is to set the fixed HI and LO value at which to trigger

the alarm relay. Refer to Figure 20.Refer to the Process HI and Process

LO sections for detailed descriptions of the operation of each alarm

setpoint.

ALARM MODE

PROCESS HILO

FIGURE 20. PROCESS HILO SCREEN

2. Select PROCESS-HILO bypressing the MENUkey.Thefollowingscreen

will appear (refer to Figure 21).Set the alarm temperatures by using the

arrow keys.Once the first alarm value is set, press the LEFT arrow key to

adjust for the other alarm variable.

PROCESS ALARM °F

HI XXXX.X LO XXXX.X

FIGURE 21. PROCESS HILO SETTINGS SCREEN

Deviation Alarms

Deviation alarms are offset values relative to the setpoint (SP). The values

change with the SP temperature setting.For example:if an operator sets the

deviation HI alarm to 10 degrees Fahrenheit and the SP temperature is at 50

degrees Fahrenheit, the alarm will trigger when the PV reaches 60 degrees

Fahrenheit. If the operator then changes the previously set SP temperature

to 55 degrees Fahrenheit, then the alarm will trigger at 65 degrees Fahren-

heit.The 10-degree Fahrenheit difference stays the same.

There are four possible deviation alarms settings: DEVIATION LO, DEVIA-

TION HI, DEVIATION HILO, and DEVIATION BAND. Refer to the following

paragraphs.

16

Deviation LO

Deviation LO adjusts the alarm value as the SP temperature value is adjusted.

Whatever value deviation LO is set at, it will remain the same until changed.

Refer to Figure 22.

ALARM MODE

DEVIATION LO

FIGURE 22. DEVIATION LO SCREEN

For example: if the Deviation LO value is set for 10 degrees Fahrenheit and

the SP temperature is set for 50 degrees Fahrenheit, the alarm will trigger at

40degreesFahrenheit.If the SP temperaturevalueischangedto45 degrees

Fahrenheit, the Deviation LO will trigger the alarm at 35 degrees Fahrenheit.

If the Control Action is set to HEAT and the alarm condition exists when the

RUN key is pressed, the alarm will not be activated. The PV temperature

must first rise above the alarm setpoint before the alarm is enabled. This

allows for normal system startup without activating the alarm.

Select the DEVIATION - LO screen by pressing the MENU key.The following

screen will appear (refer to Figure 23). Move the cursor to the left using the

LEFT arrow key. When the setting is correct, press the MENU key to enter

that setting and to move the program to the alarm hysteresis screen.

DEVIATION ALARM

LO XXXXX °F

FIGURE 23. DEVIATION LO SETTINGS SCREEN

Deviation HI

Deviation HI will adjust the alarm value as the SP temperature value is ad-

justed. Whatever value Deviation HI is set at, it will remain the same until

changed. Refer to Figure 24.

ALARM MODE

DEVIATION HI

FIGURE 24. DEVIATION HI SCREEN

This manual suits for next models

1

Table of contents

Popular Temperature Controllers manuals by other brands

Bühler technologies

Bühler technologies Nivotemp NT 67-XP Brief instructions

Sensit

Sensit TG8 instruction manual

Ropex

Ropex RESISTRON RES-401 operating instructions

CardioQuip

CardioQuip MCH-1000 Operators & service manual

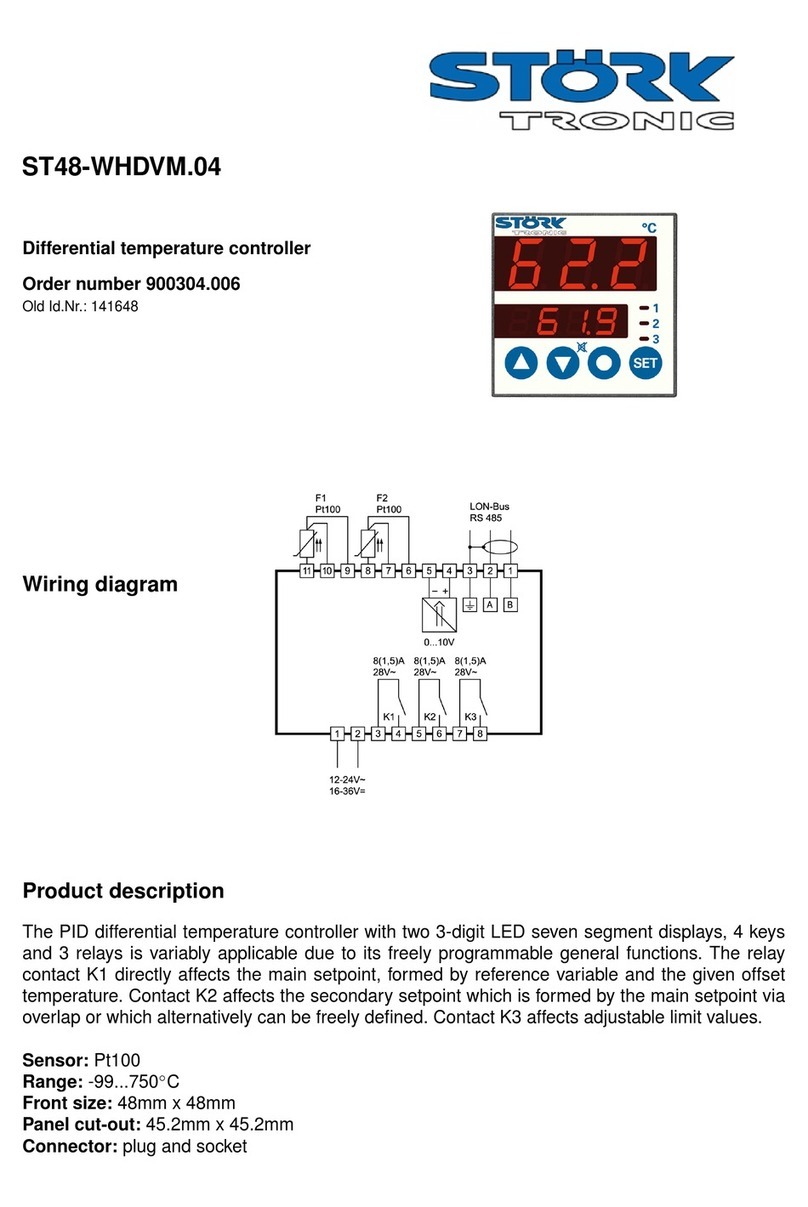

STORK TRONIC

STORK TRONIC ST48-WHDVM.04 manual

MULTISPAN

MULTISPAN UTC-221P quick guide

Steinberg Systems

Steinberg Systems SBS-TS-100 user manual

Adeunis RF

Adeunis RF ARF8054AA user guide

LK Systems

LK Systems ICS.2 Assembly instructions

ILX Lightwave

ILX Lightwave LDT-5525 user guide

SRS Labs

SRS Labs CTC100 user manual

Thermal Care

Thermal Care Aquatherm RQT Advanced Operation, installation, and maintenance manual