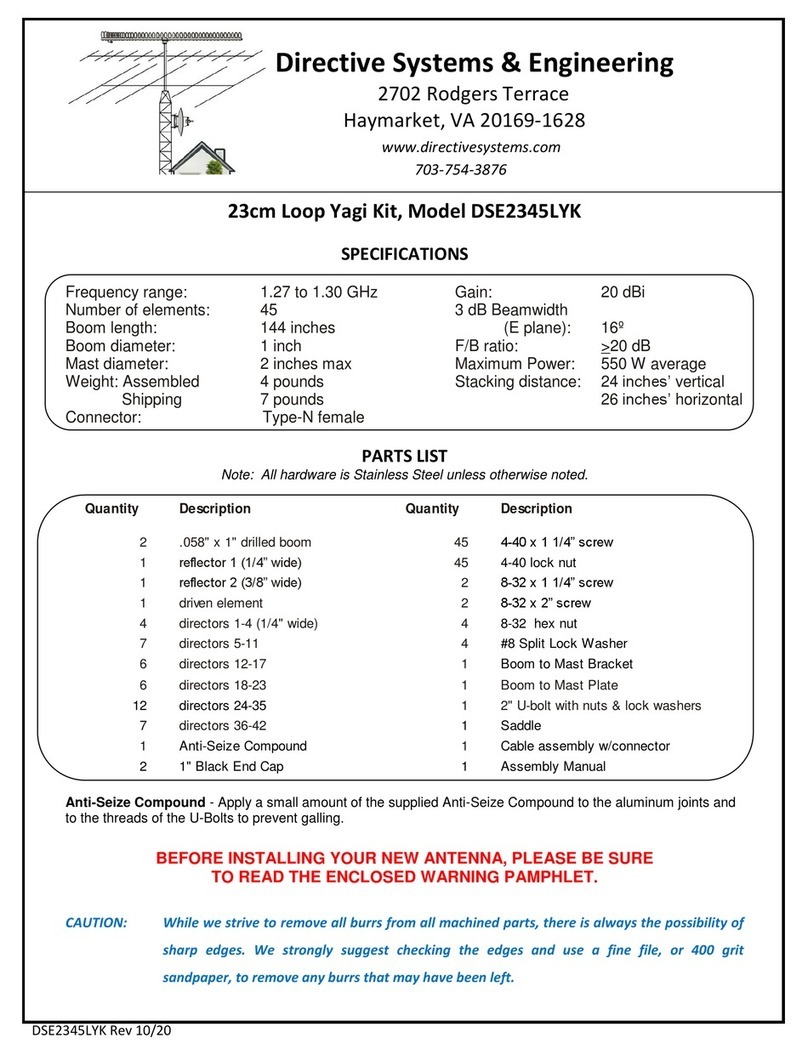

Barrett 2018 Specification sheet

No part of this manual may be copied, transcribed, translated or reproduced in any manner or form whatsoever, for

commercial purposes, without obtaining prior written permission from Barrett Communications Pty. Ltd. However,

limited copying is permitted for private use providing authorship is acknowledged.

The 2018 Mobile magnetic loop HF antenna design is protected by Australian patent 2001100423. Unlicensed

replication of the design is expressly forbidden.

BCM201800/6

© Barrett Communications

Head Office:

Barrett Communications Pty Ltd

47 Discovery Drive, Bibra Lake, WA 6163 Australia

Tel: +61 8 9434 1700 Fax: +61 8 9418 6757

Email: [email protected]

www.barrettcommunications.com.au

2 of 31

Introduction...........................................................................................................................................4

Features.........................................................................................................................................4

General ..........................................................................................................................................5

About this Guide...........................................................................................................................6

Glossary of Terms........................................................................................................................6

Warnings and Advice...........................................................................................................................7

High Radio Frequency Voltages .................................................................................................7

Power Supply Cables...................................................................................................................7

Radio Frequency Field Exposure................................................................................................7

Explosion Hazard .........................................................................................................................7

Storage of Other Goods...............................................................................................................8

Frequency Hopping Use ..............................................................................................................8

Operation in Rough Terrain.........................................................................................................8

Overview................................................................................................................................................9

Installation...........................................................................................................................................11

Fitting on Vehicles With Gutters.......................................................................................................11

Setting Up the Roof Rack ..........................................................................................................12

Preparing the Vehicle.................................................................................................................15

Fitting on Vehicles Without Gutters .................................................................................................17

Setting Up the Roof Rack ..........................................................................................................17

Preparing the Vehicle.................................................................................................................18

Maintenance........................................................................................................................................21

Removal of Rack.................................................................................................................................21

Retrofitting the 2018 Barrett Mobile Magnetic Loop Antenna........................................................21

Cabling.................................................................................................................................................22

Operation.............................................................................................................................................23

To Deploy the Antenna ..............................................................................................................23

To Stow the Antenna..................................................................................................................24

Barrett Transceiver to 2018 Barrett Mobile Magnetic Loop Antenna Setup .................................25

Supported Barrett Transceivers................................................................................................25

Testing and Troubleshooting............................................................................................................25

Troubleshooting .........................................................................................................................26

Testing.........................................................................................................................................27

External Connectors ..........................................................................................................................28

ATU 6 Pin Connector Functions ...............................................................................................28

Internal Jumper Configurations................................................................................................28

3 of 31

J5 Jumper Settings ....................................................................................................................29

J6 Jumper Settings (DC Supply on RF Cable).........................................................................29

J7 Jumper Settings ....................................................................................................................29

Parts List .............................................................................................................................................30

Technical Specifications....................................................................................................................31

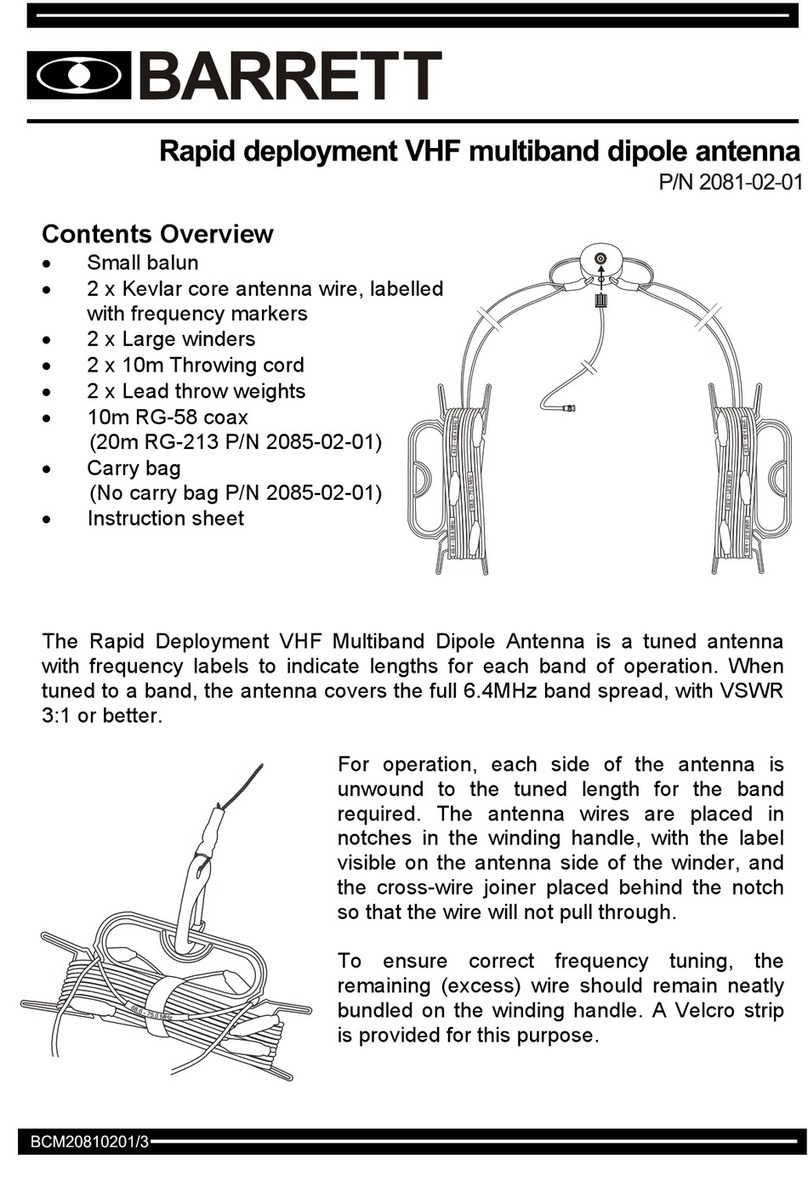

Introduction

Features

•Highly efficient antenna, radiating 10 dB to 14 dB more than whip antennas.

•Simpler installation – no need to weld on a mounting plate for a whip, and no separate tuner

to install. Installation is therefore quicker and cheaper, and the system can be moved

simply between vehicles.

•Free roof rack with every package. The antenna can be used as a conventional roof rack

for storing luggage.

•Eliminates Skip Zones. A HF system that can be used in ranges from 0-1,000 km and more.

•Increased immunity to ignition and power line noise.

•Broadband low-noise scan amplifier.

4 of 31

5 of 31

General

The 2018 Mobile magnetic loop HF antenna is a technological breakthrough in vehicle-based HF radio

communications.

The 2018 Mobile magnetic loop HF antenna is available in a range of packages for fixed or removable

installations and can be used with Barrett 2000 Series transceivers. The removable package can be

installed without any drilling of holes in the vehicle.

The 2018 Mobile magnetic loop HF antenna is without doubt the best type of antenna for vehicular

NVIS (Near Vertical Incidence Skywave) operations. Skip zones are eliminated and coverage (with

the correct selection of frequency) is from 0 to 1000 km or more. Within this range it is significantly

more efficient than any whip-type vehicle antenna; producing considerably more transmit and receive

strength. The actual gain over whip antenna systems varies between +10 dB and +14 dB. The

benefit to the user is that it radiates significantly more power, and magnifies received signal strength,

giving overall performance much higher than can be achieved from any vehicle whip antenna system.

The 2018 Mobile magnetic loop HF antenna tuner unit is a highly efficient, continuously variable

capacitor unit which is driven by a stepper motor to give the best VSWR reading.

When tuned the 2018 antenna has a very narrow bandwidth for transmission. This characteristic is

also beneficial for reception since interfering signals separated from the tuned frequency by just a few

percent are greatly attenuated, protecting the front end of the receiver from intermodulation and

blocking effects.

During scanning the tuning capacitor is bypassed and a low-noise high-linearity amplifier is inserted in

the signal path. This allows the loop to retain its desirable NVIS characteristics whilst offering

broadband receive capability.

6 of 31

About this Guide

The main purpose of this guide is to provide you with all the information you require to ensure optimum

performance from your 2018 Mobile magnetic loop HF antenna.

The Guide explains in detail how to operate the 2018 antenna once it has been installed by an

authorised Barrett Communications representative.

The Guide also covers the basic principles of installation. However, we recommend that the

installation of your 2018 be carried out by a qualified Barrett Communications representative.

Glossary of Terms

ATU Antenna Tuning Unit

HF High Frequency

kHz Kilohertz (measure of frequency)

km Kilometre

MHz Megahertz (measure of frequency)

PEP Peak envelope power

PTT Press To Talk

Selcall Selective Call

Telcall Selective Call with Telephone Call facility

VSWR Voltage standing wave ratio

W Watt

Warnings and Advice

High Radio Frequency Voltages

When transmitting, radio-frequency voltages up to 1500 V RMS are present on the

radiating arm and associated cables of the 2018 Barrett Mobile Magnetic Loop

Antenna. These voltages are sufficient to cause electrocution or severe radio

frequency burns. Personnel must not under any circumstances come into contact

with the radiating arm of the antenna or the associated cables when the unit is in

operation.

Power Supply Cables

7 of 31

High Frequency transceivers require adequate supply current. It is essential that the

supplied cables are utilised to reduce the likelihood of system malfunction. Please

use the specified cables.

Radio Frequency Field Exposure

The 2018 Barrett Mobile Magnetic Loop Antenna produces high localized radio

frequency fields. As long as personnel are beneath the level of the roof rack,

exposure to fields will be well below safe operating levels.

Explosion Hazard

Highly flammable materials (e.g. gasoline, petrol, butane, propane, etc) should

not be stored on the roof rack when the equipment is in operation. The induced

RF field during transmission may cause spark discharges between adjacent metal

objects which could cause the material to ignite.

Storage of Other Goods

Goods of normal flammability (for example, tyres, suitcases, tents, etc) may be

safely stored on the roof rack, however metallic items like tent poles should be

secured away from the radiating arm to avoid degrading the ATU's performance.

They should be secured so that no movement occurs during transport.

Important:- Do not use the antenna arm to tie any object down. Keep goods

at least 0.3 m away from antenna arm and feed cables.

Frequency Hopping Use

8 of 31

Due to the narrow operating bandwidth of the loop antennae, they are not ideally

suited for frequency hopping use. However, at higher frequencies (approximately 7

MHz) and when there is adequate signal to noise ratio, adequate results may be

obtained.

Operation in Rough Terrain

Following operation in rough terrain, the mounting leg fixings should be checked and

re-secured as necessary.

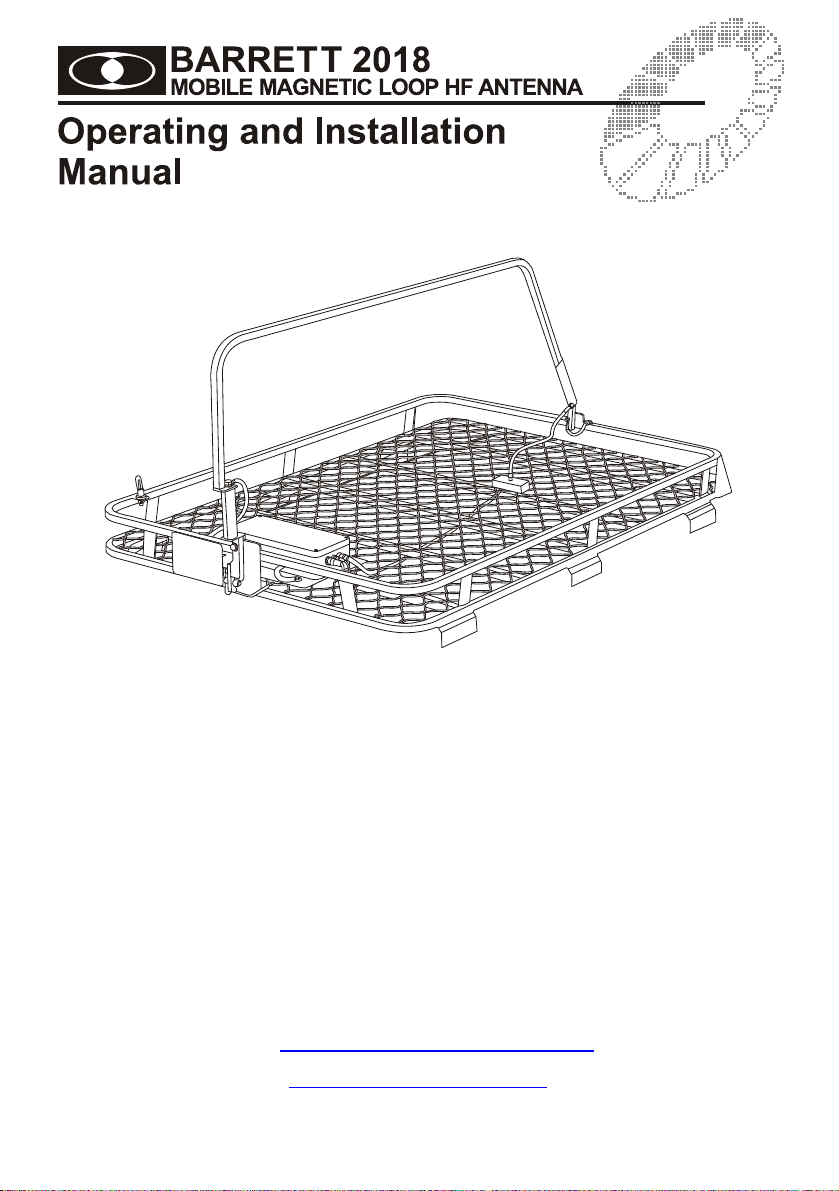

Overview

The roof rack has been designed by Barrett Communications Pty. Ltd. as an integral part of the

antenna system. The ground plane is a heavy-duty aluminium mesh floor, welded to an enclosing

frame which maximises current in the radiating loop. The 2018 Barrett Mobile Magnetic Loop Antenna

shields and isolates vehicle ignition noise and interference from adjacent power lines providing greater

communication clarity.

The 2018 Barrett Mobile Magnetic Loop Antenna can be fitted to almost any surface. The roof rack

comes in a range of mounting bracket options. Solutions are available that will allow clamping to the

roofs of 4WD’s, sedans, buses, trucks and prime movers. It is designed to minimise head wind noise

with an angled deflector mounted on the front of the unit.

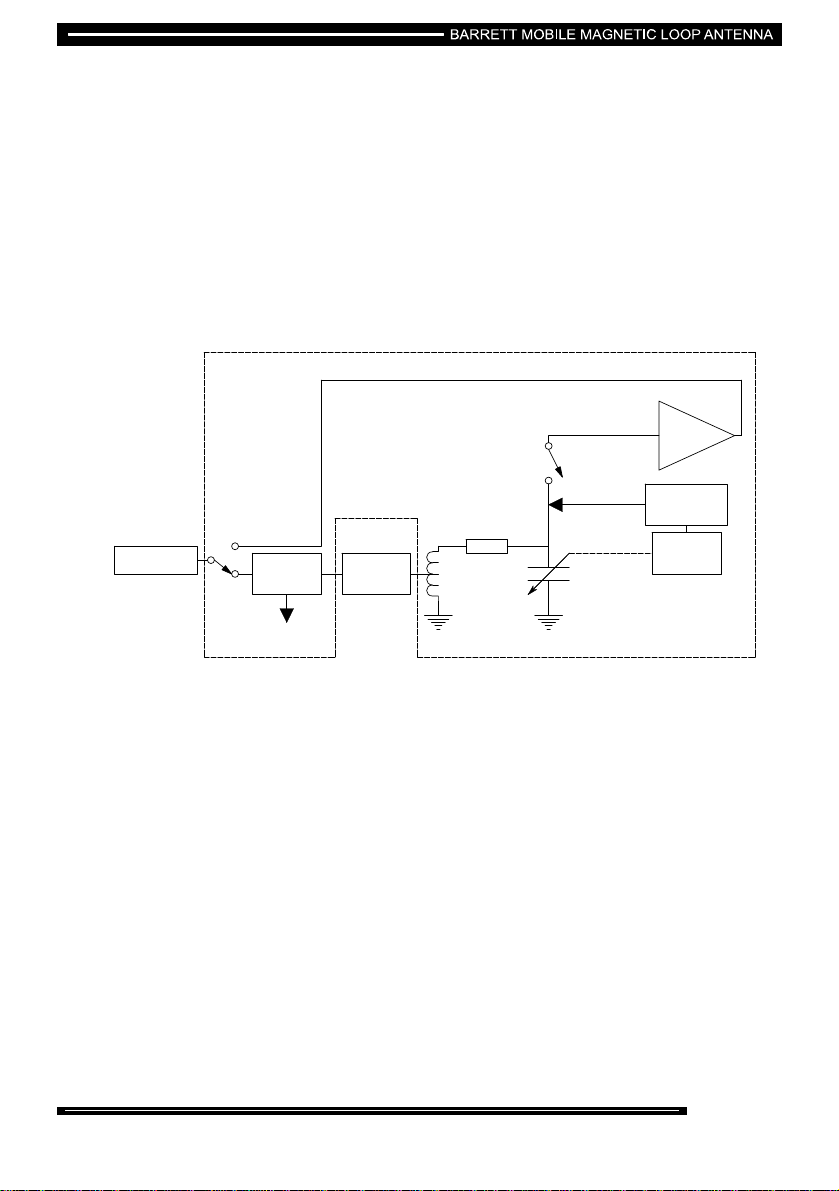

A simplified diagram of the parts that make up the 2018 Mobile magnetic loop HF antenna is shown

below.

9 of 31

The antenna consists of a looped aluminium arm hinged to an aluminium roof rack which forms an

effective ground plane.

RF and DC power is supplied to the 2018 Barrett Mobile Magnetic Loop Antenna system from the

transceiver. The vehicle battery supplies the transceiver with its DC power.

The RF Feed box receives its RF input from the transceiver via the ATU box and an RF coaxial cable

(supplied). The output is connected to the antenna.

The scan amplifier and the associated receive-transmit switching are incorporated within the ATU.

A simplified block diagram of the circuit is shown below:

10 of 31

Stepper

motor

Microprocessor

control

Scan

amplifier

Antenna

Radiation resistance +

ohmic losses

Variable

capacitor

RF

feedbox

Voltage

sample

SWR

detector

Transceiver

To

microprocessor

Antenna tuner

Transmit/receive

switching

The antenna is effectively a parallel tuned resonant circuit, with the feed-point forming an auto-

transformer in the inductive arm of the tank. Resonance is achieved through a stepper driven variable

capacitor. An on-board microprocessor monitors loop current, with final tune based on system VSWR.

Installation

Fitting on Vehicles With Gutters

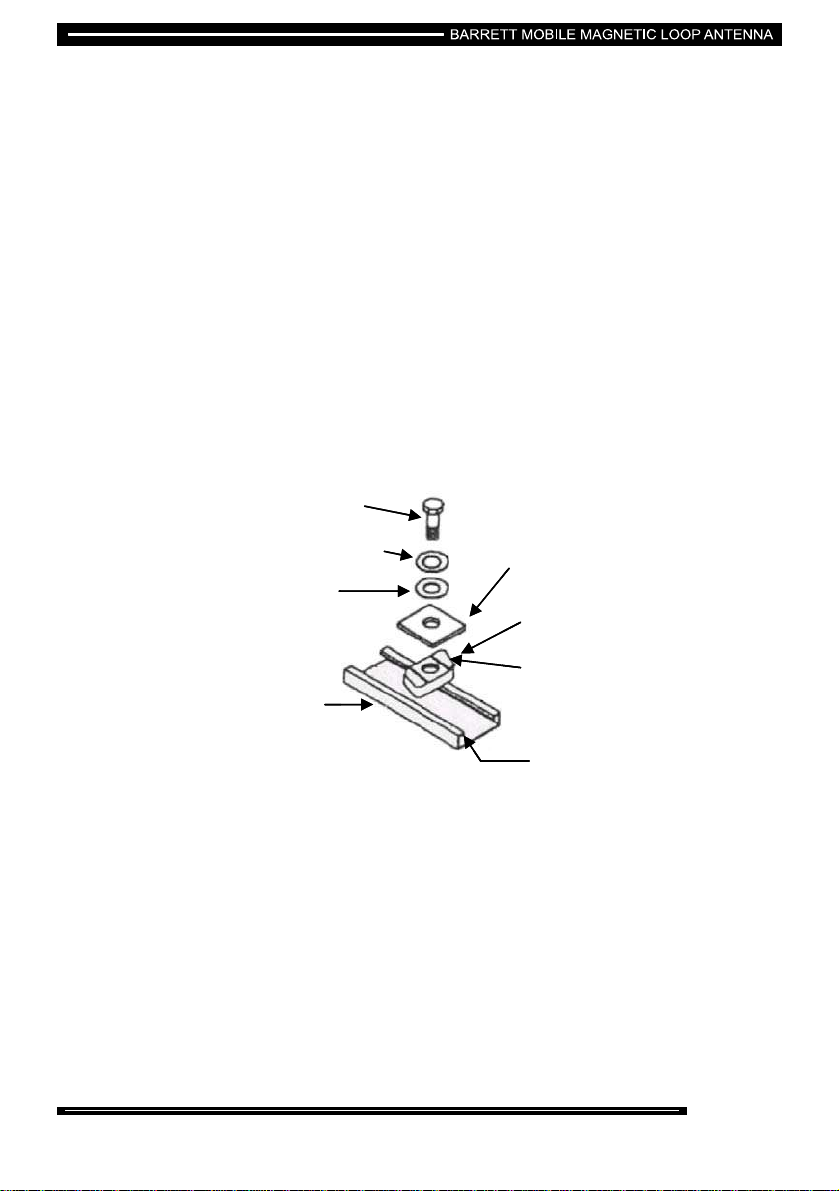

M10 Strut Nut (x16)

Leg Spacer

Viewing Hole

Leg Mount (x8)

M10 Flat Washer (x16)

M10 Star Washer (x16)

M10x25 Hex Bolt (x16)

M10x30 Hex Bolt

(for leg spacer)

U Bolt (x8)

Nylon (x16)

Full Gutter Support (x16)

Full Gutter Support Nylon (x16)

Locating Rod

(welded)

Clamp (x8)

M6 Flat Washer (x16)

M6 Nyloc Nut (x16)

M6 PVC Cap (x16)

M10 Strut Nut (x16)

Leg Spacer

Viewing Hole

Leg Mount (x8)

M10 Flat Washer (x16)

M10 Star Washer (x16)

M10x25 Hex Bolt (x16)

M10x30 Hex Bolt

(for leg spacer)

U Bolt (x8)

Nylon (x16)

Full Gutter Support (x16)

Full Gutter Support Nylon (x16)

Locating Rod

(welded)

Clamp (x8)

M6 Flat Washer (x16)

M6 Nyloc Nut (x16)

M6 PVC Cap (x16)

M10 Strut Nut (x16)

Leg Spacer

Viewing Hole

Leg Mount (x8)

M10 Flat Washer (x16)

M10 Star Washer (x16)

M10x25 Hex Bolt (x16)

M10x30 Hex Bolt

(for leg spacer)

U Bolt (x8)

Nylon (x16)

Full Gutter Support (x16)

Full Gutter Support Nylon (x16)

Locating Rod

(welded)

Clamp (x8)

M6 Flat Washer (x16)

M6 Nyloc Nut (x16)

M6 PVC Cap (x16)

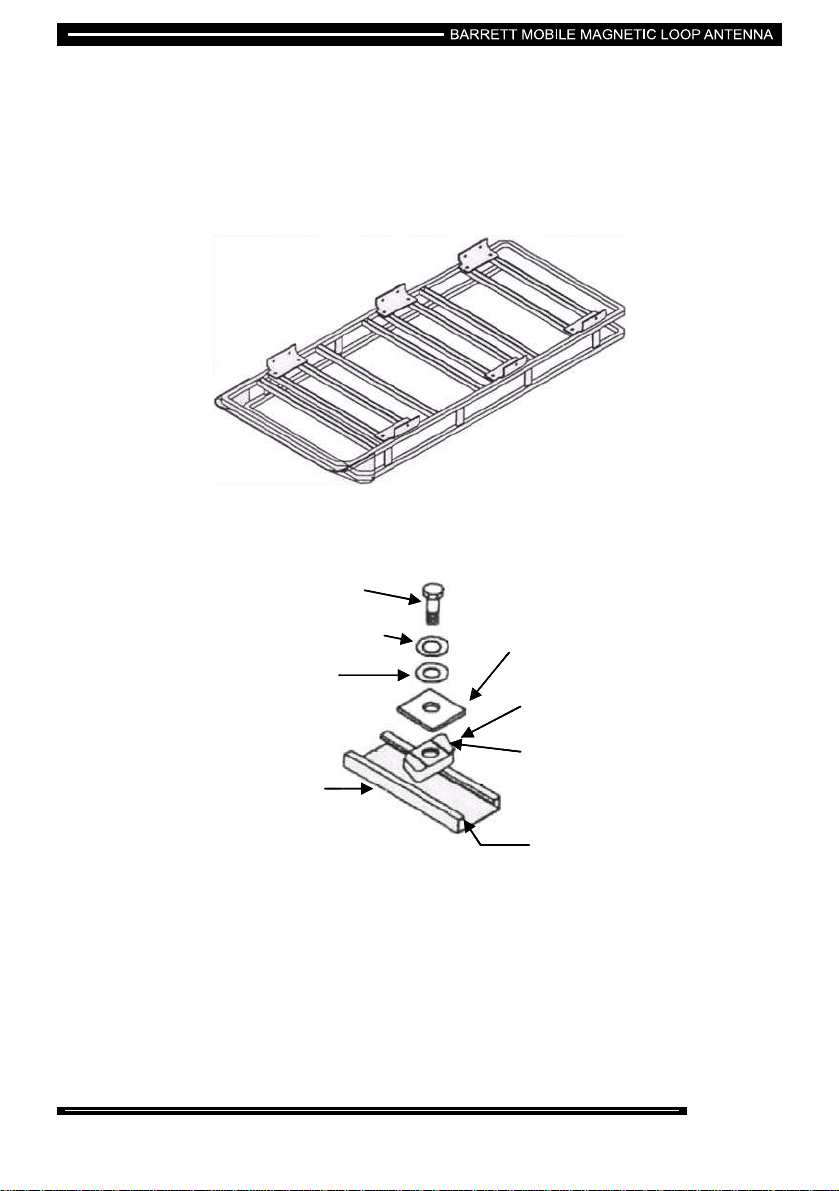

Exploded Diagram of the Leg Mount Assembly

11 of 31

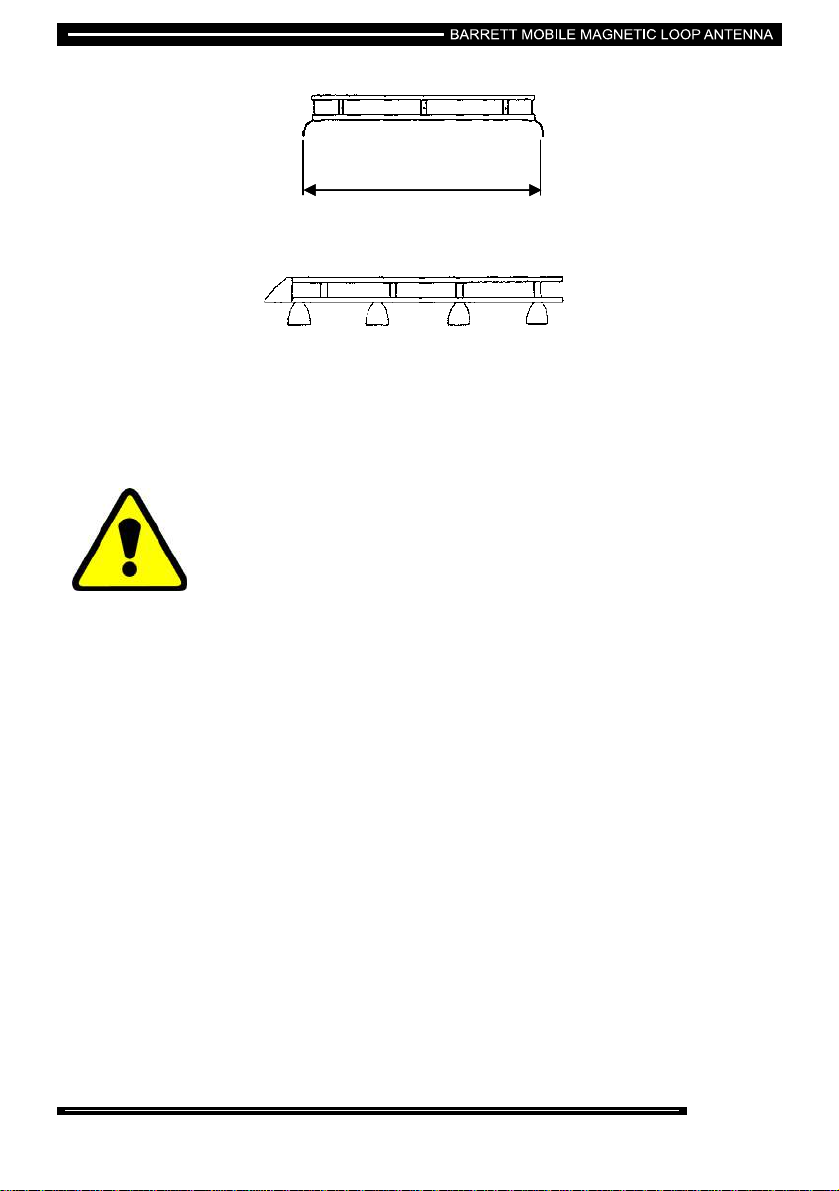

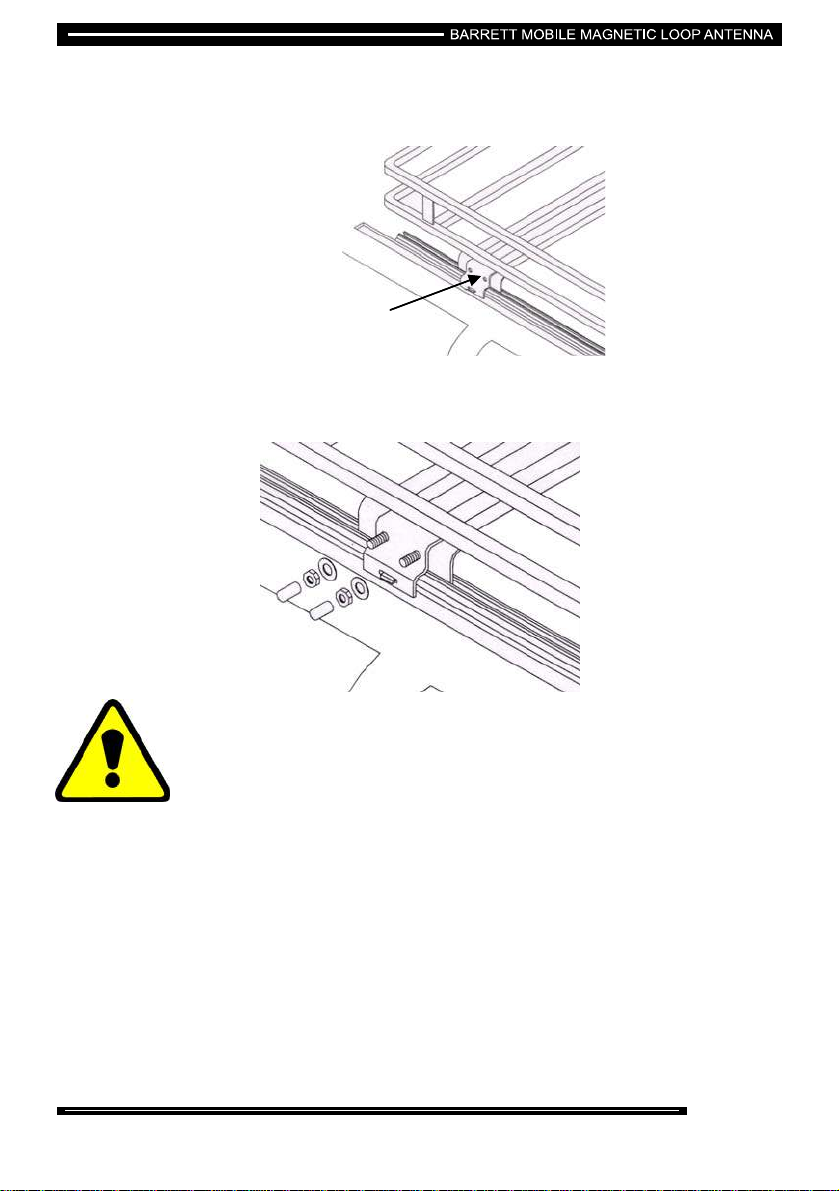

Setting Up the Roof Rack

Turn the rack upside down on either a bench or soft, non-abrasive surface.

The diagram below illustrates how the strut nut works. Position the legs in the correct channels and

tighten to the correct tension.

M10 Bolt

M10 Star Washer

Part of Leg Mount

Strut Nut

Mounting Channel

M10 Washer

Serrated Grooves

Turned down lips

M10 Bolt

M10 Star Washer

Part of Leg Mount

Strut Nut

Mounting Channel

M10 Washer

Serrated Grooves

Turned down lips

M10 Bolt

M10 Star Washer

Part of Leg Mount

Strut Nut

Mounting Channel

M10 Washer

Serrated Grooves

Turned down lips

Important:- Ensure each strut nut is rotated 90° and the serrated grooves in the strut nut located into

the channel's turned down lips. There is a viewing hole located on the leg mount to check that the

strut nut has rotated correctly. If it has not turned, insert a screwdriver into the hole and turn the strut

nut appropriately.

First set and tighten legs A & D, use the supplied packing pieces as necessary.

12 of 31

A =

B =

C =

D =

Use legs with packers at positions A & D

if necessary

AB CD

A =

B =

C =

D =

Use legs with packers at positions A & D

if necessary

AB CD

A =

B =

C =

D =

Use legs with packers at positions A & D

if necessary

AB CD

The measurements A-D vary according to the vehicle type. Use the supplied chart (in the above

diagram) to determine these.

Use a straight edge to line up the centre legs before tightening.

Double check the tension on all bolts.

Note:- Nylon channel pieces should be fitted to the tops of each clamp as shown in the exploded

diagram on page 11.

13 of 31

I

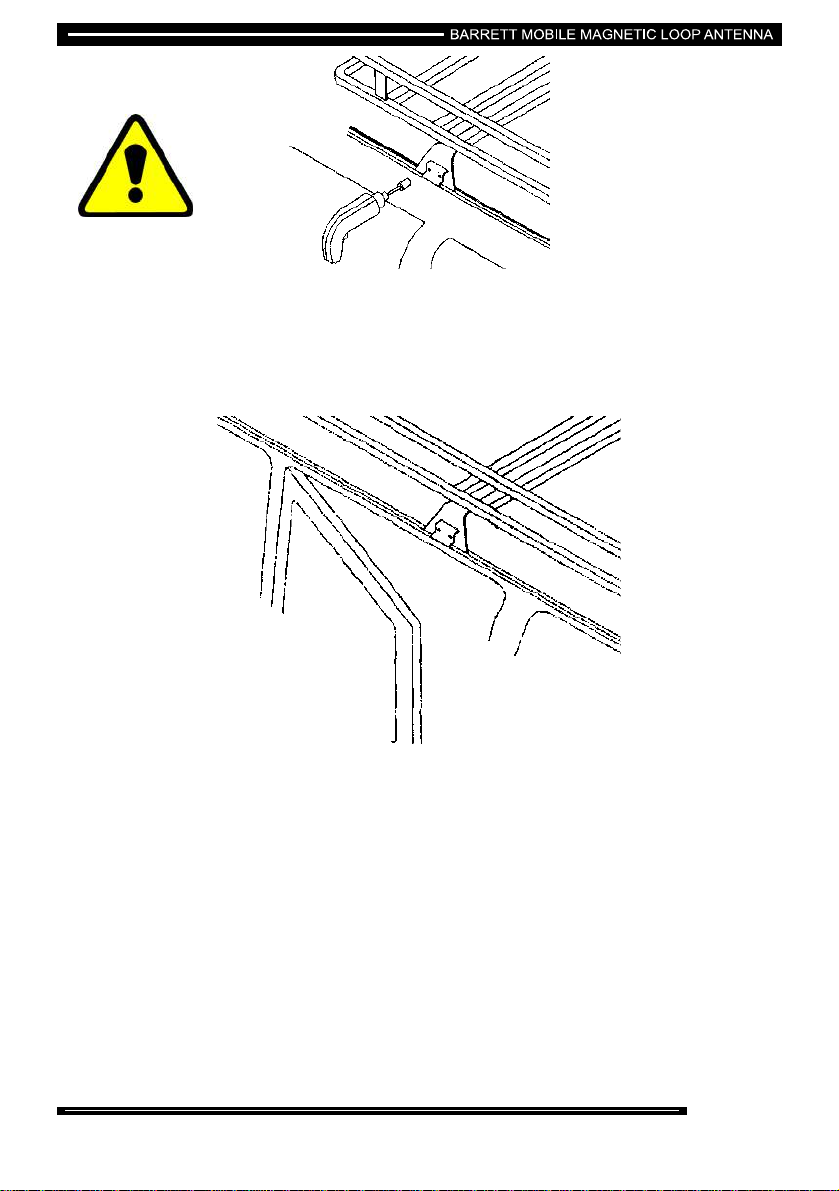

Important:- Ensure the feed cable is not damaged by being trapped between the ski bar mount and

the roof-rack, shown below:-

The correct position for the cable, running underneath the ski-bar mount, is shown below:-

8

9

14 of 31

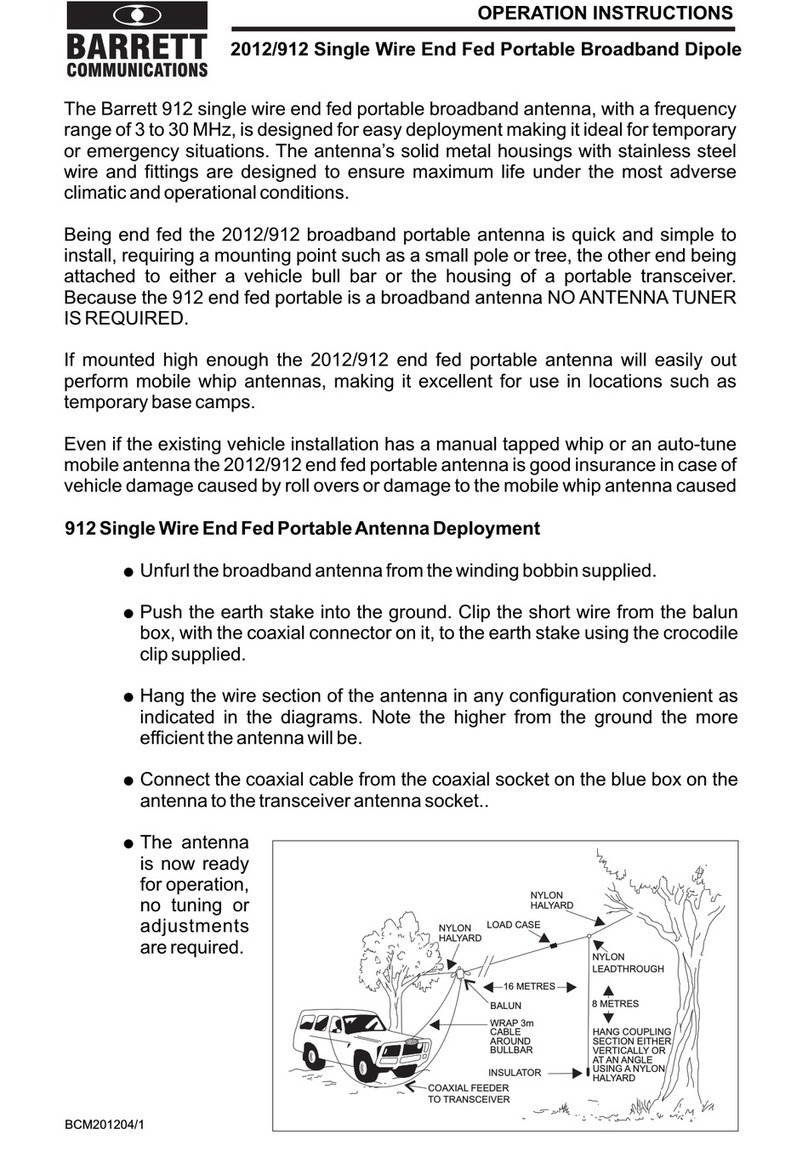

Preparing the Vehicle

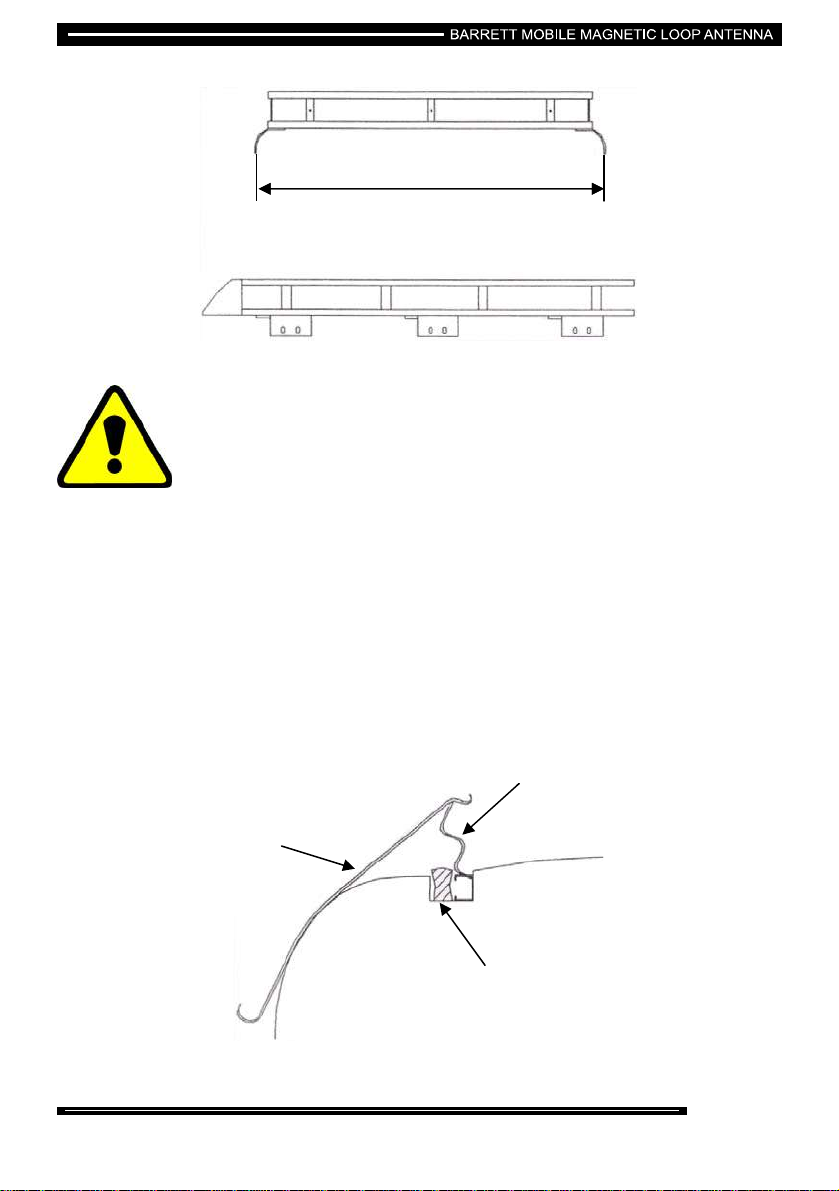

Press the nylon channel to the bottom of the full gutter support and place in the gutter of the vehicle

with the long edge against the vehicle and the short edge facing outwards. The following diagrams

illustrate this.

Full Gutter

Support

Ny lon Channel

Push on

Full Gutter Support

Roof

Turret

Nylon Channel

Full Gutter Support

Roof

Turret

Nylon Channel

Full Gutter Support

Roof

Turret

Nylon Channel

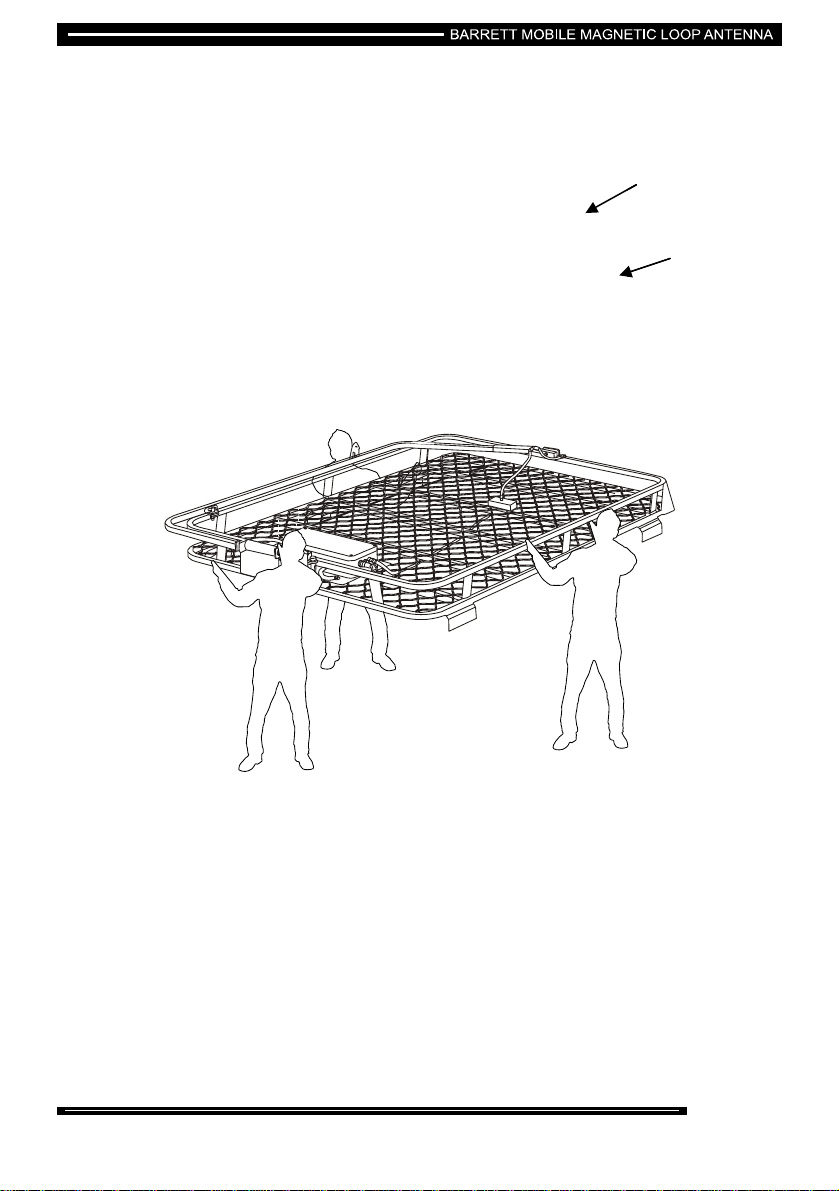

The rack may be lifted onto the vehicle by two people, one either side. However, it is preferable for a

third person to help at the rear of the rack. Lift by the bottom of the leg mounts.

Note:- The sloped edge of the antenna faces towards the front of the vehicle, i.e. the RF Feedbox is

at the front and the Tuner Box is to the rear.

Position the rack into the full gutter support and tighten the clamps using an M10 socket driver

The Nyloc®clamp nuts are easily tightened using an M10 socket using a cordless drill/driver.

15 of 31

Caution: Be careful not to over tighten the clamps. The clamps should be firm but not deformed.

Re-check the tightness of all mounting hardware when done.

Important:- Ensure the door seals at the top of the door do not catch on the clamp when fitted. If

they do, check the clamps are sitting flat against the underside of the surface and tighten until the door

seals clear. See the illustration below.

Note:- On some vehicles, the hinge bolts of the doors may require loosening and the door and latch

lowering. Contact your Barrett Communications representative if you have any problems.

Barrett Communications Pty Ltd accepts no liability for damage to door seals, as correct fitting will

ensure door seals are protected.

16 of 31

Fitting on Vehicles Without Gutters

Setting Up the Roof Rack

Turn the rack upside down on either a bench or a soft non-abrasive surface.

The diagram below illustrates how the strut nut works. Position the legs in the channels and tighten to

the correct width.

M10 Bolt

M10 Star Washer

Part of Leg Mount

Strut Nut

Mounting Channel

M10 Washer

Serrated Grooves

Turned down lips

M10 Bolt

M10 Star Washer

Part of Leg Mount

Strut Nut

Mounting Channel

M10 Washer

Serrated Grooves

Turned down lips

M10 Bolt

M10 Star Washer

Part of Leg Mount

Strut Nut

Mounting Channel

M10 Washer

Serrated Grooves

Turned down lips

Important:- Ensure each strut nut is rotated 90° and the serrated grooves in the strut nut have

located into the channel's turned down lips. There is a viewing hole located on the leg mount to check

that the strut nut has rotated correctly. If it has not turned, insert a screwdriver into the hole and turn

the strut nut appropriately.

17 of 31

Use the following measurements to set the rack up correctly and tighten the bolts.

A, B, C = 1055mm

CBA

A, B, C = 1055mm

CB

A, B, C = 1055mm

ACBA

Important:- Double check the tightness of all the bolts.

Preparing the Vehicle

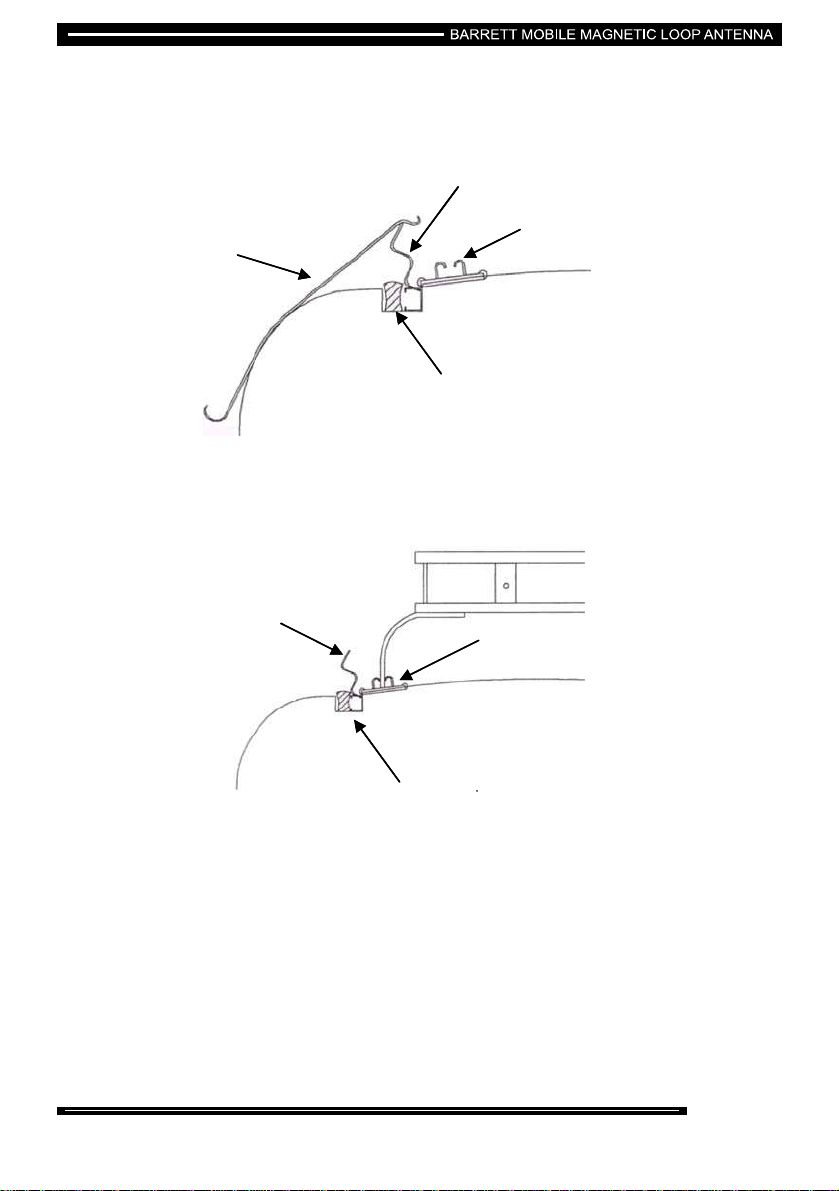

There are six fitting points on the vehicle, positioned at the front, centre and rear of the roof. The

standard size roof rack uses all six points.

Locate the hooks on the inner side of the rubber strips on the roof. There are three hooks per side.

The roof rack clamp has a slot at the bottom which the hook passes through. Make sure the hook is

the correct way round. Temporarily hold the clamp in an upright position with the masking tape as

shown in the following diagram, so the rack can be placed on the roof top without interference.

Tape

Vehicle

Clamp

Rubber Strip

Tape

Vehicle

Clamp

Rubber Strip

18 of 31

Place the leg support rails on the inner side of the clamp (which have been hooked in position and are

taped back, now standing upright). Pull the leg support rail gently against the clamps, ensuring that

the rail is protruding the same distance forwards and backwards from the front and rear clamps. See

the following diagram.

Tape

Vehicle

Clamp

Rubber Strip

Leg Support Rail

Tape

Vehicle

Clamp

Rubber Strip

Leg Support Rail

Tape

Vehicle

Clamp

Rubber Strip

Leg Support Rail

The rack may be lifted onto the vehicle with two people (one either side), but it is ideal to have a third

person at the rear for extra stability. Lift the rack carefully over the roof from the rear and position the

legs into the leg support rails. Refer to the following diagram.

Clamp

Rubber Strip

Located into the

Leg Support Rail

Vehicle

Clamp

Rubber Strip

Located into the

Leg Support Rail

Vehicle

Clamp

Rubber Strip

Located into the

Leg Support Rail

Vehicle

Note:- The sloped edge of the antenna faces towards the front of the vehicle, i.e. the RF Feed box is

at the front with the ATU to the rear.

19 of 31

Align the leg mounts with the clamps and check that the rack is centred on the vehicle. Place the “U”

bolts through the slots in the leg mounts from the inside, and pass the threaded ends through the

holes in the clamp. Re-attach the M6 washers and nuts. See the following diagram.

Rubber Strip removed

from drawing for clarity

Rubber Strip removed

from drawing for clarity

Rubber Strip removed

from drawing for clarity

Ensure the “U” bolt is hooked above the welded locating rod on the inside of the leg mount, then

tighten firmly without deforming the clamp bracket. Place PVC caps over the threaded ends of the “U”

bolt. Refer to the following diagram.

Note:- The Nyloc®clamp nuts can easily be tightened using an M10 socket driver with a cordless

drill.

20 of 31

Table of contents

Other Barrett Antenna manuals

Barrett

Barrett 912 User manual

Barrett

Barrett 2019 Automatic Tuning Mobile HF Antenna User manual

Barrett

Barrett 912 Series User manual

Barrett

Barrett 2090-02-01 User manual

Barrett

Barrett 912 User manual

Barrett

Barrett 2019 User manual

Barrett

Barrett 912 Series User manual

Barrett

Barrett 912 User manual

Barrett

Barrett BC91201 User manual

Barrett

Barrett 912 User manual

Popular Antenna manuals by other brands

Hy-Gain

Hy-Gain AV-680 instruction manual

MFJ

MFJ MFJ-1784 instruction manual

M2 Antenna Systems

M2 Antenna Systems EB-432/RK70CM Assembly manual

Andrew

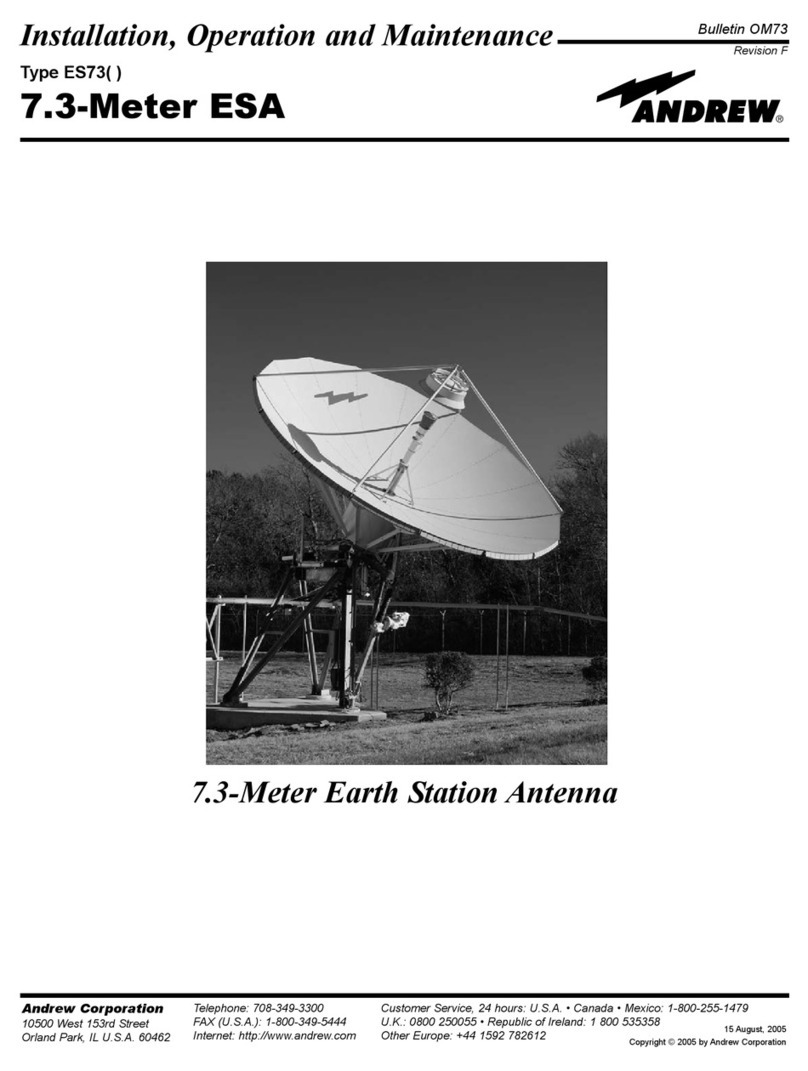

Andrew 7.3-Meter ESA Installation, operation and maintenance

Offel

Offel LNB user manual

Shakespeare Electronic

Shakespeare Electronic PHASE 6420-R installation instructions