Bartels Mikrotechnik mpSmart-Lowdosing User manual

1

Rev. 1.1 (01.2021)

Flow Controlled System –

“mpSmart-Lowdosing”

2

Rev. 1.1 (01.2021)

Content

...........................................................................................................................................................................................................................1

Flow Controlled System –“mpSmart-Lowdosing”..............................................................................................................................1

General............................................................................................................................................Fehler! Textmarke nicht definiert.

Declaration of conformity.....................................................................................................Fehler! Textmarke nicht definiert.

Description of functions........................................................................................................Fehler! Textmarke nicht definiert.

Proper use.......................................................................................................................................Fehler! Textmarke nicht definiert.

Intended purpose.....................................................................................................................Fehler! Textmarke nicht definiert.

Misuse.........................................................................................................................................Fehler! Textmarke nicht definiert.

Staff selection and qualification. .......................................................................................Fehler! Textmarke nicht definiert.

About this operating manual...............................................................................................Fehler! Textmarke nicht definiert.

Getting started with GUI ...........................................................................................................................................................................6

3

Rev. 1.1 (01.2021)

General

This operating manual contains all necessary instructions for the installation, commissioning, operation and

maintenance of the evaluation board mpSmart-Lowdosing controller. The manual is intended to help you achieving

optimal results in a short time and shall assist avoiding possible sources of errors. The operating manual of the

micropumps and other controllers are available separately.

The products have been designed with state-of-the-art technology and in accordance with all relevant safety

regulations. However, a risk of damage to the units, other property, the operator and/or other persons cannot be fully

excluded.

Always ensure that specialized and trained personnel will comply with the following general instructions.

Therefore, please keep this manual and hand out copies as required.

Bartels Mikrotechnik GmbH rejects any responsibility for damages to persons or property resulting from non-

compliance with the instructions in this manual. In this case all warranties shall be void.

Declaration of conformity.

Bartels Mikrotechnik GmbH declares that the products are compliant to the RoHS directive 2011/65/EU. The controller

comply with the requirements of EMV 2014/30/EU and CE markings have been affixed to the devices. Additionally,

the controllers are also compliant to the EU Low Voltage Directive 2014/35/EU.

Description of function.

The mpSmart-Lowdosing have been developed for the transport of liquids. The controller has been developed for

operating the micropump. Bartels Mikrotechnik can assume no liability for damages resulting from the pump media.

This applies especially for hazardous fluids.

The pump must be operated with Bartels Mikrotechnik electronics. Bartels Mikrotechnik GmbH cannot guarantee the

proper work of the units with customer specific electronics. If other controllers than the ones from Bartels

Mikrotechnik are used, Bartels Mikrotechnik disclaims any warranty.

Moreover, please note that components of the controller and pump are operating with high-voltage. Therefore,

persons wearing pacemakers are recommended to avoid the operating system.

Bartels Mikrotechnik assumes no liability for abnormal handling, improper or negligent use of the micropump and

the controller that is not conform to the specified purpose of the system. This applies especially for micropump

controllers, components and systems of other manufacturers, which have not been certified by Bartels Mikrotechnik.

We guarantee that the micropumps comply with the actual state of scientific and technical knowledge and due to

this, the operational risks are limited to a minimum.

Do not open the housing of the micropump and the controllers. In those cases, Bartels Mikrotechnik cannot issue a

guaranty anymore. Please keep this manual safe and give a copy to all users.

4

Rev. 1.1 (01.2021)

Proper use

Intended purpose.

The micropump is intended for pumping liquids with varying flow rates controlled by the electronics. The controllers

are intended for operating the micropumps. Any other use of the micropump or controller unit is deemed improper.

Do not make any modifications or extensions to the pump or controller without the prior written consent of the

manufacturer. Such modifications may impair the safety of the unit and are prohibited! Bartels Mikrotechnik GmbH

rejects any responsibility for damage to the unit caused by unauthorized modifications to the pump and risk and

liability are automatically transferred to the operator.

Misuse.

The use of liquids, which may alone or in combination create explosive or otherwise health-endangering conditions

(including vapors) is not permitted.

Staff selection and qualification.

All work in connection with the installation, assembly, commissioning/decommissioning, disassembly, operation,

servicing, cleaning and repairing of the pump and the controller must be carried out by qualified, suitably trained

and instructed personnel. Work on electrical components and assemblies must be carried out by personnel with the

necessary qualifications and skills.

About this operating manual.

Warnings and important notes are clearly identified as such in the text. The relevant text sections feature a specific

sign. However, this icon cannot replace the safety instructions. Therefore, carefully read all safety instructions in this

manual. Warnings and important notes in this text are highlighted as shown below, according to the severity of the

damage that might result from non-compliance.

DANGER

DANGER indicates a hazard with a high level of RISK THAT, if not avoided, will result in death or serious injury.

5

Rev. 1.1 (01.2021)

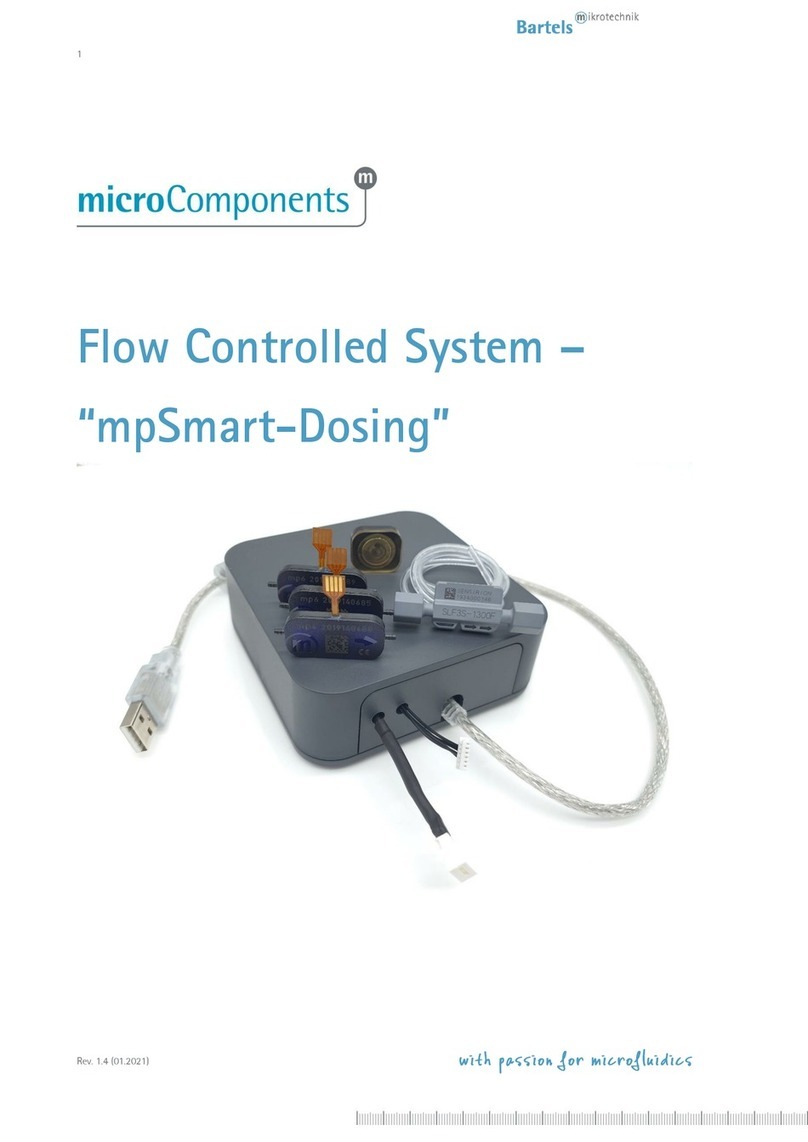

The flow-controlled system: mpSmart-Lowdosing

Flow Controlled System –„mpSmart-Lowdosing“

This Flow Control System is a smart module for precise and regulated dosing of liquids. An onboard

Arduino reads out a flowmeter made by Sensirion, comparing it to a target value and operates the

mp6 micropump corresponding to a PID-regulator. The attached PC-software can be used to monitor,

control and log the flowrate

Components

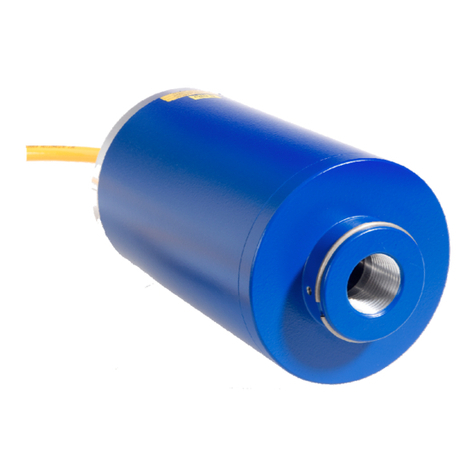

mp6-hyb micropump

Damper

Flowmeter (Sensirion SLF3s-0600F)

Tubing

Tubing connectors

Driver Board

Software with GUI

min. Flowrate

5 µl/min1

max. Flowrate

1000 µl/min1

Accuracy

<±5%

Software calibration

Water

USB-port

one

Input Voltage

5V

Operating temperature

+5°C bis +45°C

Materila in Contact with Fluid

PPSU, silicon, PP, PPS, stainless steel, Tygon,

epoxy based adhesive

Lifetime

5000 h

Self-priming

yes

Dimensions

9.5 cm x 9.5 cm x 3.5 cm

Pumping media

Liquid (water)

1 Bedingung: Destilliertes Wasser (25°C), Raumtemperatur 23°C

2 Bedingungen: Saugdruck < 10 mbar, DI-Wasser, max. Förderleistung wird erst nach wenigen Minuten Betriebszeit erreicht

³ Bedingungen: Luft, Raumtemperatur 23°C, mp-x: 100 Hz, 250 V, SRS

6

Rev. 1.1 (01.2021)

Getting started with GUI

The mpSmart-Lowdosing includes 3 main components:

A mp6 micropump, a mp-damper and a SFL3s-0600F flowrate sensor.

For the fluid channel, use the included Tygon tubing in the kit to connect them as shown in the following figure.

As for the tube lengths between mp6 micropump & mp-damper or mp-damper & SLF3s-0600F we recommend at

least 50 mm.

To make sure that there is no air in the fluid channel, we recommend priming the system with a syringe by pulling

the fluid through the channel.

For the wiring, use the included cable to connect the mp6 micropump and SLF3s-0600F to the Flow Controller and the

USB cable to connect the kit with your PC / Laptop.

Starting the Evaluation Software

After installing the included software execute the mpSmart-Lowdosing.exe to start it up. The Connection Manager

can be found in the top left corner. Make sure the USB cable is plugged in and the device is recognized. When selected

click on „Connect“ to start the communication between the program and the driver. If the device was not found you

might need to install the driver for the Arduino nano microcontroller manually.

To start your mpSmart-Lowdosing kit all you need to do is to choose one of the four flowrate ranges, which sets the

pump frequency, e.g. 150 –500 µl/min, and the exact flowrate with the regulator underneath (or the text field next

to it). Afterwards the mp6 can be started or stopped with the on or off button. The actual flowrate is displayed

underneath or as a time plot in the second tab of the Evaluation software.

7

Rev. 1.1 (01.2021)

To log your measurements, you can simply click on “Save chart data” to save your measurements. The Data will be

stored in a .csv file.

Since the Sensor used is calibrated for water and you plan on using a different fluid, we added an option to calibrate

your system for other fluids (ideally water-like fluids). This “Calibration Factor” is multiplied with the sensor

measurements displayed in the GUI. To determine what factor your fluid needs, you will need to make a reference

measurement by e.g. electronic scale and adjust the error with a new calibration factor.

8

Rev. 1.1 (01.2021)

All values are approximate and no guarantee of specific technical properties.

Changes in the course of technical progress are possible without notice.

Contact Data:

Bartels Mikrotechnik GmbH

Konrad-Adenauer-Allee 11

44263 Dortmund Germany

www.bartels-mikrotechnik.de

info@bartels-mikrotechnik.de

Tel: +49-231-47730-500

Fax: +49-231-47730-501

Visit our Website

www.bartels-mikrotechnik.de/produkte/downloads

for further information on applications.

Tutorials and helpful answers to frequently asked

questions can be found in our FAQ

www.bartels-mikrotechnik.de/en/faq-english/

or on our YouTube channel

https://www.youtube.com/user/BartelsMikrotechnik

Find us on Social Media:

Table of contents

Other Bartels Mikrotechnik Controllers manuals

Popular Controllers manuals by other brands

Pegasus Astro

Pegasus Astro Dual Motor Focus Controller v3.x manual

Microtech

Microtech e-GATE instruction manual

System air

System air SAVE VTC 500 user manual

BFI Automation

BFI Automation CFC 2000 Original operating instructions

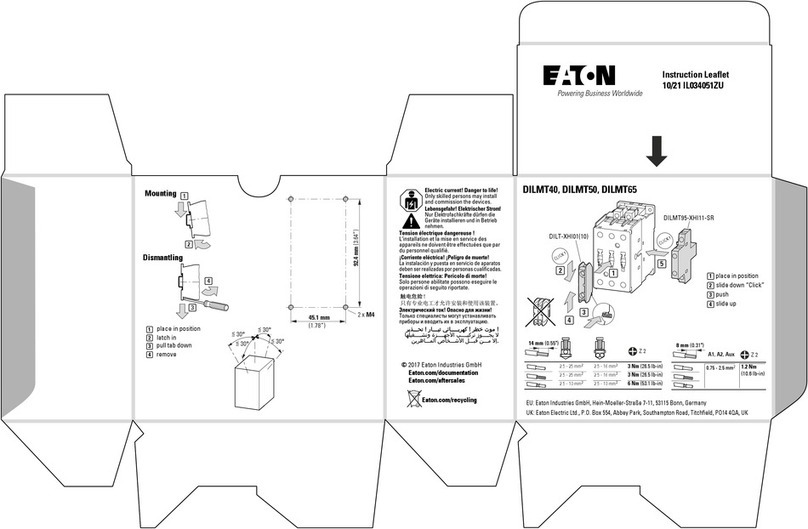

Eaton

Eaton DILMT40 Instruction leaflet

Oceanic

Oceanic OCS45 Assembly and operating manual