Proxel DTSF3+ User manual

Proxel Engineering Ltd ------------------------www.proxel-bg.com----------------- -DTSF3+ v2.4 /2 17

„DTSF3+” Temperature Controller For Solar Thermal And Heating

Application With 8 Schemes

B IEF DESC IPTION

The unit is a programmable digital temperatute controller for solar thermal and

heating plants. It manages the interaction between the solar collector, hot water tank,

storage tank, boiler, pumps, valves and electric heater. The unit helps to improve

thermal comfort by combining high efficiency with autonomy of the system. The

joint functional work of differential temperature, built-in clock and a flexible treshold temperatures

further helps to increase energy savings. It has 8 pre-programmed functional diagrams which cover

vast range of prooved by practice application. The application of the device extends from thermo-

syphonic solar water heaters to more complex solar systems with a combination of hot water tank

and storage tank, boiler and heating. It also can control one HF pump with PWM input.

Functional diagrams, schemes, sensors and outputs arrangement:

1

Scheme 0 – Thermosyphonic panel with integrated tank and trace heating

Sensors

Schm=0; “TSyphTrH”

• TS1 – trace temperature

• TS2 – solar tank temperature

• TS3 – not used;

• Level sensor - Terminals 3 and 4

Outputs

• R1 – trace heater

• R2 – electric heater of solar operated tank

•

R3 – refill valve (N.C.)

Level sensor: Controls electric valve for proper boiler fill up while monitoring the water level with submerged

electrode.

2

Scheme 1- Thermosyphonic panel with integrated tank and recirculation;

Sensors

Schm=1; “TSyph eC”

• TS1 – temperature of suplimentary tank/recirculation point

• TS2 – solar tank temperature

• TS3 – trace temperature

Outputs

• R1 – recirculation pump

• R2 – electric heater of solar operated tank

• R3 – * valve – not used

3

Scheme 2- Solar panel with one storage tank and electric heater (standard)

Sensors

Schm=2; „dT.EL+T1”

• TS1 – temperature of solar panel

• TS2 – tank temperature at bottom (at coil position)

• TS3 – tank temperature at top (for heater control)

Outputs

• R1 – solar pump

• R2 – electric heater of tank

• R3 – emergency draining valve

4

Scheme 2а - Solar panel with two storage tanks – Ta-with electric heater, Tb-with solar heating,

Sensors

Schm=2; „dT.EL+T1”

• TS1 – temperature of solar panel

• TS2 – temperature of electric heater operated tank

• TS3 – temperature of solar operated tank

Outputs

• R1 – solar pump

• R2 – electric heater of tank

• R3 – emergency draining valve

2

5

Scheme 3 - Solar panel with two storage tanks – main and suplimentary with priority

Sensors

Schm=3;“dTETa/Tb”

• TS1 – temperature of solar panel

• TS2 – temperature of tank („A”) - main

• TS3 – temperature of tank („B”) -suplimentary

Outputs

• R1 – solar pump

• R2 – electric heater of tank („A”)

• R3 – 3-way valve main/suplimentary tank

6

Scheme 3а - Solar panel with one tank with two solar coils and electric heater

Sensors

Schm=3;“dTETa/Tb”

• TS1 – temperature of solar panel

• TS2 – temperature of tank – top („A”)

• TS3 – temperature of tank – bottom („B”)

Outputs

• R1 – solar pump

• R2 – electric heater of tank

• R3 – 3-way valve top/bottom

7

Scheme 4 - Solar panel with one tank with two coils, electric heater and suplimentary heater

Sensors

Schm=4; “1B+2C+EL”

• TS1 – temperature of solar panel

• TS2 – tank temperature

• TS3 – suplimentary heating source temperature

Outputs

• R1 – solar pump

• R2 – electric heater of tank

• R3 – DHW suplimentary heating valve/pump

8

Scheme 5 - Solar panel with one tank with two coils, suplimentary heater and heating pump

Sensors

Schm=5; “SolDhwCh”

• TS1 – temperature of solar panel

• TS2 – tank temperature

• TS3 – suplimentary heating source temperature

Outputs

• R1 – solar pump

• R2 – circulation pump for domestic heating

• R3 – DHW suplimentary heating valve/pump

9 Scheme 6 – Solar/supplementary heater with two tanks and two pumps, no priority

Sensors

Schm=6; “SOL+2P2T”

• TS1 – temperature of heat source

• TS2 – temperature of tank – “A”

• TS3 – temperature of tank – “B”

Outputs

• R1 – pump for tank “А“

• R2 – electric heater of tank “А”

• R3 – pump for tank “B”

1 Scheme 7 – Unpreasurized solar panel (open to air system) with el. heater and refill function

Sensors

Schm=7; “dT.EL.T1+ ”

• TS1 – temperature of solar panel

• TS2 – temperature of solar tank

• TS3 – not used

• Level sensor - Terminals 3 and 4; reads level of liquid

Outputs

• R1 – solar pump

• R2 – electric heater of tank

• R3 – refill valve (N.C.)

Level sensor: Controls electric valve for proper solar panel fill up while monitoring the water level with

submerged electrode.

3

TABLE OF AVAILABLE PARAMETERS:

Shceme participation:

Name

Range

Защита

с

Парола

Parameter description

1 2 3 4 5 6 7

1

Clock

h:m:s

Clock

*

*

*

*

*

*

*

2

ОN

24h/15min

Beginning of time zone (El. Heater)

*

*

*

*

*

*

*

3

Off

24h/15min

End of time zone (El. Heater)

*

*

*

*

*

*

*

4

GoodTnk

min÷max

Comfort t

°

°°

°C

in main tank

*

*

*

*

*

*

*

*

5

dT1-Sol

3÷35°C

*

Temperature difference – solar/ tank

*

*

*

*

*

*

*

5а

dT1-hst

2 or 5°C

*

Hysteresis of dT1-Sol

*

*

*

*

*

*

*

6

dT2-Kot

3÷15°C

*

Temperature difference supplementary heater / tank

*

*

*

6а

dT2-hst

2 or 5°C

*

Hysteresis of dT2-Kot

*

*

*

7

MinTank

5÷75°C

*

Minimal tank t

°

°°

°C

maintained by El. heater

*

*

*

*

*

*

*

8

CH Pump

5÷75°C

*

Suplimentary source t

°

°°

°C

to start CH pump

*

9

Ma Tank

1 ÷95°C

*

Maximal t

°

°°

°C

in tank

*

*

*

*

*

*

*

*

1

Min Sol

5÷8 °C

*

Temperature in solar source to enable solar pump

*

*

*

*

*

*

1 а

Min Sol

-hst

2 or 5°C

*

Hysteresis of Min Sol

*

*

*

*

*

*

11

DefrSol

-4 ÷1 °C

*

Defrost t

°

°°

°C

of solar (to starts solar pump)

*

*

*

*

*

*

12

MinKot

5÷9 °C

*

Minimal t

°

°°

°C

of supplementary heating to enable

DHW valve/pump

*

*

*

13

TankA/B

5÷9 °C

*

Tank switching t

°

°°

°C

Main/Storage or (coil 1 / 2)

*

14

PumpSec

2÷128sec

*

Pump operation hold time

*

*

*

*

*

*

15

Act Sol

÷24 min

*

Delay of electric heater activation

*

*

*

*

*

16

AutCool

Y / N

*

Automatic cooling of tank to „GoodTnk” t

°

°°

°c

*

*

*

*

*

*

17

Passwrd

Password for majour parameter access

*

*

*

*

*

*

*

*

18

Schm

÷ 5

*

Application select scheme 0

1

2

3

4

5

6

7

19

Lt./Min

. ÷5.

*

Expected flow of solar pump

(for statistics purpouse)

*

*

*

*

*

*

2

dTLoss

÷1 °C

*

Expected t

°

°°

°C

losses of trace

(for statistics purpouse)

*

*

*

*

*

*

21

Pump%Lo

25÷1 %

*

Minimal opperation speed of HF pump

*

*

*

*

*

*

*

22

PumpºcdT

÷25°C

*

Sets upper t

°

°°

°C

margine obove dT1-Sol for HF

pump to operate at 1 % (speed vs t

°

°°

°c

distributuion)

*

*

*

*

*

*

*

23

SolOvrh

N

*

Solar panel overheating counter

- can be cleared

*

*

*

*

*

*

*

24

TnkOvrh

N

*

Tank overheating counter

- can be cleared

*

*

*

*

*

*

*

*

25

AutoVac

Y / N

*

Automatic activation of “Vacancy” mode

*

*

*

*

*

*

*

*

26

LimTnkА

Y / N

Limiting of Main tank t

°

°°

°C

to “GoodTnk”, excess

energy is transferred to storage tank

*

MEANS FOR PREVENTION AND PROTECTION:

Type Action

1

Anti frost of Solar Forced circulation of solar pump

2

Overheat of solar Forced circulation of solar pump

3

Thermal shock of solar “Slow” solar pump activation

4

Thermal shock of pipeline “Slow” solar pump activation

5

Anti frost of pipeline Trace heating/ Forced circulation of solar pump

6

Tank overheat “Vacancy” mode

Operation with “maximal thermal losses”

Auto cooling to “TBGood”

*Heat transfer to supplementary heating system

*Activation of emergency drainig valve

7

Pumps blockage Forced activation on certain period of inactivity

8

Current time lost (time not being set after power

failure with longer duration)

Blinking display

* Available only for certain operational schemes

4

OTHERS:

„Vacancy” mode - forced cooling of tank (during night time) to have full heat storage for next day.

Selectable hysteresis 2 or 5 ºC Fault notification - entire screen blinking

Displays sensor failure message: „no” – no sensor; “sc” – sensor short circuited

Displays state of R1, R2 and R3 Manual activation/test of pumps

Important parameter change is password protected

Automatical switching to “Vacancy” mode if unit is left unattended and possible tank overheating is sensed

PWM output for HF pump speed control ; PWM – 1kHz

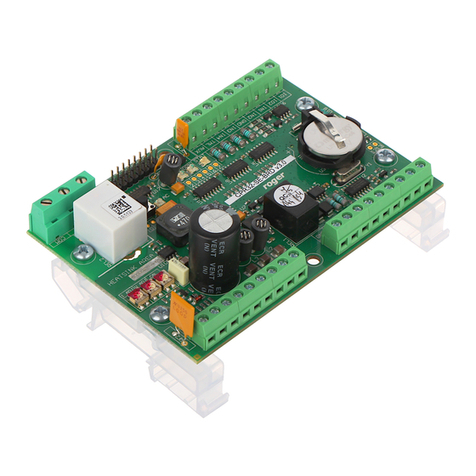

TECHNICAL DATA

Power supply: 23 V±1 % /5 Hz. ≤ 2VА Instalation on DIN rail 35mm; to be incorporated

Enviroment: -5T45, RH8 %

Storage and transportation-2 /+6 º C

Overall dimentions 68x85x58 mm.

Protection casing IP2

Sensors: durability 2 ºC

Measurment and display: -4 ºC÷15 ºC;

Accuracy ±1ºC in range (-5ºC ÷ +1 ºC);

±4ºC not in range

Outputs:

-Relay R1(SPST)- 23 V - 5A or 18 W/AC3 (motor)

-Relay R2(SPDT)- 23 V -16А or 15 W/AC3 (motor)

-Relay R3(SPDT)- 23 V - 5A or 18 W/AC3 (motor

)

Real time clock authonomy up to 2h

MAIN CHA ACTE ISTICS:

1. Supplies directly power for electrical heater (up to3kW) and two circulation pumps / trace heater or

directional valve.

2. Reads three temperatures.

3. Build in conductivity sensor - terminals 3 and 4 – (TS3 not used) for water level monitor and filling

4. Fully programmable by 29 parameters

5. Fast and direct selection of heater operation mode by separate button among „Auto” /On./ Off./Vacancy

6. Build in real time clock with programmable time zone for additional electric heater activation.

7. Relay outputs 3 (separate) for:

- R1 n.o. SPST, supplies phase for pump/trace heating (HFпомпа)

- R2 n.o./n.c SPDT, voltage free contact for electric heater

- R3 n.o./n.c SPDT, supplies phase for pump/direction valves

8. Backup power supply for real time clock

9. Alphanumeric LCD display 8х2 rows.

1 . Navigation – 3 push buttons. One button for elecric heater activation

11. Statistics (solar energy accumulated, alarm events)

12. Diagnostic information for sensor failure.

13. A set of functional means for independatnt action at critical events.

WI ING DIAG AM

Attention!:

Junction for heater’s neutral “N” should be made on external terminal block (not provided)!

All conections to PE should be made to external terminal block (not provided)!

- Power supply 23 V AC – (internal and R1) – #17 (Live “La”); #16 („N”);

- R1: Pump/trace heating – #18 (switches Live); #15 („N”); – 5А max.

- R2: Electric heater – #2 (separate Live ”Lb”); #22 output – 16А max.

- R3: Pump2/Valve(Open/Close) – (switches Live) #13 (n.o); #14 (n.c. ) – 5А max.

Terminals 3 and 4 – level sensor input (measures conductivity of water)

Terminals 1 and 2 – PWM output for HF pumps

Attention!

Power supply should be applied via fuses:

- La – Circuit Breaker max 6А for trm. 17

- Lb - Circuit Breaker max 20А for trm. 20

- If UPS is used, tem. 17/16 should be

supplied by UPS while trm.20 and heater

“N” should be connected before UPS

(directly to mains).

5

S:XX°cAUT

B:YYºcA:ZZ

Instalation and commusioning

This device is dedicated to be incorporated in apartment electrical box with size of 4 or more poles or a cabinet and

can be attached on 35mm DIN rail.

USAGE

Front pannel

Description

- LCD display, alphanumeric type with two rows and back light [5]

- 3x push buttons: [1] for Down „Dn↓”, [2] for Up „Up↑”, to select „Set” [3]

- Push button for selection of operation mode (of heater): [4] „-^v^v-”

- Indicaton of alarm event – blinking of backlight (if a sensor is defective or

current time is lost).

Usage of buttons:

- buttons [1]„Dn-↓”/ [2] „Up- ↑”: navigates among list of parameter screens previous/next;

increase / decrease selected value wih 1;

- button [3] „Set” toggles buttons [1] and [2] usage, to select parameters or change value of selected parameter

-

button [4] „-^v^v-” – selects the operational mode of the unit (heater) AUTO/ ON/ OFF/ VACANCY

Available windows and usage

Window #1 - Main window

Displays temperature reading of sensors and operational mode of outputs.

- ow 1: temperature reading of solar sensor ”XX” / % of HF pump (if password is set),

Operational mode of the unit (electric heater): AUTO/OFF/ON/VAC.

Each one second the mode and state of the R2 output’s state is displayed alternatively

if R2 is switched on (activated) and if R2 is switched off (not active).

Modes:

- “AUTO” – auto mode, El. heater operates according to preset temperature setpoint and selected time zones.

- “OFF” – El. heater is de-activated, automatically switches on as frost protection of tank if temperature is

<1 ºC

- “ON” – El. heater is automatically activated/de-activated to continiouslly keep TBGOOD temperature in

tank, it is de-activated if temperature is >TBGOOD.

- “VAK” - vacancy mode of the system, the El. Heater is shut off (can be activated for defrost of tank). Cools

down the tank by tranfering back the available heat energy from tank to solar (if possible).

Mode of R1: if active – (solar pump), the symbol „S” blinks

ow 2: reading ”YY” - temperature of main tank, reading “ZZ” – temperature of storage tank/boiler

Mode of R2: if active – (valve/pump), the symbol „A” blinks

- If selected scheme of unit is # - „TSyphTrH ” on Row2 currnet time as HH:MM:SS is displayed while

during defrost “DeIce” is displayed.

- If level sensor is “open” or terminals 9 & 1 are open, also displays „Fill-up”

- If selected scheme of unit is #1 -„TSyph eC” on Row2 currnet time as HH:MM:SS is displayed while if re-

circulation is activated - displays „ eCirc.”.

- If selected scheme of unit is #7 -„dT.EL.T1+ ” after ZZ : -level is reached - low level

* If there is no sensor „no” is displayed, if sensor is shor circuit or resistance is <6 Ohm “

sc”

is displayed

.

Manual activation of outputs:

1 – solar pump 3 – valve/pump

Press and hold [2]„Up- ↑” button.

Press and hold [1] „Dn-↓” button Press and hold [3] „Set” button

* As long as the buttons are keeped pressed, the output is activated

.

Attention!

Keep all protections and comutation devices required by tank manufacturer to operate

the electric heater (circuit breakers, temperature regulator, safety temperature switch)!

DTSF

3

+

is not safety device as by means of

EN

60730

-

1

-

Annex

H

Attention!

Danger of electric shock!

All activities involving installation and commissioning should be done while electric power is off

6

ParamXX

1

15ºC 3

ParamXX

1

[15ºC ]

Parameter Visualization:

-

row 1 - name of the selected parameter "ParamXX" and screen number (of tenths-"1 .. 2")

- row 2 - value of the selected parameter and screen number (of small numbers "3")

Change of parameters:

Navigate to the required parameter "ParamXX" using the buttons [1] „Dn-↓”and [2]„Up- ↑”

Press the [3] "Set" button and the selected value is displayed in square brackets “[“ „]”.

Adjust the value using the buttons [1] „Dn-↓”и [2]„Up- ↑”

Confirm with the button [3] “Set”

* To correct the basic parameters, it is necessary first to enter a correct password in the "Password" field!

LEVEL CONT OL

– applicable in schmemes and 7, for systems with valve for automatic filling up of fluid:

Connect terminal no.3 tank’s body, terminal no.4 connect to the electrode. The electrode must be electrically

insulated from tanks body and needs to be partially submerged in the water.

If the reguired level of the fluid is reached (the conductivity between tank’s boady and electrode is enough - the

electrode is partially submerged ) the filling is stopped (R3=Off)

If the level is decreased (there is no water between the electrode and tank body - no conductivity is senced) the

filling process is activated (R3=ON), if scheme is used, the text “Fill-up” is displayed, if scheme 7 is used, the

icons and are blinking alternatively.

Забележка: 1. If the level sensor function is used, the sensor TS3 can not be used and have to be left free.

2. If the level sensor is not necessary, place bridge connection on TS3

Connection to HF pumps:

Connect pump’s power supply to terminals no.18 and no.15. Connect pump speed input to terminals no.1 and no.2.

Initially the pump is activated on 1 % for 1 sec. and this time the preset speed by parameter Pump%Lo and the

remaining temperature related conditions are followed.

LOGICS OF OPE ATION

Scheme :

Output

General Condition Additional condition Device’s Mode

R1 TS1< 8’C All modes

R2 TS2< MinTank Auto

R2 TS2< GoodTnk During preset time interval (time zone) Auto

R2 TS2< GoodTnk On

R2 TS2< 5’C Off/Vakc

R3 Level sensor TS2<7 ’С All modes

Scheme 1:

R1 TS2>TS1+dTSol TS1<Max Tank All modes

R1 TS3<5’C TS2>1 ’C All modes

R2 TS2< MinTank Auto

R2 TS2< GoodTnk During preset time interval (time zone) Auto

R2 TS2< GoodTnk On

R2 TS2< 5’C Off/Vakc

R3 TS2> MaxTank All modes

Scheme 2:

R1 TS1>TS2+dTSol TS2<Max Tank; TS3<Max Tank; TS1> MinSol All modes

R1 TS1< DefrSol TS2>1 ’C All modes

R2 TS2/TS3< MinTank R1 was not activated longer than ActSolar value Auto

R2 TS2/TS3< GoodTnk During preset time interval (time zone) Auto

R2 TS2/TS3< GoodTnk On

R2 TS2/TS3< 5’C Off/Vakc

R3 TS2> MaxTank All modes

7

Scheme 2а:

R1 TS1>TS3+dTSol TS3<Max Tank; TS2<Max Tank; TS1> MinSol All modes

R1 TS1< DefrSol TS3>1 ’C All modes

R2 TS2< MinTank R1 was not activated longer than ActSolar value Auto

R2 TS2< GoodTnk During preset time interval (time zone) Auto

R2 TS2< GoodTnk On

R2 TS2< 5’C Off/Vakc

R3 TS2> MaxTank All modes

Scheme 3; 3а:

R1 TS1>TS2+dTSol TS2< TankA/B; TS1> MinSol All modes

R1 TS1< DefrSol TS2>1 ’C All modes

R1 TS1>TS3+dTSol TS2> TankA/B; TS1> MinSol; TS3< Max Tank All modes

R2 TS2< MinTank R1 was not activated longer than ActSolar value Auto

R2 TS2< GoodTnk During preset time interval (time zone) Auto

R2 TS2< GoodTnk On

R2 TS2< 5’C Off/Vakc

R3 TS2> TankA/B TS2> TankA/B; TS3> TankA/B; TS3<TS2

TS2 < GoodTnk & LimTnkB=ON

All modes

Scheme 4:

R1 TS1>TS2+dTSol TS2< Max Tank; TS1> MinSol All modes

R1 TS1< DefrSol TS2>1 ’C All modes

R2 TS2< MinTank R1 was not activated longer than ActSolar value Auto

R2 TS2< GoodTnk During preset time interval (time zone) Auto

R2 TS2< GoodTnk On

R2 TS2< 5’C Off/Vakc

R3 TS3> TS2+dTKot TS3> MinKot; TS2< GoodTnk All modes

R3 TS2> Max Tank TS3<9 ’C All modes

Scheme 5:

R1 TS1>TS2+dTSol TS2< Max Tank; TS1> MinSol All modes

R1 TS1< DefrSol TS2>1 ’C All modes

R2 TS3> CH Pump All modes

R2 TS2> Max Tank TS3<9 ’C All modes

R3 TS3> TS2+dTKot TS3> MinKot; TS2< GoodTnk All modes

R3 TS2> Max Tank TS3<9 ’C All modes

Scheme 6:

R1 TS1>TS2+dTSol TS2< Max Tank; TS1> MinSol All modes

R1 TS1< DefrSol TS2>1 ’C All modes

R2 TS2 или TS3 < MinTank R1 was not activated longer than ActSolar value Auto

R2 TS2&TS3< GoodTnk During preset time interval (time zone) Auto

R2 TS2&TS3< GoodTnk On

R2 TS2&TS3< 5’C Off/Vakc

R3 TS3> TS2+dTКot TS2> Max Tank; TS1>MinSol All modes

R3 TS1< DefrSol TS3>1 ’C All modes

Scheme 7:

R1 TS1>TS3+dTSol TS2<Max Tank; TS1> MinSol All modes

R1 TS1< DefrSol TS2>1 ’C All modes

R2 TS2< MinTank R1 was not activated longer than ActSolar value Auto

R2 TS2< GoodTnk During preset time interval (time zone) Auto

R2 TS2< GoodTnk On

R2 TS2< 5’C Off/Vakc

R3 Level sensor TS2<7 ’С All modes

8

WA ANTY THE MS AND CONDITIONS:

The warranty period of the product is 24 months from the day of sale or installation by the installer but no more

than 3 months from the date of manufacture. The warranty covers defects attributable to the manufacturer

(manufacturing defects or defective materials). They are not subject to warranty defects in the product or damage to

other equipment as a result of improper or unskilled installation, improper workflow selection and / or adjustment,

unauthorized change of the product, natural disasters, non-standard power supply, improper storage or

transportation.

Warranty card

Please completely fill this card for valid guarantee

Manufacturer: Proxel Engineering Ltd Type: Temperature controller DTSF 3+

Plovdiv, Bulgaria, [email protected]

Serial number: Data of manufacture:

............................. .................................

Seller/Installer:.............................................................................................................................

.

Address: ........................................................................................................................................

Date of (sale) Instalation: .........................................................................................

Installer/ seller :.........................................................................................................

(name and signature )

Instalation is made by

Installer

Client

(please mark the true one)

2004/108/EC

2006/95/EC

Popular Controllers manuals by other brands

easydriver

easydriver Pro Installation and instruction manual

Schalk

Schalk UMS 5 manual

Helios

Helios 90 770 Installation and operating instructions

HomeMatic

HomeMatic HM-LC-Sw4-SM-2 Installation and operating manual

GE

GE PACSystems RX7i CPU Programmer's Reference Manual

ABB

ABB AC500 Series installation instructions

Data Technology

Data Technology 5160X installation guide

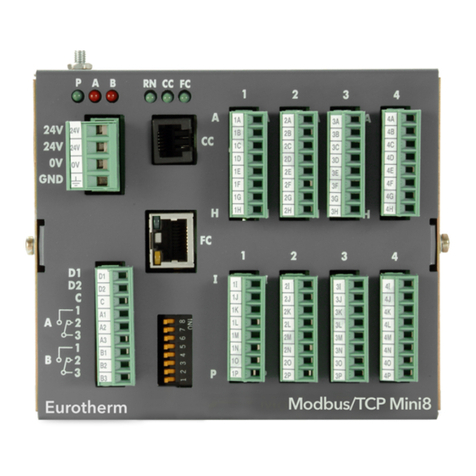

Eurotherm

Eurotherm Invensys Mini8 Engineering manual

GESTRA

GESTRA LRR 1-50 Original Installation & Operating Manual

DirectConnect

DirectConnect VCIR70DSW instructions

Curtiss-Wright

Curtiss-Wright Tritex EVA080 Installation & service instructions

YASKAWA

YASKAWA SI-EP3 Technical manual