Trox Technik LVC Installation and operation manual

Control component

BC0-Compact

for VAV terminal units

Installation and commissioning instructions

Read the instructions prior to performing any task!

LVC • TVR • TVJ • TVT • TZ-/TA-Silenzio • TVZ • TVA • TVM

GB/en

A00000088377, 1, GB/en

© TROX GmbH 2019

TROX GmbH

Heinrich-Trox-Platz

47504 Neukirchen-Vluyn, Germany

Germany

Telephone: +49 (0) 2845 202-0

Fax: +49 (0) 2845 202-265

E-mail: [email protected]

Internet: www.trox.de

06/2021

Control component BC0-Compact for VAV terminal units

2

General information

Information about installation and commissioning

instructions

These installation and commissioning instructions

enable the safe and efficient handling of the BC0-Com-

pact type control components and the associated VAV

terminal unit. Also referred to as control component or

compact controller in the following document.

The manual must be kept near the unit to be available

for use at all times.

The personnel performing work on the device must read

and understand this manual carefully before starting any

work. The basic prerequisite for safe working is to

comply with the safety notes and all instructions in this

manual.

In addition, the local health and safety regulations and

general safety regulations apply to the area of applica-

tion of the device.

Illustrations in this manual are mainly for information

and may differ from the actual unit design.

Other applicable documentation

In addition to these instructions, the following docu-

ments must be observed:

Installation and commissioning instructions of the

VAV terminal unit

Product data sheets

Project-specific wiring documents of the system

planner if any

TROX Technical Service

To ensure that your request is processed as quickly as

possible, please keep the following information ready:

Product name

TROX order number

Delivery date

Brief description of the fault

Online www.troxtechnik.com

Phone +49 2845 202-400

Safety notes

Symbols are used in this manual to alert readers to

areas of potential hazard. Signal words express the

degree of the hazard.

Comply with all safety instructions and proceed carefully

to avoid accidents, injuries and damage to property.

DANGER!

Imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING!

Potentially hazardous situation which, if not avoided,

may result in death or serious injury.

CAUTION!

Potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE!

Potentially hazardous situation which, if not avoided,

may result in property damage.

ENVIRONMENT!

Environmental pollution hazard.

Tips and recommendations

Useful tips and recommendations as well as informa-

tion for efficient and fault-free operation.

General information

Control component BC0-Compact for VAV terminal units 3

Safety notes as part of instructions

Safety notes may refer to individual instructions. In this

case, safety notes will be included in the instructions

and hence facilitate following the instructions. The

above listed signal words will be used.

Example:

1. Loosen the screw.

2.

CAUTION!

Danger of finger entrapment when closing

the lid.

Be careful when closing the lid.

3. Tighten the screw.

Specific safety notes

The following symbols are used in safety notes to alert

you to specific hazards:

Warning signs Type of danger

Warning – high-voltage.

Warning – danger zone.

General information

Control component BC0-Compact for VAV terminal units4

1 Safety ................................................................ 6

1.1 Correct use ................................................ 6

1.2 Safety signs ............................................... 6

1.3 Residual risks ............................................ 6

1.3.1 Electric shock hazards ........................... 7

1.4 System owner's responsibility ................... 7

1.5 Staff ........................................................... 7

1.6 Personal protective equipment .................. 8

1.7 General safety measures .......................... 8

1.8 Repair and replacement parts ................... 8

2 Transport, storage and packaging ................. 9

2.1 Delivery check ........................................... 9

2.2 Transport on site ........................................ 9

2.3 Bearing ...................................................... 9

2.4 Packaging .................................................. 9

3 Structure and functional description ........... 10

3.1 Product overview ..................................... 10

3.2 Position of the damper blade ................... 11

3.3 Function description ................................. 11

3.4 Operating modes ..................................... 12

3.4.1 Operation with constant volume flow

rate setpoint value ................................ 12

3.4.2 Operation with variable volume flow rate

setpoint value ....................................... 13

3.4.3 Override control .................................... 13

3.4.4 Supply/extract air tracking control ........ 14

3.5 Characteristics ......................................... 15

4 Installation ...................................................... 17

5 Wiring ............................................................. 18

5.1 Installation instructions ............................ 18

5.2 Connection diagrams .............................. 18

6 Information on the MP bus ........................... 21

7 Commissioning and operation ..................... 22

7.1 Setting of the control component ............. 23

7.1.1 Control ranges of VAV terminal units .... 23

7.1.2 Factory settings .................................... 25

7.1.3 Setting constant volume flow control .... 25

7.1.4 Setting variable volume flow control ..... 25

7.2 Functional test ......................................... 26

7.2.1 with service tool .................................... 26

7.2.2 with voltmeter ....................................... 26

7.3 Switching the direction of rotation ........... 27

8 Troubleshooting ............................................ 28

8.1 Common mistakes ................................... 28

8.1.1 Volume flow rate deviation due to unfav-

ourable installation situation ................. 28

8.1.2 Incorrect wiring ..................................... 28

8.1.3 System pressure too low ...................... 28

8.1.4 Use outside the control area ................ 28

8.1.5 Deviation between setpoint value and

actual value signal ................................ 29

8.2 Systematic troubleshooting ..................... 29

8.3 Further diagnostic options ....................... 29

8.3.1 Use of voltmeters to control setpoint

values and feedback signals ................ 29

8.3.2 Sample calculations ............................. 29

8.3.3 Order of replacement control compo-

nents ..................................................... 30

9 Disposal .......................................................... 31

10 Technical data ................................................ 32

11 Declaration of conformity ............................. 34

12 Index................................................................ 35

Appendix......................................................... 37

A ZTH menu structure ................................... 38

B Systematic troubleshooting ........................ 39

Table of contents

Control component BC0-Compact for VAV terminal units 5

1 Safety

1.1 Correct use

The electronic control component type BC0-Compact is

used in combination with a TROX air terminal unit for

variable volume flow rate control in ventilation and air

conditioning systems.

The Compactregler is designed for use indoors to con-

trol clean indoor air.

Supply air area of application:

–The usual conditioning in ventilation and air con-

ditioning systems allows use in the supply air

without additional dust protection measures.

Extract air area of application:

– Extract air with a low content of dust or lint (e.g.,

office) allows use without additional dust protec-

tion measures.

– For dry extract air with a higher proportion of

dust or lint, a suitable filter must be used in front

of the VAV terminal unit.

– For extract air with a high content of dust, lint or

sticky components, or extract air with aggressive

operating fluids, use a TROX controller with a

static differential pressure transducer.

– Do not use VAV terminal units in extract air sys-

tems in commercial kitchens unless the extract

air has been cleaned as much as possible with

high-efficiency aerosol separators; see

VDI 2052.

In unspecified applications, or when combined with con-

taminated air (e.g., dust) and moisture, a TROX con-

troller with static differential pressure transducer should

be used.

Incorrect use

WARNING!

Danger of injury or risk of damage to property

due to incorrect use!

Misuse of the control component can lead to dan-

gerous situations.

Never use the control component/device:

–in explosion-proof areas

– in aircraft

– outdoors without sufficient protection against the

effects of weather

– in humid air (even temporarily, i.e., in wet areas,

such as bathrooms with showers)

– for areas of application that are not described in

this manual

Modifying the unit or using replacement parts that have

not been approved by TROX is not permitted.

1.2 Safety signs

The following symbols and signs are usually found in

the work area. They apply to the very location where

they are found.

WARNING!

Danger due to illegible signage!

Over time, stickers and signs may fade or become

otherwise illegible, meaning that hazards cannot be

identified and necessary operating instructions

cannot be followed. There is then a risk of injury.

– Ensure that all of the safety, warning and oper-

ating information is clearly legible.

–Replace illegible signs or stickers immediately.

Electrical voltage

Only skilled qualified electricians are allowed to work in

areas marked as having electrical voltage.

Unauthorised people must not enter areas, open cabi-

nets or work on components where an electrical voltage

is present and which are hence marked with this

symbol.

1.3 Residual risks

The VAV terminal unit is state of the art and designed in

accordance with current safety requirements. Residual

risks cannot be excluded, however, and you should pro-

ceed with caution. This section describes the residual

risks that have been identified in a risk assessment.

Always follow the safety notes in this manual to reduce

health hazards and prevent any hazardous situations.

Safety

Residual risks

Control component BC0-Compact for VAV terminal units6

1.3.1 Electric shock hazards

Electric current

DANGER!

Danger of death due to electric current!

Danger of electric shock! Do not touch any live com-

ponents! Damaged insulation or damaged parts are

a life threatening hazard.

– Have work on the electrical system carried out

only by skilled qualified electricians.

–If the insulation is damaged, switch off the supply

voltage immediately and have the insulation

repaired.

– Before you start working on electric systems and

equipment, switch off the supply voltage and

secure it against being switched on accidentally.

Comply with the following safety rules:

– Switch off the power supply.

– Secure it against being switched on acciden-

tally.

– Ensure that no voltage is present.

– Connect to the earth; short circuit connection.

– Do not bypass or disable any circuit breakers. Be

sure to maintain the correct current rating when

you replace a circuit breaker.

– Ensure that live parts do not come into contact

with moisture. Moisture can cause a short circuit.

1.4 System owner's responsibility

System owner

The system owner is a natural or legal person who for

commercial or business purposes owns or manages the

ventilation system or component or allows third parties

to use or operate it, but continues to bear legal respon-

sibility for the safety of users, staff or third parties while

the product is in use.

System owner's obligations

The unit is intended for commercial use. The system

owner is therefore subject to the legal obligations of

occupational health and safety regulations.

In addition to the safety notes in this manual, the appli-

cable regulations for safety, accident prevention and

environmental protection must also be complied with.

In particular:

The system owner must be aware of the applicable

occupational health and safety regulations and carry

out a risk assessment to determine any additional

hazards that may exist or result from the specific

working conditions at the installation location. The

system owner has to create operating instructions

for the unit that reflect the results of this risk assess-

ment.

The system owner has to ensure, throughout the

entire operating period of the unit, that these oper-

ating instructions conform to applicable standards

and guidelines; in case of any deviation, the system

owner has to adapt the instructions.

The system owner must secure the unit to prevent

access by unauthorised individuals.

The system owner must clearly define the responsi-

bilities for operation, maintenance, cleaning, trouble-

shooting and removal.

The system owner has to ensure that all individuals

who handle or use the unit have read and under-

stood this manual.

The system owner must provide the employees with

the required personal protective equipment.

The system owner must observe the local fire regu-

lations.

Hygiene requirements

The system owner has to comply with the local regula-

tions and harmonised standards for hygiene require-

ments. These include, among other things, compliance

with the corresponding maintenance and test intervals.

1.5 Staff

Qualification

The work described in this manual has to be carried out

by individuals with the qualification, training, knowledge

and experience described below:

HVAC technician

HVAC technicians are individuals who have sufficient

professional or technical training in the field they are

working in to enable them to carry out their assigned

duties at the level of responsibility allocated to them and

in compliance with the relevant guidelines, safety regu-

lations and instructions. HVAC technicians are individ-

uals who have in-depth knowledge and skills related to

HVAC systems; they are also responsible for the profes-

sional completion of the work under consideration.

HVAC technicians are individuals who have sufficient

professional or technical training, knowledge and actual

experience to enable them to work on HVAC systems,

understand any potential hazards related to the work

under consideration, and recognise and avoid any risks

involved.

Safety

Staff

Control component BC0-Compact for VAV terminal units 7

Skilled qualified electrician

Skilled qualified electricians are individuals who have

sufficient professional or technical training, knowledge

and actual experience to enable them to work on elec-

trical systems, understand any potential hazards related

to the work under consideration, and recognise and

avoid any risks involved.

TROX Technical Service

Staff of TROX Technical Service or of service partner

companies approved and assigned by TROX GmbH.

1.6 Personal protective equipment

Personal protective equipment is equipment that pro-

tects the user against health or safety risks at work.

Personal protective equipment must be worn for various

types of work; the protective equipment required is

listed in this manual together with the description of

each type of work.

Description of personal protective equipment

Industrial safety helmet

Industrial safety helmets protect the head from falling

objects, suspended loads, and the effects of striking the

head against stationary objects.

Protective gloves

Protective gloves protect hands from friction, abrasions,

punctures, deep cuts, and direct contact with hot sur-

faces.

Safety shoes

Safety shoes protect the feet from crushing, falling parts

and prevent slipping on a slippery floor.

1.7 General safety measures

NOTICE!

Risk of damage to property due to large tempera-

ture differences

If any electronic components have been kept in an

unheated area, condensation may form and damage

the electronic components beyond repair.

– Before you start commissioning, make sure that

all devices have warmed up to the ambient tem-

perature. Only after about 2 hours will the system

have reached ambient temperature.

Foreign matter and liquids

NOTICE!

Risk of damage to property due to foreign matter

and liquids!

Foreign matter and liquids that get into the unit may

damage the electronic parts.

–Do not use any liquids for cleaning.

– Remove foreign matter, if any.

– If the device emits a smell or smoke, have it

checked by the manufacturer.

– If liquid gets into the module, let the module com-

pletely dry before commissioning.

1.8 Repair and replacement parts

Only qualified personnel can repair the devices, and

only genuine replacement parts are allowed to be used.

This applies to work on the electrical equipment. There-

fore, for safety reasons, have defective devices repaired

by TROX Technical Service,

Ä

‘TROX Technical

Service’ on page 3 .

Safety

Repair and replacement parts

Control component BC0-Compact for VAV terminal units8

2 Transport, storage and

packaging

Sharp edges and sheet metal parts

CAUTION!

Danger of injury from sharp edges and sheet

metal parts.

– Always wear protective gloves when handling the

unit.

Damage to the VAV terminal unit

NOTICE!

Risk of damage to the VAV terminal unit!

– Handle the unit with care.

–Do not lift the VAV terminal unit by its control

components, the damper blade or differential

pressure sensor.

– Lift the unit only by lifting the entire casing.

2.1 Delivery check

Check delivered items immediately after arrival for

transport damage and completeness. In case of any

damage or an incomplete shipment, contact the ship-

ping company and your supplier immediately.

The delivery is typically completed mounted on a VAV

terminal unit.

Check the following items on delivery:

Compactregler

– mounted on the VAV terminal unit and fixed with

anti-rotation lock

– Measuring hoses without kinks connected to the

VAV terminal unit

– Adjustment sticker on the VAV terminal unit

With replacement controllers:

– Check differential or effective pressure connec-

tions for blockage and cleanliness.

2.2 Transport on site

If possible, transport the VAV terminal unit to the

installation location in the shipping container.

Do not remove the protective wrapping until just

before installation.

2.3 Bearing

If the product must be stored:

Moisture and lack of ventilation can lead to oxida-

tion, even on galvanised components. Remove any

plastic wrapping in order to avoid oxidation.

Protect the product from dust and contamination.

Store the product in a dry place and away from

direct sunlight.

Do not store the product below -10 °C or above +50

°C.

After storage and prior to installation, first allow the

unit to acclimatise to the installation temperatures

for at least 2 hours.

2.4 Packaging

Properly dispose of packaging material.

Transport, storage and packaging

Packaging

Control component BC0-Compact for VAV terminal units 9

3 Structure and functional description

3.1 Product overview

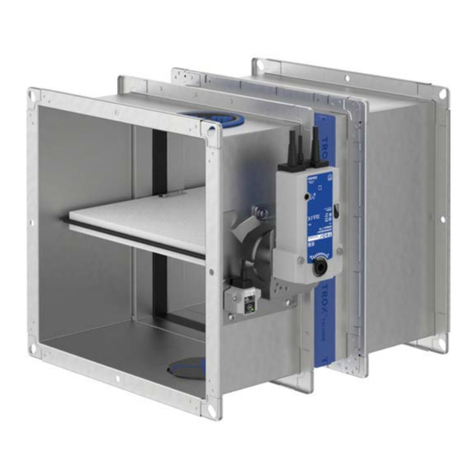

Fig. 1: BC0 Compact controller mounted on the terminal unit e.g., TVR

1 BC0 Compact controller

2 Test hoses

3 VVS basic unit

4 Damper blade

Fig. 2: BC0 Compact controller

1 Type designation

2 Gear release button

3 Tube connections differential pressure

4 Service socket

5 Connecting cable

6 NFC interface

7Power/Test push button LED (green) function see table

Ä

11

8Status LED (yellow) function see table

Ä

11

9 Rotation stop

10 Axle mounting (clamping device or positive connection)

Structure and functional description

Product overview

Control component BC0-Compact for VAV terminal units10

Detection of operating states

Power LED (green)

State Operating status

OFF No supply voltage or fault

ON Operation

Press key Triggering of the rotation angle

adaptation (CLOSED-OPEN)

Status LED (yellow)

State Operating status

OFF Normal operation

ON Adaptation or synchronisation

process active

Flashing (irreg-

ular)

MP communication active

Flashing (reg-

ular)

Request for addressing from the

MP master or connected ZTH.

Press key Triggering of the addressing

3.2 Position of the damper blade

The position of the damper blade corresponds to the

mark on the shaft and is thus recognisable from the out-

side.

Positive lock connection

Fig. 3: Controller with lock connection

1 Shaft with marking for position indication

2 Damper blade

Clamping device (frictional connection)

Fig. 4: Controller with clamping device

1 Shaft with marking for position indication

2 Damper blade

3.3 Function description

Basic function

The Compactregler is an electronic control component

for variable volume flow control for various TROX VAV

terminal units. Its functional units consist of a dynamic

differential pressure transducer, the controller elec-

tronics and the actuator.

Closed control circuit

The controller operates in closed control circuit, i.e., to

measure – compare – control.

Fig. 5: Principle of operation of control components

1 Compact controller

2 Differential pressure transducer

3 Volume flow controller

4 Actuator

5 Setpoint value signal

6 Differential pressure sensor

The determination of the current volume flow rate takes

place by the differential pressure sensor (6) measuring

a differential pressure (effective pressure). The effective

pressure is forwarded through the measuring hoses to

the differential pressure transducer (2) integrated in the

control component and converted here into a voltage

signal.

Structure and functional description

Function description

Control component BC0-Compact for VAV terminal units 11

The volume flow rate actual value is thus available to

the internal control loop as well as an external use, e.g.,

central BMS or master-slave sequential circuit, either as

analogue voltage signal 0-10 V / 2-10 V or as digital MP

bus information.

The volume flow rate setpoint (5) is specified as a con-

stant value either by an analogue voltage signal or digi-

tally via MP bus at the setpoint value input. In regular

operation, the integrated actuator (4) is controlled by

permanent evaluation of the system deviation (setpoint

value-actual) of the volume flow controller (3) that

adjusts the damper blade of the air terminal unit via the

axle mounting and thus regulates the volume flow rate

to the setpoint value.

Due to the factory adjustment, the maximum output

value 10 VDC always corresponds to the nominal flow

rate (qvnom) indicated on the adjustment sticker on the

VAV terminal unit. The factory-set qvmin and qvmax values

can also be taken from the adjustment sticker or the

order code. The qvmin and qvmax value can be individually

adjusted at any time using the corresponding service

tools.

Setpoint value control independent of the duct pres-

sure

Fig. 6: Pressure independent control characteristics

The controller detects and corrects changes of the duct

pressure that may occur, for example, due to volume

flow rate changes from other units. The Compact con-

troller thus operates independently of the duct pressure,

and pressure fluctuations cause no lasting changes to

the volume flow rate.

In order to prevent the volume flow control from

becoming unstable, the controller maintains a dead

band (hysteresis) within which the damper blade is not

moved. This dead band and the tolerances of the meas-

urement lead to a volume flow rate deviation Δqv in

accordance with the product data sheets of the VAV ter-

minal units. If the conditions specified in the product

data sheets (e.g., minimum differential pressure,

upstream conditions) are not met, the controller will no

longer function correctly or more significant system

deviations can be expected.

Diagnostic options

A functional test is possible by means of test push

button ( Fig. 1 /8) and LED indicator light ( Fig. 1 /9).

The LED makes it possible to distinguish between oper-

ating and fault states.

Setting the controller,

Ä

7.1 ‘Setting of the control

component’ on page 23 .

3.4 Operating modes

3.4.1 Operation with constant volume flow

rate setpoint value

3.4.1.1 Operation with a fixed setpoint value

Fig. 7: Constant control

1 Compact controller

2 Factory-set volume flow rate setpoint value (qvmin)

3 Volume flow rate actual value as analogue voltage

signal or digital via MP bus e.g., to the central BMS

or slave controller

In the simplest case, the controller is operated with a

constant volume flow rate setpoint value specification.

The constant setpoint value (qvmin) is already set by the

factory presetting. Adaptation of the factory-set constant

values,

Ä

7.1 ‘Setting of the control component’

on page 23 .

The control signal at terminal Y is not allowed to be con-

nected in this case.

Structure and functional description

Operating modes > Operation with constant volume flow rate setpo...

Control component BC0-Compact for VAV terminal units12

3.4.1.2 Operation with two fixed setpoint values

(min./max. switching)

Fig. 8: Min./max. switching

1 Compact controller

2 Factory set volume flow rate setpoint values (qvmin

and qvmax)

3 Switch or relay for switching between qvmin and qvmax

4 Volume flow rate actual value as analogue voltage

signal or digital via MP bus e.g., to the central BMS

The factory-set constant values (qvmin and qvmax) can be

activated alternately by volt-free switch contacts.

Switching is accomplished by switches or relays, e.g.,

day/night switching. Adaptation of the factory-set con-

stant values with adjustment device,

Ä

7.1 ‘Setting of

the control component’ on page 23

3.4.2 Operation with variable volume flow

rate setpoint value

Fig. 9: Variable volume flow control

1 Compact controller

2 Factory-set volume flow rate setpoint value (qvmin

and qvmax)

3 Control signal as analogue voltage signal or digitally

via MP bus as setpoint value specification e.g., from

room temperature controller or DDC outstation or

the like.

4 Volume flow rate actual value as analogue voltage

signal or digital via MP bus e.g., to the central BMS

For the use of variable volume flow rate setpoint values,

the specification of an electrical control signal must be

made by a higher-level controller (e.g., room tempera-

ture controller, air quality controller, central building

management system, etc.). If the input signal is

changed, the controller adjusts the volume flow rate to

the new setpoint. The variable volume flow rate is

limited to a minimum and maximum volume flow rate

value,

Ä

Chapter 3.5 ‘Characteristics’ on page 15 .

Adaptation of the factory-set constant values,

Ä

7.1

‘Setting of the control component’ on page 23

3.4.3 Override control

The constant or variable control can be disabled by

override controls, e.g., when the sash is open, a window

switch stops ventilation of the room by closing the

damper blade.

Further application examples:

Circuits for intensive ventilation (boost / qvmax)

Opening the damper blade

Structure and functional description

Operating modes > Override control

Control component BC0-Compact for VAV terminal units 13

3.4.4 Supply/extract air tracking control

Fig. 10: Supply/extract air tracking control

1 Master controller, e.g., Compact controller

2 Slave controller, e.g., Compact controller

3 Volume flow rate limit specification (qvmin and qvmax)

4 Room temperature controller (control signal for

supply air controller)

5 Volume flow rate actual value as analogue voltage

signal or digital via MP bus to the extract air con-

troller

6 Volume flow rate actual value as analogue voltage

signal or digital via MP bus e.g., to the central BMS

In individual rooms and closed-off office areas, where the balance between supply and extract air flow rate has to be

maintained. Otherwise, annoying whistling noises can occur at door gaps, and the doors can be difficult to open. For

this reason, the extract air should also have variable control in a VAV system.

The control signal from the room temperature controller is switched to the supply air controller in this example. The

actual value signal of the supply air controller is then connected to the extract air controller (slave controller) as a

setpoint value signal. The volume flow rate actual value of the supply air controller (master) is used as a reference

variable for the extract air controller (slave). The connection can be made as an analogue signal or digitally via the

Modbus. As a consequence, the extract air always follows the supply air.

Setting for the slave controller in the simplest case (same VAV terminal units and dimensions):

qvmin = 0 m³/h

qvmax = qvnom

ð qvnom is specified on the adjustment sticker.

When using different air terminal unit types or dimensions for tracking control, special setting instructions for qvmin

and qvmax of the slave controller must be observed due to the different nominal volume flow rates.

Alternatively, the control signal of the room temperature controller can also be connected in parallel to the supply air

and the extract air controller. The limitation due to the technical data of the controller outputs (current) and the con-

troller inputs (input resistances) must be observed.

Structure and functional description

Operating modes > Supply/extract air tracking control

Control component BC0-Compact for VAV terminal units14

3.5 Characteristics

Setpoint value signal

Fig. 11: Characteristic of the setpoint value signal

1 Characteristic with signal voltage range 0 – 10 VDC

2 Characteristic with signal voltage range 2 – 10 VDC

qvVolume flow rate

Y Set value input

In order to specify a volume flow rate setpoint value to

the Compactregler, a DC voltage signal in the range of

0–10 VDC or 2–10 VDC must be applied to terminal (Y).

The relationship between the volume flow rate setpoint

value and the associated voltage signal can be calcu-

lated from the formula below. The setting for qvmin and

qvmax must be considered in this case.

0 – 10 V DC

×

(q – q ) + q

qY

10 V

=vmin

vsoll vmin

vmax

2 – 10 V DC

q×(q – q )+q

Y– 2

(10 V– 2 V)

vsoll=vmax vmin vmin

Sample calculations

Ä

Chapter 8.3.2 ‘Sample calculations’ on page 29

Actual value signal

Fig. 12: Characteristic of the actual value signal

1 Characteristic with signal voltage range 0 – 10 VDC

2 Characteristic with signal voltage range 2 – 10 VDC

qvVolume flow rate

U Actual value signal

The volume flow rate actual value can be tapped as a

voltage signal at the terminal (U). The measuring range

is factory-set to the size of the VAV terminal unit, so that

the respectively rated nominal flow rate (qvnom) always

corresponds to an actual value signal of 10 VDC.

The current volume flow rate actual value can be calcu-

lated from the measured voltage at the output (U) using

the formula below.

0 – 10 V DC

q× q

U

10 V

vist vnenn

=

2 – 10 V DC

q× q

U – 2

(10 V – 2 V)

vist vnenn

=

Structure and functional description

Characteristics

Control component BC0-Compact for VAV terminal units 15

Activation of override control CLOSED via characteristic

0 – 10 V characteristic 2 – 10 V characteristic

Setpoint value

signal Y

qvmin = 0 qvmin > 0 Setpoint value

signal Y

qvmin = 0 qvmin > 0

≤ 0.5 V Damper

CLOSED

Operation ≤ 2.4 V Damper

CLOSED

Operation

> 0.5 V Operation Operation > 2.4 V Operation Operation

Structure and functional description

Characteristics

Control component BC0-Compact for VAV terminal units16

4 Installation

Personnel:

HVAC technician

Protective equipment:

Protective gloves

Safety shoes

Industrial safety helmet

Only specialist personnel are allowed to perform the

described work on the VAV terminal unit.

Only skilled qualified electricians are allowed to work on

the electrical system.

CAUTION!

Danger of injury from sharp edges and sheet

metal parts.

– Always wear protective gloves when handling the

unit.

The Compactregler is delivered mounted on the VAV

terminal unit, so that the work is limited to the electrical

wiring

Ä

5 ‘Wiring’ on page 18 and to the setting

Ä

7.1 ‘Setting of the control component’ on page 23 .

When installing the VAV terminal unit, take note of the

following points:

Upstream section

Direction of airflow

Fixing/suspension

Accessibility for service work

Information on this can be found in the VAV terminal unit

installation and commissioning instructions.

Installation orientation

The installation orientation of the VAV terminal unit is

arbitrary due to the dynamic differential pressure trans-

ducer in the Compactregler. The Compactregler can be

mounted on, under or at the side of the duct.

Installation

Control component BC0-Compact for VAV terminal units 17

5 Wiring

Safety instructions

DANGER!

Danger of electric shock! Do not touch any live com-

ponents! Electrical equipment carries a dangerous

electrical voltage.

– Only skilled qualified electricians are allowed to

work on the electrical system.

–Switch off the power supply before working on

any electrical equipment.

5.1 Installation instructions

The VAV terminal unit was manufactured and configured

on a project-specific basis. The control components are

factory-mounted and balanced. For installation, the

supply voltage and, if necessary, signal lines, must be

connected for electrical control components.

The connection is made according to the information

given on the control components or connection dia-

grams in this manual. These must be observed for

project-specific wiring diagrams. The voltage ranges

and the terminal connections specified on the control

components must be observed!

Personnel:

Skilled qualified electrician

Please note during installation:

Legal and official regulations, in particular VDE

guidelines.

Consideration of the technical connection rules

(TCR) of the local network operators.

Wiring work for supply voltage and signal lines to be

performed by others.

The rating and manufacture of customer-side con-

nections and wiring must be carried out in accord-

ance with the recognised rules of electrical engi-

neering.

Observe wiring guidelines and project-specific circuit

diagrams of the control component.

The electrical connection to the terminal unit must

only be made if the installation has been carried out

correctly.

The 24 V supply voltage must only be supplied with

a safety transformer.

If several volume flow rate controllers are connected

to a 24 V network, it must be ensured that a

common neutral or ground line is defined and not

interchanged.

The control component contains no parts that can

be replaced or repaired by the user and must only

be opened by the manufacturer.

Lay connecting cables in such a way that they

cannot be accidentally damaged by mechanical

impact or by heat.

Electrical safety

The control component complies with all relevant stand-

ards and guidelines, see declaration of conformity.

5.2 Connection diagrams

Connecting cable

2

+

1

-

Compact

5

U

3

Y

Fig. 13: Connecting cable

No. Function Wire colour

1 Ground, neutral Black (BK)

2 Supply voltage 24 VAC/DC Red (RD)

3 Setpoint value signal (Y)

0–10 or 2–10 VDC

White (WH)

5 Actual value signal (U)

0–10 VDC or 2–10 VDC or MP-

BUS

Orange (OG)

Wiring

Connection diagrams

Control component BC0-Compact for VAV terminal units18

Control constant volume flow rate qvmin

-+YU

1

Compact

235

24 V AC/DC

Fig. 14: Constant volume flow rate qvmin

After the 24 V supply voltage is applied, the controller

performs a synchronisation and then restricts the

volume flow rate to qvmin (factory setting). A setpoint

signal is not required. The current volume flow rate

actual value can be tapped at the terminal (U).

Control of constant volume flow rate qvmin or qvmax

(switching)

-+YU

1

Compact

235

24 V AC/DC

S1

Fig. 15: Switching volume flow rate qvmin / qvmax

If the volume flow rate between two constant values can

be switched (i.e., day/night switching), it is possible to

switch over between the volume flow rate setpoint

values qvmin and qvmax (factory setting) using an on-site

volt-free switch contact.

Switch S1 open - qvmin

Switch S1 closed - qvmax

Control constant mode / override controls

If the volume flow rate between several constant values

can be switched (e.g., day/night switching / CLOSED /

OPEN), it is possible to switch between four different

fixed volume flow rate setpoint values using on-site volt-

free switch contacts. A service tool is required to adjust

the volume flow setpoint values,

Ä

‘Overview of the

service tool functions’ on page 23 .

24 V AC/DC

Compact

+YU

1

-

235

TVOC CO2DDC

y

S5

S4

S3

S2

S1

Fig. 16: Staged operation

T Temperature sensor

VOC Room air quality sensor

CO2Carbon dioxide sensor

DDC Building automation

The functions shown in the tables refer to the switch

that is actuated in the case, more than one switch must

never be actuated.

Override controls CLOSED / qvmin / qvmax / OPEN

Switch 0 – 10 V control

input signal

2 – 10 V control

input signal

S1 closed qvmin CLOSED

S2 closed OPEN OPEN

S3 closed CLOSED CLOSED

S4 closed qvmax qvmax

S5 closed Room tempera-

ture control

Room tempera-

ture control

Note:

With DC supply, the functions S2 and S3 are not

available.

Wiring

Connection diagrams

Control component BC0-Compact for VAV terminal units 19

Control of variable volume flow rate qvmin…qvmax

24 V AC/DC

Compact

+YU

1

-

235

TVOC CO2DDC

y

Fig. 17: Variable volume flow control

If the volume flow rate is to be specified by a higher-

level controller (e.g., for room temperature, air quality or

a DDC outstation), its 0 – 10 (2 – 10) VDC output must

be connected by at least 2 wires (wires 1 and 3) to the

wires for the control signal (Y) of the Compact controller

in accordance with the connection diagram. With a

common supply voltage of 24 V, note that wire 1 on the

Compact controller is also ground for the control signal.

Parallel connection

24 V AC/DC

Compact

S1

+YU

1

-

235

+YU

1

-

235

+YU

1

-

235

Compact

Fig. 18: Parallel connection

If several Compact controllers are to be switched simul-

taneously with a switch contact between qvmin und qvmax,

the switch S1 must be designed as a changeover

switch, and the contact for qvmin operation must be con-

nected to the ground (wire 1)

Wiring

Connection diagrams

Control component BC0-Compact for VAV terminal units20

This manual suits for next models

8

Table of contents

Other Trox Technik Controllers manuals

Popular Controllers manuals by other brands

Metso

Metso VALVCON QX Series Installation maintenance and operating instructions

ABB

ABB ACS55 user guide

Jung

Jung 3210 UP operating instructions

Synology

Synology UC3200 Hardware installation guide

GE

GE Multilin F650 instruction manual

Moxa Technologies

Moxa Technologies ioLogik R1210 Series: ioLogik R1212 Series: ioLogik R1214 Series: ioLogik R1240 Series: ioLogik R1241... quick start guide