Bartington Mag900 User manual

www.bartington.com

INNOVATION IN MAGNETICS

Bartington Instruments Ltd

5, 8, 10, 11 & 12 Thorney Leys Business Park

Witney, Oxford, OX28 4GE. England

®The copyright of this document is the property of Bartington Instruments Ltd.

Bartington is a registered trademark of Bartington Instruments Limited in the following countries: Australia, Brazil, Canada, China, European Union, India,

Israel, Japan, Mexico, New Zealand, Norway, Russia, Singapore, South Korea, Switzerland, Turkey, United Kingdom, United States of America and Vietnam.

Operation Manual for

Mag900 & Mag901

Three-Axis Magnetic Field Sensors

OM4550/1

BARTINGTON INSTRUMENTS

Page 2 of 10 OM4550/1

Table of Contents

1. About this Manual 3

1.1. Symbols Glossary 3

2. Safe Use 3

3. Introduction 4

4. Overview 5

4.1. Vector Measurements and Conventions 5

5. Installation 6

5.1. Unpacking 6

5.2. Orientation 6

5.3. Mounting 6

5.4. Cable Recommendations 6

5.5. Pre-Installation Tests 7

6. Operating Instructions 8

7. Troubleshooting 8

8. Storage & Transport 9

10. Environmental Precautions 9

11. End of Life Disposal 9

BARTINGTON INSTRUMENTS

Page 3 of 10 OM4550/1

1. About this Manual

This manual provides the information necessary to help customers connect, install and operate

the Mag900 & Mag901 three-axis magnetic field sensor.

Technical specifications of the products, including power supply requirements and analogue

output details, can be found in DS4550, whilst outline drawings of both sensor head, electronics

board and cable can be found on Mag900/Mag901 product page.

1.1. Symbols Glossary

The following symbols used within this manual call your attention to specific types of

information:

WARNING: Indicates a situation in which serious bodily injury or death could result if the

warning is ignored.

Caution: Indicates a situation in which bodily injury or damage to your instrument, or both,

could result if the caution is ignored.

Identifies items that must be disposed of safely to prevent unnecessary damage to the

environment.

Note: A paragraph in this format provides useful supporting information on how to make

better use of your purchase.

2. Safe Use

WARNING: These products are not qualified for use in explosive atmospheres or life

support systems. Consult Bartington Instruments for advice.

WARNING: Environmental and electrical specifications should not be exceeded.

To prevent irreparable damage, electrostatic discharge (ESD) protection and precautions

must be used when handling the unpackaged sensor electronics board.

Note: Do not expose to strong magnetic fields while being stored as this can magnetise

the sensor and affect its offset performance.

BARTINGTON INSTRUMENTS

Page 4 of 10 OM4550/1

3. Introduction

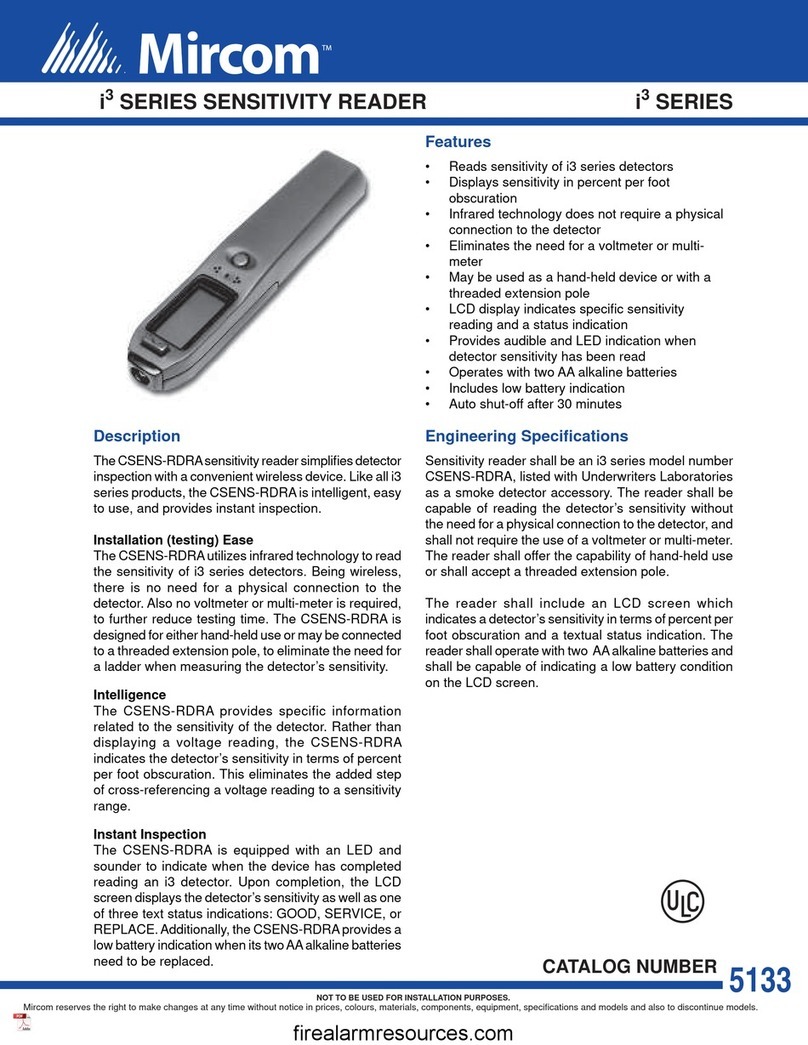

Figure 1. Mag900 & Mag901.

The Mag900 & Mag901 is an unpackaged, three-axis, low power sensor intended for customer

system integration.

Technical specifications for the Mag900 & Mag901 are provided in datasheet DS4550.

BARTINGTON INSTRUMENTS

Page 5 of 10 OM4550/1

4. Overview

The Mag900 & Mag901 consists of a cluster of three feedback stabilised, fluxgate sensors

arranged along X, Y and Z axes. Each axis provides a highly linear magnetic response with

low hysteresis, and low crosstalk between axes. These characteristics, combined with the

compact design and very low power consumption, make this product ideally suited for perimeter

surveillance with a multi-sensor network.

Internal regulation of the power supply ensures the Mag900 & Mag901 is suitable for battery

powered operation, over both long and short cables (subject to the minimum supply voltage

specified in datasheet DS4550).

4.1. Vector Measurements and Conventions

Each sensor produces three independent analogue output voltages in response to the magnitude

and direction of the orthogonal components of a magnetic field. A “right-hand” coordinate

system is adopted. In this system the X, Y and Z axis correspond to the thumb, first and second

finger respectively of the right hand.

North

+X

Thumb

Down

+Z

2nd Finger

East

+Y

1st Finger

Figure 1.The “right hand” tool

The centres of the three vector sensors are superimposed. Refer to outline drawing DR4576 for

the orientation of each sensor and the centre of the sensing elements. The point of each vector

arrow in DR4576 indicates the positive direction of each axis.

BARTINGTON INSTRUMENTS

Page 6 of 10 OM4550/1

5. Installation

The Mag900 & Mag901 is intended for integration into the customer’s own system. Bartington

Instruments cannot advise on the operation of third-party systems.

5.1. Unpacking

Safe handling precautions must be observed. The Mag900 and Mag901 fluxgates are wound with

thin copper wire. While these wires are covered with silicone coating and are recessed inside the

coil block, extra care must be taken not to break these delicate wires. Doing so will render the

magnetometer inoperable.

5.2. Orientation

Note: The direction of the geomagnetic field will vary with geographical location. It is

generally vertical at the poles, becoming horizontal at the equator.

5.3. Mounting

The Mag900 & Mag901 sensor assembly should be mounted in a stress-free manner using the

six mounting holes on the PCB. Dimensions and locations of the holes are shown in outline

drawing DR4576.

5.4. Cable Recommendations

The Mag900 & Mag901 provides differential output lines for analogue signal transmission.

The advantages of this differential arrangement are very high common-mode noise rejection and

the suitability of readily available cable types. Each of the two anti-phase output lines has low

output impedance at the signal source, damping the lines and preventing ringing.

The cable must be terminated with a differential amplifier having a circa 50kΩ input impedance,

due to cable inductance and capacitance considerations. This arrangement will provide some

damping to high frequencies but will attenuate the signals above the frequency range of the

sensor.

Note: Due to these effects:

• The cable pair loop resistance should not exceed 0.1 Ω per metre.

• The pair loop inductance should not exceed 0.5 micro-Henry per metre.

• The capacitance between should not exceed 52pF per metre.

• The capacitance between conductors and shield should not exceed 120pF per metre.

BARTINGTON INSTRUMENTS

Page 7 of 10 OM4550/1

5.5. Pre-Installation Tests

Prior to the installation into the customer’s system, the Mag900 & Mag901 must be fully tested to

ensure correct function as follows:

Caution: Take care to avoid bending or otherwise damaging the contacts whilst conducting

the tests.

Caution: Ensure the polarity is correct. Incorrect polarity is likely to damage the sensor

irreparably.

Note: Use a current-limited power supply.

• Check the power supply output voltage using a voltmeter. Refer to datasheet DS4550

for the required values.

• Connect the sensor to the cable connector.

• Connect the power supply to the other end of the cable connector.

• Switch on the power supply and wait until the sensor has stabilised. Refer to datasheet

DS4550 for magnetic settling times.

• Confirm no magnetic objects are moving in the vicinity.

• For each of the three (X, Y and Z) axes in turn:

a. Connect a voltmeter to the axis sensor outputs.

b. Whilst monitoring the voltmeter readings, align the sensor with the terrestrial field

until the maximum voltage value is determined.

c. Confirm the measured readings approach the local geomagnetic field value.

Note: Geomagnetic field values can be provided by your local magnetic observatory. A

margin of error due to local disturbance should be taken into account.

BARTINGTON INSTRUMENTS

Page 8 of 10 OM4550/1

6. Operating Instructions

Switch on the power supply to the Mag900 & Mag901.

Allow the system to warm up after switching on. Refer to datasheet DS4550 for magnetic settling

times.

The Mag900 & Mag901 is designed to have an extremely low magnetic hysteresis.

However, your sensor should not be subjected to magnetic fields greater than their stated

measuring range for extended periods as this could alter the DC offset and other performance

specifications. If this occurs, the offset will exhibit drift as it returns to its original offset

specification.

Caution: Subjecting the Mag900 & Mag901 to fields in excess of 2 x the nominal range may

cause inaccuracy in future measurements. Degaussing the sensor can reverse such an

effect.

7. Troubleshooting

Your sensor is unlikely to suffer any defects in normal use: no internal components are

serviceable. The most likely causes of failure, and their solutions, are detailed in the following

table.

In the event of any apparent malfunction beyond those described in the table below, please email

[email protected]om, or telephone the Bartington Instruments service team on +44 (0)1993

706565.

Cause Solution

No operation Check the power supply. If this is operating

correctly then contact Bartington

Instruments.

Damaged sensor If any physical damage is apparent to the

sensor then it may need to be replaced. For

information about disposal of a damaged

unit, refer to End of Life Disposal.

High stability circuitry ensures that no interim calibration should be required.

BARTINGTON INSTRUMENTS

Page 9 of 10 OM4550/1

8. Storage & Transport

Your sensor is a precision electronic instrument and should be treated as such.

Note: Avoid exposing this instrument to shocks or continuous vibration.

Note: The sensor should be stored and transported in the original shipment packaging, or

that of similar protective standard.

Note: Store only within the temperature range specified in datasheet DS4550.

Caution: Do not expose this instrument to strong magnetic fields while being stored.

Caution: Take particular care when cleaning around electrical connections. Bent or

damaged pins may cause the Mag900 & Mag901 to malfunction.

10. Environmental Precautions

Refer to datasheet DS4550 for maximum environmental, electrical and mechanical ratings.

Caution: Exceeding the maximum environmental ratings may cause irreparable damage to

the probe and electronics board.

Caution: This unpackaged product is susceptible to damage by electrostatic discharge.

11. End of Life Disposal

This product (electrical and electronic equipment) should not be placed in municipal waste.

Check local regulations for disposal of electronic products.

www.bartington.com

INNOVATION IN MAGNETICS

Bartington Instruments Ltd

5, 8, 10, 11 & 12 Thorney Leys Business Park

Witney, Oxford, OX28 4GE. England

®The copyright of this document is the property of Bartington Instruments Ltd.

Bartington is a registered trademark of Bartington Instruments Limited in the following countries: Australia, Brazil, Canada, China, European Union, India,

Israel, Japan, Mexico, New Zealand, Norway, Russia, Singapore, South Korea, Switzerland, Turkey, United Kingdom, United States of America and Vietnam.

This manual suits for next models

1

Table of contents

Popular Security Sensor manuals by other brands

Emerson

Emerson Dixell GDS41 Installing and operating instructions

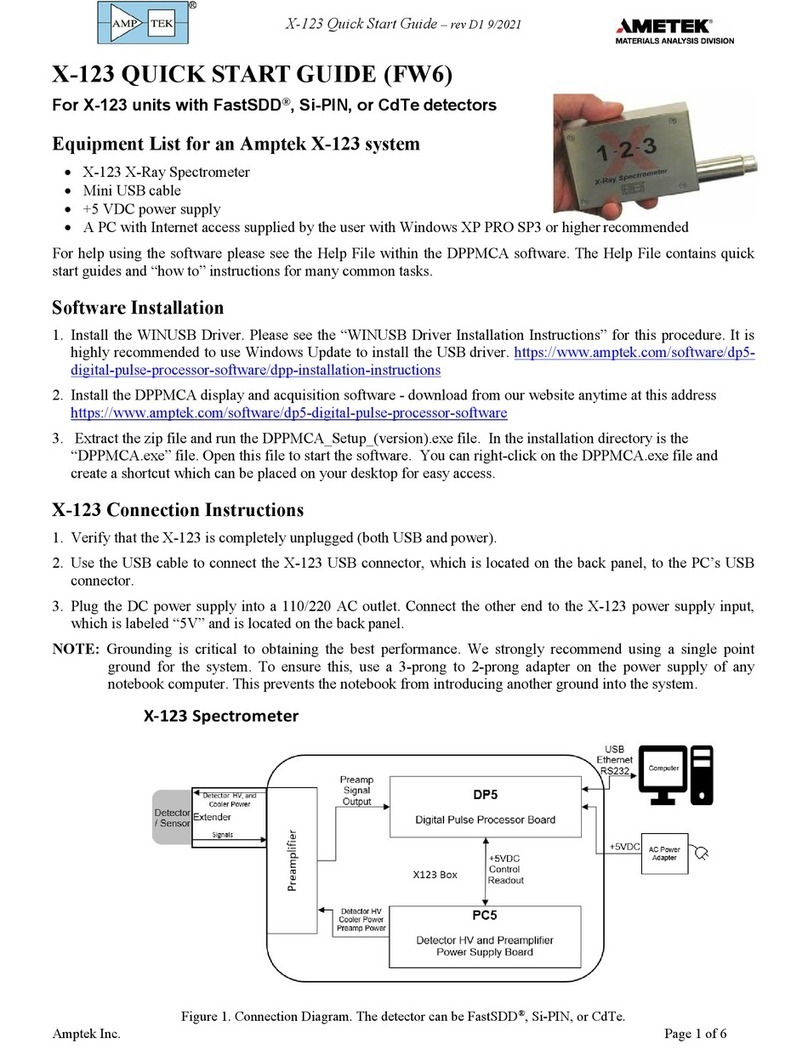

Ametek

Ametek X-123 quick start guide

Lince

Lince 1597ZENITHDT Programming and operating manual

STEINEL

STEINEL Multisensor True Presence DALI-2 IPD manual

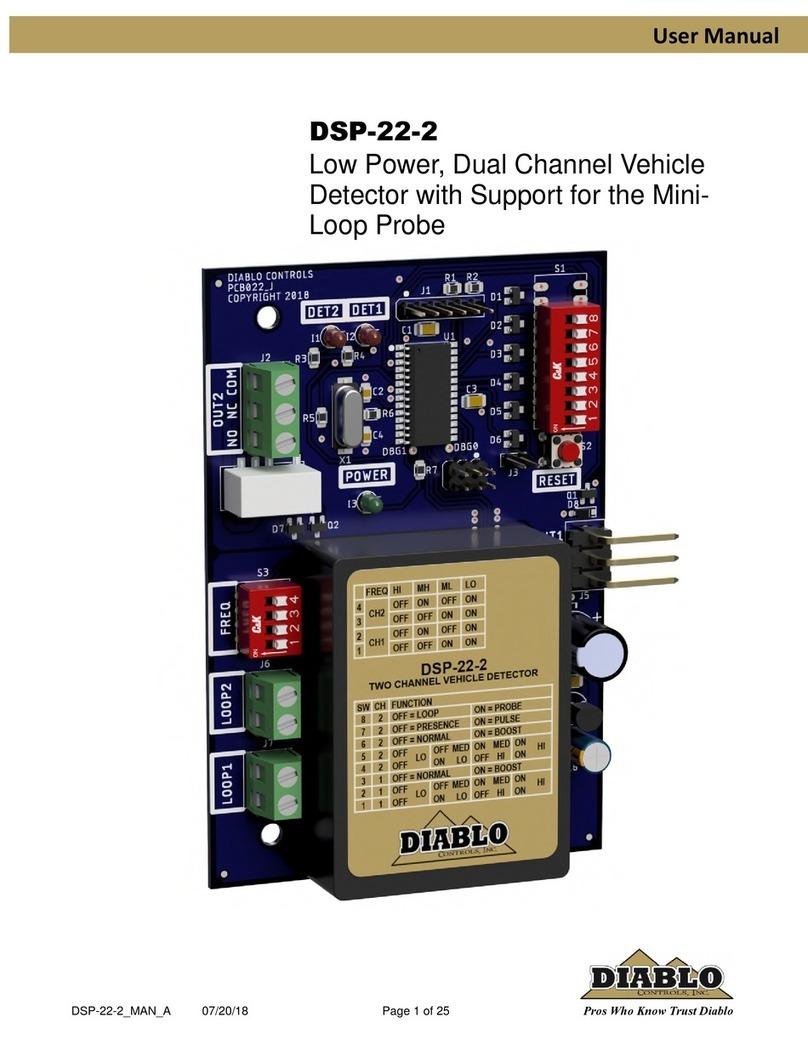

Diablo

Diablo DSP-22-2 user manual

PCB Piezotronics

PCB Piezotronics 109C11/PCS-2AF Installation and operating manual

Elko

Elko iNELS Air AirWD-100NB instruction manual

Risco

Risco Industrial LuNAR RK200DTG3 installation guide

Datalogic

Datalogic SG4-14-030-OO-P instruction manual

Fellow Kogyo

Fellow Kogyo FOCAS-2000 instruction manual

NuAire

NuAire 230-PIR installation manual

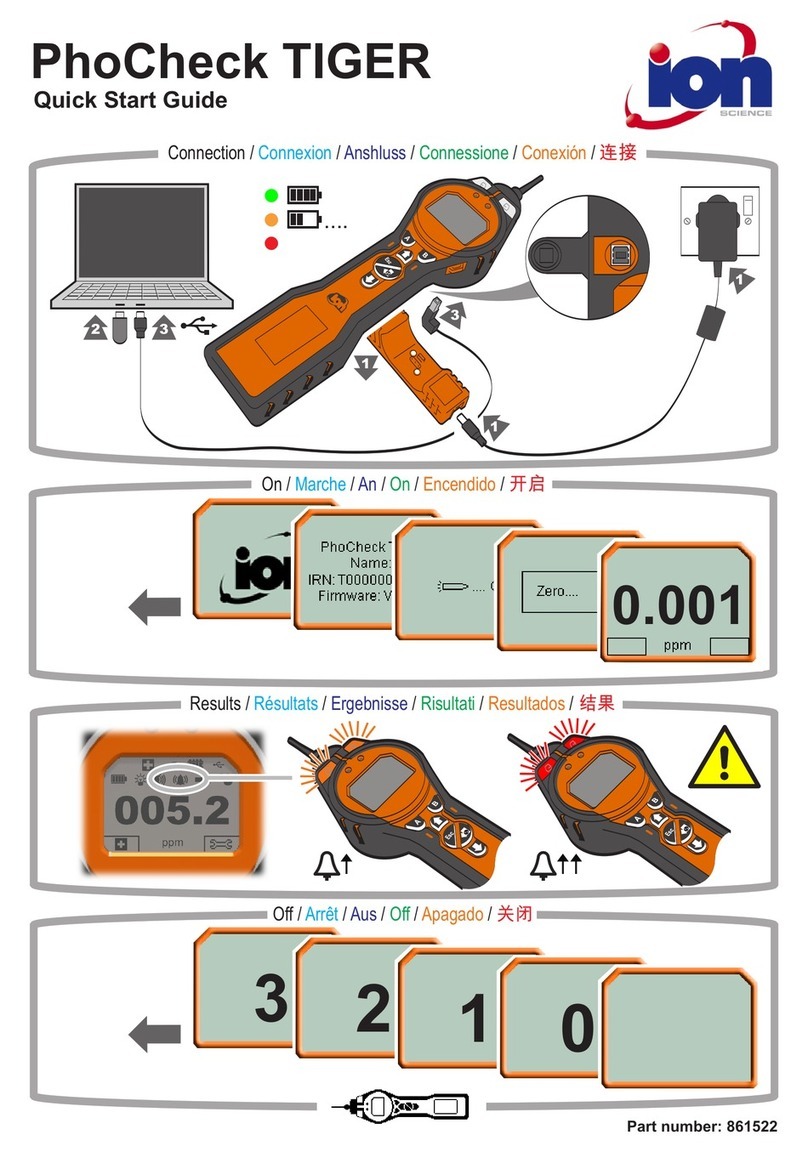

ion science

ion science PhoCheck TIGER quick start guide