1 General Information

Seismic vibration detector “Udar” (hereinafter, the Detector) is designed to

detect attempts of premeditated destruction of the following building structures:

concrete walls and floors with the thickness not less than 0.12m, brick walls with

the thickness not less than 0.15m, wooden structure with the thickness range 20

– 40 mm, plywood with the thickness not less than 4 mm, wood chipboard with

the thickness not less than 15 mm, standard metal safes, cabinets and ATMs.

Alarm message is generated by the relay contacts opening.

The Detector provides immunity against acoustic noise, accidental impacts

on monitored structures and electromagnetic interference.

The Detector generates Alarm messages by the relay contacts opening for the

time not less than 2 s followed by the LED indication ( See Table 1).

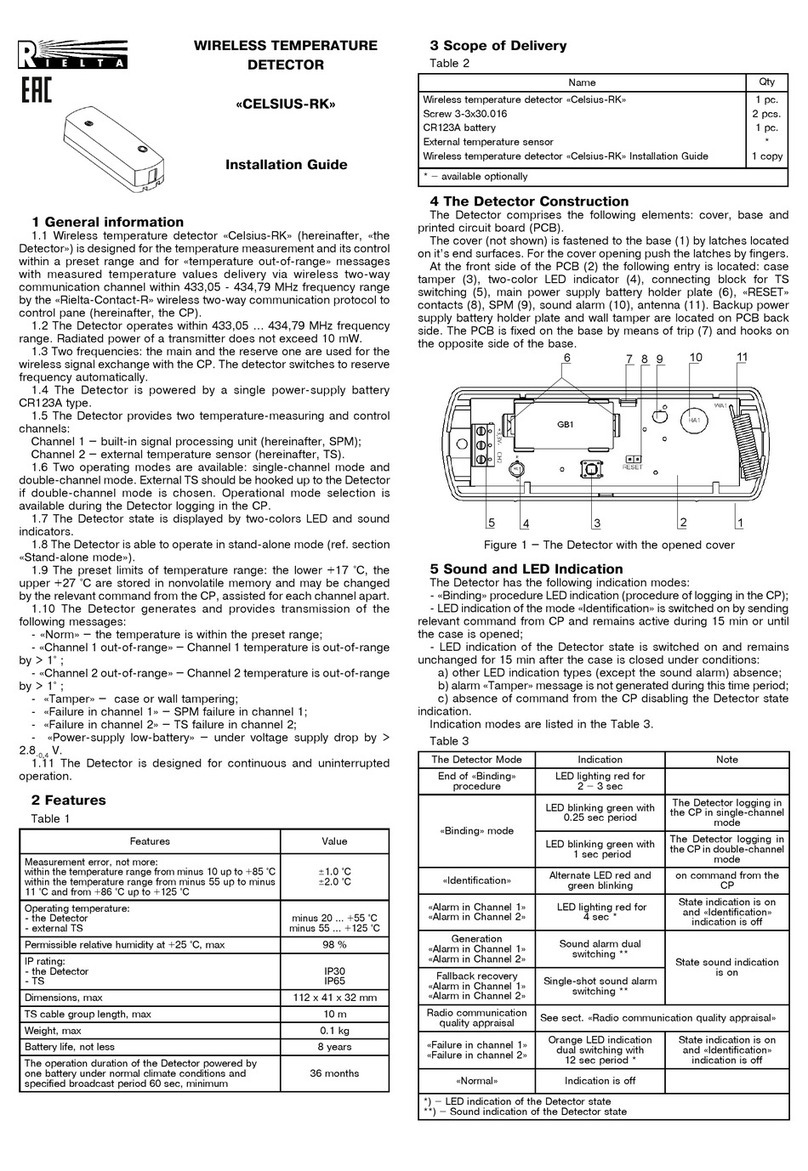

Table 1

Mode Description

Contacts

ALARM

LED Indicators 1)

Red Green

Yellow

Messages

«Norm» Standby mode Closed O O O

«Destruction

alarm»

Destractive impact on the

secured construction Opened •Х Х

«Supply voltage

alarm»

Supply voltage lowering below

8 V Opened •• Х Х

LED Indication

«Switching ON» Self-testing after energizing Opened • • •

«Vibration»2)

Vibration of the secured

construction

Closed Х •Х

«Memory»3)

Detented LED indication of

«Destruction alarm» or «Supply

voltage alarm» messages

Closed •Х Х

«TEST 1»4) LED indication of impact tools

group I testing mode Х Х Х ••

«TEST 2»4) LED indication of impact tools

group II testing mode Х Х Х •••

«TEST 3»4) LED indication of impact tools

group III testing mode Х Х Х •

Opened – contact is opened; Closed – contact is closed; Х – do not affect;

O– LED is OFF; •– LED is ON;

•• –intermittent infrequent (two times per second) blinking;

••• – intermittent infrequent (five times per second) blinking.

1

)

–

LEDs are switched ON if DIP-switch IND is in ON position;

2) – If the Detector is operating in standby mode, LED indication “Vibration” is switched ON

in case of interference or destructive impact on the secured construction (DIP-switch TEST

in OFF position) or in case of nothing else but destructive impact of tested tools group (DIP-

switch TEST in ON position);

3

)

– LED is ON till deenergizing the Detector;

4

)

– Testing mode management is fulfilled by consequent setting DIP-switch “TEST” in ON

position and backward (Quit TEST mode).

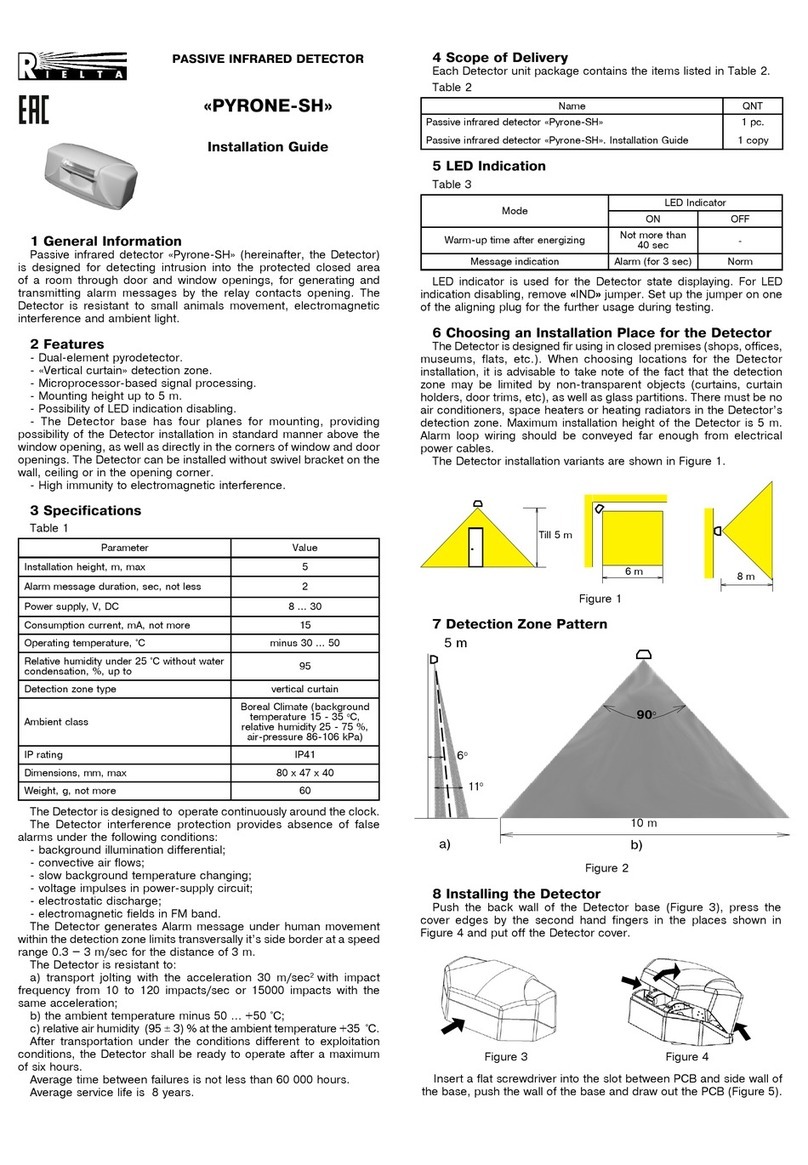

2 Specifications

Table 2

Parameter Value

Secures area, not less:

- solid concrete, brick or wooden construction,

- metal cabinet, door, ATM upper cabinet,

- safe, ATM low cabinet

12 m2(circle with radius 2 m)

6 m2(maximum removal from the

Detector 1.4 m)

3 m2(maximum removal from the

Detector 1.4 m)

Nominal supply voltage 12 V

Supply voltage range 9-17 V

Maximum consumption current 25 mA

Detector contacts permissible current 30 mA

Detector contacts permissible voltage 72 V

Sensitivity changing 20±3 dB

Warm-up time, not more than 10 s

Ambient class Boreal climate (background

temperature 15 - 35 °С, relative

humidity 25 – 75 %, air-pressure

86-106 kPa)

Operating temperature from minus 30 to +50 °С

Relative humidity at a temperature +25 °С 90 %

IP rating IP41

Dimensions, not more 105х45х34 mm

Weight, not more 150 g

Average service life 8 years

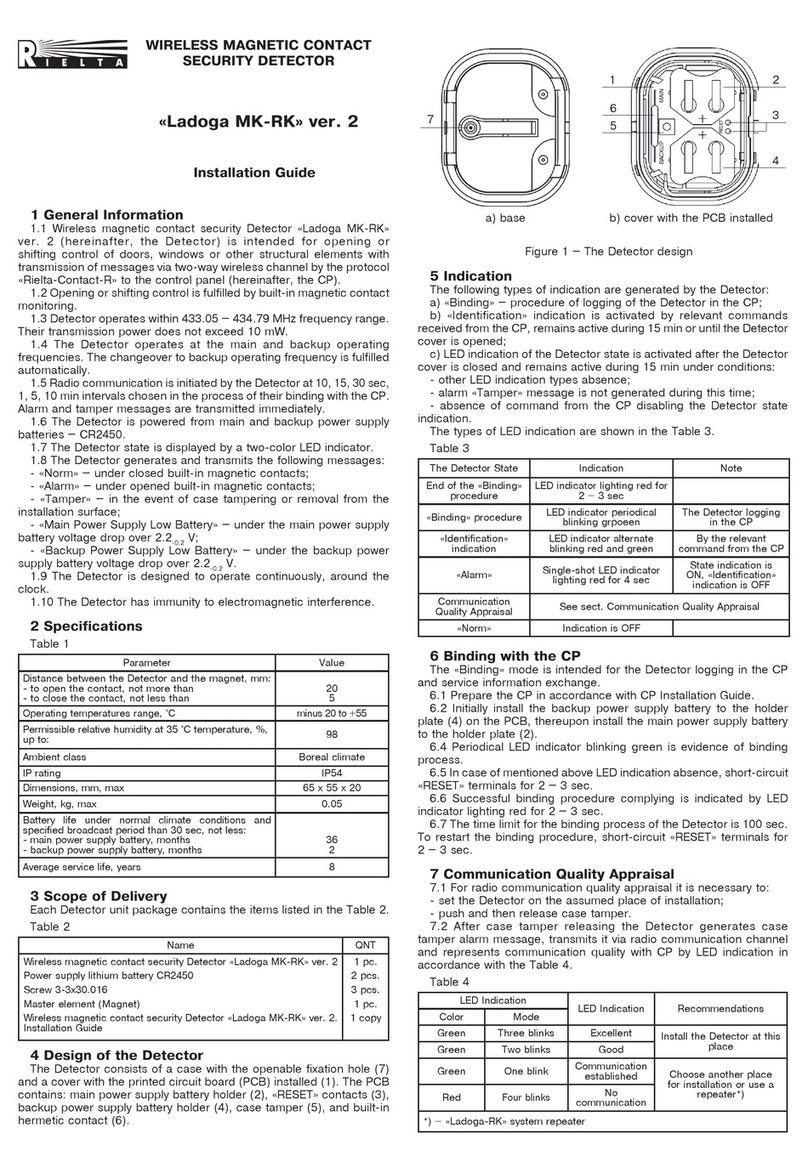

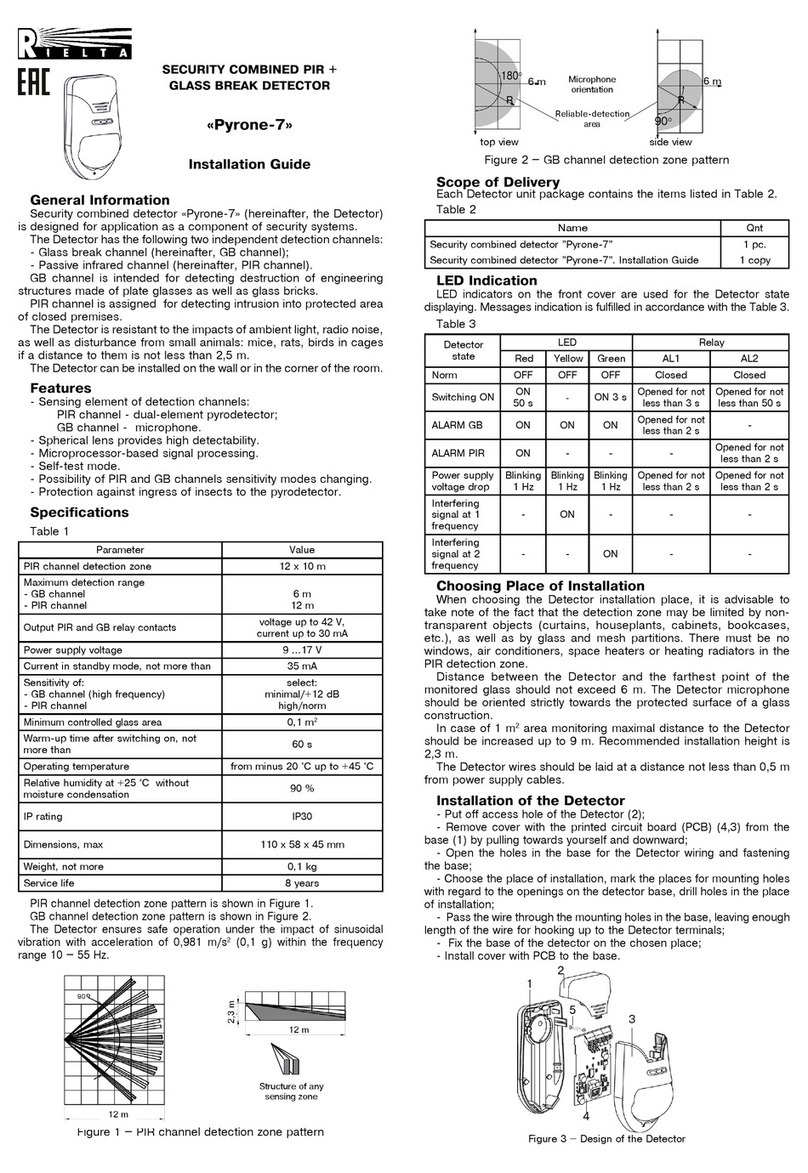

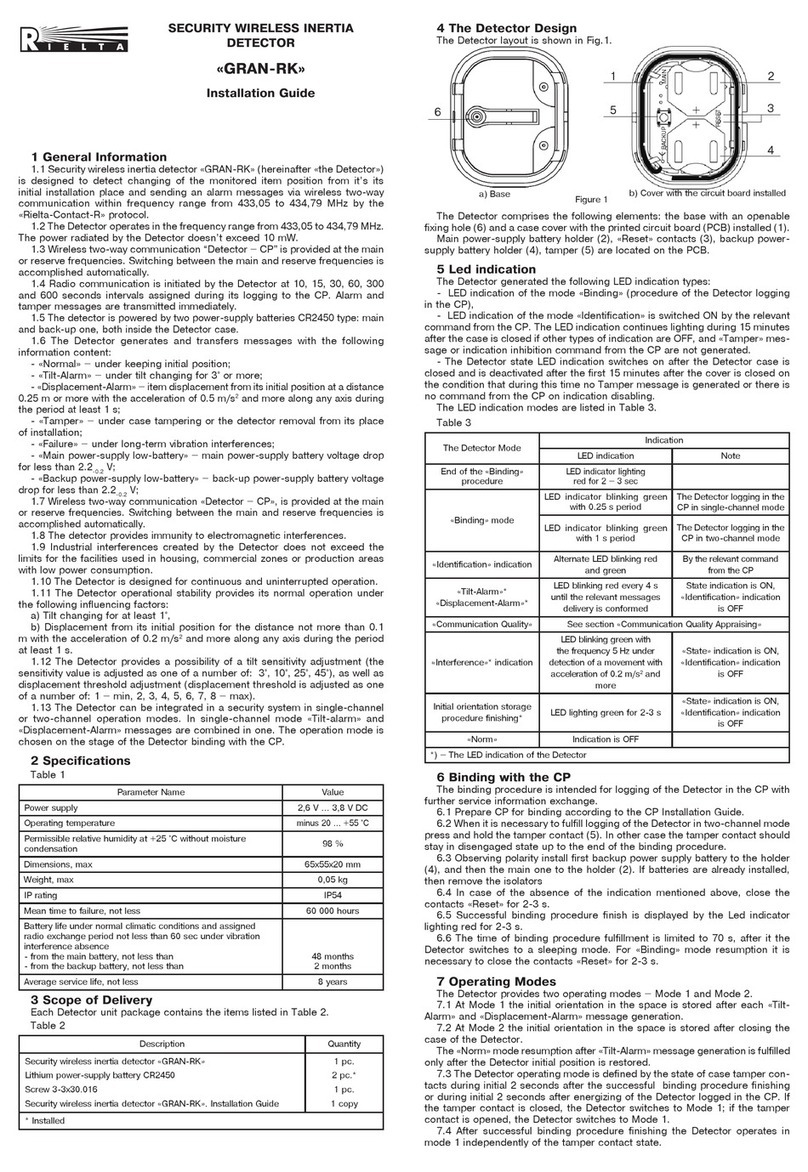

3 Design of the Detector

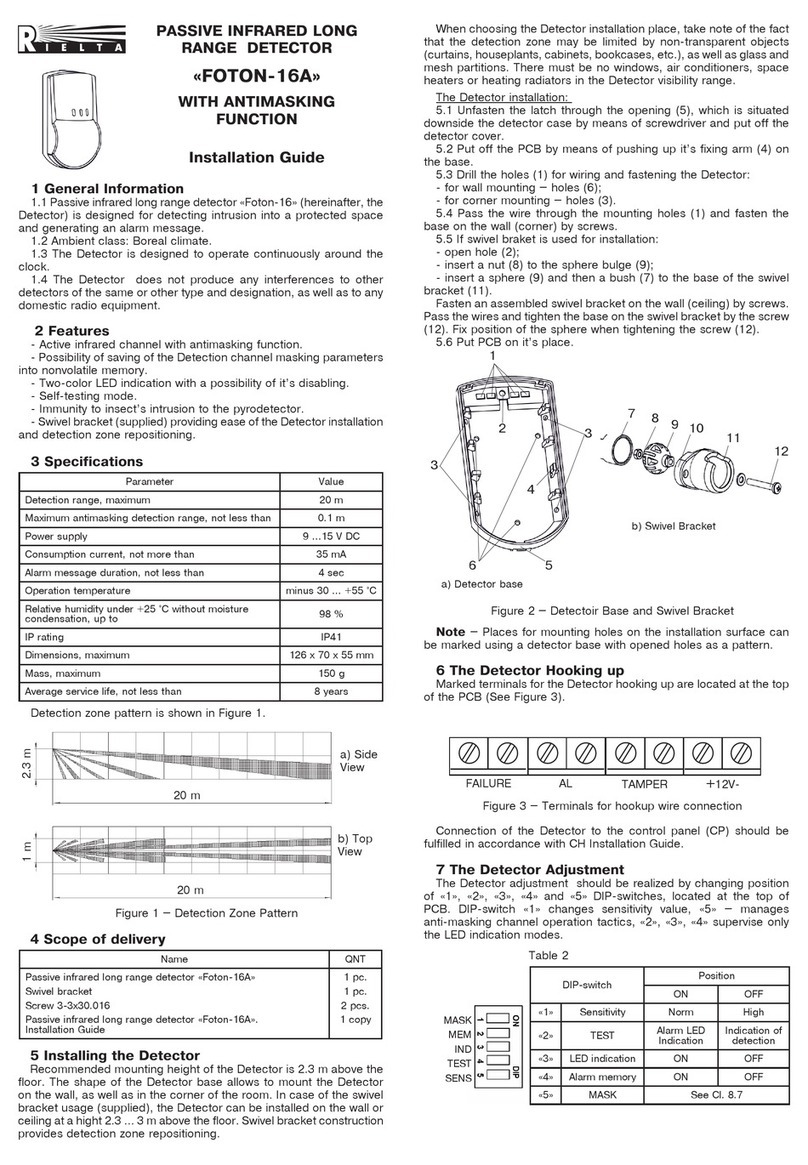

Design of the Detector is shown in Figure 1

Figure 1

The base with the printed circuit board (PCB) is shown in Figure 2

4 The Detector Mounting

The Detector mounting and sensitivity adjustment is fulfilled uncovered. To

remove the cover it is necessary to loosen the latch by pushing it through the

rectangularly shaped opening (Figure 1)

Depending on the type and material of the secured surface, mounting of the

Detector is fulfilled by male screws and framing nails through the holes (See Figure

2, position 3) in the base (a distance between the holes is 35 mm) or by means

of glue. It is important that the installed Detector should have firm contact with

the surface of the secured construction.

For the Detector mounting on the brick or concrete construction metal rockbolt

(it is forbidden to mount the Detector on plastic wall plug). The depth of the

holes for the Detector mounting should be enough to provide full-length entry

of rockbolts in basic material of the secured construction without regard to the

thickness of the decorative or (and) finish coating. For mounting the Detector

on wooden constructions, it is possible to use screws (self tappers) with entry in

the basic material of the secured construction at a depth not less than 20 mm.

For mounting of the Detector on metal constructions it is recommended to

ground it. Use connection by screws with nuts M4 via openings or tap screws

M4 through openable holes. If openable holes are used, in advance tap a thread

by cutting.

The Detector mounting in a safe or ATM low cabinet is recommended to

fulfill by means of screws M4 or super glue in accordance with its manual or

recommendations on its package. Glue joint is permissible for other metal

constructions, where screw joint appliance is impossible.

5 Connection

Connection of the Detector to the control panel (hereinafter, the CP) should

be realized in accordance with connection pattern contained in CP instruction

manuals in accordance with the Detector terminal blocks designation (see Figure

2, position 5). Two openable holes in the Detector case are provided for wiring

(See Figure 2, position 7).

6 The Detector Controls

DIP-switch IND is used for LED indication switching on.

Setting DIP-switch MEM to ON position turns the Detector to alarm memory

mode.

DIP-switch TEST changes modes of a vibration sensor signal processing in

accordance with the presumed impact tools group.

TEST modes are changing cyclically after each setting DIP-switch TEST in

ON position. Chosen mode is displayed by yellow LED indicator. (See Table 1).

Sensitivity regulator component SENS (See Figure 2, position 8) provides

smooth sensitivity decrease in the range (20 ± 3) dB from it’s maximum value.

7 Adjustment

Open the Detector cover, set DIP-switch IND in ON position.

7.1 Noise level control in the place of installation

Adjust maximum sensitivity level by turning sensitivity regulator component

clockwise manner until tight

Energize the Detector, make sure in “Switching ON” indication availability with

further “NORM” message generation.

SEISMIC VIBRATION

DETECTOR

“UDAR”

Installation Guide

a)Top view without cover

1 – Hook on the cover;

2 – DIP Switch;

3 – Mounting Holes;

4 – PCB Latch;

5 – Terminal Block;

Figure 2 - Base with the PCB

6 – Cover Latch;

7 – Openable holes for wiring;

8 – Sensitivity corrector;

9 – LED indicators;

10 – Vibration sensor.

Push

b) Bottom view

10

7

3

4

3

2

5

6

8

9

1

1 2 3

TEST

MEM

IND

+12В- ALARM

ON

SENSITIVITY

Где: