1

ENGLISH

GB

1. TABLE OF CONTENTS

1.

TABLE OF CONTENTS ..................................................................................................................... 1

2.

INDEX ................................................................................................................................................. 2

3.

SAFETY .............................................................................................................................................. 3

4.

GENERAL INFORMATION AND WARNINGS ................................................................................... 4

4.1.

General g idelines ................................................................................................................... 4

4.2.

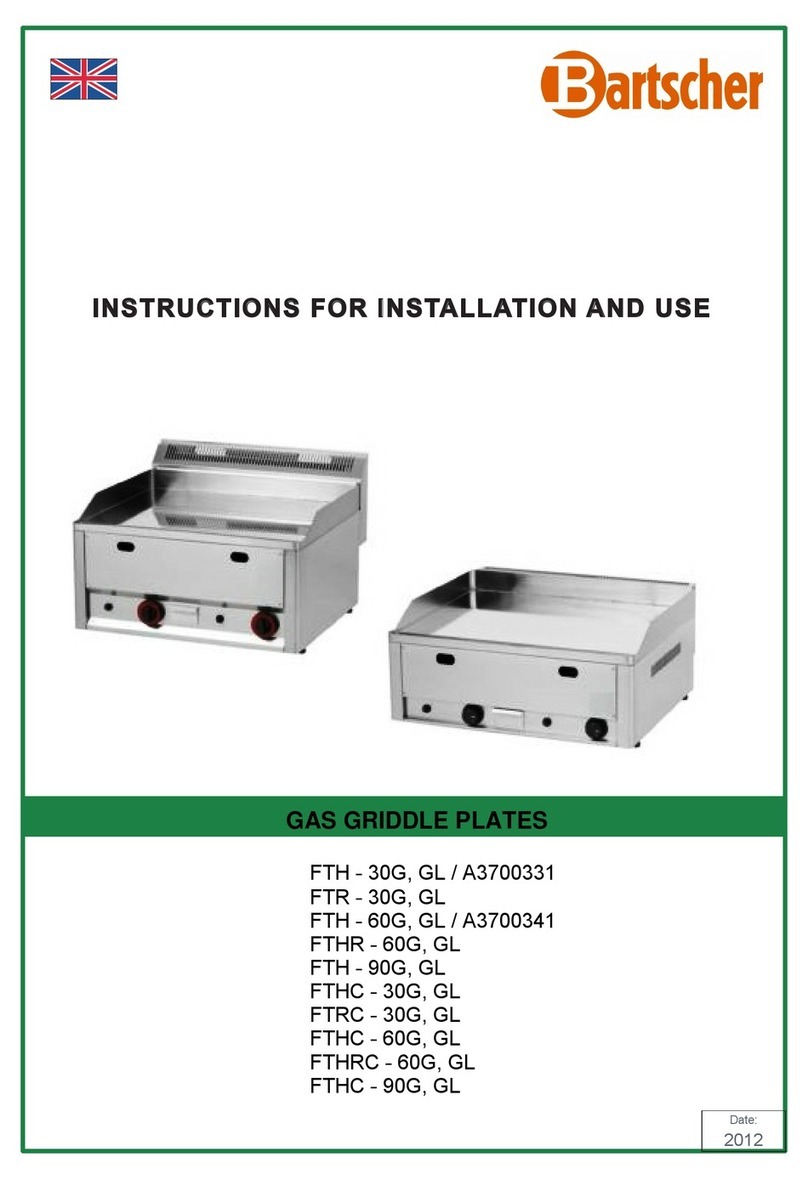

Description of the device .......................................................................................................... 4

4.3.

Elements and accessories ....................................................................................................... 4

4.4.

Protection devices .................................................................................................................... 5

4.5.

Index plate ................................................................................................................................ 5

4.6.

Exchange of components (service technician) ........................................................................ 6

5.

USE AND OPERATION ..................................................................................................................... 6

5.1.

Description of the controls. ....................................................................................................... 6

5.2.

B rner ignition .......................................................................................................................... 6

5.3.

Installation of anti-splash cover ................................................................................................ 7

5.4.

G idelines on how to se the device ....................................................................................... 7

6.

CLEANING AND MAINTENANCE ..................................................................................................... 8

6.1.

G idelines on cleaning and maintenance ................................................................................ 8

6.2.

Correct maintenance ................................................................................................................ 8

6.3.

Cleaning of the grill plate .......................................................................................................... 8

7.

PROBLEMS DURING OPERATION .................................................................................................. 9

8.

INSTALLATION .................................................................................................................................. 9

8.1.

Packaging and npacking ........................................................................................................ 9

8.2.

Installation (service technician) .............................................................................................. 10

8.3.

Gas connection (service technician) ...................................................................................... 11

8.4.

Extraction of f mes ................................................................................................................. 11

8.5.

Installation of the appliance in a line ...................................................................................... 12

8.6.

Modification for other type of gas (service technician) ........................................................... 12

8.7.

Inspection (service technician) ............................................................................................... 12

9.

SETTINGS (service technician)........................................................................................................ 13

9.1.

Setting a minim m val e on the gas valve 25-ST .................................................................. 13

9.2.

Setting a minim m val e of 630 valve ................................................................................... 13

9.3.

Replacement of b rner nozzles ............................................................................................. 14

9.4.

Setting the air inlet on the b rner ........................................................................................... 15

9.5.

Replacement of the ignition flame nozzle .............................................................................. 15

10.

APPLIANCE DISPOSAL .................................................................................................................. 16

ATTACHMENTS ....................................................................................................................................... I

Bartscher GmbH phone: +49 5258 971-0

Franz-Kleine-Str. 28 fax: +49 5258 971-120

33154 Salzkotten Service-Hotline: +49 5258 971-197

Germany www.bartscher.com