Page 4 For technical questions, please call 1-888-866-5797. Item 58214

SAFETY OPERATION MAINTENANCESETUP

4. Power tool use and care

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer

at the rate for which it was designed.

b. Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch

is dangerous and must be repaired.

c. Disconnect the plug from the power

source and/or remove the battery pack,

if detachable, from the power tool before

making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures reduce the

risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e. Maintain power tools and accessories.

Check for misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power tool’s

operation. If damaged, have the power tool

repaired before use. Many accidents are

caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

h. Keep handles and grasping surfaces

dry, clean and free from oil and grease.

Slippery handles and grasping surfaces

do not allow for safe handling and control

of the tool in unexpected situations.

5. Service

a. Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that

the safety of the power tool is maintained.

b. Maintain labels and nameplates on the tool.

These carry important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

6. Safety instructions for all operations

a. Wear ear protectors when Impact drilling.

Exposure to noise can cause hearing loss.

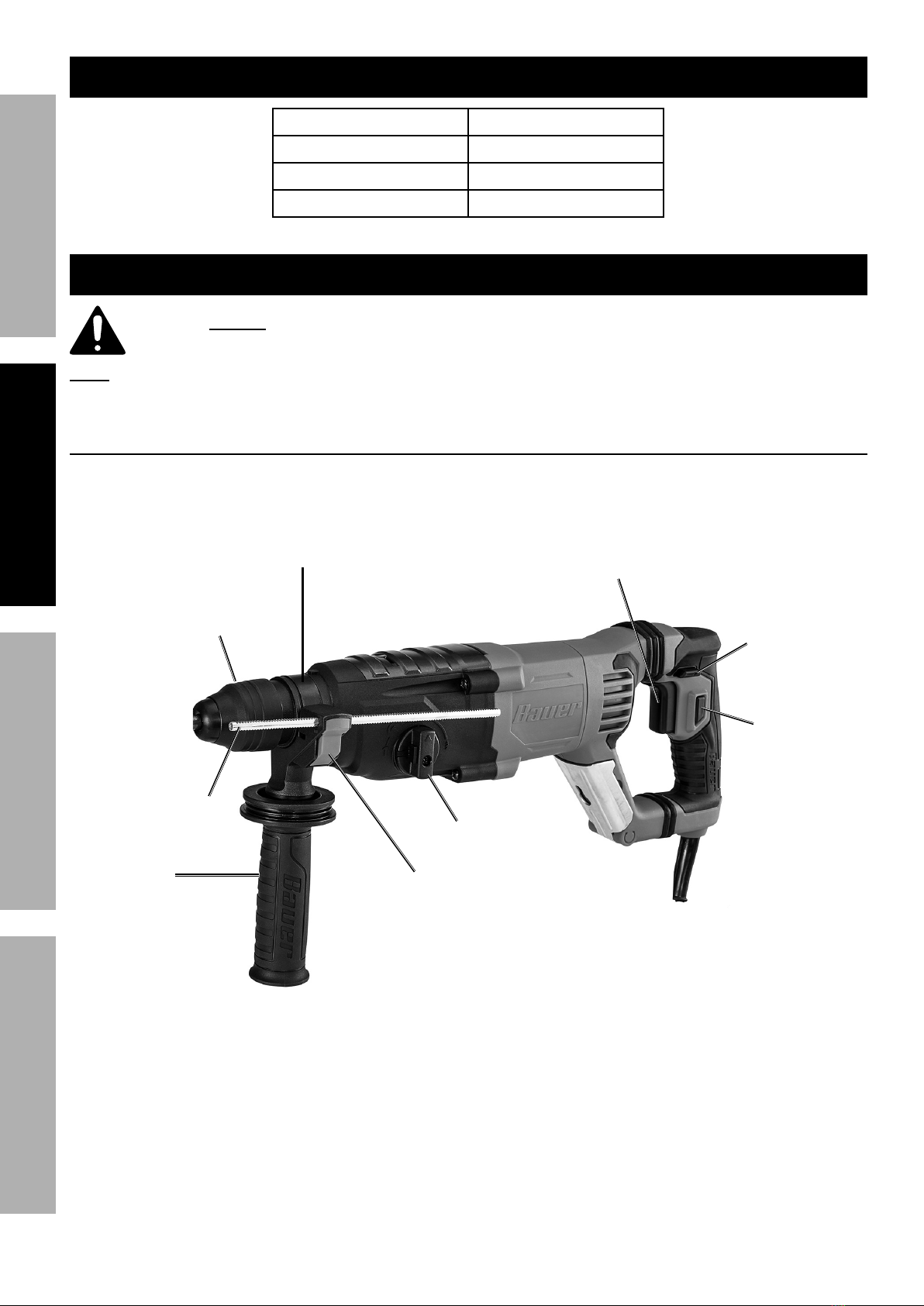

b. Use the auxiliary handle(s). Loss of

control can cause personal injury.

c. Brace the tool properly before use. This

tool produces a high output torque and without

properly bracing the tool during operation, loss

of control may occur resulting in personal injury.

d. Hold the power tool by insulated gripping

surfaces, when performing an operation

where the cutting accessory or fasteners

may contact hidden wiring or its own cord.

Cutting accessory contacting a “live” wire may

make exposed metal parts of the power tool “live”

and could give the operator an electric shock.

e. Let bit cool before touching, changing

or adjusting it. Bits heat up dramatically

while in use, and can burn you.

f. If the drill bit jams, release the

Trigger immediately; drill torque

can cause injury or break bit.

7. Safety Instructions when using long drill bits

a. Never operate at higher speed than the

maximum speed rating of the drill bit.

At higher speeds, the bit is likely to bend if

allowed to rotate freely without contacting

the workpiece, resulting in personal injury.

b. Always start drilling at low speed and with

the bit tip in contact with the workpiece.

At higher speeds, the bit is likely to bend if

allowed to rotate freely without contacting

the workpiece, resulting in personal injury.

c. Apply pressure only in direct line with the

bit and do not apply excessive pressure.

Bits can bend causing breakage or loss

of control, resulting in personal injury.

8. Silicosis Safety Measures

Masonry drilling on materials such as

concrete (which contains crystalline silica)

can cause silicosis (a serious lung disease),

cancer and death. To reduce crystalline silica

exposures in the workplace and prevent

silicosis and silicosis-related deaths:

a. Conduct air monitoring to measure

worker exposures.

b. Use containment methods to control the hazard

and protect adjacent workers from exposure.

c. Practice good personal hygiene to avoid

unnecessary exposure to silica dust.

d. Wear washable or disposable protective

clothes at the work site. Shower and change

into clean clothes before leaving the work site

to prevent contamination of cars, homes and

other work areas. Avoid skin exposure.

e. Always wear a NIOSH approved respirator and

safety goggles. Ventilate the work area properly.

f. Provide periodic medical examinations for all

workers who may be exposed to crystalline silica.