Bauerfeind Uniprox A6 User manual

Socket adapter

A6, A8, A9, A15, A17,

A18, A19, A20, A21

Knee disarticulation

adapter A86

unique prosthetic solutions

A company of the Bauerfeind GroupEin Unternehmen der Bauerfeind Gruppe – www.uniprox.de

Rev.3 2022 01_A6,A8,A9,A15,A17,A18,A19,A20,A21,A86_101727

Qualität und Funktion

Gebrauchsanweisun

Instruction Manual

Uniprox GmbH & Co.KG

H. Heine Str.4

07937 Zeulenroda Triebes

Tel. +49 (0) 36628 66 33 00

Fax +49 (0) 36628 66 33 55

E Mail info @uniprox.de

2 3

Please read the IFU carefully before fittin . Only correct usa e will

warrant the function.

1. Intended Use

The lamination anchors are for usage in a modular prosthetic limb prosthesis und

laminated into the prosthetic socket.

2. Technical data

2.1 A6 Socket Adapter

•lamination anchor, incl. dummy

•water resistant: A6 St, A6 Ti

2.2 A8, A9 Socket Adapter

•lamination anchor for direct fixation to locking systems

•incl. screws and dummy

Order No. Material Wei ht Limit Wei ht Article No.

A6 Al Aluminum < 75 kg 62 g 4 114 010 00 11 000

A6 St Steel < 100 kg 87 g 4 114 010 00 22 000

A6 Ti Titanium < 100 kg 53 kg 4 114 010 00 33 000

Order No. Material Wei ht Limit Wei ht Article No.

A8 Ti Titanium < 100 kg 66 g 4 147 019 19 00 000

A9 Ti Titanium < 100 kg 69 kg 4 147 009 20 00 000

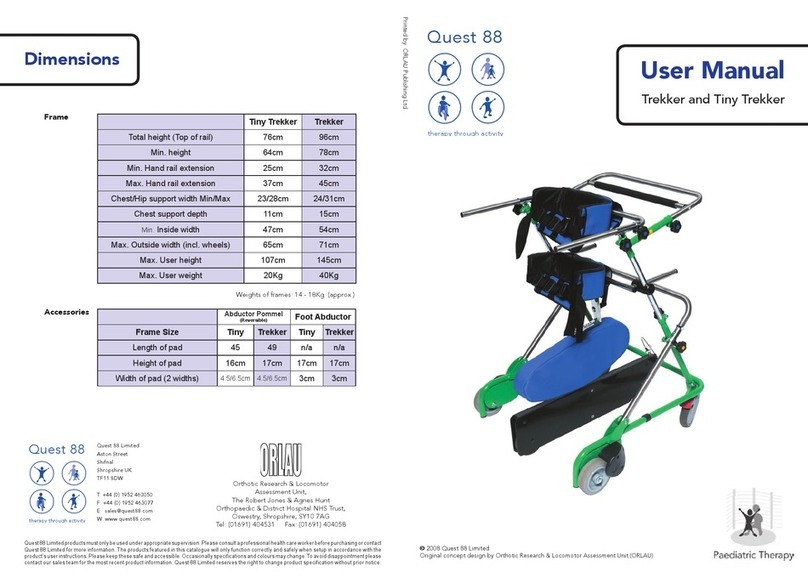

2.3 A15, A17, A18 Socket Adapter

•A15: lamination anchor with pyramid fixed

•A17, A18 : lamination anchor with inner thread (M36 x 1,5)

incl. rotatable pyramid and lamination dummy

•water resistant (with specially waterproof coated screws; not included in the delivery!)

2.4 A19, A20, A21 Socket Adapter

•3 arm lamination anchor w/thread M36x1,5

•incl. Dummy

•water resistant (with specially waterproof coated screws; not included in the delivery!)

2.5 A86 Knee Disarticulation Anchor

•lamination anchor w / thread M36 × 1,5

•incl. dummy

•water resistant (with specially waterproof coated screws; not included in the delivery!)

Order No. Material Wei ht Limit Wei ht Article No.

A15 St Steel, 3 arm long < 125 kg 110 g 4 114 100 01 22 000

A17 St Steel, 3 arm long < 125 kg 167 g 4 114 070 99 22 000

A18 St Steel, 3 arm long < 125 kg 135 g 4 114 070 77 22 000

Order No. Material Wei ht Limit Wei ht Article No.

A19 St Steel, 3 Arm long < 125 kg 110 g 4 114 080 01 22 000

A20 St Steel, 4 arm long < 150 kg 120 g 4 114 080 02 22 000

A21 St Steel, 4 arm short < 125 kg 91 kg 4 114 080 03 22 000

Order No. Material Wei ht Limit Wei ht Article No.

A86 Steel < 125 kg 170 g 4 114 080 06 22 000

4 5

2.6 Spare parts for Socket Adapter

Outside thread M36 x 1,5

Hex socket head screw (for A17):

Cylinder screw with hexagon socket

3. Indication/Contraindication

Indication:

•Amputation of lower extremities

Contraindication:

•not known

4. Side effects

There are no known side effects.

Order No. Description Article No.

E A02 Lamination Dummy made of special rubber 4 114 019 01 00 000

Order No. Material Article No.

E A04 Steel 4 114 110 00 00 000

Order No. Model Len ht Packa in Unit Article No.

M28 12 Steel M8 x 12 10 4 226 050 00 00 012

M28 16 Steel M8 x 16 10 4 226 050 00 00 016

E A11 12 Steel with waterproof

coating

M8 x 12 4 4 113 018 11 20 612

Order No. Model Len ht Packa in Unit Article No.

M33 Steel M5 x 18 10 4 226 030 05 00 018

E A12 20 Steel with waterproof

coating

M5 x 20 1 4 113 018 12 20 520

5. General safety instructions

•This medical product is designed for: single patient, multiple use.

•Fitting/service of this medical device is only allowed by a certificated orthopedic

professional.

•Improper modification or application to the product is not allowed. In case of non

observance, the function of the product may be impaired, so that product liability

is excluded.

•Only approved screws may be used.

•The maximum weight loads are listed under “2. Technical Data”. Additional loads

must be taken into account when calculating the weight.

•In case of insufficient laminate reinforcement, the Socket Adaptor A6, A8, A9, A15

could break out from the prosthetic socket.

•Pay attention to sufficient form fit (A8).

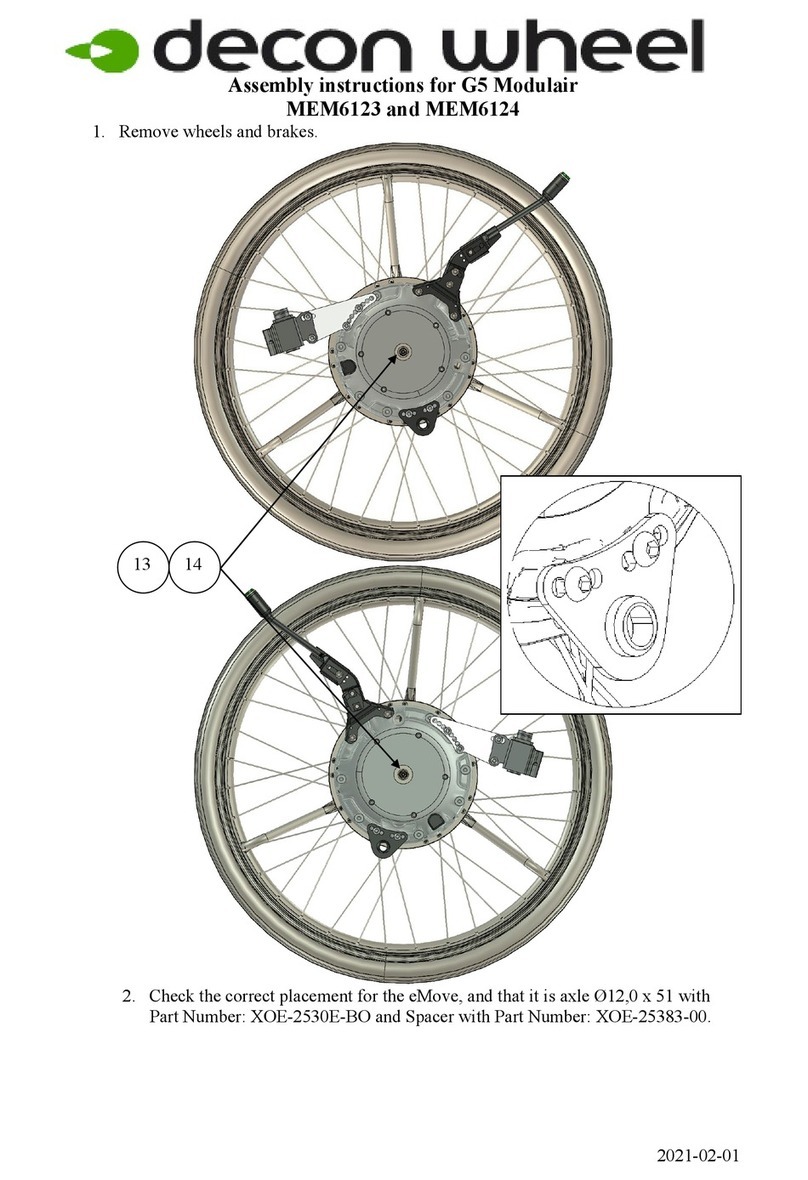

6. Installation

6.1 A6, A8, A9, A15 Socket Adapter

•Bending of the Socket Adapter A6 an A9 could result in crackings in the titanium.

•Seal the male pyramid and the distal holes with plastilina.

•Before placing the socket adaptor put some layers of reinforcement material over

the plaster model.

•Then position socket adaptor on the model and tie off the following layers of

reinforcement in the groove of the adapter with carbon fibre roving.

•Fix the enclosed Lamination Dummy E A02 on the socket adaptor.

•The Lamination Dummy E A02 covers and protects the pyramid during lamination

procedure and provides a precisely fitting brim of the laminate.

•During hardening process of A8 and A9 the laminate in the area of the adapter

must be cooled.

•After lamination expose the attachment side and holes of the adaptor. Do not

damage the socket adaptor.

6 7

6.2 A17-A21 Socket Adapter

A17, A19-A21

Screw the E A04 bending protection in the thread M36x1,5 before bending.

For bending the adapter only use bending iron with rounded tines. The

bore hole area should not be round off too strongly as failure and/or

Rupture of the material could occur.

A17-A21

Before lamination remove pyramid receptacle from the socket adapter. Protect the

thread and the clamping of the socket adapter from resin with e.g. plastilina. Before

placing the socket adapter put some layers of reinforcement material over the plaster

model. Then position socket adapter on the model and tie off the following layers of

reinforcement before the thread. Expose thread after lamination, insert pyramid

receptacle and tighten clamp screw with Torque Wrench.

Torque: 10 Nm

A17

Handling of the Headless Screws

By using the adjusting screws M28 12 or M28 16, static corrections are possible at any

time. If a module has to be replaced or removed the previously adjusted position is

maintained if only two adjacent adjusting screws (not opposite), the ones screwed in

at the deepest, are removed.

If the adjusting screws are, too long (damage of the foam cover) or too short (reduced

stability) these have to be replaced with appropriate ones.

Use a toque wrench to tighten the adjusting screws.

Tightening torque: 12 Nm.

Secure the various screws, used for assembly, with Loctite 222.

6.3 A86 Knee Disarticulation Anchor

Screw the E A04 bending protection in the thread M36x1,5 before bending.

For bending the adapter only use bending iron with rounded tines. The

bore hole area should not be round off too strongly as failure and/or

Rupture of the material could occur.

Use the dummy included in the scope of delivery to protect the thread from

penetrating resin with plasticine. The adapter A86 can also be secured with screws for

assembly. These screws are to be held in the definitive socket. When laminating, glass

or carbon fiber threads are pulled through the holes in the adapter. These serve as a

firm anchorage in the laminate.

The technician must ensure that the processing and reinforcement in the socket are

adapted to the weight and mobility of the patient.

Attention: When the knee joint is fully flexed, there must be no contact

between the socket and the knee joint. Defect of the prosthesis components

possible.

Secure the clamp screw with Loctite 222 and tighten with 8 Nm.

8 9

7. Maintenance

The adapters must be checked as part of regular prosthetic service/maintenance.

8. CE-Conformity

The product satisfies the requirements of Regulation (EU) 2017/745 of the European

Parliament and of the Council (MDR) and bears the CE mark. All major incidents related

to the product needs to be informed to Uniprox and the competence European

Authority.

9. Warranty an Guarantee

Warranty is provided under the terms of sale and supply of Uniprox GmbH & Co. KG

provided that the above conditions are met.

10. Sora e and Disposal

The product is disposable with standard household garbage.

There are no storage recommendations.

Please direct any questions to:

Customer Service: + 49 (0) 36628 66 33 70

Fax: + 49 (0) 36628 66 33 77

This manual suits for next models

20

Table of contents